Concrete outer wall protective agent and preparation method thereof

A protective agent, concrete technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of freeze-thaw damage, leakage damage, multi-factor comprehensive damage, etc., to achieve simple preparation process, prolong service life, improve protection performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The present invention also provides a preparation method of the above-mentioned concrete exterior wall protective agent, comprising the steps of:

[0033] (1) Weigh deionized water, acrylic polyurethane emulsion, fluorocarbon emulsion, wetting agent, defoamer, propylene glycol monoethyl ether, thickener, sulfonic acid benzophenone derivative and preservative according to the formula, and deionize Add deionized water into the stirring tank, start the mixer to stir;

[0034] (2) Add acrylic polyurethane emulsion, fluorocarbon emulsion, wetting agent, defoamer, propylene glycol monoethyl ether, thickener and sulfonic acid benzophenone derivatives into the stirring tank in sequence, and stir while adding, and the stirring time is T 1 30~40min; wherein, the speed of the mixer is 200r / min, and the stirring time T 1 Preferably 40min;

[0035] (3) Add preservatives into the stirring tank, stir while adding, stirring time T 2 10~20min, the concrete exterior wall protective ag...

Embodiment 1

[0038] A concrete exterior wall protective agent is made of the following components in weight percent:

[0039] Deionized water 28%

[0040] Acrylic Polyurethane Emulsion 45%

[0041] Fluorocarbon emulsion 20%

[0042] Sodium hexametaphosphate 0.1%

[0043] Polysiloxane 0.2%

[0044] Isothiazolinone derivatives 0.1%

[0045] Propylene Glycol Monoethyl Ether 6%

[0046] Polyvinyl alcohol 0.3%

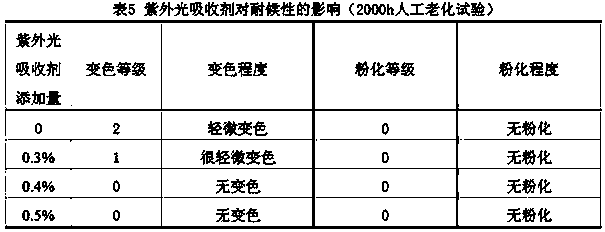

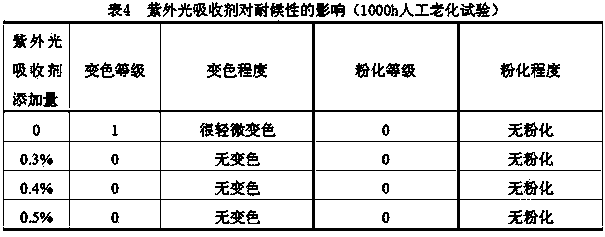

[0047] Sulfonic acid benzophenone derivative 0.3%

[0048] The preparation method of above-mentioned concrete exterior wall protective agent, comprises the steps:

[0049] (1) Weigh deionized water, acrylic polyurethane emulsion, fluorocarbon emulsion, sodium hexametaphosphate, polysiloxane, propylene glycol monoethyl ether, polyvinyl alcohol, sulfonic acid benzophenone derivatives and isothiazoline according to the above formula Ketone derivatives, deionized water and deionized water are added to the stirring tank, and the stirrer is started to stir;

[0050] (2) Add acrylic pol...

Embodiment 2

[0056] A concrete exterior wall protective agent is made of the following components in weight percent:

[0057] Deionized water 25.4%

[0058] Acrylic Polyurethane Emulsion 35%

[0059] Fluorocarbon emulsion 33%

[0060] Sodium metasilicate 0.2%

[0061] Perfluoroalkyl esters 0.3%

[0062] Benzimidazole derivatives 0.2%

[0063] Propylene Glycol Monoethyl Ether 5%

[0064] Polyvinyl alcohol 0.5%

[0065] Sulfonic acid benzophenone derivative 0.4%

[0066] The preparation method of above-mentioned concrete exterior wall protective agent, comprises the steps:

[0067] (1) Weigh deionized water, acrylic polyurethane emulsion, fluorocarbon emulsion, sodium metasilicate, perfluoroalkyl ester, propylene glycol monoethyl ether, polyvinyl alcohol, sulfonic acid benzophenone derivative and benzophenone according to the above formula. Imidazole derivatives, deionized water and deionized water are added in the stirring tank, and the stirrer is started to stir;

[0068] (2) Add ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com