Mildew-proof and antibacterial adhesive tape and preparation method thereof

A technology of anti-mildew and anti-bacterial tape, applied in the direction of adhesives, anti-fouling/underwater coatings, film/sheet adhesives, etc., can solve the problems of unreachable, labor-intensive and disinfection materials, good disinfection effect, etc., to achieve Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

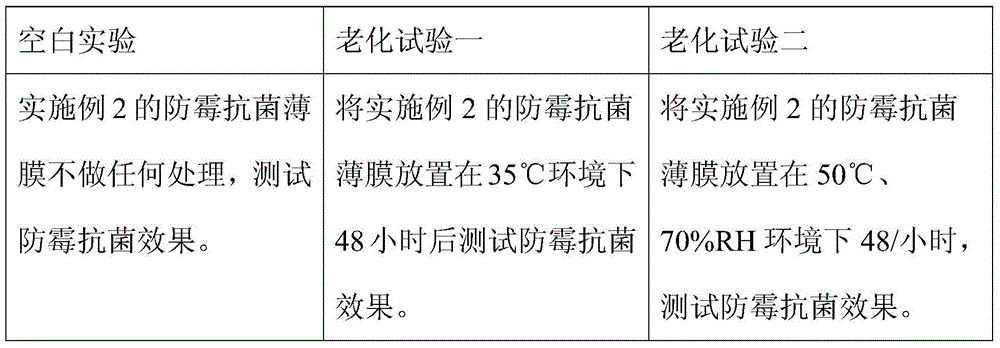

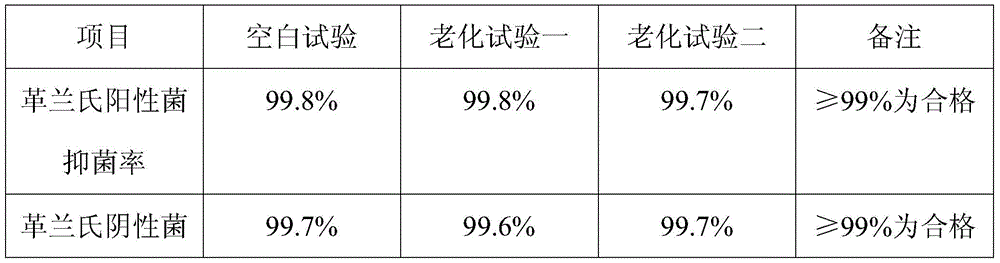

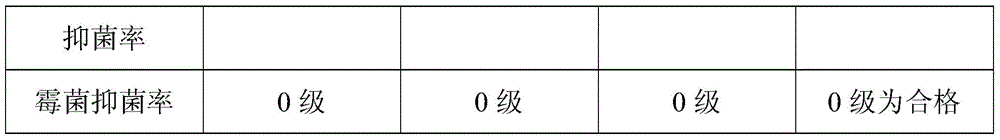

Examples

Embodiment 1

[0024] It should be noted that the sources and trade names of the materials used, as well as those whose components must be listed, are all indicated when they appear for the first time, and the same materials used thereafter have the same contents as those indicated for the first time unless otherwise specified.

[0025] The preparation of embodiment 1 mildew-proof antibacterial adhesive tape, its steps are as follows successively:

[0026] 1) Preparation of antibacterial film layer. In the present embodiment 1, quaternary ammonium salt is used as antibacterial agent, and PET is used as the base material of film to carry out mixing preparation. First, the quaternary ammonium salt produced by Dow Corning Corporation of the United States is uniformly mixed with the PET produced by DuPont Corporation of the United States, and the mixture is passed through an extruder to produce a PET film with anti-mildew and antibacterial effects, that is, an antibacterial film layer. Among th...

Embodiment 2

[0030] The preparation of embodiment 2 mildew-proof and antibacterial adhesive tapes, its steps are as follows successively:

[0031] a) Preparation of antibacterial coating. In Example 2, titanium dioxide and quaternary ammonium salt are used as antibacterial agents, ethyl acetate is used as a cosolvent, and PET is used as a plastic substrate. Dissolve titanium dioxide and quaternary ammonium salt in ethyl acetate, disperse and mix evenly under a high-speed mixer. Be prepared into antibacterial coating, its proportioning ratio is as shown in the following table 1:

[0032] Material

Weight ratio / part

Titanium dioxide

1

Quaternary ammonium salt

1

ethyl acetate

100

[0033] Table 1

[0034] b) corona treatment of PET to obtain a PET film with a surface dyne value ≥ 38 dyne;

[0035] c) Preparation of antibacterial film layer. Using coating technology, the anti-mold and anti-bacterial coating is coated on one side of the coro...

Embodiment 3

[0038] The preparation of embodiment 3 mildew-proof and antibacterial adhesive tapes, its steps are as follows successively:

[0039] a) Preparation of antibacterial coating. In Example 3, titanium dioxide and quaternary ammonium salt are used as antibacterial agents, ethyl acetate is used as a cosolvent, and PET is used as a plastic substrate. Dissolve titanium dioxide and quaternary ammonium salt in ethyl acetate, disperse and mix evenly under a high-speed mixer. Be prepared into antibacterial coating, its proportioning ratio is as shown in the following table 2:

[0040] Material

Weight ratio / part

Titanium dioxide

20

Quaternary ammonium salt

20

ethyl acetate

80

[0041] Table 2

[0042] b) corona treatment of PET to obtain a PET film with a surface dyne value ≥ 38 dyne;

[0043] c) Preparation of antibacterial film layer. Using coating technology, the anti-mold and anti-bacterial coating is coated on one side of the cor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com