Environment-friendly flexible interior wall putty and preparation method thereof

A kind of interior wall putty and flexible technology, applied in the direction of filling slurry, etc., can solve the problems of construction workers and owners, such as great harm to the body, easy decomposition and peeling, poor environmental protection performance, etc., to achieve good market development prospects, fine and smooth texture , Strong waterproof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

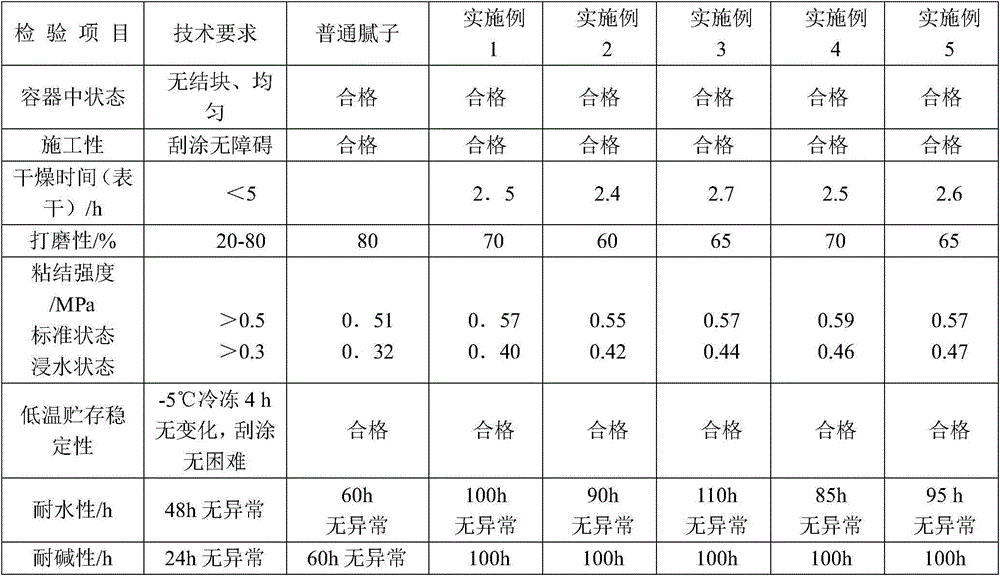

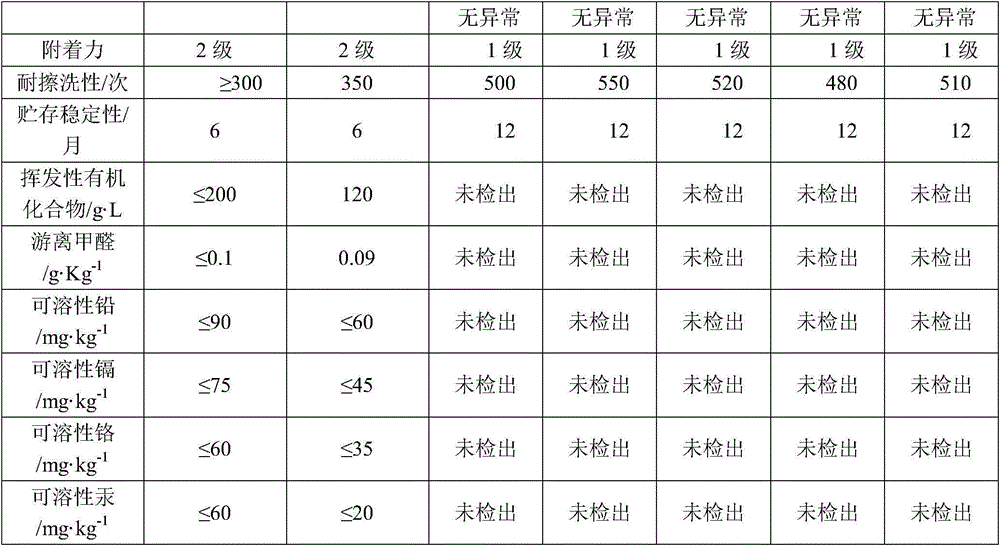

Examples

Embodiment 1

[0020] 20wt% of water was added to the container, and 8wt% of ultrafine bentonite and 3wt% of hydroxyethyl methylcellulose ether (MHEC) were added to the water under stirring conditions of 800r / min. Disperse under stirring conditions for 30 minutes to form a homogeneous gel, and place it for 24 hours to obtain ultra-fine bentonite gel; after stirring the above-mentioned ultra-fine bentonite gel for 15 minutes under stirring conditions of 2800r / min, continue at 2800r / min Under stirring conditions, add 10wt% ultrafine light calcium carbonate powder, 10wt% ultrafine heavy calcium carbonate powder, 18wt% ultrafine talc powder and 7wt% ultrafine barite powder and stir for 30min, and the dispersion will be uniform; at 2800r / min Under stirring conditions, add 1.7wt% antifreeze propylene glycol, 0.2wt% strong dispersant and 0.1wt% defoamer S-220 to the container, stir for 20 minutes; finally add 22wt% BLJ-963M modified flexible acrylic emulsion, low speed Stir for 45 minutes to get put...

Embodiment 2

[0022] Add 25wt% of water into the container, and under the stirring condition of 700r / min, add 6wt% of ultrafine bentonite and 2wt% of hydroxyethyl methyl cellulose ether (MHEC) into the water, respectively, at a temperature of 2500r / min. Disperse for 40 minutes under stirring conditions to form a homogeneous gel, and leave it for 26 hours to obtain an ultra-fine bentonite gel; after stirring the above ultra-fine bentonite gel for 20 minutes under a stirring condition of 2500r / min, continue at 2500r / min Under stirring conditions, add 11wt% ultrafine light calcium carbonate powder, 8wt% ultrafine heavy calcium carbonate powder, 15wt% ultrafine talc powder and 5wt% ultrafine barite powder, stir for 35min, and disperse uniformly; at 2500r / min Under stirring conditions, add 2.7wt% antifreeze propylene glycol, strong dispersant 0.1wt% and defoamer S-2200.2wt% to the container, stir for 20 minutes; finally add 25wt% BLJ-963M modified flexible acrylic emulsion, low speed Stir for 40 ...

Embodiment 3

[0024] 26wt% of water was added to the container, 5wt% of ultrafine bentonite and 2wt% of hydroxyethyl methyl cellulose ether (MHEC) were added to the water under stirring conditions of 700r / min, at a temperature of 2500r / min Disperse for 40 minutes under stirring conditions to form a homogeneous gel, and leave it for 26 hours to obtain an ultra-fine bentonite gel; after stirring the above ultra-fine bentonite gel for 20 minutes under a stirring condition of 2500r / min, continue at 2500r / min Under stirring conditions, add 13wt% ultrafine light calcium carbonate powder, 7wt% ultrafine heavy calcium carbonate powder, 12wt% ultrafine talc powder and 6wt% ultrafine barite powder, stir for 40min, and disperse uniformly; at 2500r / min Under stirring conditions, add 1.5wt% antifreeze propylene glycol, strong dispersant 0.2wt% and defoamer S-2200.3wt% to the container, and stir for 30min; finally add 27wt% BLJ-963M modified flexible acrylic emulsion, stir at low speed Putty for interior ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com