Stainless steel plate for mineral screen piece and manufacturing method thereof

A manufacturing method and stainless steel technology, applied in the field of stainless steel plate preparation, can solve the problems of high price, poor strength and wear resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

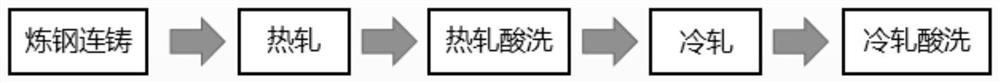

[0024] Embodiment 1, as shown in Fig. 1 (a), the method for manufacturing this mine sieve sheet with stainless steel plate, comprises steps as follows:

[0025] (1) Steelmaking and continuous casting includes electric arc furnaces, converters, vacuum refining furnaces and billet continuous casting machines. Refining includes argon oxygen decarburization and ladle refining, and the temperature after ladle refining is about 1500°C;

[0026] (2) In continuous hot rolling, the strip width is 800mm, the strip thickness is 2mm, the rolling pass is 10 times, the heating furnace has ten sections, the temperature is between 1050-1250°C, and the furnace temperature is about 1200°C.

[0027] (3) During pickling of hot-rolled strip steel, the steel plate passes through a rust crusher and a sandblasting machine in sequence to ensure a good shape, and then pre-washed with water. The temperature of the steel strip in the pickling zone is 1120°C, and the concentration in the sulfuric acid zon...

Embodiment 2

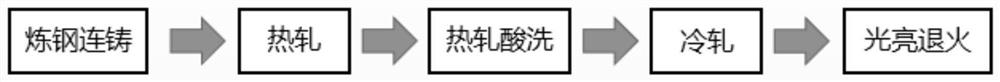

[0031] Embodiment 2, as shown in Fig. 1 (b), the method for manufacturing this mine sieve sheet with stainless steel plate, comprises steps as follows:

[0032] (1) Steelmaking and continuous casting includes electric arc furnaces, converters, vacuum refining furnaces and billet continuous casting machines. Refining includes argon oxygen decarburization and ladle refining, and the temperature after ladle refining is about 1500°C;

[0033] (2) In continuous hot rolling, the strip width is 800mm, the strip thickness is 2mm, the rolling pass is 10 times, the heating furnace has ten sections, the temperature is between 1050-1250°C, and the furnace temperature is about 1200°C.

[0034] (3) During pickling of hot-rolled strip steel, the steel plate passes through a rust crusher and a sandblasting machine in sequence to ensure a good shape, and then pre-washed with water. The temperature of the steel strip in the pickling zone is 1120°C, and the concentration in the sulfuric acid zon...

Embodiment 3

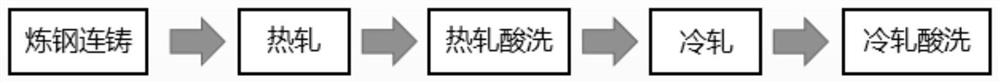

[0037] Embodiment 3, as shown in Fig. 1 (c), the method for manufacturing this mine sieve sheet with stainless steel plate, comprises steps as follows:

[0038] (1) Steelmaking and continuous casting includes electric arc furnaces, converters, vacuum refining furnaces and billet continuous casting machines. Refining includes argon oxygen decarburization and ladle refining, and the temperature after ladle refining is about 1500°C;

[0039] (2) In hot continuous rolling, the strip width is 1000mm, the strip thickness is 4mm, the rolling pass is 8 times, the heating furnace has ten sections, the temperature is between 1050-1250°C, and the furnace temperature is about 1150°C.

[0040] (3) During the pickling of hot-rolled strip steel, the steel plate passes through a rust crusher and a sandblasting machine in sequence to ensure a good shape, and then pre-washed. The temperature of the steel strip in the pickling zone is 1150°C, and the concentration in the sulfuric acid zone is 20...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com