Oil-proof and antibacterial food packaging film

A food packaging film and oil-proof technology, applied in coatings and other directions, can solve problems such as oil pollution, achieve the effects of preventing oil penetration, increasing compactness, and inhibiting bacterial growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

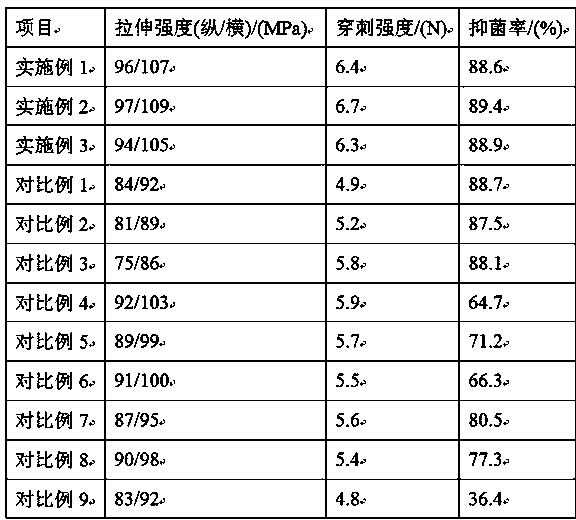

Examples

Embodiment 1

[0024] An oil-proof and antibacterial food packaging film, made of the following raw materials in parts by weight: polyethylene terephthalate 32, modified polypropylene 25, polytetrafluoroethylene 21, modified chitosan 7, ethylene glycol Base methyl cellulose 2.2, cinnamaldehyde 1.3.

[0025] For the modified polypropylene, heat the polypropylene to 180°C in vacuum, stir until fully melted, add a tartaric acid solution of 6% by weight of the polypropylene, stir evenly, keep it warm for 10 minutes, and then add the colorless nano-silver solution in an amount of poly 0.4% by weight of propylene, continue to increase the temperature to 200°C, stir in vacuum for 20 minutes, decompress to normal pressure, place in an extruder and extrude into pellets to obtain modified polypropylene.

[0026] Described tartaric acid solution, concentration is 3g / L, and temperature is 40 ℃.

[0027] Described modified chitosan, chitosan is added in the acetic acid solution that volume fraction is 1...

Embodiment 2

[0038] An oil-proof and antibacterial food packaging film, made of the following raw materials in parts by weight: polyethylene terephthalate 33, modified polypropylene 26, polytetrafluoroethylene 22, modified chitosan 8, ethylene glycol Base methyl cellulose 2.3, cinnamaldehyde 1.4.

[0039] For the modified polypropylene, heat the polypropylene to 185°C in vacuum, stir until fully melted, add tartaric acid solution with 7% weight of polypropylene, stir evenly, keep warm for 12min, then add colorless nano-silver solution in an amount of poly 0.5% of the weight of propylene, continue to increase the temperature to 210 ° C, stir in vacuum for 25 minutes, decompress to normal pressure, place in an extruder and extrude into pellets to obtain modified polypropylene.

[0040]Described tartaric acid solution, concentration is 4g / L, and temperature is 45 ℃.

[0041] Described modified chitosan, chitosan is added in the acetic acid solution that volume fraction is 1%, heat and stir u...

Embodiment 3

[0052] An oil-proof and antibacterial food packaging film, made of the following raw materials in parts by weight: polyethylene terephthalate 34, modified polypropylene 27, polytetrafluoroethylene 23, modified chitosan 9, ethylene glycol Base methyl cellulose 2.4, cinnamaldehyde 1.5.

[0053] For the modified polypropylene, heat the polypropylene to 190°C in vacuum, stir until fully melted, add tartaric acid solution with 8% weight of polypropylene, stir evenly, keep warm for 15min, then add colorless nano-silver solution in an amount of poly 0.6% of the weight of propylene, continue to increase the temperature to 220 ° C, stir in vacuum for 30 minutes, decompress to normal pressure, place in an extruder and extrude into pellets to obtain modified polypropylene.

[0054] Described tartaric acid solution, concentration is 5g / L, and temperature is 50 ℃.

[0055] Described modified chitosan, chitosan is added in the acetic acid solution that volume fraction is 1%, heat and stir ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com