Patents

Literature

48 results about "Ethyl methyl cellulose" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ethyl methyl cellulose is a thickener, vegetable gum, foaming agent and emulsifier. Its E number is E465. Chemically, it is a derivative of cellulose with ethyl and methyl groups attached by ether linkages. It can be prepared by treatment of cellulose with dimethyl sulfate and ethyl chloride in the presence of an alkali.

Controlled release composition

InactiveUS20080254124A1Easy for to follow prescribed regimenConstant of releasePowder deliverySolution deliveryEthyl(hydroxyethyl)celluloseCellulose acetate

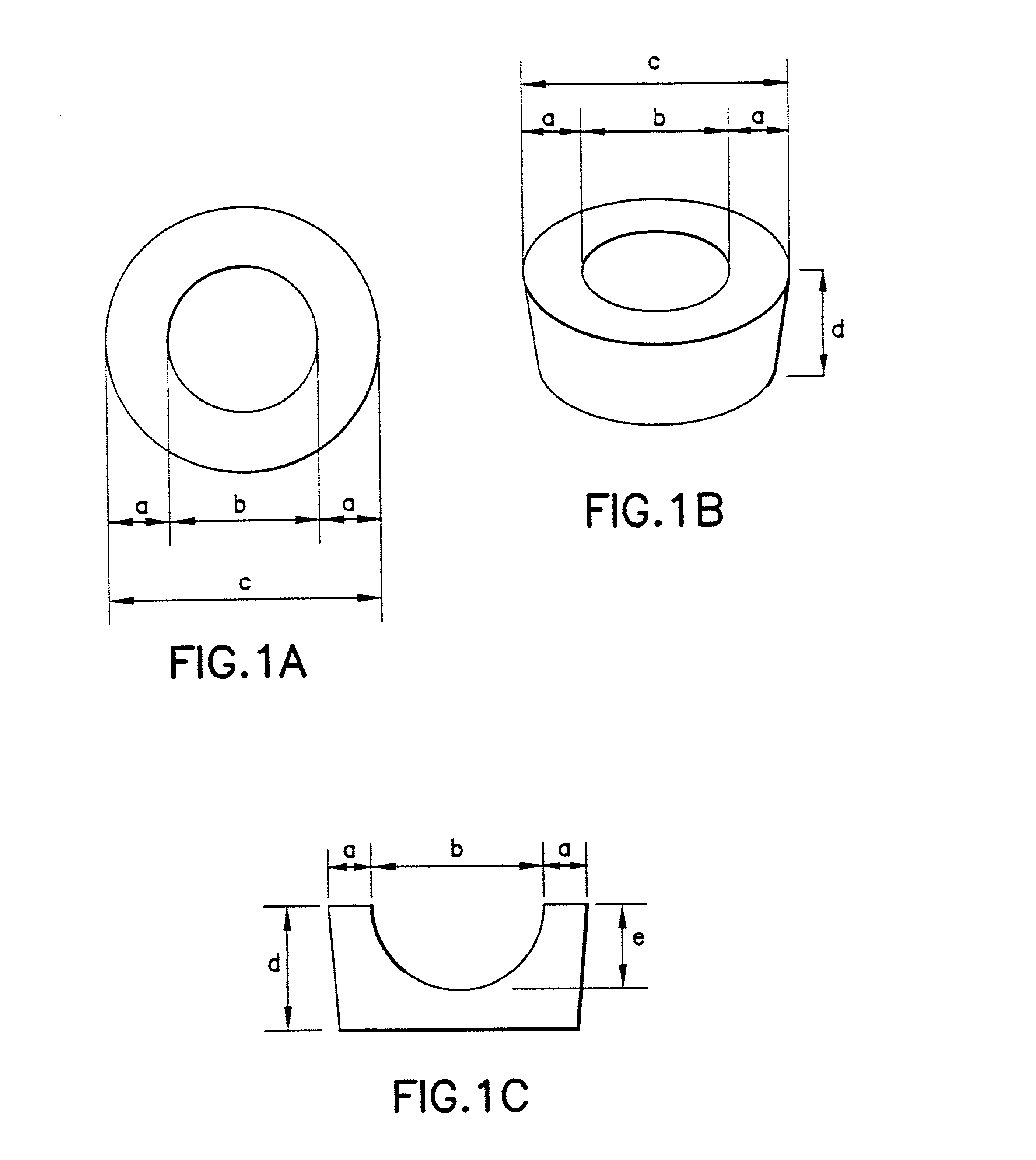

A composition for controlled delivery of at least one active substance into an aqueous medium by erosion at a preprogrammed rate of at least one surface of the composition, comprising a matrix comprising the active substance, the matrix being erodible in the aqueous medium in which the composition is to be used, and a coating having at least one opening exposing at least one surface of said matrix, the coating comprising a first cellulose derivative which has thermoplastic properties and which is substantially insoluble in the aqueous medium in which the composition is to be used, and at least one of a second cellulose derivative which is soluble or dispersible in water, a plasticizer, and a filler. The coating is a coating which crumbles and / or erodes upon exposure to the aqueous medium such as a body fluid. The first cellulose derivative may be, e.g., ethylcellulose, cellulose acetate, cellulose propionate or cellulose nitrate, and the second cellulose derivative may be, e.g. methylcellulose, carboxymethylcellulose or salts thereof, cellulose acetate phthalate, microcrystalline cellulose, ethylhydroxyethylcellulose, ethylmethylcellulose, hydroxyethylcellulose, hydroxyethylmethylcellulose, hydroxypropylcellulose, hydroxypropylmethylcellulose, hydroxymethylcellulose or hydroxymethylpropylcellulose.

Owner:EGALET LTD

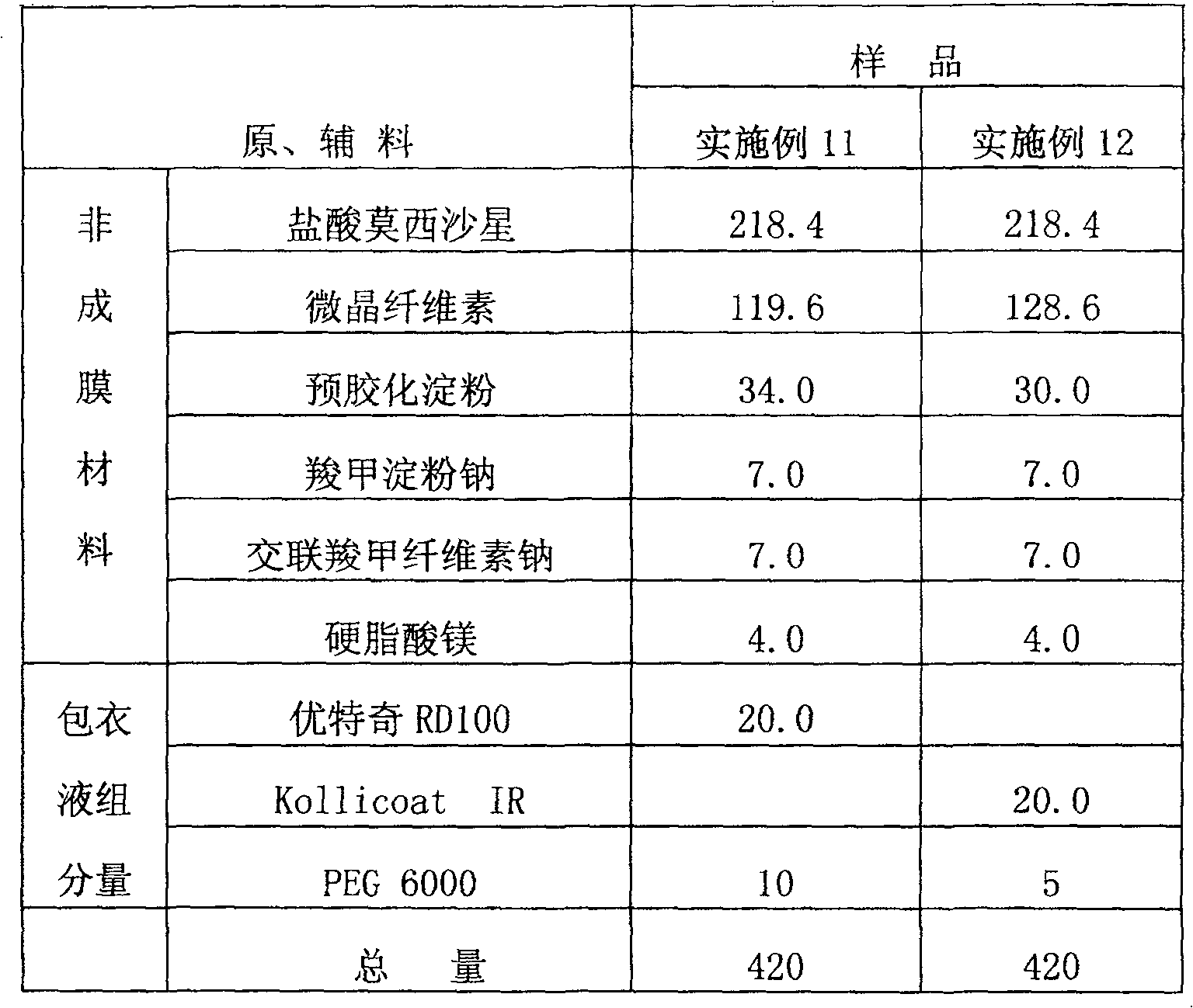

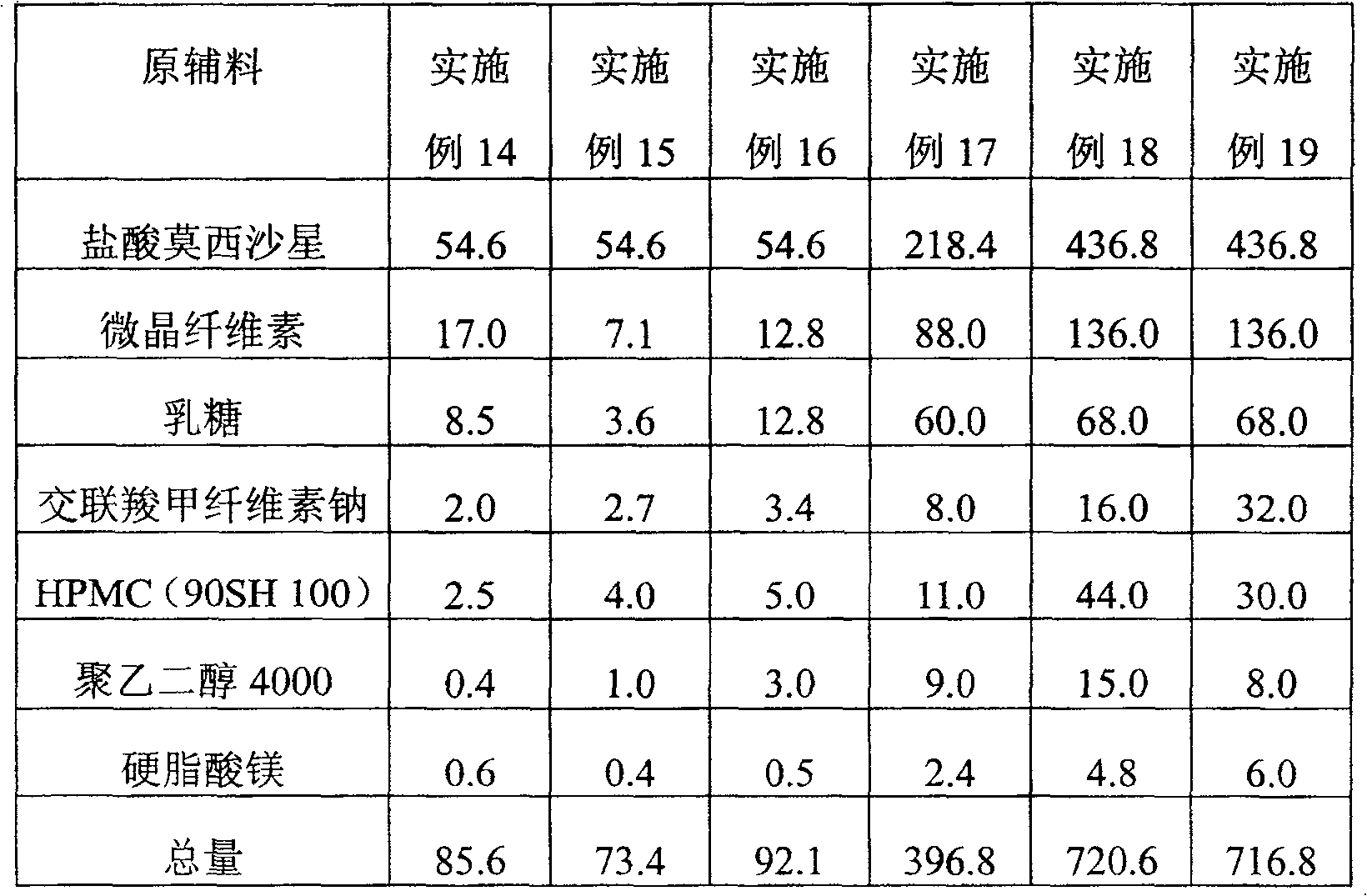

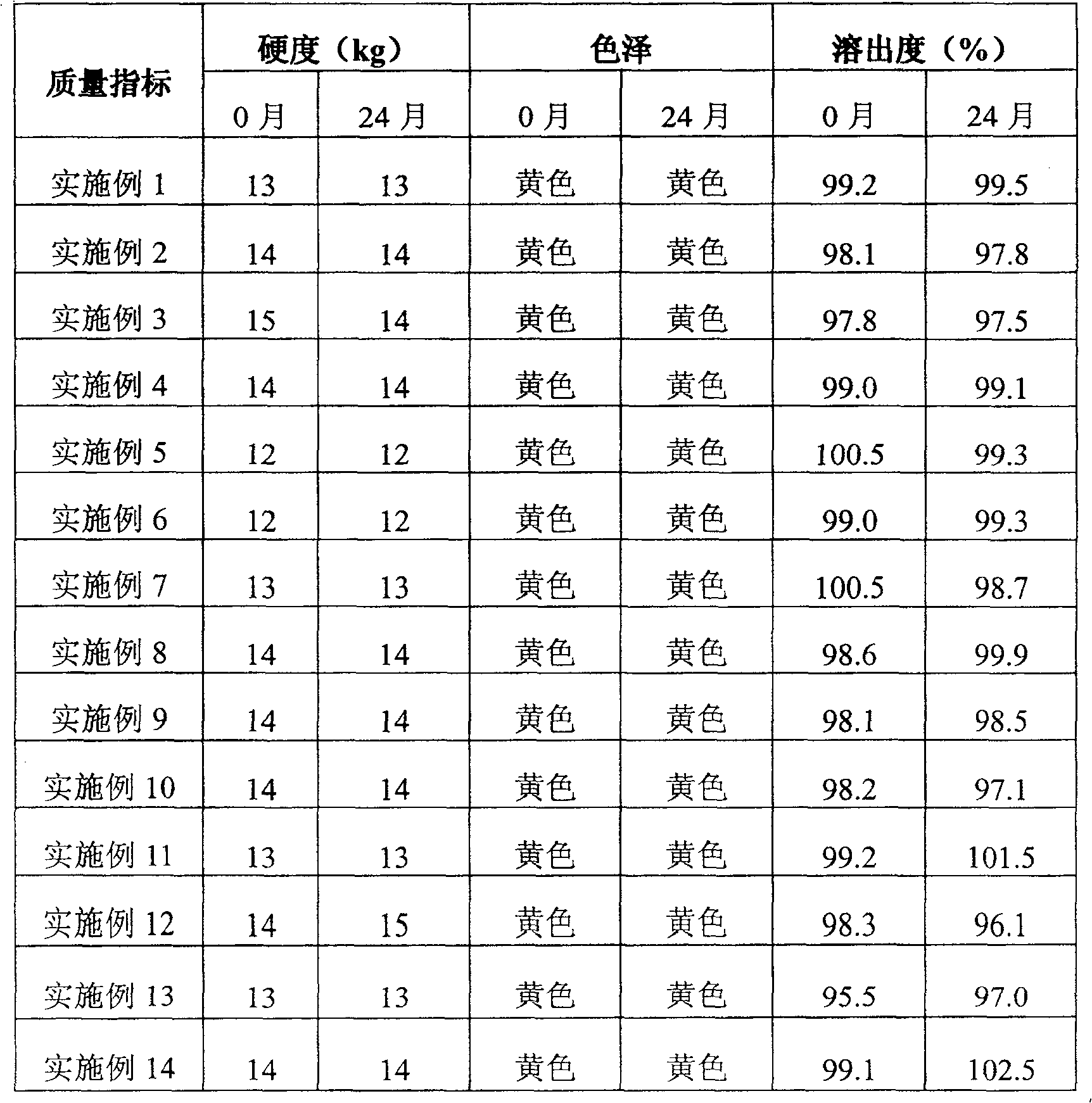

Oral medicinal formulation of moxifloxacin and its preparation method

ActiveCN1762357APromote dissolutionDissolution unchangedAntibacterial agentsOrganic active ingredientsCarboxymethyl cellulosePolyethylene glycol

The invention relates to an oral medicinal formulation of moxifloxacin and its preparation method, which comprises Moxifloxacin or its salt and / or its hydrate, and at least one film forming material for preparing intermediate particles of the preparation selected from hydroxy propyl methyl cellulose, hydroxy ethyl methyl cellulose, cellulose methyl, hydroxy propyl cellulose, hydroxy ethyl cellulose, sodium carboxymethyl cellulose, polyacrylic resins, polyethylene glycol, polyvinyl pyrrolidon-vinyl acetate copolymer, polyvinyl alcohol-polyethylene glycol grafted copolymer, carbopol, gelatine, poloxamer and polyvinyl pyrrolidon. The invention also discloses the process for preparing the pharmaceutical preparation.

Owner:JIANGSU TIANYISHI PHARMA

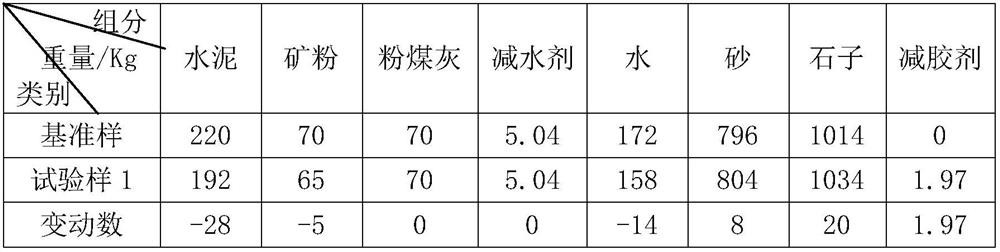

Concrete glue reducing agent and preparation process and application method thereof

ActiveCN109574538AAdjust and control viscosityImprove liquidityPolyethylene glycolMethyl palmoxirate

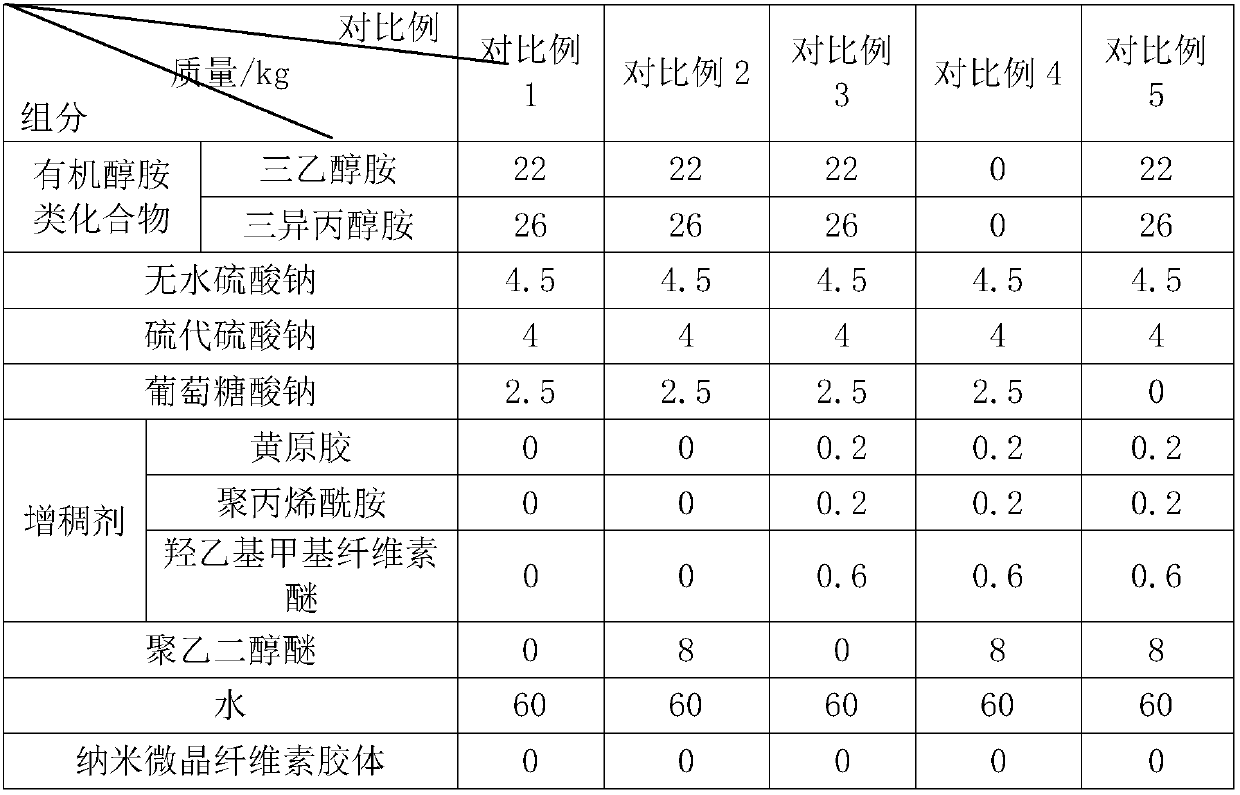

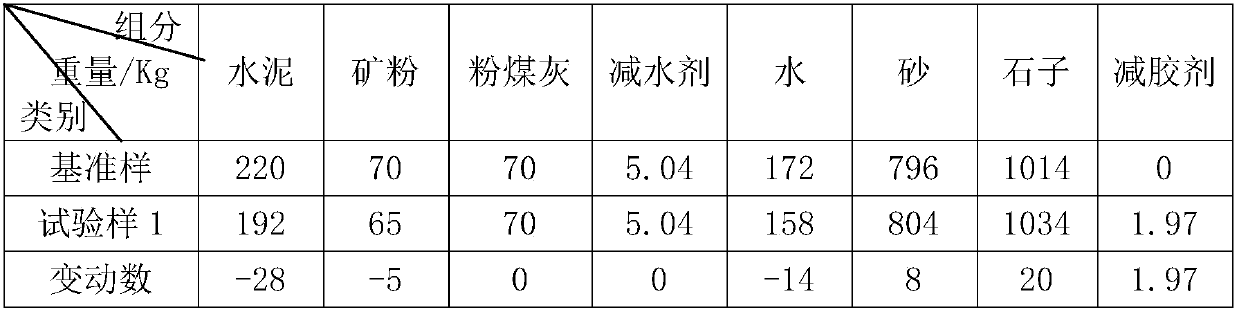

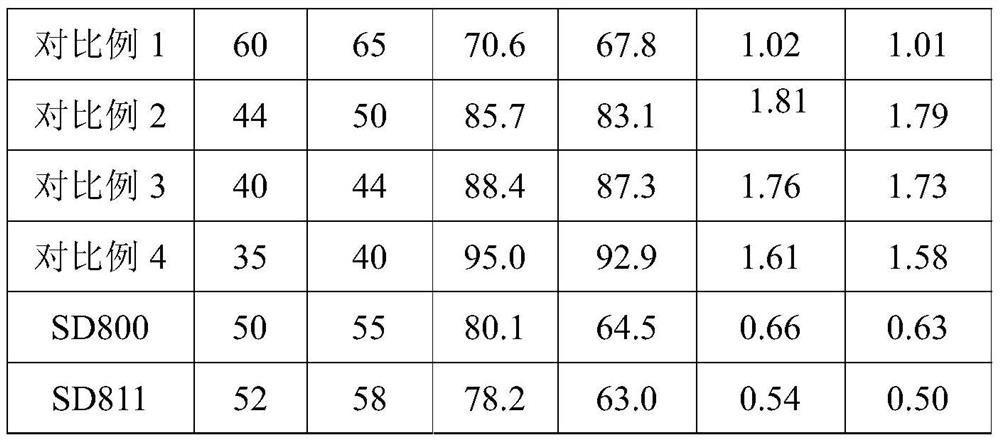

The invention discloses a concrete glue reducing agent and a preparation process and application method thereof. The concrete glue reducing agent comprises the following components in parts by weight:35-50 parts of an organic alkylol amines compound, 1-5 parts of anhydrous sodium sulfate, 2-10 parts of sodium thiosulfate, 0.1-3 parts of sodium gluconate, 1-5 parts of a thickening agent, 3-10 parts of polyglycol ether and 55-70 parts of water. The organic alkylol amines compound comprises at least one of triethanolamine and triisopropanolamine; and the thickening agent comprises at least one of xanthan gum, polyacrylamide and hydroxyethyl methyl cellulose. The concrete glue reducing agent can be used for a concrete blending process, does not have irritating odor, has the advantage of environmental protection, and has effects of reducing the using amount of cement and improving the strength of the concrete when added in the concrete.

Owner:HANGZHOU LIPING IND & TRADE CO LTD

Biodegradable microbicidal vaginal barrier device

An intravaginal bio-erodible microbicidal barrier device. The device comprises (a) at least one micronized compound selected from the group consisting of cellulose acetate phthalate and hydroxypropylmethylcellulos- e phthalate, and (b) at least one water soluble or water dispersible cellulose compound selected from the group consisting of hydroxypropylmethylcellulose, methylcellulose, hydroxyethylcellulose, hydroxypropylcellulose, hydroxyethylmethylcellulose, hydroxyethylethylcellulose and hydroxypropylethylcellulose; or a pectin, such as an apple pectin. The device is prepared by a combination of foaming, freezing and freeze-drying processes.

Owner:NEW YORK BLOOD CENT

Volumizing Agents

ActiveUS20070037712A1Improve maximizationImprove brittlenessPowder deliveryBiocideHydroxyethyl methyl celluloseEthyl methyl cellulose

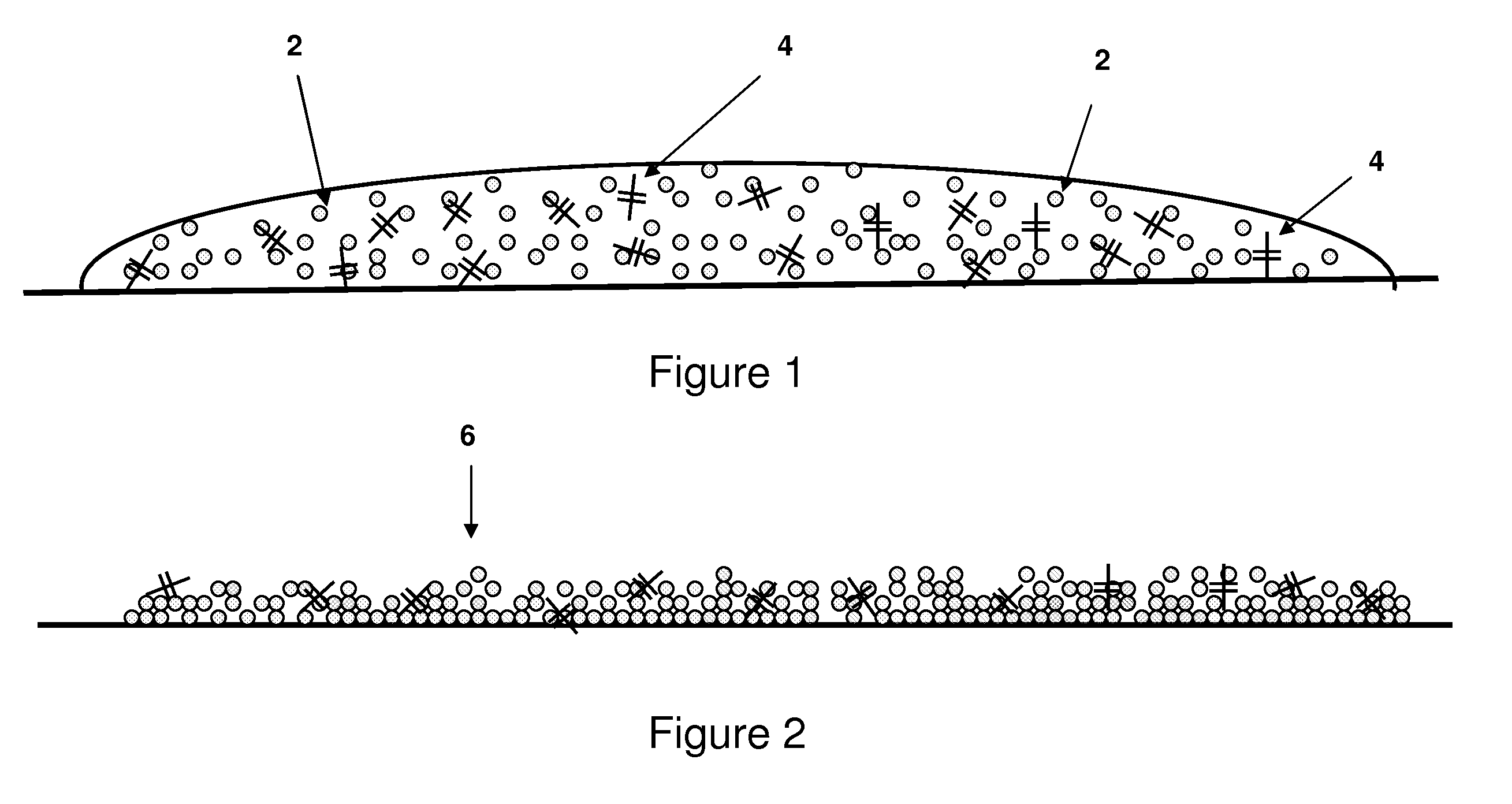

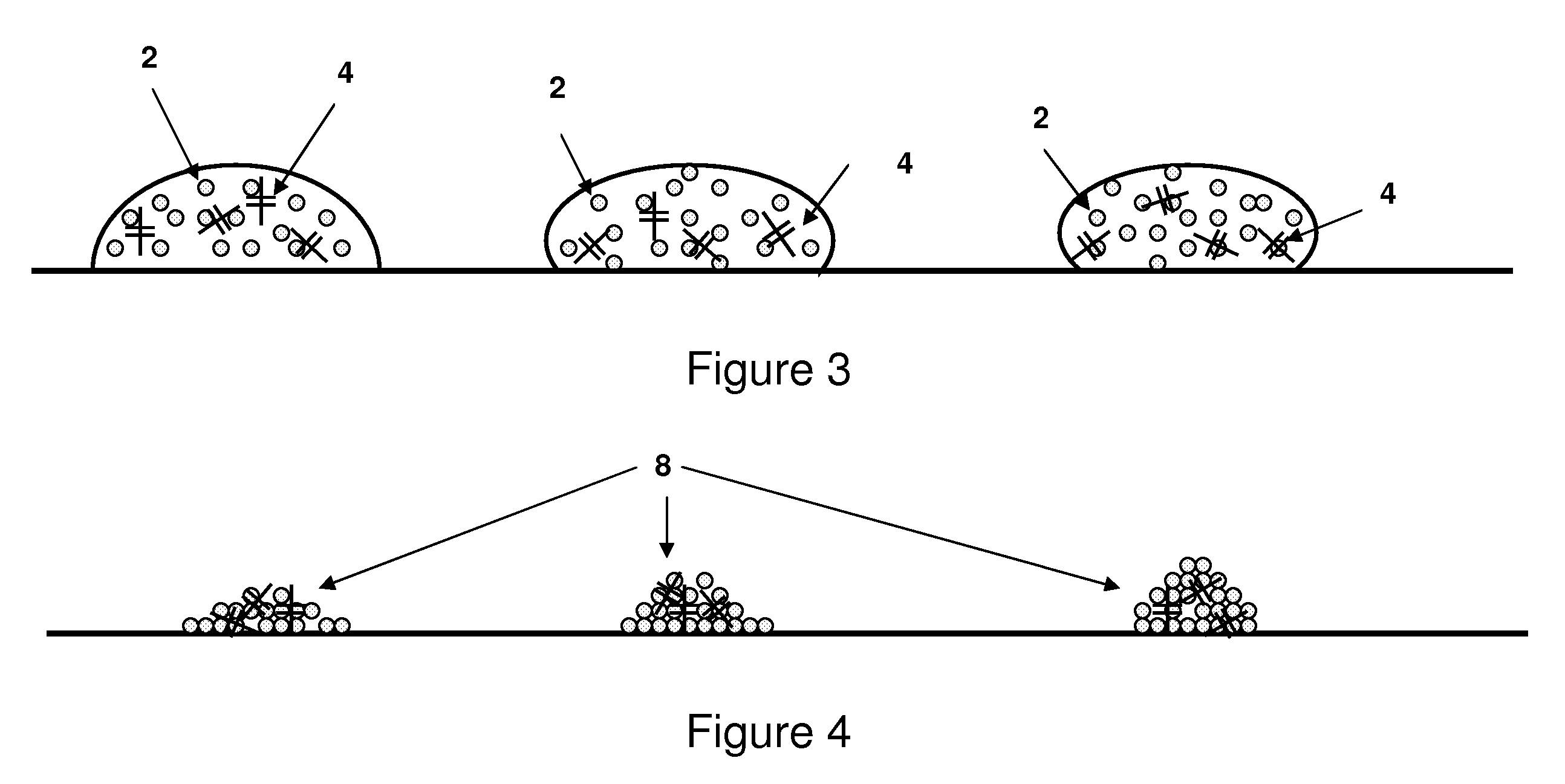

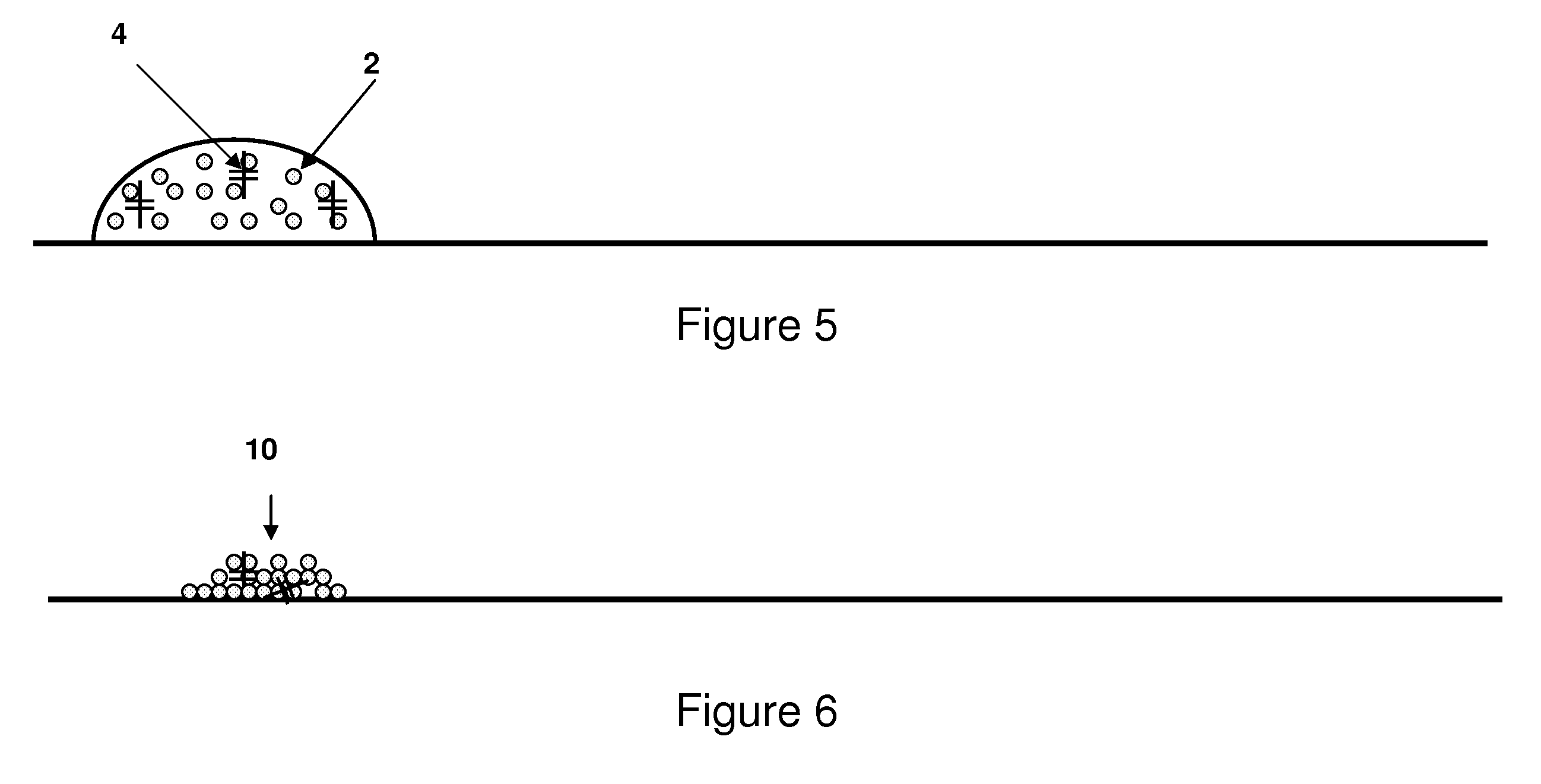

The present composition is capable of forming a particle film and comprises: (a) less than 99.65% by weight of at least one particle; (b) at least one volumizing agent selected from the group consisting of: (i) cellulose selected from the group consisting of ethyl hydroxy ethyl cellulose, hydroxy ethyl cellulose, hydroxy propyl cellulose, hydroxy ethyl methyl cellulose, hydroxy propyl methyl cellulose, methyl cellulose, ethyl cellulose, and ethyl methyl cellulose and present in an amount greater than 0.35% by weight; and (ii) non-cellulosic component or cellulose other than said cellulose (i) present in an amount of at least 0.05% by weight; and optionally (c) at least one spreader. The composition may be used to form agricultural films.

Owner:US SEC AGRI +1

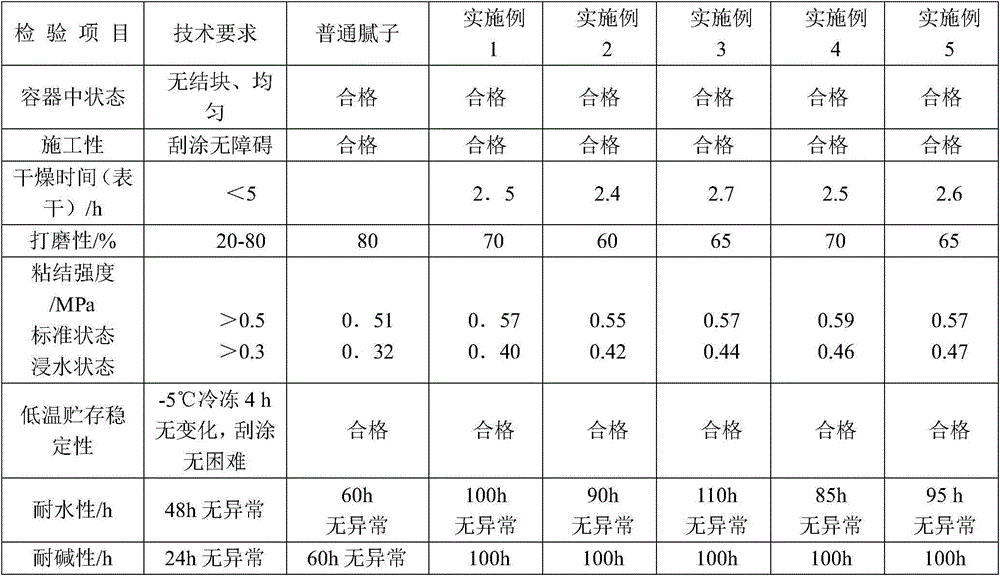

Environment-friendly flexible interior wall putty and preparation method thereof

ActiveCN103980756AImprove flexibilityImprove waterproof performanceFilling pastesEmulsionCrack resistance

The invention discloses environment-friendly flexible interior wall putty and a preparation method thereof. The environment-friendly flexible interior wall putty comprises the following components by mass percent: 20-26% of water, 20-27% of acrylic emulsion, 5-10% of heavy calcium carbonate powder, 10-15% of light calcium carbonate powder, 12-19% of talcum powder, 5-7% of blanc fixe, 5-8% of bentonite, 2-3.7% of hydroxyethyl methyl cellulose ether, 1-3% of an antifreezing agent, 0.1-0.3% of a defoamer and 0.1-0.3% of a dispersant. The interior wall putty disclosed by the invention has the advantages of good flexibility, strong waterproofness, good crack resistance, fine and smooth surface texture after being scraped and the like, and is environment-friendly and not easy to atomize.

Owner:山东恒远装饰设计工程有限公司

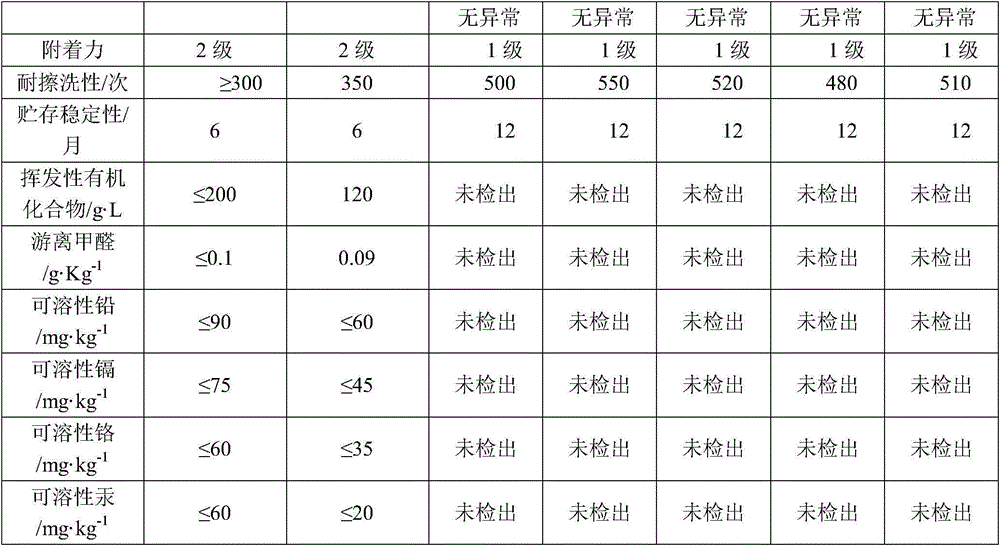

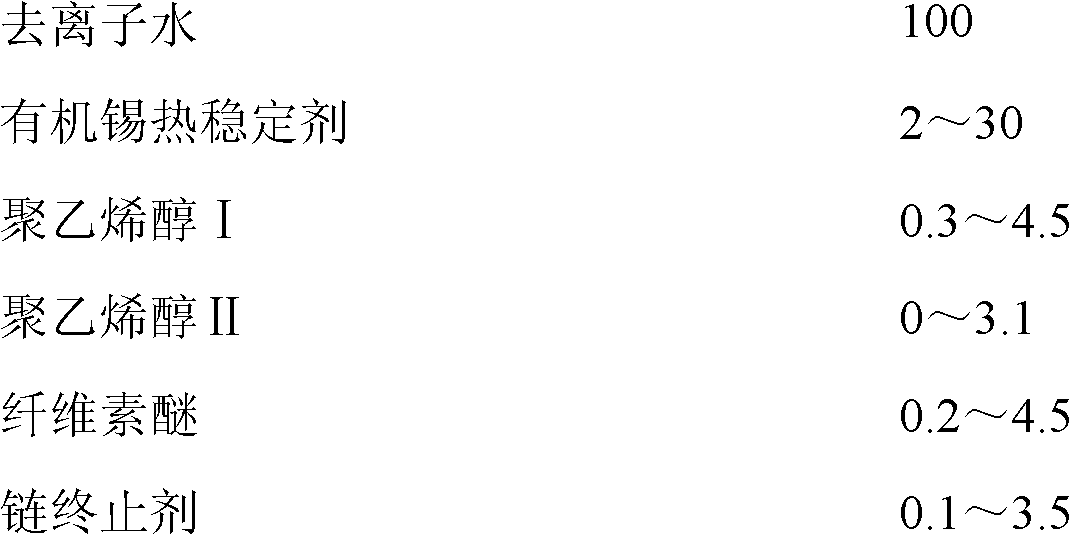

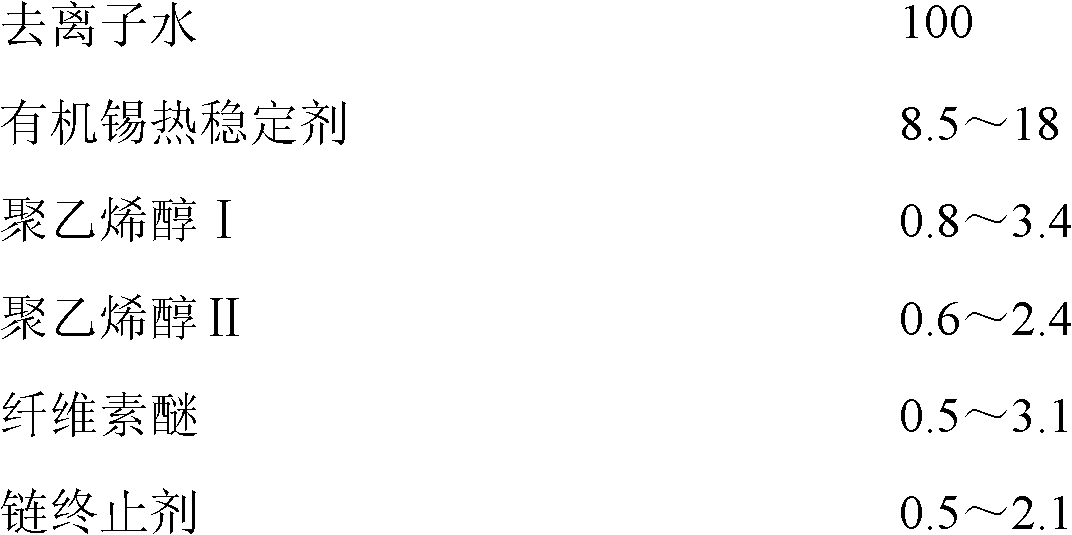

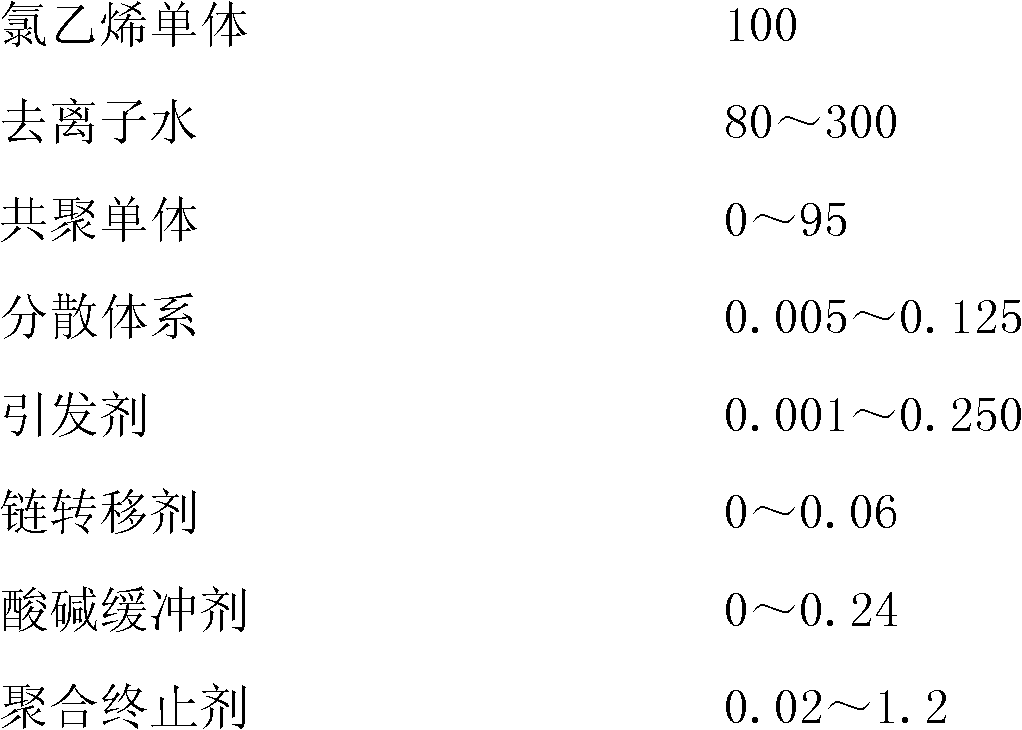

Chloroethylene suspension polymerization terminator and preparation method and use method thereof

The invention discloses a chloroethylene suspension polymerization terminator and a preparation method and a use method thereof, belonging to a terminator used in a chloroethylene polymerization process. The chloroethylene suspension polymerization terminator is characterized by being an aqueous emulsion dispersion liquid and consisting of the following raw materials in parts by weight: 100 parts of deionized water, 2-30 parts of organic tin thermal stabilizer, 0.3-4.5 parts of polyvinyl alcohol I, 0-3.1 parts of polyvinyl alcohol II, 0.2-4.5 parts of cellulose ether and 0.1-3.5 parts of chain terminator, wherein the deionized water is industrial secondary desalted water; the alcoholysis degree of the polyvinyl alcohol I is between 75-85 percent; the alcoholysis degree of the polyvinyl alcohol II is between 50-60 percent; and the cellulose ether is methyl cellulose (MC), hydroxyethylmethylcellulose (HEC) or hydroxypropyl methyl cellulose (HPMC). The invention provides a chloroethylene suspension polymerization terminator which can be used for effectively terminating a chloroethylene polymerization reaction and remarkably improving the aging whiteness and heat resistance of polymerized resin, and the preparation method and the use method thereof.

Owner:CHINA PETROLEUM & CHEM CORP

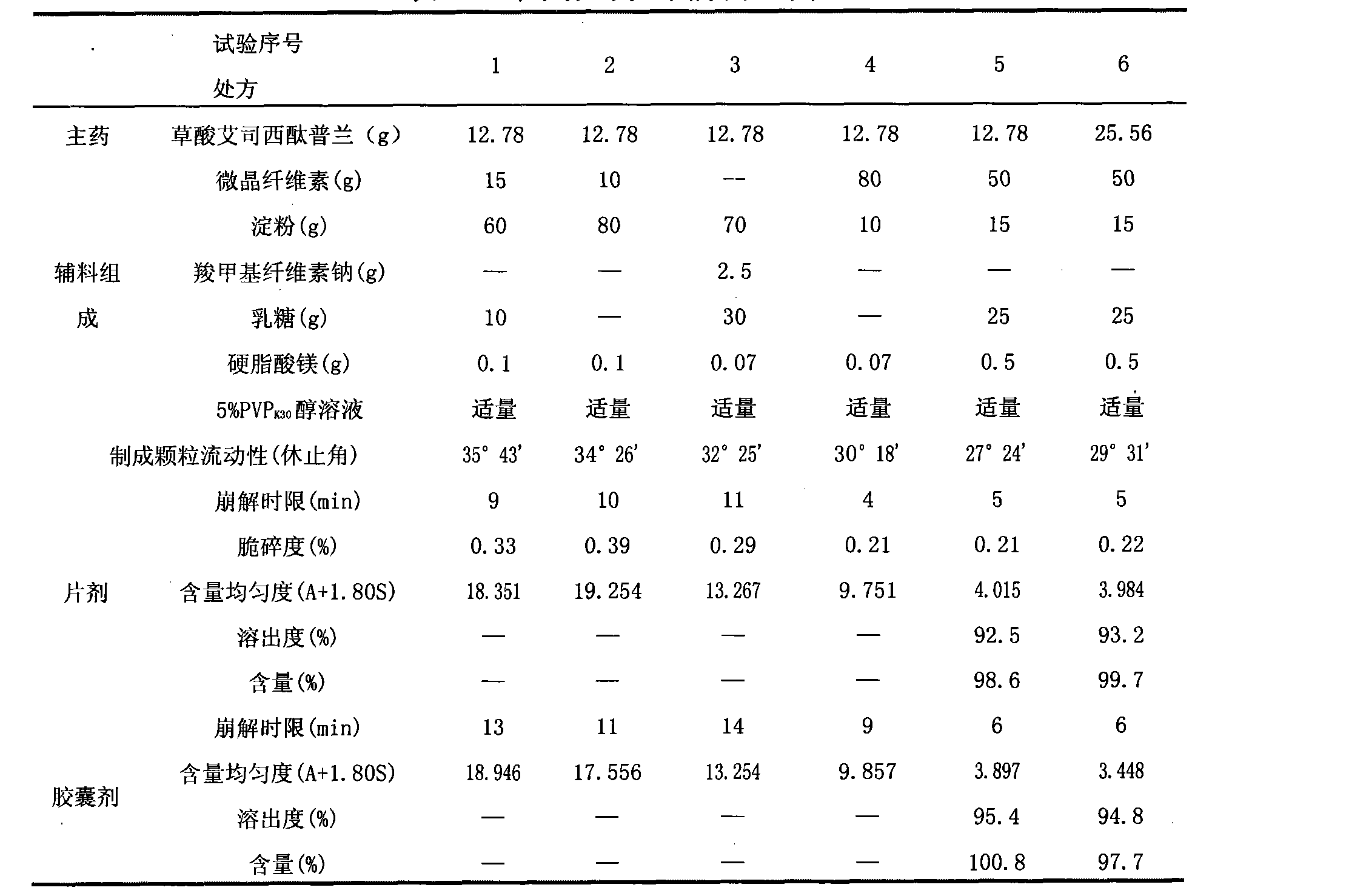

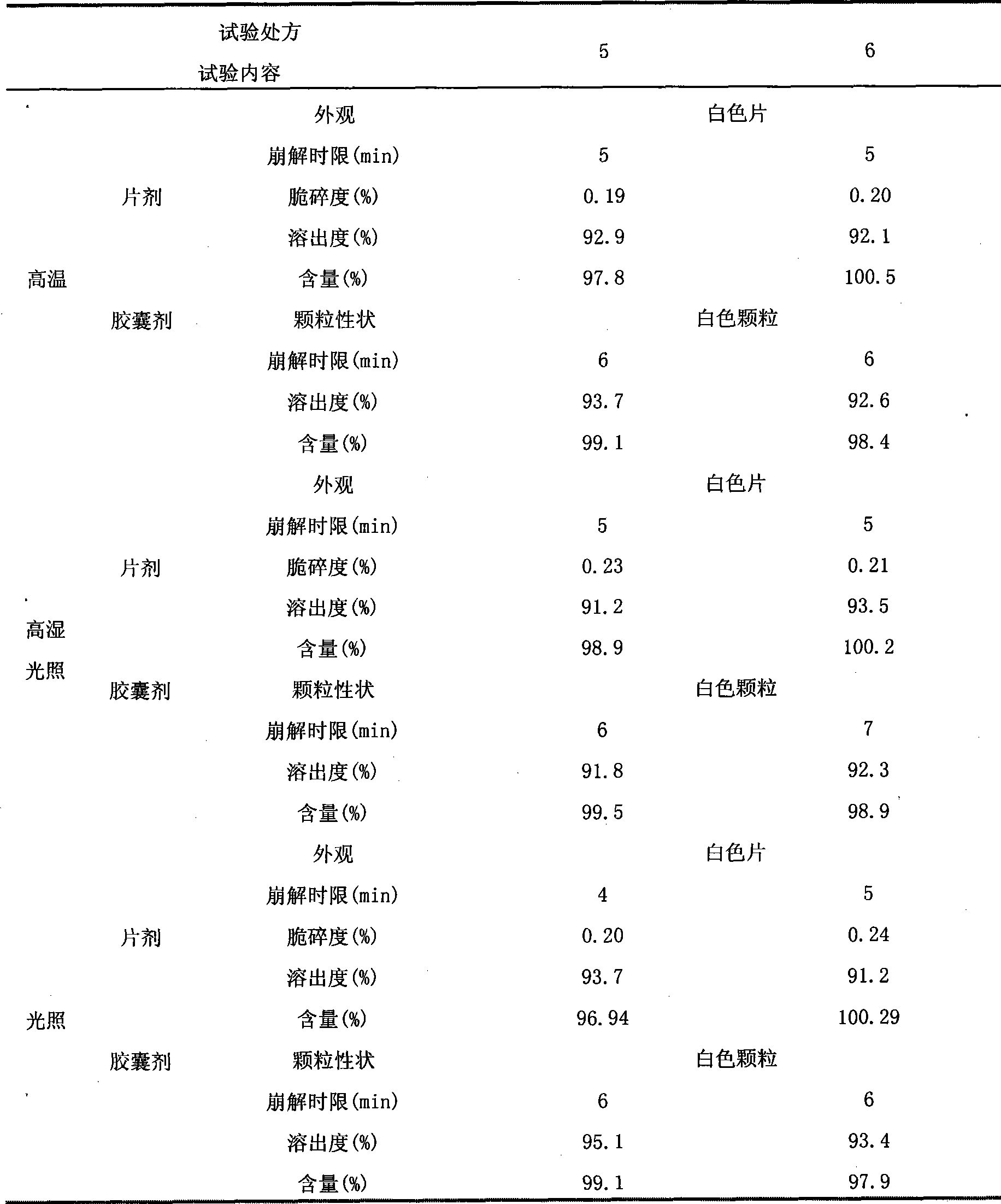

Oral solid preparation of escitalopram oxalate and preparation method thereof

The invention discloses an oxalic acid esmolol citalopram oral solid preparation and a preparation method. The oral solid preparation comprises raw materials of: 2-40 parts by weight of oxalic acid esmolol citalopram, 5-60 parts by weight of starch, 5-200 parts by weight of microcrystalline cellulose, 5-60 parts by weight of lactose, 0.05-5 parts by weight of binding agent and 0.05-3 parts by weight of lubricant; the binding agent is one or a plurality of mixed aqueous solutions or alcoholic solutions from the group consisting of polyvinyl pyrrolidone, hydroxyethyl methylcellulose, methylcellulose, hydroxypropyl cellulose and ethyl cellulose, the concentration of the binding agent is 0.1-10.0%; and the lubricant is stearic acid, magnesium stearate, calcium stearate, talcum or superfine silica gel powder.

Owner:SICHUAN KELUN PHARMA CO LTD

Heat-insulating dried-powder mortar of sticking furring brick and manufacture method

The invention discloses an insulating dry powder mortar to stick face brick, which comprises the following parts: polystyrene foam particle, cement, ultrafine yarn, fly ash, hydroxyethylmethylcellulose ether, vinyl acetate / ethane copoly-gel powder, wood fiber and carboxylic group block copolymer gel powder, wherein the cement, hydroxyethylmethylcellulose ether, vinyl acetate / ethane copoly-gel powder, wood fiber and fly ash are blended evenly to obtain middle dried powder A; the cement and carboxylic group block copolymer gel powder are mixed evenly to obtain the middle dried powder B; the cement, fly ash and polystyrene foam particle are blended evenly to generate middle dried powder C; the middle dried powder A, B and C are mixed together to produce dried powder of insulating mortar, which can be stirred into slurry after adding fitful water in the dried powder.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

Preparation method of hydroxyl-ethyl methyl cellulose

The invention discloses a preparation method of hydroxyl-ethyl methyl cellulose; according to the method, refined cotton is used as the raw material, and ethylene oxide is used as the etherifying agent so as to prepare hydroxyl-ethyl methyl cellulose; compared with the existing cellulose ether technology, the hydroxyl-ethyl methyl cellulose prepared by the method has advantages that as the ethylene oxide is used as the etherifying agent to prepare the hydroxyl-ethyl methyl cellulose, the anti-mildew ability is high due to the hydroxyethyl group, and hydroxyl-ethyl methyl cellulose prepared by the method is high in the viscosity stability and the anti-mildew ability when being stored for a long time and can replace other cellulose ethers.

Owner:新疆光大山河化工科技有限公司

Flexible insulation exterior wall putty and preparation method

The invention discloses flexible insulation exterior wall putty which is prepared from the raw materials, by mass, of 20-30 parts of deionized water, 40-54 parts of heavy calcium carbonate powder, 8-14 parts of aluminum powder, 8-12 parts of amino resin, 20-24 parts of pure acrylic emulsion, 5-9 parts of asbestos fiber, 2-5 parts of magnesium stearate, 1-3 parts of mannitol, 1-5 parts of dibutyl phthalate, 1-4 parts of sodium hexametaphosphate, 1-5 parts of carboxymethylcellulose, 2-4 parts of methyl 2-hydroxyethyl cellulose, 2-5 parts of bactericide and 3-6 parts of antifoaming agent. The prepared flexible insulation exterior wall putty is stable in quality, high in bonding strength, good in flexibility and constructability, low in heat conductivity coefficient, good in insulating effect and worth popularizing.

Owner:吕凤荣

Oral medicinal formulation of moxifloxacin and its preparation method

ActiveCN1762357BPromote dissolutionDissolution unchangedAntibacterial agentsOrganic active ingredientsPolyvinyl alcoholPolyethylene glycol

Owner:JIANGSU TIANYISHI PHARMA

Grouting material

The invention relates to a grouting material. The grouting material is prepared by mixing silicate cement, hydroxyl ethyl methyl cellulose, natural guar gum, silica fume, glycine betaine and water in a weight ratio of (1-1.2):(0.001-0.008):(0.001-0.01):(0.1-0.2):(0.001-0.005):1. According to the grouting material, the slurry viscosity and condensing performance can be improved due to the interaction of silica fume, hydroxyl ethyl methyl cellulose and natural guar gum, the viscosity and strength can be further improved due to the glycine betaine and natural guar gum, the elastic performance can be regulated according to the condition, and the aqueous dispersion effect in various water qualities can be resisted.

Owner:DONGHAI CONSTR GRP

Method for imparting stress tolerance to plant, plant stress tolerance imparting composition and use thereof

ActiveUS20130116121A1Improve the growing environmentLower metabolismBiocideDead animal preservationStress levelMethylethylcellulose

A method for imparting a stress tolerance to a plant that can provide the plant with such a stress tolerance that enhances growth in an environment where a variety of stresses on the plant occur is provided. The method for imparting a stress tolerance to a plant includes the step of applying, to a plant placed under a stressful cultivation condition that yields a plant stress level of 111 to 200%, a plant stress tolerance imparting composition containing at least one cellulose derivative selected from the group consisting of methyl cellulose (MC), hydroxymethyl cellulose (HMC), ethyl cellulose (EC), hydroxyethyl cellulose (HEC), propyl cellulose (PC), hydroxypropyl cellulose (HPC), hydroxypropyl methyl cellulose (HPMC), hydroxyethyl methyl cellulose (HEMC), hydroxyethyl propyl cellulose (HEPC), methyl ethyl cellulose (MEC), methyl propyl cellulose (MPC) and ethyl propyl cellulose (EPC); catechins; and water, the cellulose derivative being contained in an amount of 45.0 to 99.5 wt % of the total components of the plant stress tolerance imparting composition except water. The present invention also provides the plant stress tolerance imparting composition and use of the plant stress tolerance imparting composition.

Owner:KAO CORP

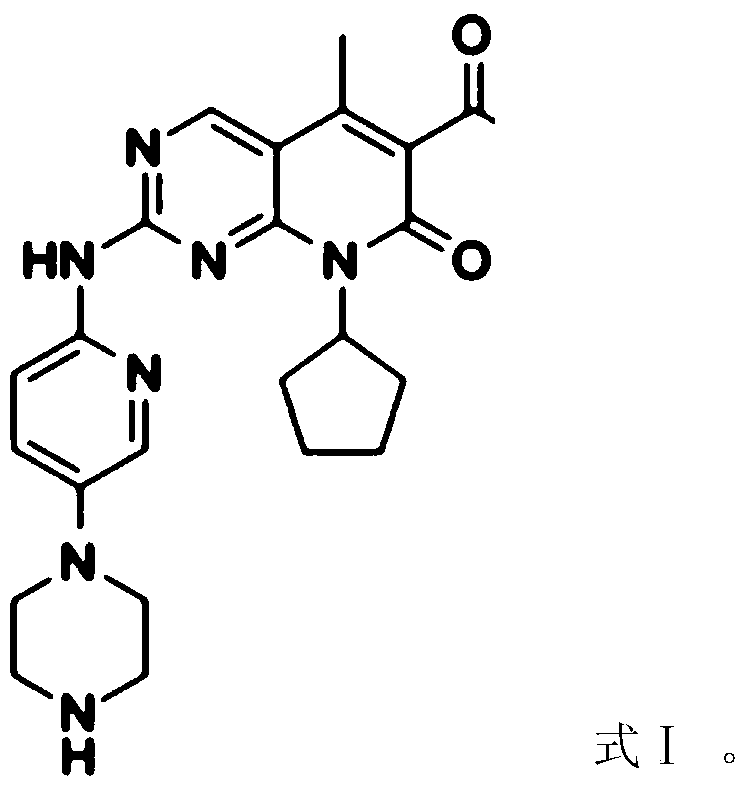

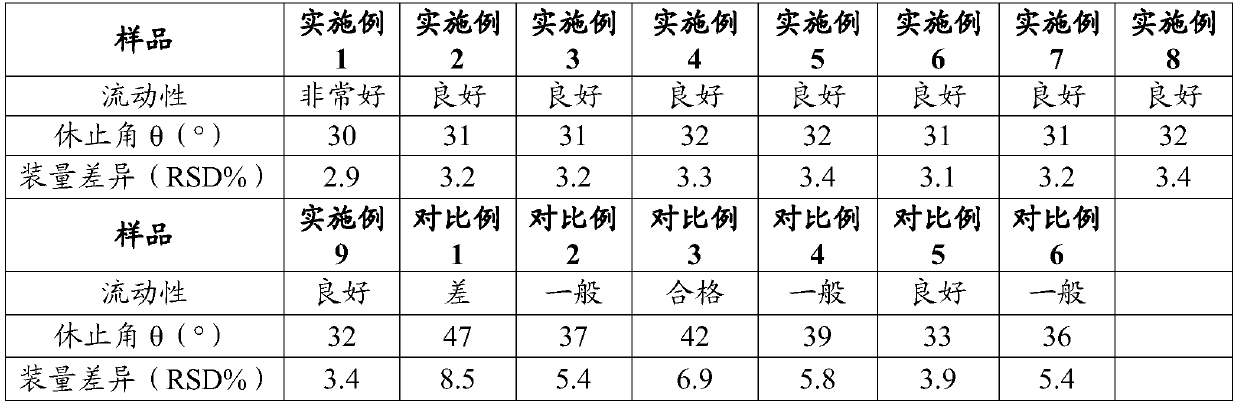

A kind of palbociclib pharmaceutical composition and preparation method thereof

ActiveCN108066312BHigh dissolution rateLow impurity contentOrganic active ingredientsGranular deliveryFatty acid glycerol estersBiology

The invention relates to the field of pharmaceutical preparations, and particularly discloses a palbociclib pharmaceutical composition and a method for preparing the same. The palbociclib pharmaceutical composition comprises, by weight, 20%-30% of palbociclib, 30%-40% of pregelatinized starch, 20%-30% of lactitol, 3%-5% of starch sodium glycollate, 4%-6% of hydroxyethyl methyl celluloses, 3%-5% ofhydroxyethyl celluloses and 1%-3% of citric acid fatty glyceride. The palbociclib pharmaceutical composition and the method have the advantages that excellent dissolution effects can be realized by the palbociclib pharmaceutical composition, the contents of related substances can be obviously reduced, the stability can be obviously enhanced, and clinical medicines can be advantageously safely used and can be advantageously stored for a long term; the particle sizes of raw auxiliary materials are controlled, accordingly, the palbociclib pharmaceutical composition is good in mixing property andflowability as discovered via experiments, and capsules can be directly filled with the palbociclib pharmaceutical composition by means of mixing.

Owner:SHANDONG YUXIN PHARMA CO LTD

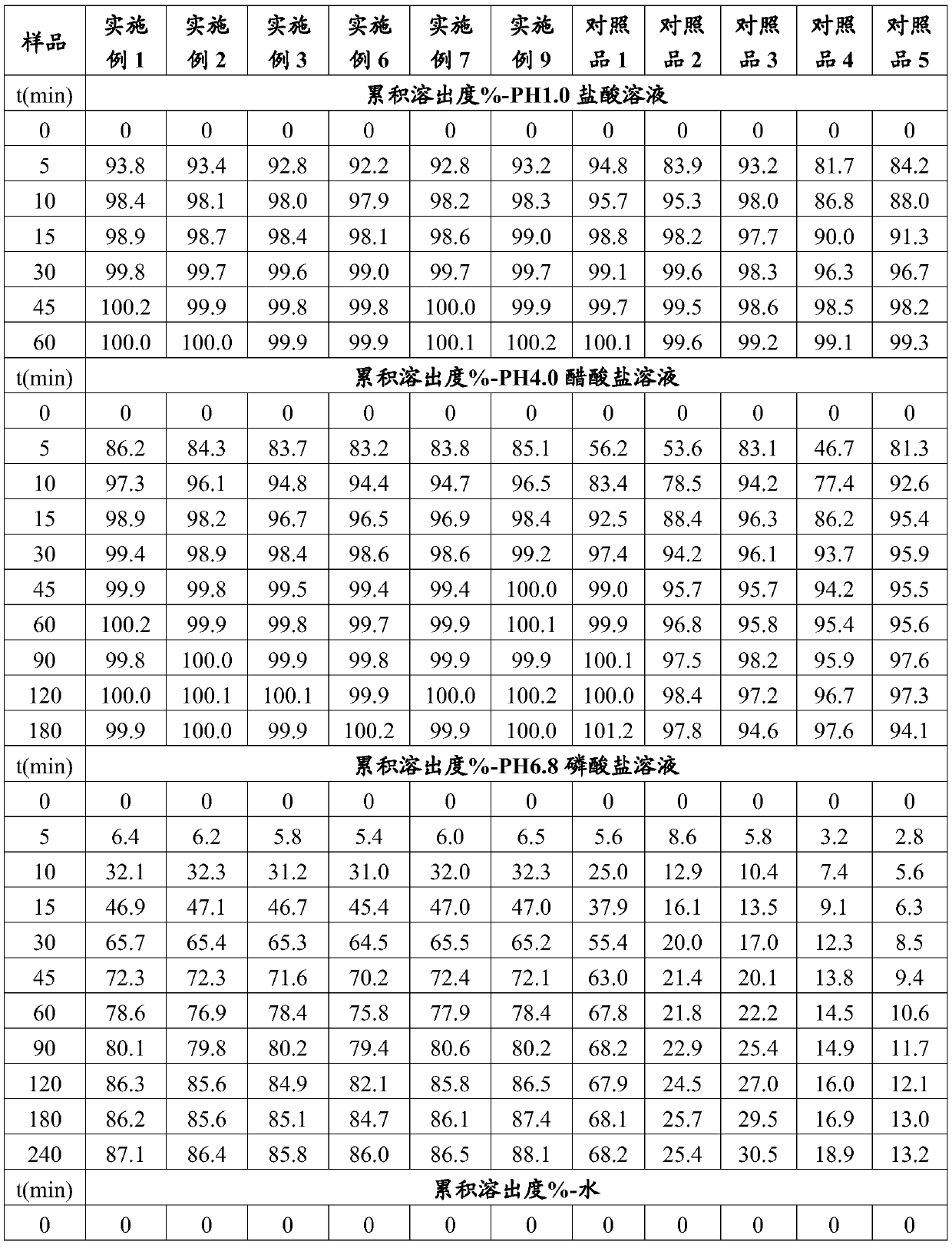

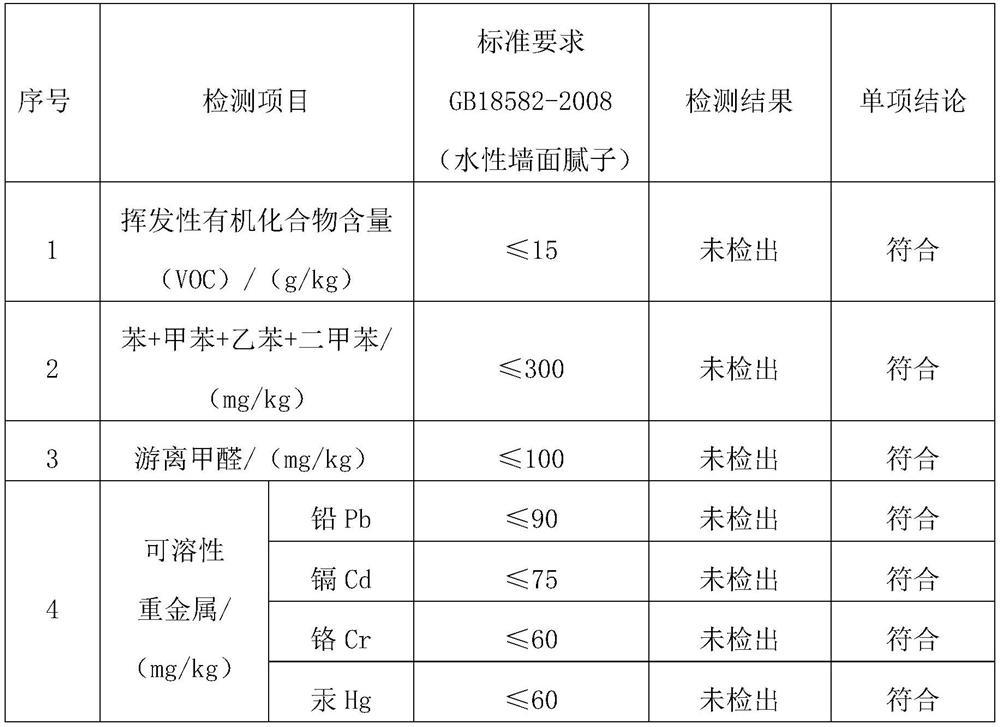

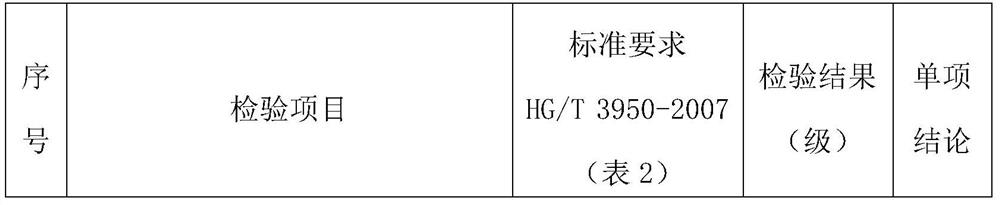

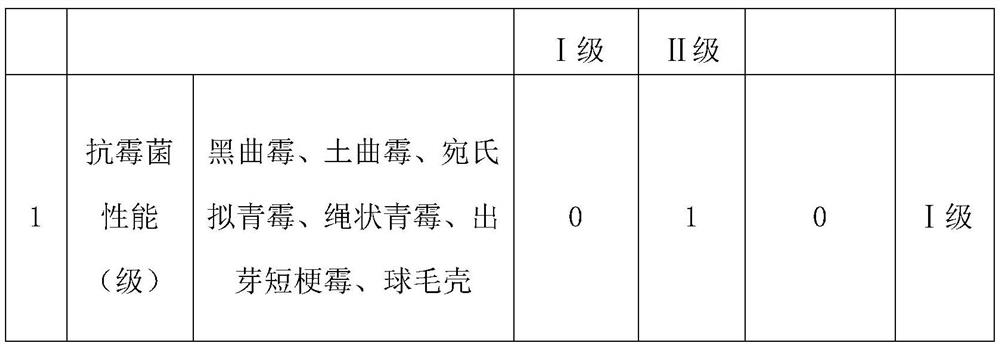

Mildew-proof antibacterial putty powder, preparation method and use method thereof

PendingCN111892837ASolve the problem of water resistance, moisture resistance and aging resistanceSolve the shortcomings of mold and black spots on the wallAntifouling/underwater paintsPaints with biocidesCelluloseAmylase

The invention relates to the technical field of building materials, particularly to mildew-proof and antibacterial putty powder, a preparation method and a use method thereof, wherein the mildew-proofand antibacterial putty powder is prepared by mixing the following materials: Portland cement, ash calcium, talcum powder, hydroethyl methyl cellulose, a mildew preventive, polyvinyl alcohol and amylase. The use method of the putty powder comprises the step of uniformly mixing the raw materials with water according to a mass ratio of (10-5):3. Compared with the prior art, the mildew-proof additive selected for specifically inhibiting mildew on the wall surface is compounded with putty to achieve the mildew-proof and antibacterial functional putty, so that water resistance, moisture resistanceand aging resistance of a wall decorative surface layer are achieved, and the defects that mildew and black spots grow on a wall due to indoor air moisture or wall surface permeation are overcome. According to the putty prepared by the method disclosed by the invention, all harmful substances, mould resistance and all physical properties meet the standards of GB18582-2008 (water-based wall putty), HG / T 3950-2007 (table 2) and JG / T 298-2020 (water-resistant N).

Owner:谭华勇

Heat-conducting wear-resisting plastic material and preparation method thereof

The invention discloses a heat-conducting wear-resisting plastic material. The heat-conducting wear-resisting plastic material comprises components in parts by weight as follows: 20-30 parts of asbestos fibers, 25-30 parts of ceramic fibers, 10-15 parts of polytetrafluoroethylene, 8-12 parts of nylon, 2-6 parts of magnesium oxide, 8-14 parts of polycarbonate, 7-13 parts of ethyl carbamate, 6-9 parts of meprobamate, 2-4 parts of zirconocene dichloride, 1-3 parts of potassium fluoromagnesate, 1-3 parts of huntite, 2-4 parts of zinc phosphinate, 6-10 parts of ethyl methyl cellulose, 9-12 parts of solketal and 3-5 parts of N-oleoylethanolamine. The plastic material can integrate good heat conductivity and good wear resistance, and the service life of the plastic material is prolonged.

Owner:SUZHOU JIN TENG ELECTRONICS TECH

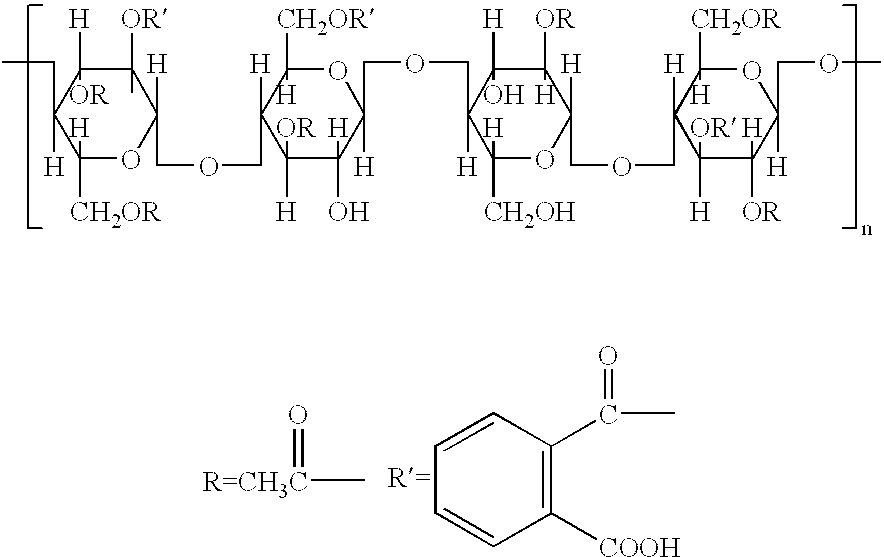

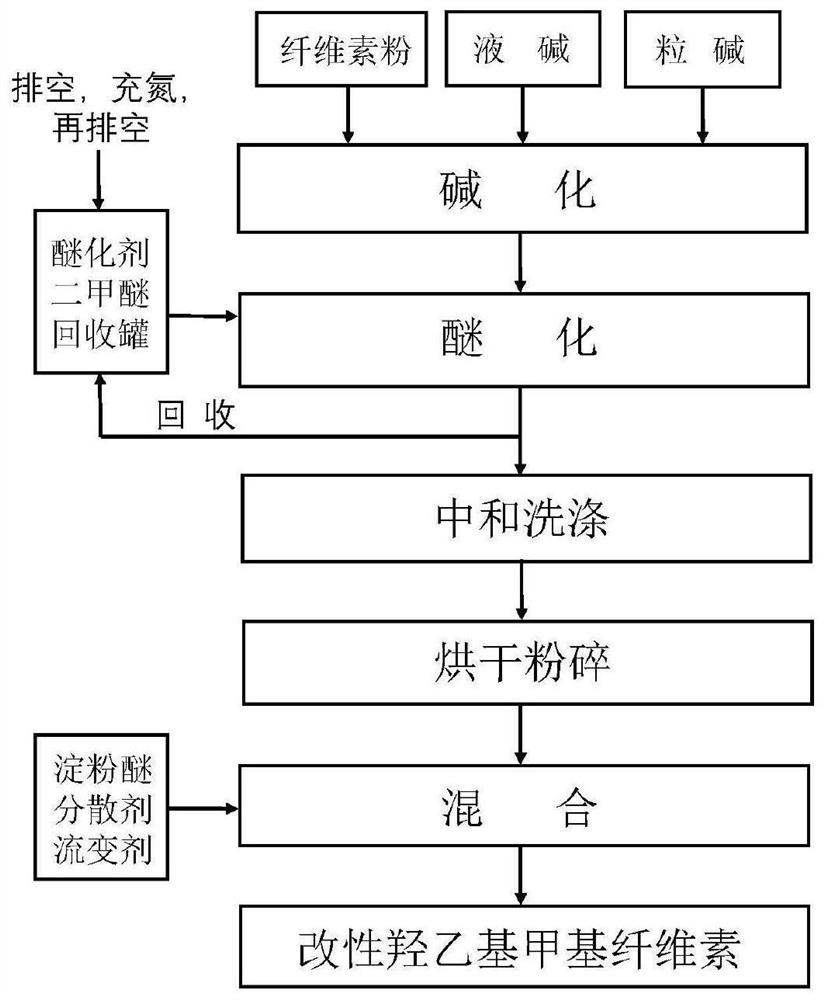

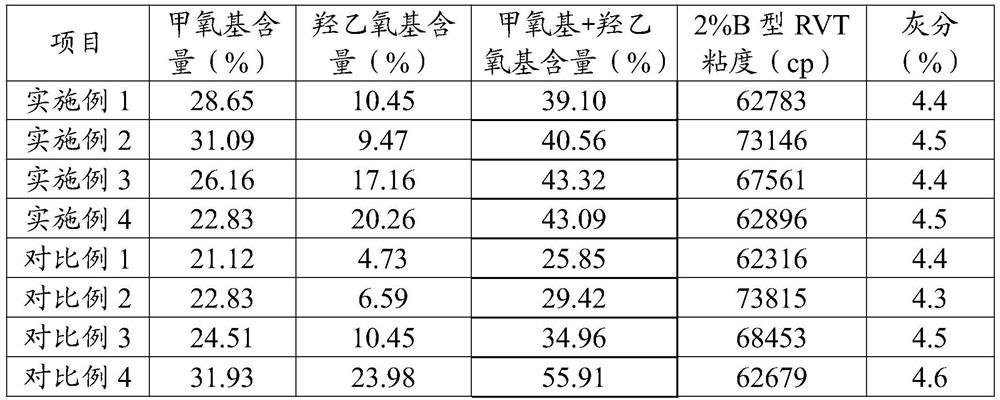

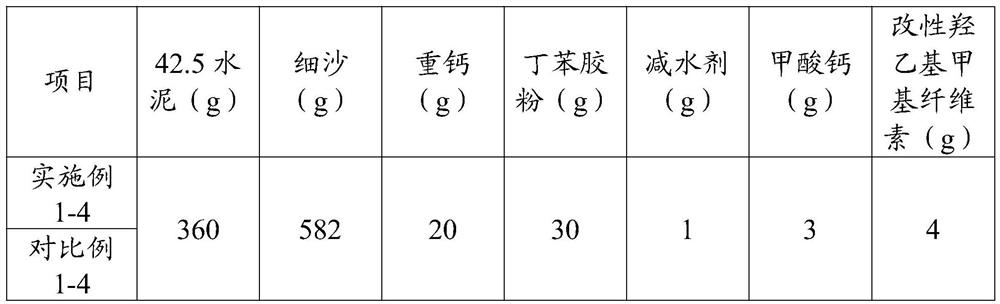

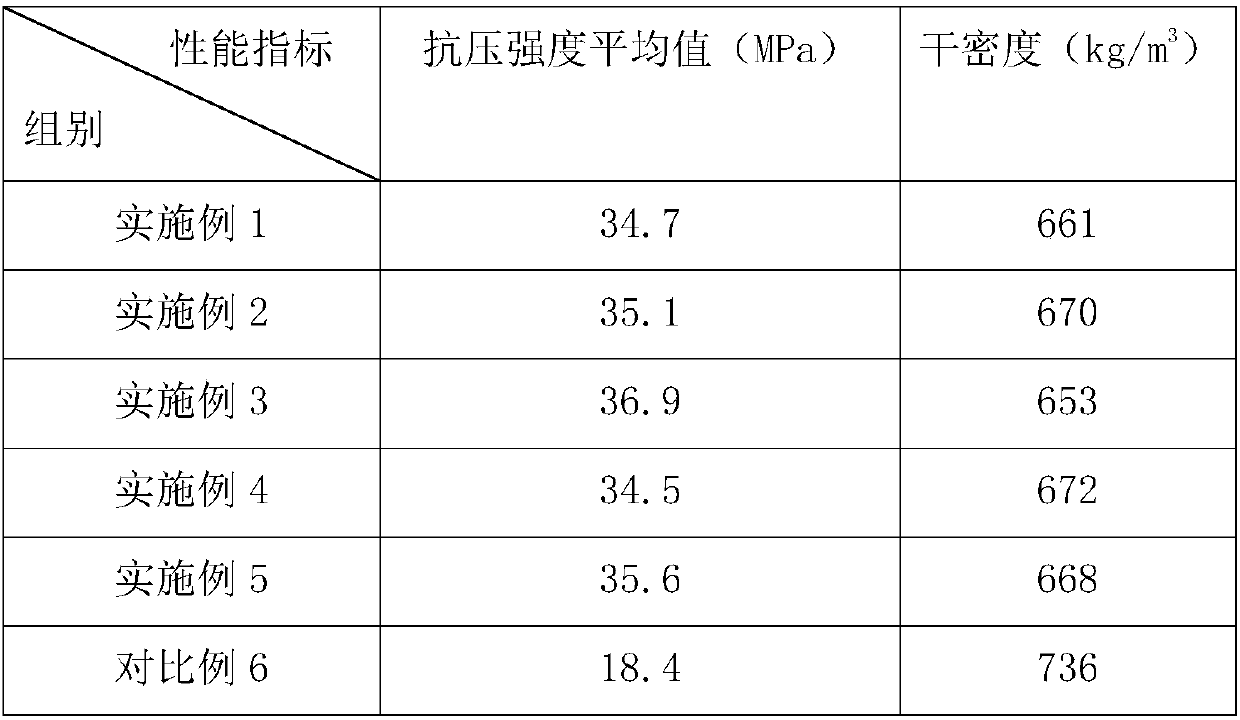

Modified hydroxyethyl methyl cellulose for enhanced ceramic tile adhesive and preparation method and application thereof

ActiveCN111748299AImprove product qualityQuality improvementStarch derivtive adhesivesMacromolecular adhesive additivesPolymer scienceAdhesive

The invention discloses modified hydroxyethyl methyl cellulose for an enhanced ceramic tile adhesive. The modified hydroxyethyl methyl cellulose is prepared from the following raw materials in percentage by mass: 54%-94% of hydroxyethyl methyl cellulose, 5%-40% of starch ether, 0.5%-3% of a dispersing agent and 0.5%-3% of a rheological agent, wherein the hydroxyethyl methyl cellulose is prepared from cellulose powder, caustic soda granules, caustic soda liquid, chloromethane and ethylene oxide. The preparation method comprises the following steps: (1) weighing the raw materials, (2) mixing cellulose powder, caustic soda particles, liquid caustic soda, chloromethane and ethylene oxide, carrying out etherification reaction, and then sequentially carrying out neutralization, washing, centrifugation, drying and crushing to obtain hydroxyethyl methyl cellulose, and (3) mixing and stirring hydroxyethyl methyl cellulose, starch ether, a dispersing agent and a rheological agent to obtain the adhesive. The obtained product is stable in quality, has the function of improving the tensile bonding strength of the ceramic tile adhesive, is applied to modern ceramic tiles with large sizes and large masses, and can remarkably improve the use safety of the ceramic tiles.

Owner:SHANDONG YITENG NEW MATERIAL CO LTD

Pressure-resistant lightweight heat-insulating brick and preparation method thereof

The invention discloses a pressure-resistant lightweight heat-insulating brick and a preparation method thereof and relates to the technical field of novel building materials. The heat-insulating brick comprises dewatered river mud, tailings iron sand, modified diatomite, floating bead, purple sand shale, ceramic fiber, shell charcoal powder, calcium peroxide, hydroxyethylmethylcellulose, methyl methacrylate, dry strength agent and foamer. The preparation method includes: stirring and mixing raw materials to obtain slurry; performing compression molding, natural maintaining, drying and high-temperature calcining on the slurry to obtain the heat-insulating brick. The heat-insulating brick has the advantages of low dry density, light volume weight, high pressure resistance and resistance tohigh temperature and corrosion and is long in service life, high in reliability, simple and convenient to prepare and suitable for popularization and application.

Owner:明光市裕阳新材料有限公司

High-flexibility relievo paint and preparation process thereof

InactiveCN105400325ASlow dryingImprove surface smoothnessLignin material coatingsMeth-Glycol synthesis

The invention discloses high-flexibility relievo paint. The high-flexibility relievo paint is prepared from the following raw materials in parts by weight: 150-200 g of deionized water, 60-70 g of a pure acrylic emulsion, 550-650 g of coarse whiting, 70-90 g of talcum powder, 30-40 g of a hydroxyethyl methyl cellulose water solution, 10-20 g of a lignocellulose water solution, 4-6 g of a film-forming additive, 1.5-2.5 g of an anti-corrosion disinfectant, 1.8-2.2 g of a dispersant, 1.8-2.2 g of a wetting agent, 3.5-4.5 g of a thickening agent and 9-11 g of ethylene glycol, wherein the hydroxyethyl methyl cellulose water solution is prepared by dissolving 2-4% hydroxyethyl methyl cellulose in water; the lignocellulose water solution is prepared by dissolving 1-3% lignocellulose in water. The invention further discloses a process for preparing a high-flexibility relievo paint. The relievo paint is low in drying speed, good in flexibility, free from cracking during construction and excellent in surface vision.

Owner:RONGJIANG RONGSHULIN BUILDING PAINTS CO LTD

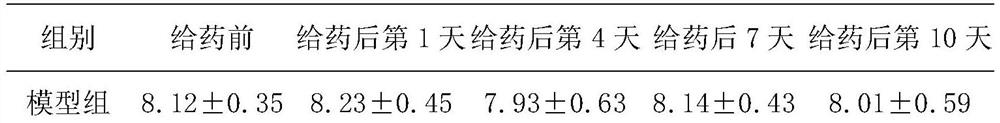

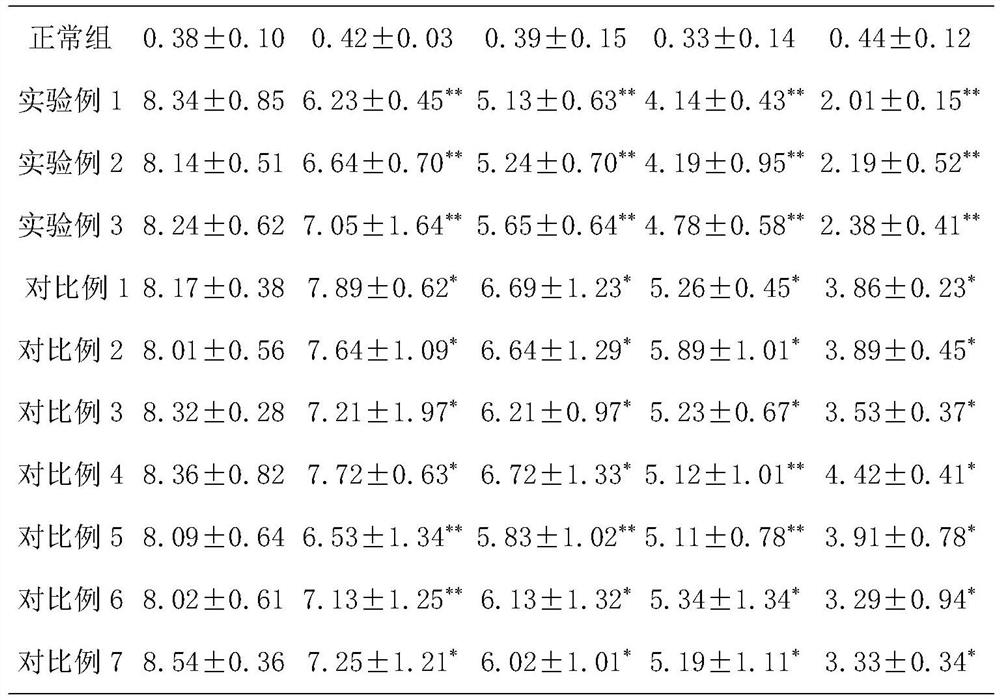

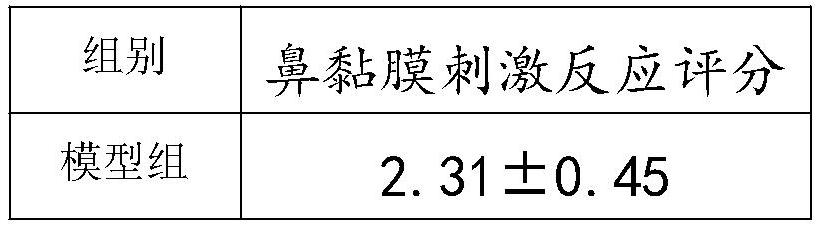

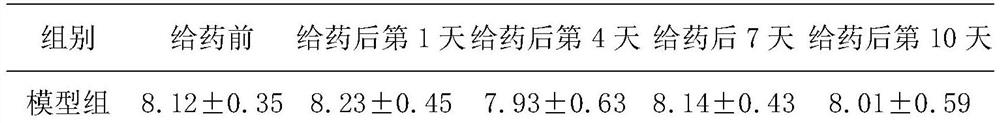

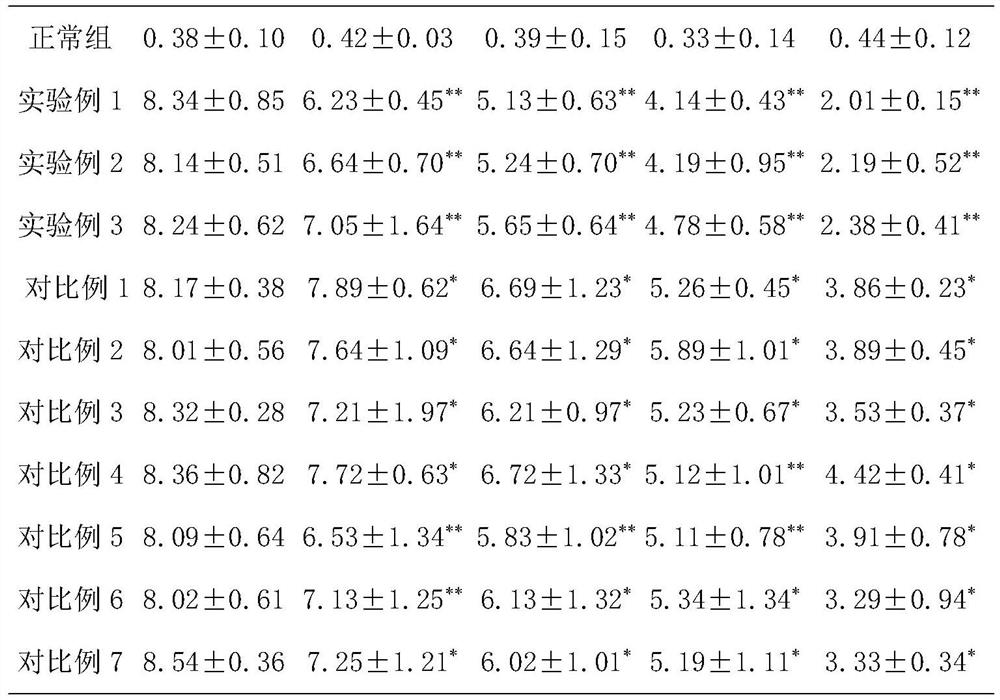

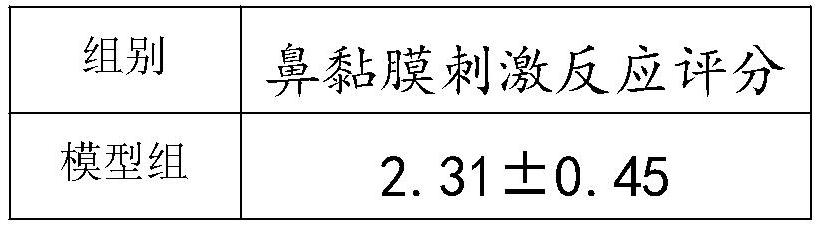

A kind of medicine for treating allergic rhinitis and preparation method thereof

ActiveCN111840226BHighlight substantive specificSignificant progressOrganic active ingredientsRespiratory disorderGlycerolMethyl palmoxirate

The invention discloses a medicine for treating allergic rhinitis, which comprises 0.04%-0.08% mometasone furoate, 0.5%-0.8% glycerin, 1.5%-2.0% sesame oil, 0.1%-0.5% chloride Sodium, 0.5-1.5% mixture of carboxypropylcellulose, hydroxyethylmethylcellulose and microcrystalline cellulose, 2%-3% mixture of Tween 80 and lecithin, 0.05-0.1% peppermint oil, Appropriate amount of sodium citrate buffer, add water for injection to 100%. Experiments show that the medicament of the present invention can effectively treat allergic rhinitis and effectively reduce the incidence of adverse reactions.

Owner:HEILONGJIANG UNIV OF CHINESE MEDICINE

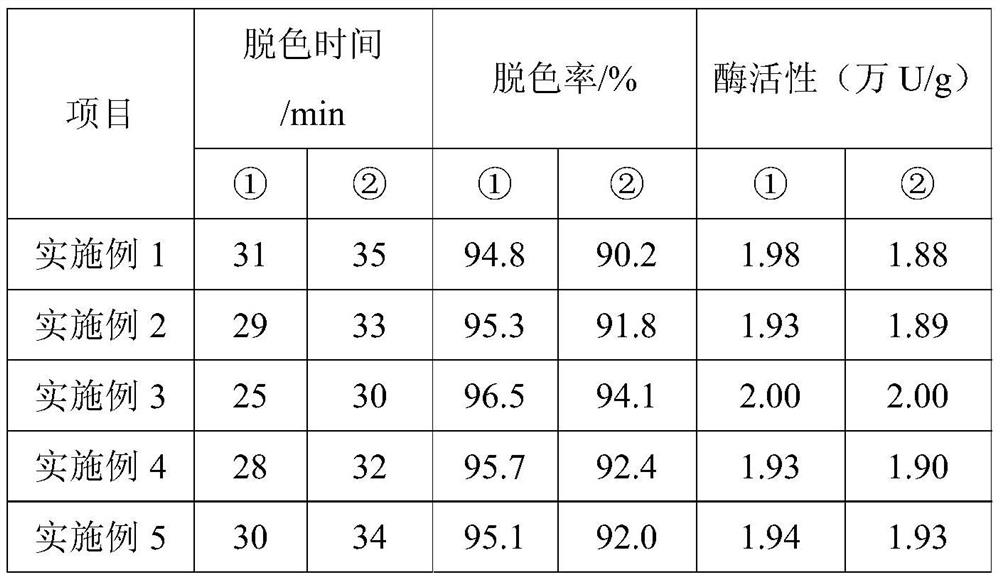

Decolorizing resin for lactase and preparation method of decolorizing resin

The invention discloses a decolorizing resin for lactase. The decolorizing resin comprises styrene, divinylbenzene, gelatin, juncus roemerianus, methyl isobutyl carbinol, hydroxyethyl methylacrylate, triallyl cyanurate, N-phenylmaleimide, chitosan, vitamin C magnesium phosphate, benzoyl peroxide, polyvinyl alcohol, tributyl phosphate, salicylic acid, hydroxyethyl methyl cellulose and a pore-foaming agent. The invention also discloses a preparation method of the decolorizing resin. The preparation method comprises the following steps of: mixing gelatin, chitosan, hydroxyethyl methyl cellulose, polyvinyl alcohol and salicylic acid to prepare a liquid phase; mixing styrene, divinylbenzene, methyl isobutyl carbinol, hydroxyethyl methylacrylate, triallyl cyanurate, N-phenylmaleimide, benzoyl peroxide, tributyl phosphate and a pore-foaming agent to prepare an oil phase; mixing the juncus roemerianus fiber with vitamin C magnesium phosphate to prepare a solid phase; and mixing the three phases to prepare the polymer. The decolorizing resin is high in decoloration efficiency, short in time and small in lactase activity loss after decoloration.

Owner:广西叁万生物科技有限公司

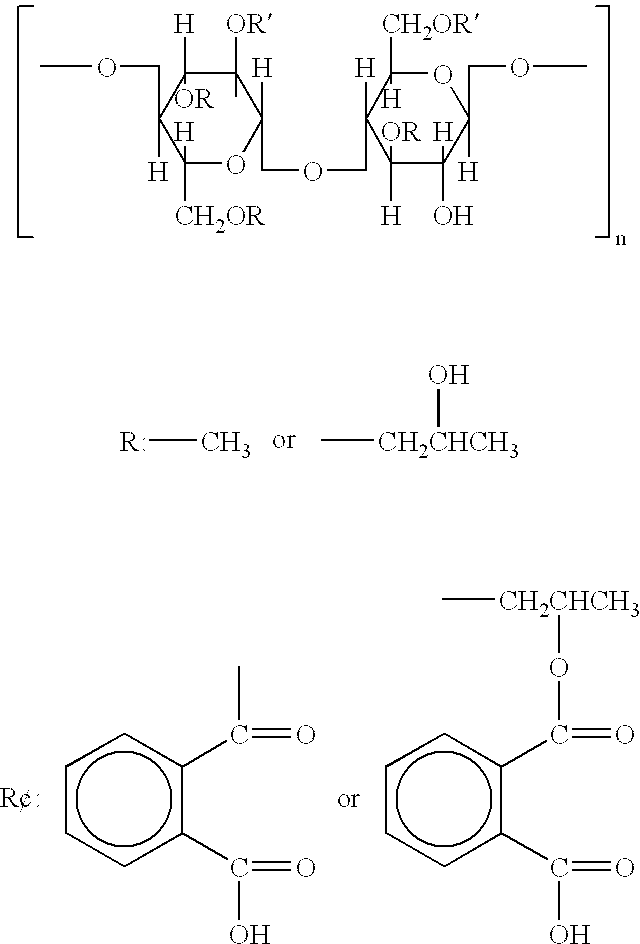

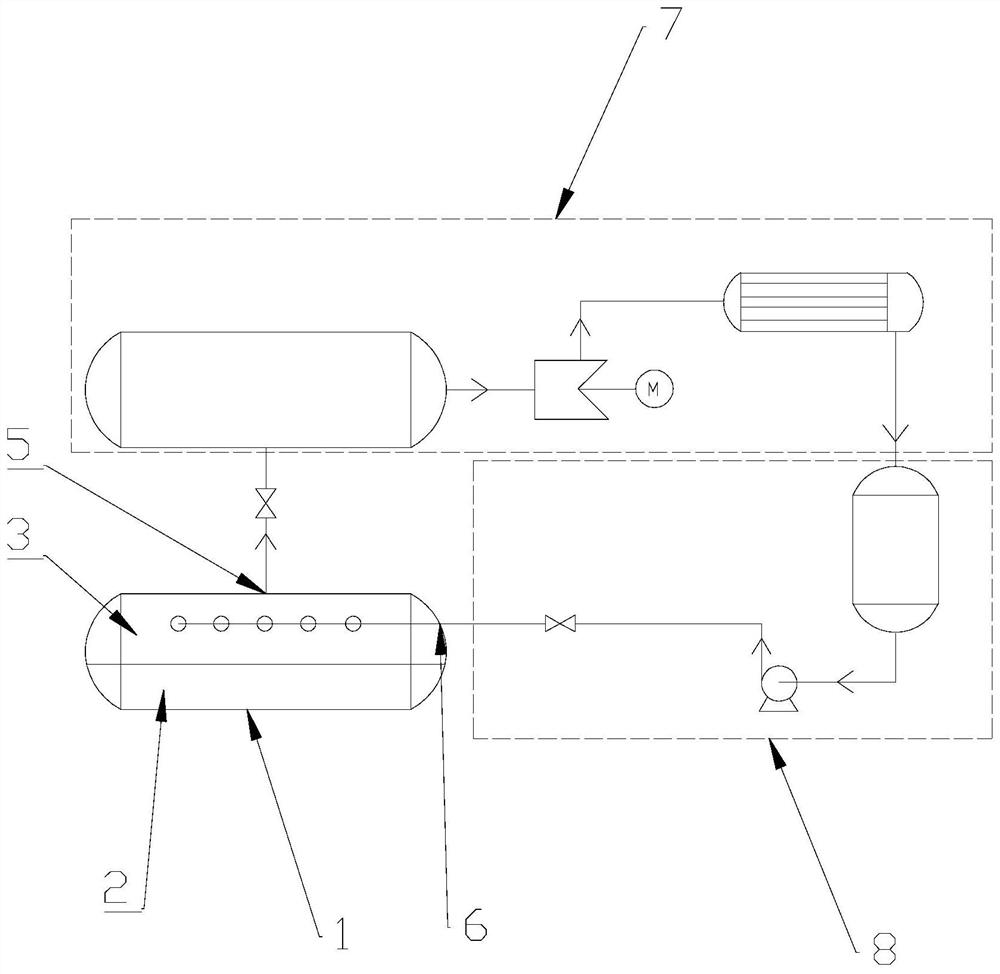

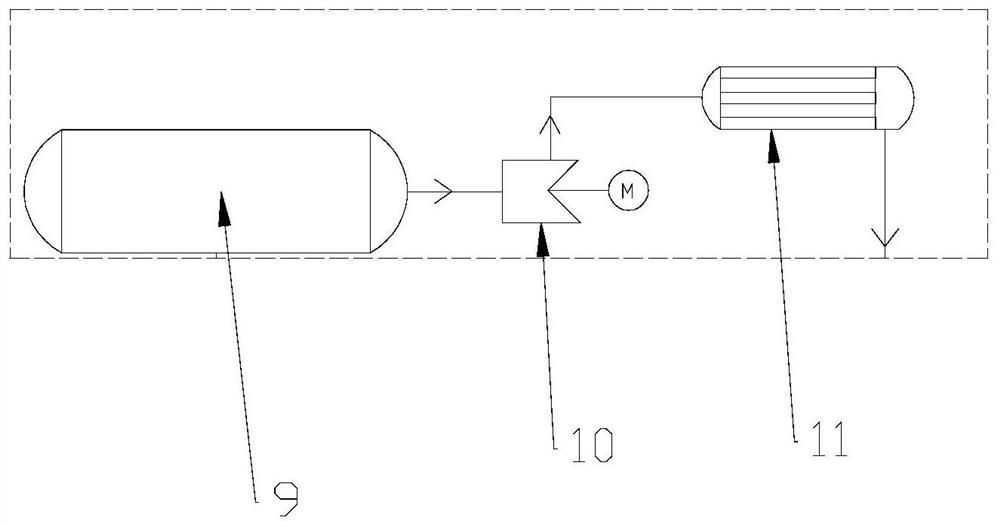

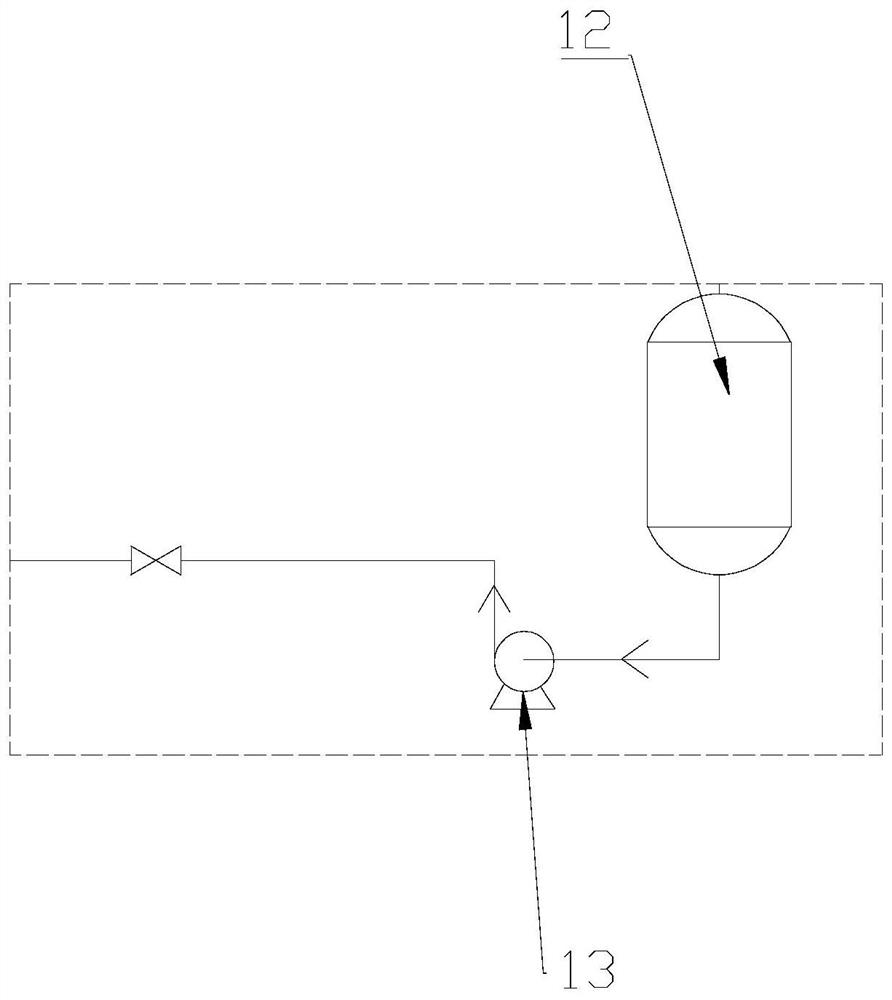

Method and device for preparing modified cellulose

PendingCN112592411ARelieve pressureSimple production processChemical/physical/physico-chemical stationary reactorsMethyl palmoxirateMaterials science

The invention relates to a method and a device for preparing modified cellulose, the device comprises a reaction kettle, the reaction kettle is internally provided with a solid-liquid space for reaction and a gas phase space for accommodating gas overflowing from the solid-liquid space, an outer circulation system is arranged outside the reaction kettle, the inlet end of the outer circulation system is communicated with the gas phase space in the reaction kettle, the inlet end of the outer circulation system is communicated with the gas phase space, and the outlet end of the outer circulatingsystem extends into the reaction kettle. The device is used for preparing hydroxypropyl methyl cellulose, hydroxyethyl methyl cellulose and other substances from cellulose, when cellulose etherification reaction is carried out, liquid in the solid-liquid space is heated and gasified, enters the gas-phase space firstly and then circularly enters the reaction kettle through the outer circulation system, so that the pressure in the kettle can be reduced, and the overall safety performance is guaranteed, the pressure resistance and sealing performance of the reaction kettle can be reduced, meanwhile, the liquid continuously passes through the outer circulation system and returns into the reaction kettle, so that the reaction liquid in the reaction kettle is always in an excessive state, the reaction speed is high, and the production efficiency is high.

Owner:SHANDONG YITENG NEW MATERIAL CO LTD

A kind of concrete reducer and its preparation process and application method

The invention discloses a concrete adhesive reducer and its preparation process and application method. Wherein, the concrete glue reducer includes the following components in parts by weight: 35-50 parts of organic alcohol amine compounds; 1-5 parts of anhydrous sodium sulfate; 2-10 parts of sodium thiosulfate; 0.1-3 parts of sodium gluconate 1-5 parts of thickener; 3-10 parts of polyethylene glycol ether; 55-70 parts of water; organic alcohol amine compounds include at least one of triethanolamine and triisopropanolamine; thickener includes yellow At least one of raw gum, polyacrylamide, and hydroxyethyl methylcellulose ether. Concrete reducer can be used in the mixing process of concrete. It has no pungent smell and has the advantages of environmental protection. When added to concrete, it can reduce the amount of cement used and improve the strength of concrete.

Owner:HANGZHOU LIPING IND & TRADE CO LTD

Liquid dietary flavoring with health-care function and preparation method thereof

The present invention provides a liquid meal flavoring agent which has health care function. The present invention comprises liquid flavoring agent, soluble or suspended differential fiber. The concentration of the soluble or suspended differential fiber is 0.005%-25 %( a weight-to-volume ratio), and the better concentration is 0.005%-10% (a weight-to-volume ratio). The soluble or suspended differential fiber is selected from methylcellulose, hydroxide propyl methyl cellulose, hydroxide propyl ethyl cellulose, hydroxide propyl cellulose, hydroxide ethyl cellulose, hydroxide ethyl methyl cellulose, hydroxide methyl cellulose, carboxymethyl cellulose and sodium, kalium, calcium salt and so on, or one kind or kinds of microcrystalline cellulose. The flavoring agents are vinegar, sauce and cooking wine. Two methods of making the two kinds of liquid meal flavoring agents are also provided. The present invention has certain viscosity and good thermal stability, can replenish the human needed soluble or suspended differential fiber, has health care function, is good to taste and convenient to take, is not easy to forget taking, and has simple and practical manufacturing method.

Owner:刘志

Medicine for treating allergic rhinitis and preparation method thereof

ActiveCN111840226AHighlight substantive specificSignificant progressOrganic active ingredientsRespiratory disorderGlycerolPharmaceutical Substances

The invention discloses a medicine for treating allergic rhinitis. The medicine comprises 0.04%-0.08% of mometasone furoate, 0.5%-0.8% of glycerol; 1.5%-2.0% of sesame oil; 0.1%-0.5% of sodium chloride, 0.5%-1.5% of a mixture of carboxypropyl cellulose, hydroxyethyl methyl cellulose and microcrystalline cellulose, 2%-3% of a mixture of Tween 80 and lecithin, 0.05%-0.1% of peppermint oil, a properamount of a sodium citrate buffer solution and the balance of water for injection. Experiments show that the medicine disclosed by the invention can be used for effectively treating allergic rhinitisand effectively reducing the occurrence rate of adverse reactions.

Owner:HEILONGJIANG UNIV OF CHINESE MEDICINE

A kind of thermal insulation mortar and preparation method thereof

The invention discloses a preparation method of high-strength thermal insulation mortar, and belongs to the technical field of building material preparation. The preparation method comprises the following steps: S1, mixing Portland cement, fly ash, limestone powder, polystyrene particles, bentonite, a thickening agent, heavy calcium carbonate powder, a tackifier and carboxyethyl methyl cellulose in parts by weight, and uniformly stirring to obtain slurry; S2, adding lauryl sodium sulfate into the slurry while stirring, stirring for 10 to 15min, and standing for 30 to 60min; and S3, adding calcium fluoride, a styrene-maleic anhydride copolymer or an organic silicon-polyurethane copolymer, sodium carbonate and hydrochloric acid on the basis of the step S2, and performing uniform stirring with a stirrer so as to obtain the high-strength thermal insulation mortar. The high-strength thermal insulation mortar can improve the compressive strength and reduce the dry apparent density, the heatconductivity coefficient and the volume water absorption rate.

Owner:东至安东祥源新型建材有限公司

Oil-proof and antibacterial food packaging film

The invention mainly relates to the technical field of thin film processing, and discloses an oil-proof and antibacterial food packaging film which is prepared from, by weight, 32-34 parts of polyethylene glycol terephthalate, 25-27 parts of modified polypropylene, 21-23 parts of polytetrafluoroethylene, 7-9 parts of modified chitosan, 2.2-2.4 parts of hydroxyethyl methylcellulose and 1.3-1.5 parts of cinnamyl aldehyde. The oil-proof and antibacterial food packaging film is high in strength, high in oil stain resistance, oil stain permeability can be effectively prevented, antibacterial rate reaches 89.4%, bacteria breeding on the surface of food can be effectively avoided, the shelf life of the food is prolonged, the polyethylene glycol terephthalate, the modified polypropylene and the polytetrafluoroethylene are mixed, molten and combined each other, the strength of the packaging film can be enhanced, the packaging film is resistant to scratch and abrasion, safe and free from toxicity and can be repeatedly used after being cleaned, cost is saved, and environments are protected.

Owner:含山县金中环装饰材料有限公司

Volumizing agents

ActiveUS7781375B2More benefitReduce transmissionBiocideOrganic active ingredientsEthyl groupHydroxyethyl cellulose

The present composition is capable of forming a particle film and comprises: (a) less than 99.65% by weight of at least one particle; (b) at least one volumizing agent selected from the group consisting of: (i) cellulose selected from the group consisting of ethyl hydroxy ethyl cellulose, hydroxy ethyl cellulose, hydroxy propyl cellulose, hydroxy ethyl methyl cellulose, hydroxy propyl methyl cellulose, methyl cellulose, ethyl cellulose, and ethyl methyl cellulose and present in an amount greater than 0.35% by weight; and (ii) non-cellulosic component or cellulose other than said cellulose (i) present in an amount of at least 0.05% by weight; and optionally (c) at least one spreader.The composition may be used to form agricultural films.

Owner:US SEC AGRI +1

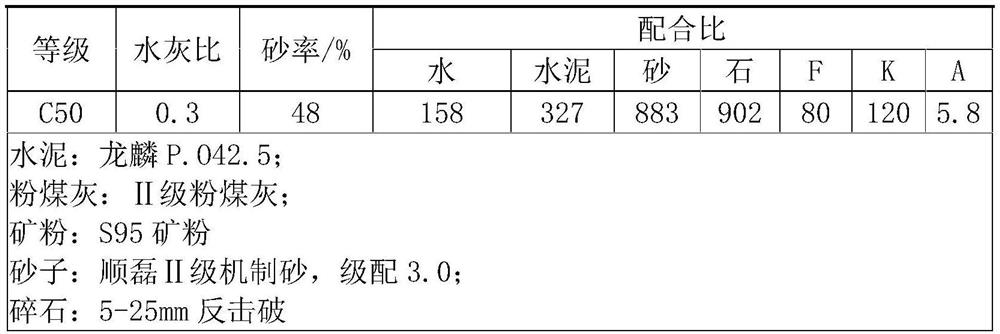

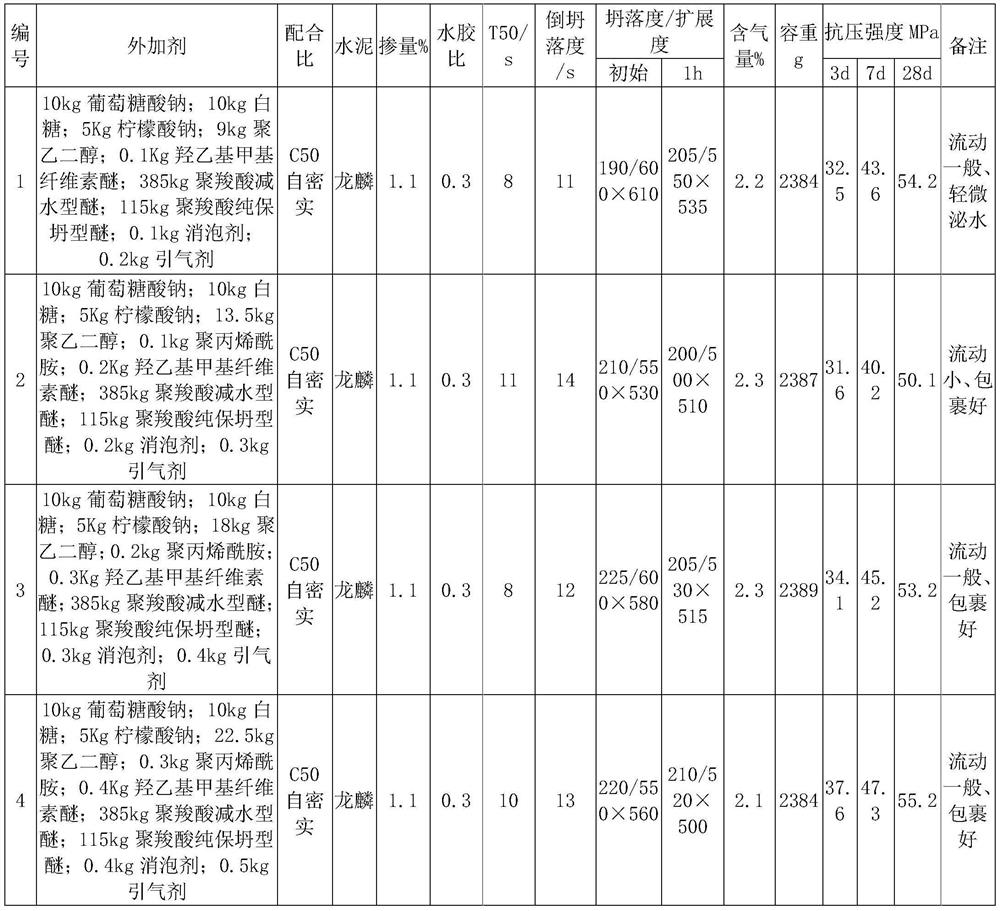

Special admixture for self-compacting concrete as well as preparation method and application of special additive

PendingCN113060969ASpeed up the flowSolution can not be constructedPolyethylene glycolCarboxylic acid

The invention provides a special admixture for self-compacting concrete and a preparation method and application thereof, and the special admixture for self-compacting concrete comprises the following materials in parts by weight: 370-400 parts of polycarboxylic acid water-reducing ether; 100 to 130 parts of polycarboxylic acid pure slump retaining type ether; 0-20 parts of borax; 8 to 12 parts of sodium gluconate; 8-12 parts of white sugar; 3-7 parts of sodium citrate; 9-27 parts of polyethylene glycol; 0.1 to 0.4 part of polyacrylamide; 0.1 to 0.5 percent of hydroxyethyl methyl cellulose ether; 0.1 to 0.5 part of a defoaming agent; 0.2 to 0.6 part of an air entraining agent; and 430-460 parts of water. The admixture special for the self-compacting concrete provided by the invention is large in flowability and good in wrapping, can solve the problem of engineering structures which cannot be constructed or are difficult to construct by using common concrete, and meanwhile, avoids the engineering quality problem caused by vibration leakage and excessive vibration of the common concrete. By adopting the admixture special for the self-compacting concrete provided by the invention, when the concrete is constructed, time and labor are saved, noise is avoided, the construction speed is high, the labor intensity of workers is reduced, and energy is saved.

Owner:福建路桥翔通建材科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com