Oral solid preparation of escitalopram oxalate and preparation method thereof

A technology of escitalopram oxalate and solid preparations, which is applied in the field of oral solid preparations of escitalopram oxalate and its preparation, and achieves the effect of solving the content uniformity of preparations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

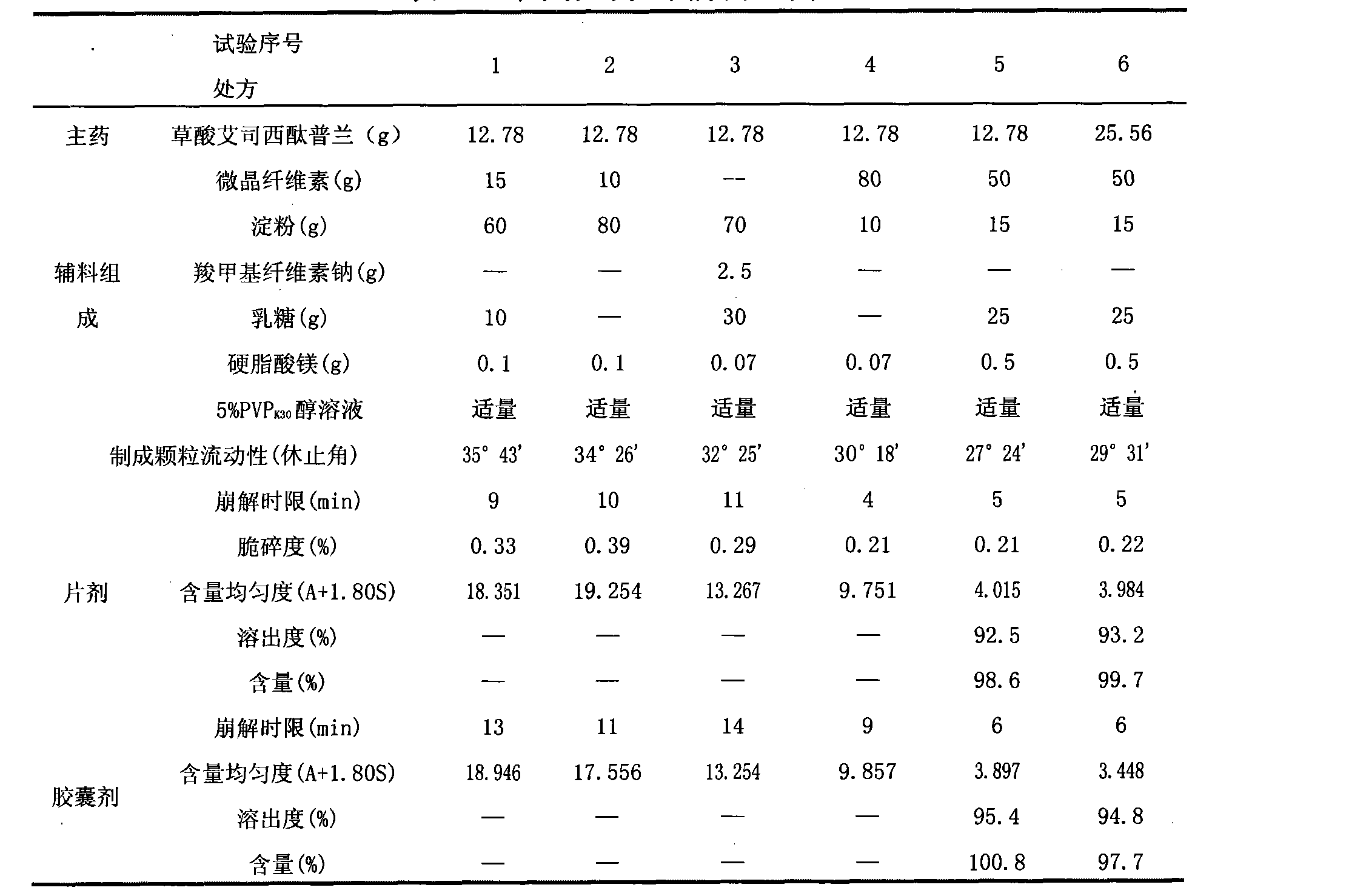

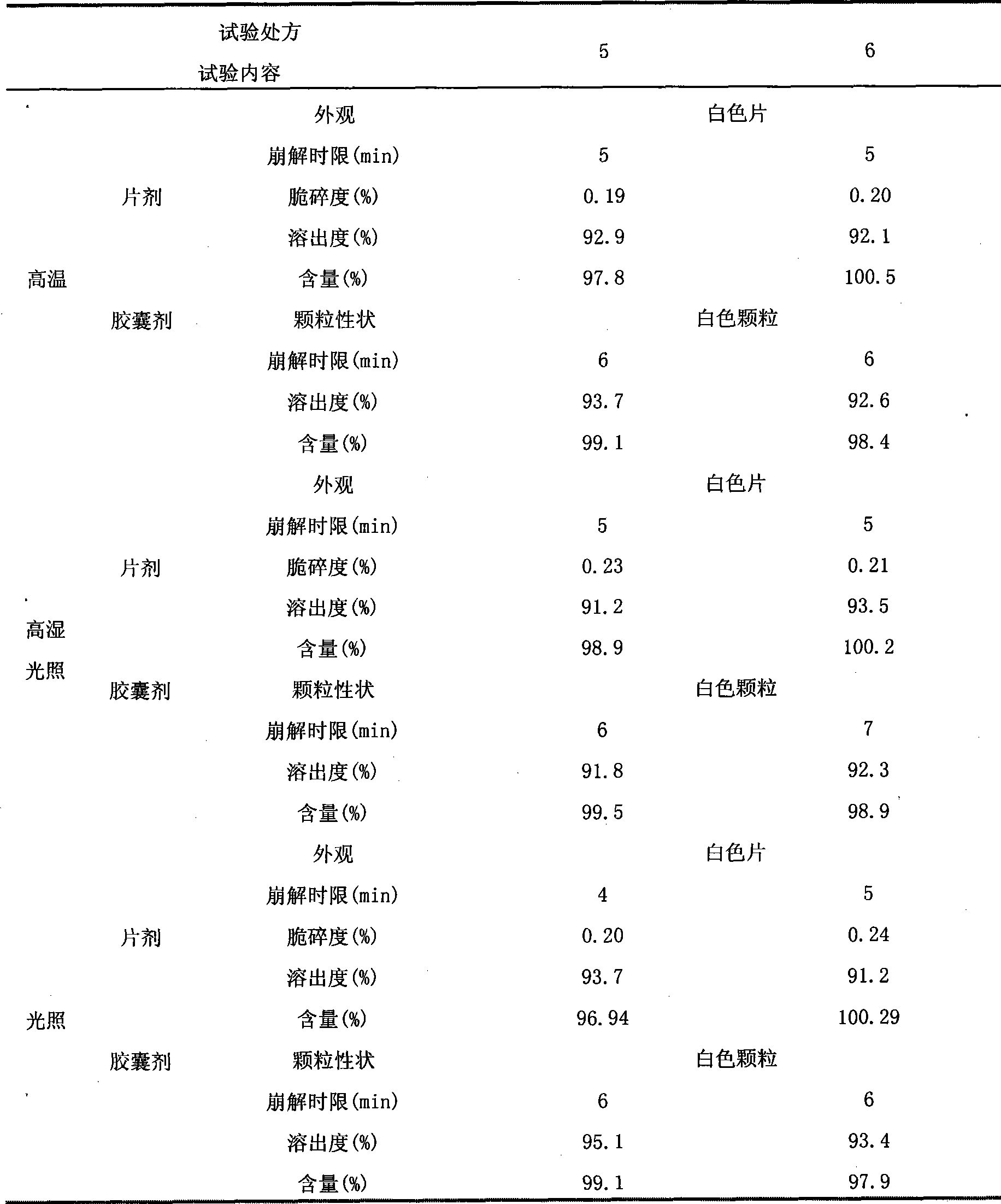

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: the preparation of tablet

[0027] Weigh 12.78g of escitalopram oxalate and 25g of microcrystalline cellulose to pass through a 100-mesh sieve, mix 20g of starch with the remaining 25g of microcrystalline cellulose and 30g of lactose, pass through a 80-mesh sieve, and grind together The substance and the mixture are mixed through an 80 mesh sieve, stirred evenly, and 5% povidone K is added 30 Ethanol liquid, made into soft material, granulated with a 20-mesh sieve, dried in an oven at 60°C for 2 hours, then granulated with a 20-mesh sieve, added with 0.2g of magnesium stearate as an auxiliary material, mixed evenly to obtain granules, and pressed into tablets , that is.

Embodiment 2

[0028] Embodiment 2: the preparation of capsule

[0029] Weigh 25.56g of escitalopram oxalate and 60g of microcrystalline cellulose to grind through a 100-mesh sieve, mix 30g of starch with the remaining 50g of microcrystalline cellulose and 40g of lactose, pass through a 100-mesh sieve, and grind together Mix the material and the mixture through a 60-mesh sieve, stir evenly, add 1% hydroxyethyl methylcellulose ethanol solution to make a soft material, granulate with an 18-mesh sieve, dry in an oven at 70°C for 1.5 hours, and then use an 18-mesh cellulose Sieve for granulation, add 0.15 g of talcum powder as an auxiliary material, mix well to obtain granules, put them into empty capsule shells, and obtain.

Embodiment 3

[0030] Embodiment 3: the preparation of tablet

[0031] Weigh 12.78g of escitalopram oxalate and 40g of microcrystalline cellulose to grind through a 60-mesh sieve, mix 5g of starch with the remaining 80g of microcrystalline cellulose and 10g of lactose, pass through a 100-mesh sieve, and grind together The material and the mixture are mixed through a 100-mesh sieve, stirred evenly, and 8% methylcellulose aqueous solution is added to make a soft material, granulated with a 40-mesh sieve, dried in an oven at 40°C for 4 hours, and then granulated with a 30-mesh sieve. Add 0.2 g of stearic acid as an auxiliary material, mix well, obtain granules, and compress into tablets.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com