Collagen-polyvinyl alcohol composite fiber modified by metallic ion, and preparation method

A metal ion modification and collagen technology, which is applied in the field of collagen-polyvinyl alcohol composite fiber and its manufacturing, can solve the problem of not being able to obtain practical fibers, and achieve the effects of uniform and bright color, good drape and delicate hand feeling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

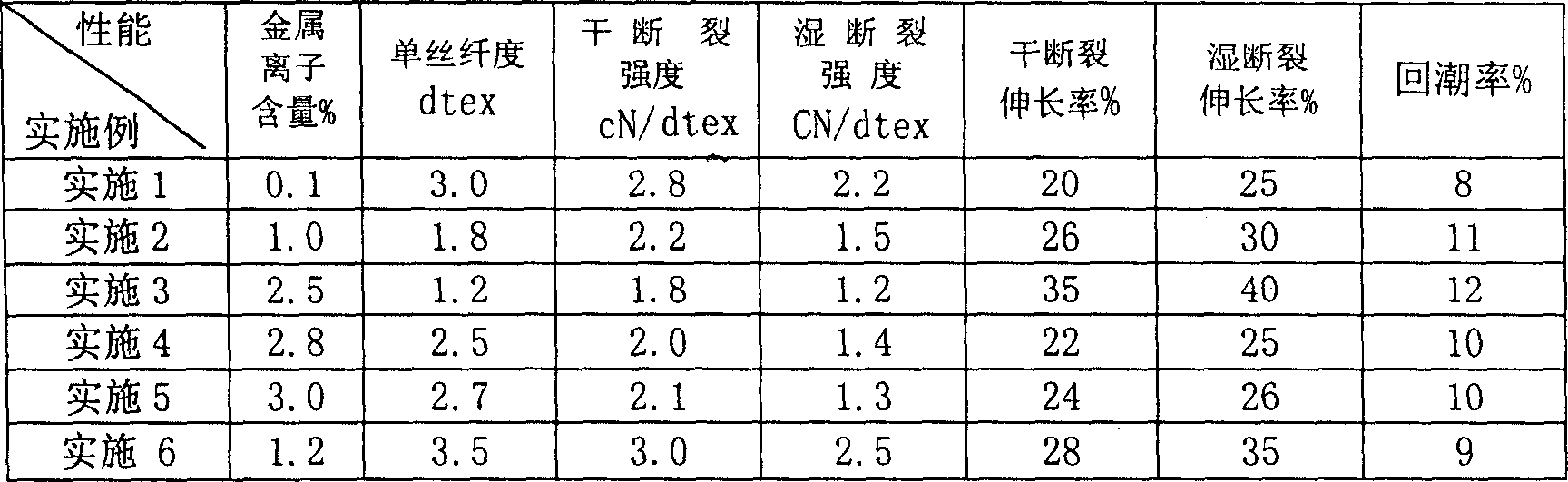

Examples

Embodiment 1

[0039] Take the gray skins from the tannery that are peeled evenly and discard the skins. After weighing and measuring, put them in a drum, wash them with 4 times warm water at 35°C for 2 times, each time for 20 minutes, drain the water and wash them with running water. 10 minutes; then add 1 times warm water at 30°C, 2% ammonium sulfate and 0.5% surfactant fatty alcohol ethylene oxide condensate, rotate for 60 minutes, and discharge the water in the drum; then use 38 Wash with warm water at ℃ until the pH of the peel is 7-8, then wash with hot water at 40°C for 10 minutes; add 1 times the hot water at 40°C and 1398 neutral protease with 0.1% of the weight of the peel, and rotate for 1.5 hours Finally, wash with flowing water and control dry; transfer the cleaned peel to a reaction kettle with a stirring device, add 2 times of water, gradually raise the temperature to 70°C, and keep it warm for 3 hours to fully dissolve the peel, and then After filtering, the filtrate was take...

Embodiment 2

[0042] Take the leather shaved from the tannery's blue wet shaved evenly, after weighing and measuring, put it in the drum, wash it with 4 times the warm water of 35 ℃ for 2 times, each time for 20 minutes, drain the water and then wash it with running water for 10 minutes. After 10 minutes, control the dryness, transfer the washed leather to the reaction kettle, add water 7 times the weight of the leather and calcium hydroxide of 3% of the weight of the leather, gradually heat up to 95 ° C, and keep it warm for 5 hours to make the leather Fully dissolve, then filter, neutralize the pH value to about 7.0 with diluted sulfuric acid solution, filter to remove calcium sulfate precipitate, and concentrate the filtrate to a concentration of 20%, then adjust the pH value to 5.5 with 1N sulfuric acid, and set aside.

[0043] Add the washed polyvinyl alcohol with a degree of polymerization of 1700 and a degree of alcoholysis of 99% into water, heat and stir until dissolved at 98°C for ...

Embodiment 3

[0045] Take the gray skins from the tannery that are peeled evenly and discard the skins. After weighing and measuring, put them in a drum, wash them with 4 times warm water at 35°C for 2 times, each time for 20 minutes, drain the water and wash them with running water. 10 minutes; add 1 times of warm water at 30°C, 2% ammonium sulfate and 0.5% surfactant fatty alcohol ethylene oxide braiding compound, rotate for 60 minutes, and discharge the water in the drum; Wash with warm water at 38°C until the pH of the peel is 7-8, then wash with hot water at 40°C for 10 minutes; add 1 times the hot water at 40°C and 1398 neutral protease with 0.1% of the weight of the peel, and turn for 1.5 After 1 hour, wash with flowing water and dry it; transfer the cleaned peels to a reaction kettle with a stirring device, add 2 times the water, gradually heat up to 70°C, and keep warm for 3 hours to fully dissolve the peels. Then filter, take the filtrate and concentrate to a concentration of 20% ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com