Preparation method of frosted card

A frosted card and sand card technology, applied in the field of card preparation, can solve the problems of increased production cost, unfavorable energy saving and environmental protection, complicated preparation process, etc., and achieve the effects of good wear resistance, good appearance effect and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

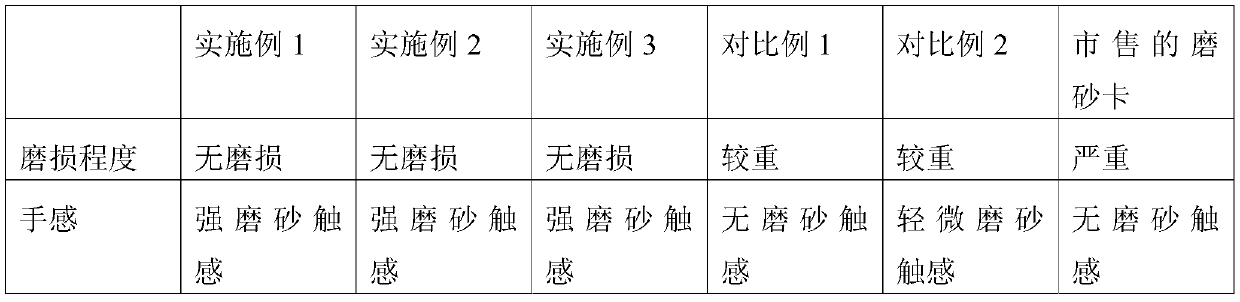

Embodiment 1

[0026] A method for preparing a frosted card, comprising the following steps:

[0027] (1) Print pictures and texts on two sheets, for standby;

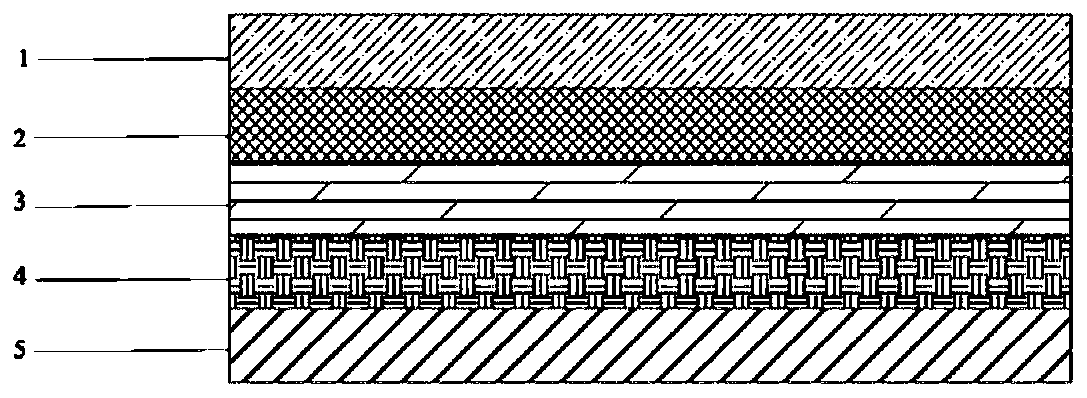

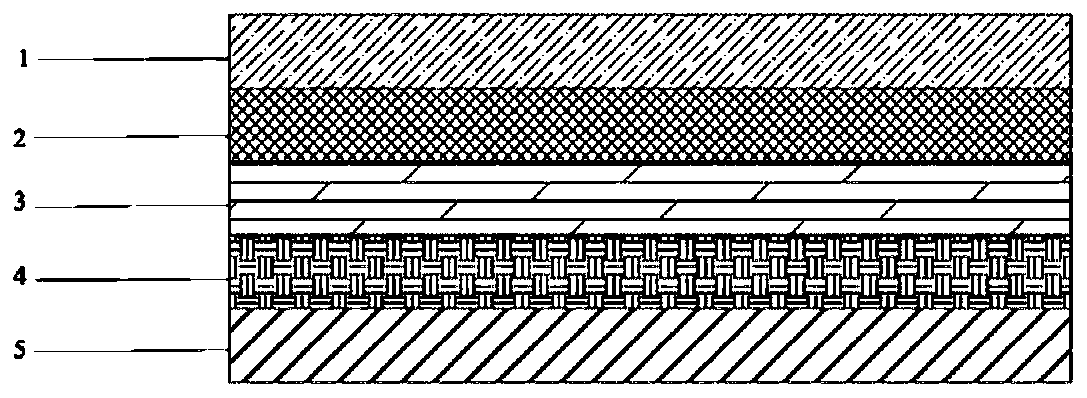

[0028] (2) Binding: The two sheets prepared in step (1) are used as the upper printing layer and the lower printing layer to sandwich the element layer from the upper and lower directions, and then a protective film (called front protection film) is placed on the upper printing layer. Film) (provided by Jiangsu Huaxin New Materials Co., Ltd.), a protective film with a magnetic stripe (called the back protective film) is also placed on the surface of the lower printing surface, and then the front protective film, upper printing layer, and component layer , the lower printing layer, and the back protective film for binding to prepare the card body;

[0029] (3) Lamination: cover the tactile film with a matte effect on the front protective film of the card body, hot press at a pressure of 2.5MPa-7MPa and a temperature of 100°C for 2 mi...

Embodiment 2

[0037] A method for preparing a frosted card, comprising the following steps:

[0038] (1) Print pictures and texts on two sheets, for standby;

[0039] (2) Binding: The two sheets prepared in step (1) are used as the upper printing layer and the lower printing layer to sandwich the element layer from the upper and lower directions, and then a protective film (called front protection film) is placed on the upper printing layer. Film) (provided by Jiangsu Huaxin New Materials Co., Ltd.), a protective film with a magnetic stripe (called the back protective film) is also placed on the surface of the lower printing surface, and then the front protective film, upper printing layer, and component layer , the lower printing layer, and the back protective film for binding to prepare the card body;

[0040] (3) Lamination: cover the tactile film with a matte effect on the front protective film of the card body, hot press at a pressure of 3MPa and a temperature of 110°C for 10 minutes,...

Embodiment 3

[0048] A method for preparing a frosted card, comprising the following steps:

[0049] (1) Printing pictures and texts on two sheets for standby;

[0050] (2) Binding: The two sheets prepared in step (1) are used as the upper printing layer and the lower printing layer to sandwich the element layer from the upper and lower directions, and then a protective film (called front protection film) is placed on the upper printing layer. Film) (provided by Jiangsu Huaxin New Materials Co., Ltd.), a protective film with a magnetic stripe (called the back protective film) is also placed on the surface of the lower printing surface, and then the front protective film, upper printing layer, and component layer , the lower printing layer, and the back protective film for binding to prepare the card body;

[0051](3) Lamination: cover the tactile film with a matte effect on the front protective film of the card body, hot press at a pressure of 7 MPa and a temperature of 130°C for 20 minute...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com