Water-based reflective insulation coating and preparation method thereof

A reflective thermal insulation coating, water-based technology, applied in reflective/signal coatings, epoxy resin coatings, coatings, etc., can solve the problems of poor wear resistance and scrub resistance, poor thermal insulation effect, etc., to improve adhesion , Significant heat insulation effect, high density and temperature change resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

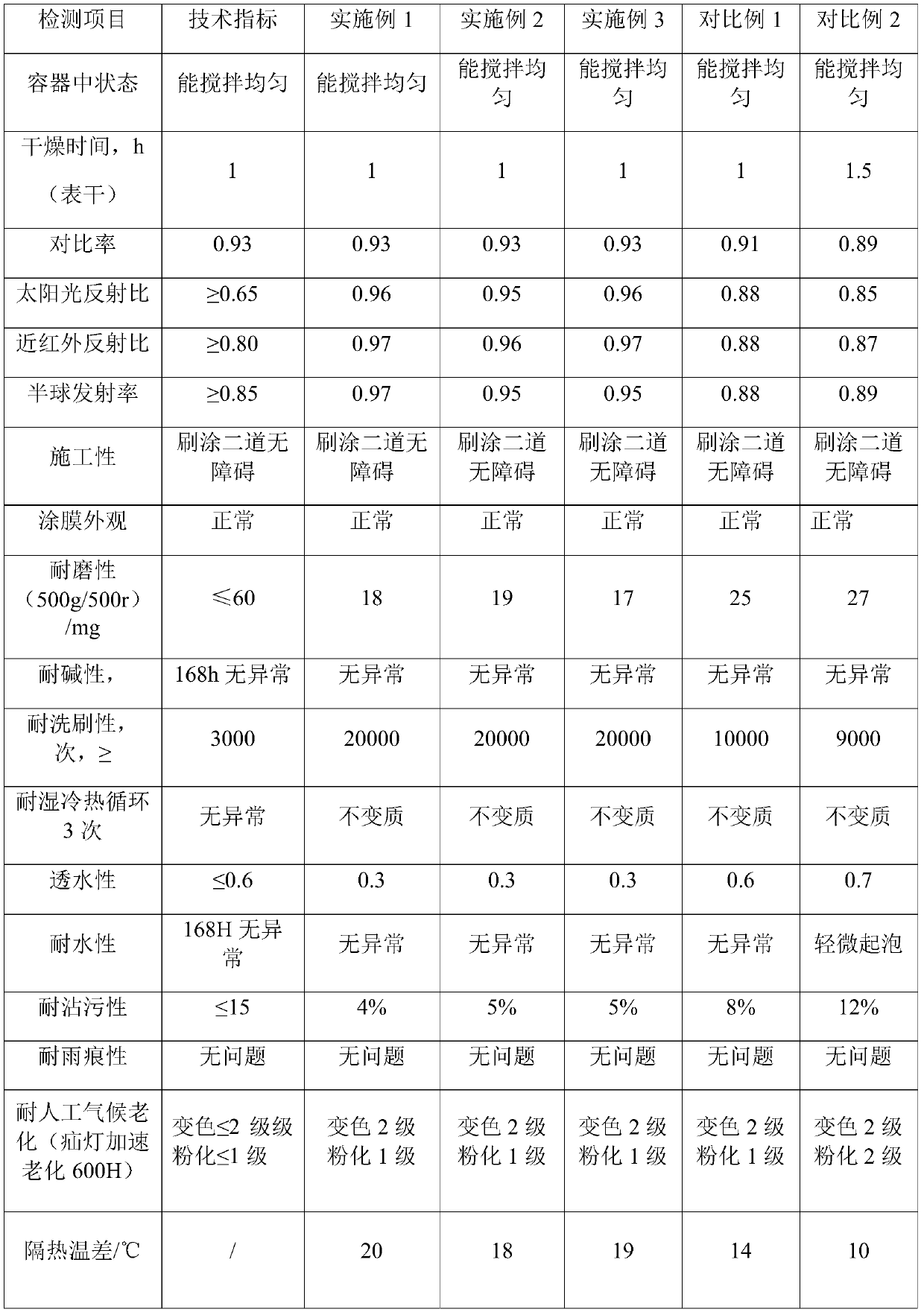

Examples

Embodiment 1

[0055] An embodiment of the present invention provides a water-based reflective heat-insulating coating, which includes the following raw material components in parts by weight: 35 parts of water-based resin emulsion, 40 parts of silicon-aluminum-coated modified nano-titanium dioxide, 8 parts of nano-ytterbium oxide, and 0.3 parts of cellulose , 0.2 parts of defoamer, 0.5 parts of leveling agent, 0.7 parts of dispersant, 0.15 parts of wetting agent, 1.8 parts of film-forming aid, 0.15 parts of pH regulator, 0.15 parts of fungicide, 0.1 part of thickener, antifreeze 1.2 parts, 4 parts of kaolin, 15 parts of heavy calcium and 25 parts of deionized water;

[0056] Wherein, the aqueous resin emulsion is a carbon nanotube modified epoxy resin and a silicone modified fluorocarbon emulsion.

[0057] Wherein, the carbon nanotube modified epoxy resin is produced by Shanghai Zhenyu Biotechnology Co., Ltd.; the organosilicon modified fluorocarbon emulsion is XWF-902 produced by Nanjing X...

Embodiment 2

[0065] An embodiment of the present invention provides a water-based reflective heat-insulating coating, which includes the following raw material components in parts by weight: 38 parts of water-based resin emulsion, 25 parts of silicon-aluminum-coated modified nano-titanium dioxide, 10 parts of nano-ytterbium oxide, and 0.33 parts of cellulose , 0.3 parts of defoamer, 0.4 parts of leveling agent, 0.8 parts of dispersant, 0.18 parts of wetting agent, 2.0 parts of film-forming aid, 0.1 part of pH regulator, 0.2 part of bactericide, 0.13 part of thickener, antifreeze 1.5 parts, 3 parts of kaolin, 12 parts of heavy calcium and 23 parts of deionized water;

[0066] Wherein, the aqueous resin emulsion is a carbon nanotube modified epoxy resin and a silicone modified fluorocarbon emulsion.

[0067] The preparation method of the above-mentioned silica-aluminum coating modified nano-titanium dioxide comprises the following steps:

[0068] Disperse nano-titanium dioxide in water to o...

Embodiment 3

[0071] An embodiment of the present invention provides a water-based reflective heat-insulating coating, which includes the following raw material components in parts by weight: 40 parts of water-based resin emulsion, 35 parts of silicon-aluminum-coated modified nano-titanium dioxide, 5 parts of nano-ytterbium oxide, and 0.35 parts of cellulose , 0.25 parts of defoamer, 0.3 parts of leveling agent, 0.6 parts of dispersant, 0.2 parts of wetting agent, 1.5 parts of film-forming aid, 0.13 parts of pH regulator, 0.1 part of fungicide, 0.15 part of thickener, antifreeze 1.8 parts, 5 parts of kaolin, 10 parts of heavy calcium and 20 parts of deionized water;

[0072] Wherein, the aqueous resin emulsion is a carbon nanotube modified epoxy resin and a silicone modified fluorocarbon emulsion.

[0073] The preparation method of the above-mentioned silica-aluminum coating modified nano-titanium dioxide comprises the following steps:

[0074] Disperse nano-titanium dioxide in water to ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com