Preparation method of formaldehyde-free soybean meal-based wood adhesive for wood-based panels

A wood adhesive and soybean meal-based technology is applied in the field of preparation of formaldehyde-free soybean meal-based wood adhesives for wood-based panels, and can solve the problems of unsatisfactory wet bonding strength of plywood, uneven raw material particles of protein adhesive, and cross-linking. Uneven distribution of structure and other problems, to achieve the effect of easy spraying and sizing, improving physical and chemical properties, and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

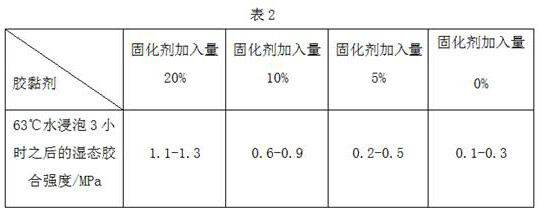

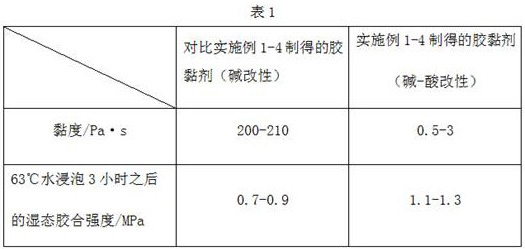

Examples

Embodiment 1

[0027] A preparation method of formaldehyde-free soybean meal-based wood adhesive for wood-based panels, comprising the following steps:

[0028] (1) Put the soybean meal into the water and mix it for 10 minutes according to the weight ratio of water: soybean meal = 75:25; use the alkaline substance sodium hydroxide to adjust the pH value of the mixture to 10.0, and continue stirring for 30 minutes.

[0029] (2) Adjust the pH value to 4.0 with acidic hydrochloric acid and stir for 25 minutes to obtain mixture A;

[0030] (3) According to the weight ratio of epoxy resin: dicyandiamide: low molecular weight polyamide is 8:1:1, mix epoxy resin, dicyandiamide and low molecular weight polyamide, and stir at 50°C for 35min to obtain Soybean gum high-efficiency composite curing agent; the molecular weight of the low molecular weight polyamide is 1000-1500;

[0031] (4) According to the weight ratio of mixture A:soybean gum high-efficiency composite curing agent of 5:1, mix mixture A...

Embodiment 2

[0033] A preparation method of formaldehyde-free soybean meal-based wood adhesive for wood-based panels, comprising the following steps:

[0034](1) Put the soybean meal into the water and mix and stir for 15 minutes according to the ratio of water:soybean meal=80:30 by weight; adjust the pH value of the mixture to 11.0 with alkaline substance potassium hydroxide, and continue stirring for 25 minutes.

[0035] (2) Adjust the pH value to 5.0 with acidic hydrochloric acid and stir for 30 minutes to obtain mixture A;

[0036] (3) According to the weight ratio of epoxy resin: dicyandiamide: low molecular weight polyamide is 8:1:1, mix epoxy resin, dicyandiamide and low molecular weight polyamide, and stir at 53°C for 33min to obtain Soybean gum high-efficiency composite curing agent; the molecular weight of the low molecular weight polyamide is 1000-1500;

[0037] (4) According to the weight ratio of mixture A: soybean gum high-efficiency composite curing agent of 5:1, mix mixtur...

Embodiment 3

[0039] A preparation method of formaldehyde-free soybean meal-based wood adhesive for wood-based panels, comprising the following steps:

[0040] (1) Put the soybean meal into the water and mix it for 20 minutes according to the weight ratio of water: soybean meal = 95:35; use the alkaline substance sodium hydroxide to adjust the pH value of the mixture to 13.0, and continue stirring for 20 minutes.

[0041] (2) Adjust the pH value to 6.0 with acidic substance phosphoric acid and stir for 33 minutes to obtain mixture A;

[0042] (3) According to the weight ratio of epoxy resin: dicyandiamide: low molecular weight polyamide is 8:1:1, mix epoxy resin, dicyandiamide and low molecular weight polyamide, and stir at 55°C for 30min to obtain Soybean gum high-efficiency composite curing agent; the molecular weight of the low molecular weight polyamide is 1000-1500;

[0043] (4) According to the weight ratio of mixture A:soybean gum high-efficiency composite curing agent of 5:1, mix m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com