Preparation method of high-strength lightweight composite honeycomb panel

A honeycomb composite board, lightweight technology, applied in the direction of chemical instruments and methods, lamination devices, lamination auxiliary operations, etc., can solve the problems of multi-energy consumption, long holding time, high hot-pressing temperature, etc., to shorten the processing cycle , reduce the hot pressing temperature, reduce the effect of energy use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Embodiments of the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, and therefore are only examples, and should not be used to limit the scope of protection of this patent.

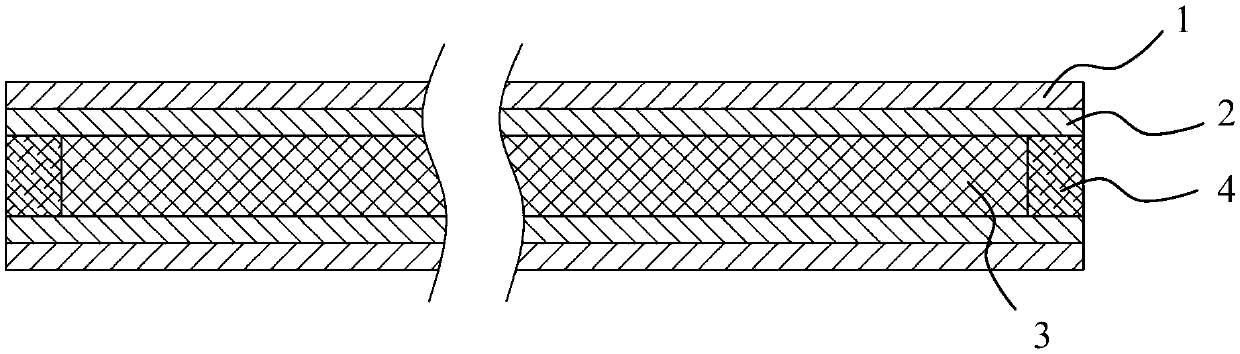

[0021] Such as figure 1 As shown, this embodiment discloses a method for preparing a high-strength and lightweight honeycomb composite panel, including the following steps:

[0022] S1: Select materials for honeycomb composite board, including aramid paper honeycomb core material 3, cured glass fiber prepreg board 2 and high-pressure decorative laminate board 1;

[0023] S2: Board cutting, cutting the aramid paper honeycomb core material 3, the cured glass fiber prepreg board 2 and the high-pressure decorative laminate board 1 into a set shape;

[0024] S3: Squeegee glue, apply glue to the adhesive surface of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive modulus | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com