Mildew-proof antibacterial putty powder, preparation method and use method thereof

An anti-mildew and antibacterial, putty powder technology, applied in anti-fouling/underwater paint, paint containing biocide, filling slurry, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

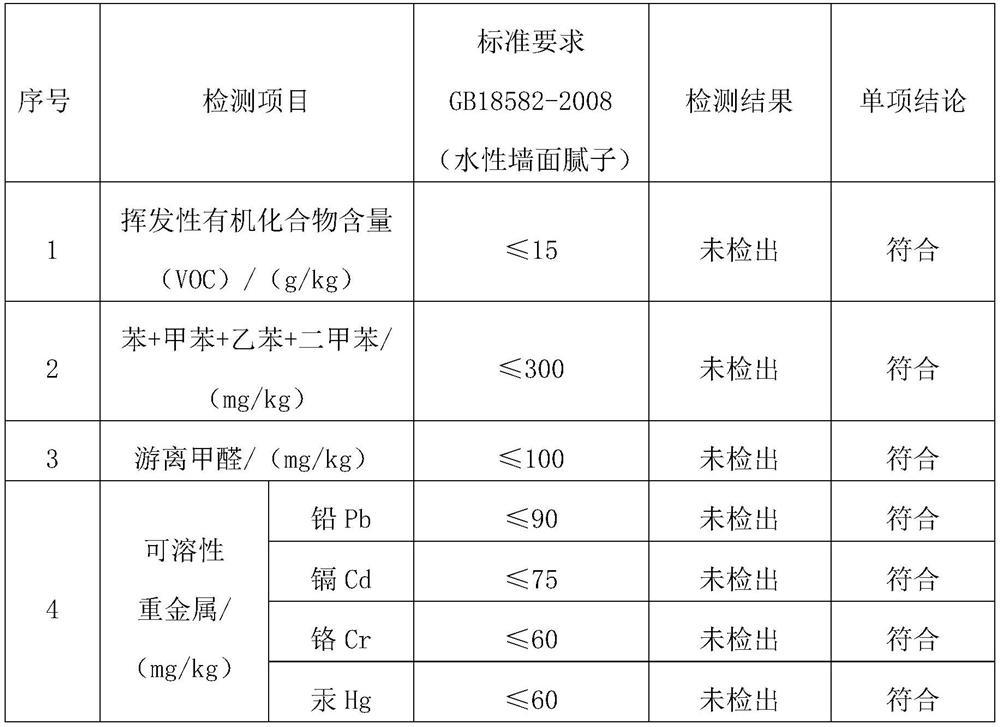

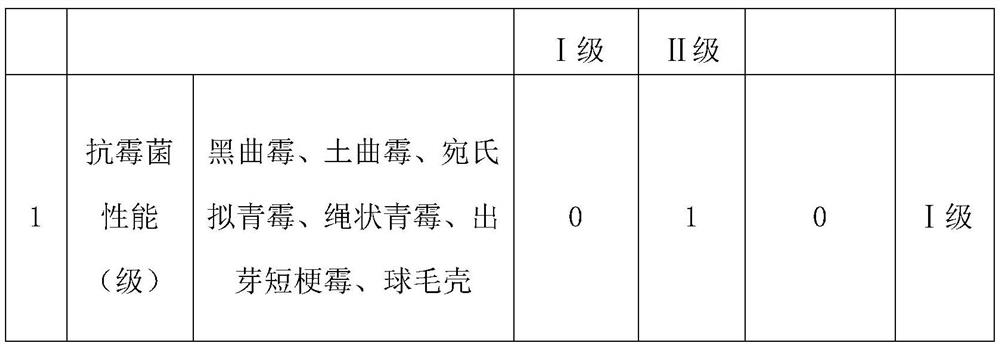

Examples

Embodiment 1

[0027] This embodiment provides a mildew-proof and antibacterial putty powder, which is formed by mixing the following materials according to the mass ratio: 10 parts of Portland cement, 10 parts of lime calcium, 60 parts of talcum powder, hydrogen ethyl methyl cellulose 0.1 part, 2 parts of thiophanate-methyl, 0.1 part of polyvinyl alcohol and 0.1 part of amylase.

[0028] The preparation method of the above-mentioned anti-mildew and antibacterial putty powder is to mix Portland cement, polyvinyl alcohol and hydropropyl methylcellulose uniformly, and then mix talcum powder, amylase, gray calcium and thiophanate-methyl evenly, Promptly get the described anti-mildew and antibacterial putty powder. The particle size of Portland cement, polyvinyl alcohol and hydropropyl methylcellulose is 80-120 mesh, and the particle size of talcum powder, amylase, lime calcium and thiophanate-methyl is 120-180 mesh.

[0029] The method of using the above-mentioned anti-mildew and antibacterial...

Embodiment 2

[0031] This embodiment provides a mildew-proof and antibacterial putty powder, which is formed by mixing the following materials according to the mass ratio: 20 parts of Portland cement, 20 parts of lime calcium, 80 parts of talcum powder, hydrogen ethyl methyl cellulose 0.5 parts, 10 parts of thiophanate-methyl, 1.0 parts of polyvinyl alcohol, and 1.0 parts of amylase.

[0032] The preparation method of the above-mentioned anti-mildew and antibacterial putty powder is to mix Portland cement, polyvinyl alcohol and hydropropyl methylcellulose uniformly, and then mix talcum powder, amylase, gray calcium and thiophanate-methyl evenly, Promptly get the described anti-mildew and antibacterial putty powder. The particle size of Portland cement, polyvinyl alcohol and hydropropyl methylcellulose is 80-120 mesh, and the particle size of talcum powder, amylase, lime calcium and thiophanate-methyl is 120-180 mesh.

[0033] The method of using the above-mentioned anti-mildew and anti-bac...

Embodiment 3

[0035] This embodiment provides a mildew-proof and antibacterial putty, which is formed by mixing the following materials according to the mass ratio: 15 parts of Portland cement, 15 parts of lime calcium, 70 parts of talcum powder, 0.38 parts of hydrogen ethyl methyl cellulose parts, 5 parts of thiophanate-methyl, 0.5 parts of polyvinyl alcohol, and 0.5 parts of amylase.

[0036] The preparation method of the above-mentioned anti-mildew and antibacterial putty powder is to mix Portland cement, polyvinyl alcohol and hydropropyl methylcellulose uniformly, and then mix talcum powder, amylase, gray calcium and thiophanate-methyl evenly, Promptly get the described anti-mildew and antibacterial putty powder. The particle size of Portland cement, polyvinyl alcohol and hydropropyl methylcellulose is 80-120 mesh, and the particle size of talcum powder, amylase, lime calcium and thiophanate-methyl is 120-180 mesh.

[0037] The method of using the above-mentioned anti-mildew and antiba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com