A kind of antibacterial soybean meal adhesive and its preparation method and application

An adhesive and antibacterial bean technology, which is applied in the field of antibacterial soybean meal adhesive and its preparation, can solve the problems of free formaldehyde release, poor mildew and antibacterial properties, poor water-resistant bonding performance, etc., and achieves short curing time and fast curing. , Improve the effect of water-resistant bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] This embodiment provides a soybean meal adhesive of the present invention and a preparation method thereof.

[0039] Specifically:

[0040] 1. Material preparation: soybean meal 28kg, performance enhancer 2.0kg, diacetyl 15kg.

[0041] The specific synthesis process of the performance enhancer is as follows: 1) add 1 g of carboxymethyl chitosan, 4.5 g of polyethyleneimine, 0.5 g of polyvinyl alcohol and 120 g of water into a three-necked flask and stir well; 2) slowly add 20 g of water within 30 minutes. glutaraldehyde with a concentration of 5% in milliliters was vigorously stirred at 25° C. for 6 hours; 3) the obtained flocculent precipitate was repeatedly centrifuged and washed, and then freeze-dried and stored for later use.

[0042] 2. The specific preparation of soybean meal adhesive:

[0043] Add butanedione to 70kg of dispersion medium water, stir mechanically for 5 minutes, then add performance enhancer and continue to stir mechanically for 5 minutes, finally...

Embodiment 2

[0045] This embodiment provides a soybean meal adhesive of the present invention and a preparation method thereof. The specific preparation method is the same as in Example 1, except that the consumption of soybean meal is 30kg, and the consumption of performance enhancer is 5.0kg.

experiment example 1

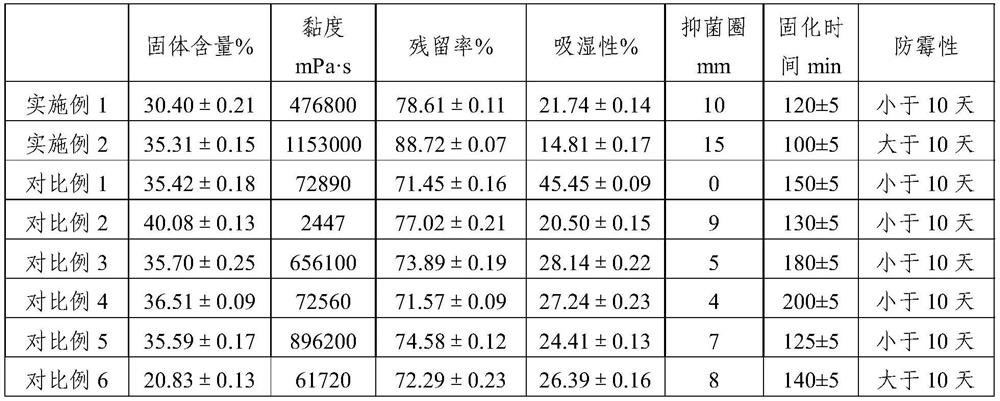

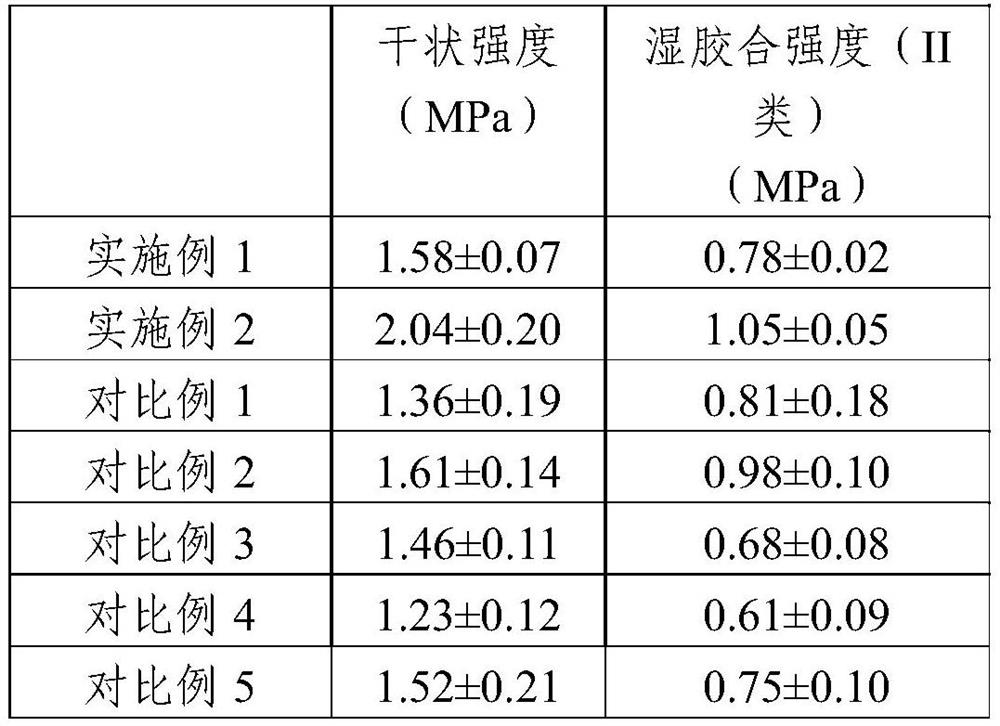

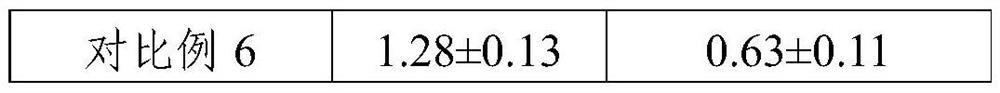

[0065] In this experimental example, the adhesives obtained in the above examples and comparative examples were tested. All tests were performed in triplicate and averaged.

[0066] Solid content test: The determination of the solid content of the adhesive is carried out with reference to the national standard "Wood Adhesive and Its Resin Inspection Method" (GB / T 14074.5-2006) weighing method. Final data are the average of three parallel experiments. The specific experimental operation is as follows: Number the folded tin boxes respectively, and weigh them, and record the mass as m 0 , and then put the adjusted soybean meal adhesive into the corresponding numbered tinfoil box, weigh the total mass of the sample and the tinfoil box, and record it as m 1 . All samples were placed in an electric blast drying oven at 120 °C for solid content testing for 3 hours. After drying to constant weight, take out the dried glue block, weigh it, and record the mass as m 2 . The solid c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com