Method for manufacturing ultra-low formaldehyde emission medium-to-high density fiberboard

A high-density fiberboard, formaldehyde emission technology, applied in the direction of manufacturing tools, flat products, pretreatment of molding materials, etc., can solve the problems of appearance defects, high cost, differences in physical properties of the board, etc., to achieve good air quality and preparation process Simple, easy-to-buy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

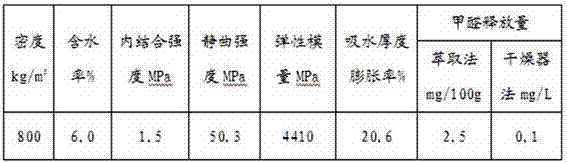

Examples

Embodiment 1

[0039] Preparation of Ultra E0 Adhesive:

[0040] A. Add 1000 parts of formaldehyde into the reaction kettle, adjust the pH to 8.7 with 9.8 parts of sodium hydroxide, and add 2.1 parts of polyvinyl alcohol after 10 minutes to form solution A;

[0041] B. When the temperature rises to 30-35°C, add 376 parts of urea and 28.7 parts of melamine to solution A, raise the temperature to 88-92°C within 30-60 minutes, and keep the temperature at 88-92°C for 30 minutes. Obtain solution B;

[0042] C. Slowly add 7.8 parts of formaldehyde to solution B, adjust the pH value to 5.8, and control the temperature at 88-90°C to react, when the viscosity reaches 20.3 seconds / 30°C as the end point, solution C is obtained;

[0043] D. Add 2.6 parts of triethanolamine to solution C, adjust the pH value to 7.4 with 5.7 parts of sodium hydroxide, add 190 parts of urea and 12.3 parts of melamine, and react at a temperature of 80-85°C for 30 minutes to obtain solution D;

[0044] E. Add 7.3 part...

Embodiment 2

[0061] Preparation of Ultra E0 Adhesive:

[0062] A. Add 1000 parts of formaldehyde into the reaction kettle, adjust the pH to 8.5 with 9 parts of sodium hydroxide, and add 2.5 parts of polyvinyl alcohol after 10 minutes to form solution A;

[0063] B. When the temperature rises to 30-35°C, add 368 parts of urea and 26.6 parts of melamine to solution A, raise the temperature to 88°C within 45 minutes, and keep the temperature at 88-92°C for 30 minutes to obtain solution B;

[0064] C. Slowly add 6.2 parts of formic acid to solution B, adjust the pH value to 6.3, and control the temperature at 88-92°C to react, when the viscosity reaches 21 seconds / 30°C as the end point, solution C is obtained;

[0065] D. Add 2.1 parts of triethanolamine to solution C, adjust the pH value to 7.2 with 5.8 parts of sodium hydroxide, add 191 parts of urea and 11.4 parts of melamine, and react at a temperature of 83-85°C for 30 minutes to obtain solution D;

[0066] E. Add 7.0 parts of sodiu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com