Impregnated high thermal conductivity nanofluid adhesive, preparation method and its application in wood-based panel decoration

A nanofluid and wood-based panel technology, which is applied to the joints of wooden veneers, adhesives, manufacturing tools, etc., can solve the problem of high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

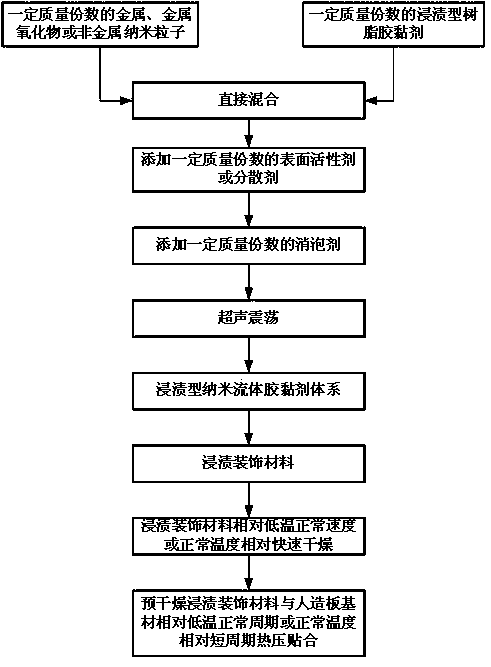

Method used

Image

Examples

Embodiment 1

[0024] Mix nano-copper particles, particle size range 20-50nm, 5 parts (parts by mass, the same below), water-soluble impregnated melamine-formaldehyde resin adhesive, 94.7 parts, in the dipping tank of a vertical dipping machine, Then add 0.2 parts of anionic surfactant sodium dodecylsulfonate, add 0.1 parts of polydimethylsiloxane, install an ultrasonic oscillator in the middle of the dipping tank, the ultrasonic frequency is 50kHz, the power is 500W, and the working mode is intermittent , Work for 3 minutes and stop for 3 minutes, forming a dispersed and stable impregnated high thermal conductivity nanofluid adhesive system, the thermal conductivity is 31% higher than that of the original impregnated melamine formaldehyde resin. Impregnation of wear-resistant surface paper, dark ordinary decorative paper and bottom paper, the drying parameters of the dryer in the vertical dipping machine remain unchanged, 125°C for the upper layer, 100°C for the middle layer, and 80°C for th...

Embodiment 2

[0026] Mix 9 parts of nano-iron particles, particle size range 30-60nm, and water-soluble impregnating melamine-modified urea-formaldehyde resin adhesive, 90.5 parts, directly in the dipping tank of a vertical dipping machine, and then add cationic surfactant 0.3 parts of cetyldimethylammonium chloride, plus 0.2 parts of polydimethylsiloxane, an ultrasonic oscillator is installed in the middle of the dipping tank, the ultrasonic frequency is 50kHz, the power is 500W, the working mode is intermittent, and the working mode is 2 Stop for 3 minutes every minute to form a dispersed and stable impregnated high thermal conductivity nanofluid adhesive system, the thermal conductivity of which is 33% higher than that of the original impregnated melamine-modified urea-formaldehyde resin. Impregnation of wear-resistant surface paper, dark ordinary decorative paper and bottom paper, the drying parameters of the dryer in the vertical dipping machine: the upper layer is reduced from 130°C to...

Embodiment 3

[0028]Mix 10 parts of nano-aluminum particles, particle size range 70-100nm, and water-soluble impregnating urea-modified melamine-formaldehyde resin adhesive, 89.2 parts, in the dipping tank of a vertical dipping machine, and then add amphoteric surfactant Add 0.4 parts of sodium laurylalanine, add 0.4 parts of polydimethylsiloxane, install an ultrasonic oscillator in the middle of the dipping tank, the ultrasonic frequency is 90kHz, the power is 2000W, the working mode is intermittent, and it works for 2 minutes After stopping for 3 minutes, a dispersed and stable impregnated high thermal conductivity nanofluid adhesive system is formed, and the thermal conductivity is 33% higher than that of the original impregnated urea-modified melamine formaldehyde resin. Impregnation of wear-resistant surface paper, dark ordinary decorative paper and bottom paper, the drying parameters of the dryer in the vertical dipping machine: the upper layer is reduced from 130°C to 120°C, the middl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com