Waterproof and moisture permeable coating

A waterproof and moisture-permeable coating technology, which is applied in the field of waterproof coatings and waterproof and moisture-permeable coatings. It can solve the problems of environmental and human hazards, poor aging resistance, and low transmittance, and achieve environmental and human harmlessness and aging resistance. Strong performance and good stain resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

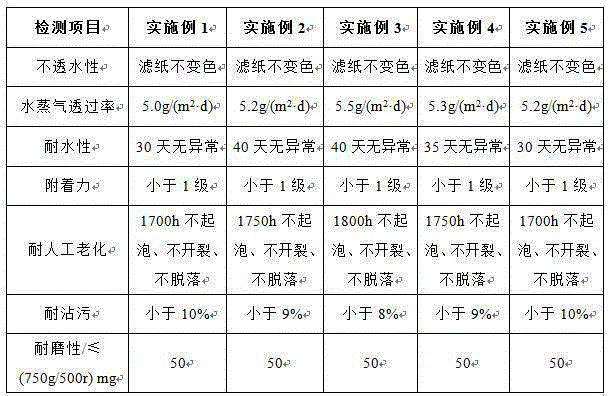

Examples

Embodiment 1

[0034] Example 1 A waterproof and moisture-permeable coating

[0035] Described coating comprises primer and surface coating;

[0036] (1) The mass composition of the surface coating is: 40 parts of water-based fluorocarbon emulsion, 15 parts of filler, 30 parts of water-based polyurethane, 1 part of defoamer, and 0.5 part of dispersant;

[0037] The water-based fluorocarbon resin is Guangdong Pine Chemical PTFE emulsion;

[0038] The filler is DuPont rutile titanium dioxide;

[0039] The water-based polyurethane is Jining Huakai Resin Co., Ltd. HK718;

[0040] Described defoamer is BASF A10;

[0041] The model of the dispersant is BYK180.

[0042] (2) Primer coating includes A component and B component;

[0043] The mass ratio of component A and component B is: component A: component B = 14:1; before using the primer, mix component A and component B according to the mass ratio.

[0044] The parts by mass of the A component of the primer are composed of:

[0045] 10 pa...

Embodiment 2

[0051] Example 2 A waterproof and moisture-permeable coating

[0052] Described coating comprises primer and surface coating;

[0053] (1) The mass composition of the surface coating is: 50 parts of water-based fluorocarbon emulsion, 13 parts of filler, 20 parts of water-based polyurethane, 1 part of defoamer, and 0.5 parts of dispersant;

[0054] The water-based fluorocarbon resin is Guangdong Pine Chemical PTFE emulsion;

[0055] The filler is DuPont rutile titanium dioxide;

[0056] The water-based polyurethane is Jining Huakai Resin Co., Ltd. HK718;

[0057] Described defoamer is BASF A10;

[0058] The dispersant is BYK180.

[0059] (2) Primer coating includes A component and B component;

[0060] The mass ratio of component A and component B is: component A: component B = 13:1; before using the primer, mix component A and component B according to the mass ratio.

[0061] The parts by mass of the A component of the primer are composed of:

[0062] 8 parts of ethyle...

Embodiment 3

[0068] Example 3 A waterproof and moisture-permeable coating

[0069] Described coating comprises primer and surface coating;

[0070] (1) The mass composition of the surface coating is: 45 parts of water-based fluorocarbon emulsion, 10 parts of filler, 30 parts of water-based polyurethane, 1 part of defoamer, and 0.5 parts of dispersant;

[0071] The water-based fluorocarbon resin is Guangdong Pine Chemical PTFE emulsion;

[0072] The filler is DuPont rutile titanium dioxide;

[0073]The water-based polyurethane is Jining Huakai Resin Co., Ltd. HK718;

[0074] Described defoamer is BASF A10;

[0075] The dispersant is BYK180.

[0076] (2) Primer coating includes A component and B component;

[0077] The mass ratio of component A and component B is: component A: component B = 15:1; before using the primer, mix component A and component B according to the mass ratio.

[0078] The parts by mass of the A component of the primer are composed of:

[0079] 10 parts of ethyle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wear resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com