A kind of concrete reducer and its preparation process and application method

A technology of concrete and adhesive reducer, which is applied in the field of concrete adhesive reducer, which can solve the problems of environmental pollution and poor effect, and achieve the effects of improving overall strength and durability, improving workability, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Embodiment 1: A concrete glue reducer, the components included and their corresponding qualities are shown in Table 1, and are prepared through the following steps:

[0061] Step 1: Mix the organic alcohol amine compound, thickener, and polyethylene glycol ether uniformly at a temperature of 45°C to obtain a mixture A;

[0062] Step 2, adding anhydrous sodium sulfate, sodium thiosulfate and sodium gluconate into water, fully dissolving, and mixing uniformly to obtain mixture A1;

[0063] Step 3: heat-insulate the mixture A obtained in step 1 at a temperature of 25° C., mix the mixture A1 obtained in step 2 with mixture A uniformly, cool to room temperature, and discharge to obtain a concrete adhesive reducer.

[0064] Wherein, the molecular weight of polyethylene glycol ether is 1600.

Embodiment 2-9

[0065] Embodiment 2-9: A concrete reducer, the difference from Embodiment 1 is that the components included and their corresponding qualities are shown in Table 1.

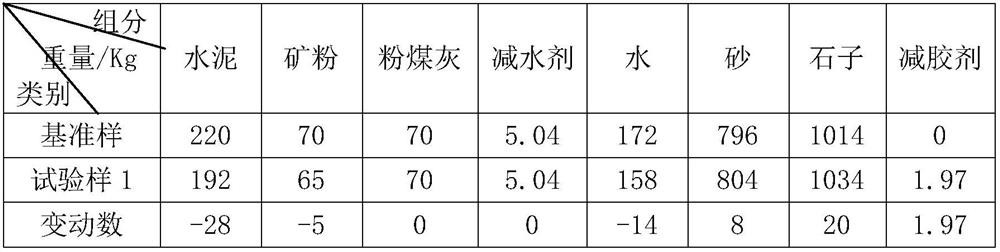

[0066] Table 1. Components of Examples 1-9 and their quality

[0067]

[0068] Wherein, in the nano-microcrystalline cellulose colloid in Example 2, the content of nano-microcrystalline cellulose is 0.01%; in the nano-microcrystalline cellulose colloid in Example 3, the content of nano-microcrystalline cellulose is 0.02%; In the nano-microcrystalline cellulose colloid in embodiment 4, the content of nano-microcrystalline cellulose is 0.03%,; In the nano-microcrystalline cellulose colloid in embodiment 5, the content of nano-microcrystalline cellulose is 0.04%; Implementation In the nano-microcrystalline cellulose colloid in example 6, the content of nano-microcrystalline cellulose is 0.05%; The content is 0.02%.

Embodiment 10

[0069] Embodiment 10: A concrete glue reducer, the difference from Embodiment 1 is that the molecular weight of polyethylene glycol ether is 2200.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com