Method and device for preparing modified cellulose

A cellulose and modification technology, which is applied in the field of preparing modified cellulose, can solve the problems of low production efficiency, long reaction time, and small feeding amount, and achieve the effects of high production efficiency, fast reaction speed, and large feeding amount

Pending Publication Date: 2021-04-02

SHANDONG YITENG NEW MATERIAL CO LTD

View PDF0 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, this kind of process reactor has a small amount of feed, long reaction time, and low production efficiency; the inert organic solvent needs to be recycled and reused, causing great pollution and high cost

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0060] Example 1 was reacted using the method described in this application, and Comparative Example 6 was reacted using a slurry process. As can be seen from Table 2, at the same reaction temperature, the reaction time of Example 1 is shorter than that of Comparative Example 6. That is, the method described in this application has a shorter reaction time than the slurry method.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

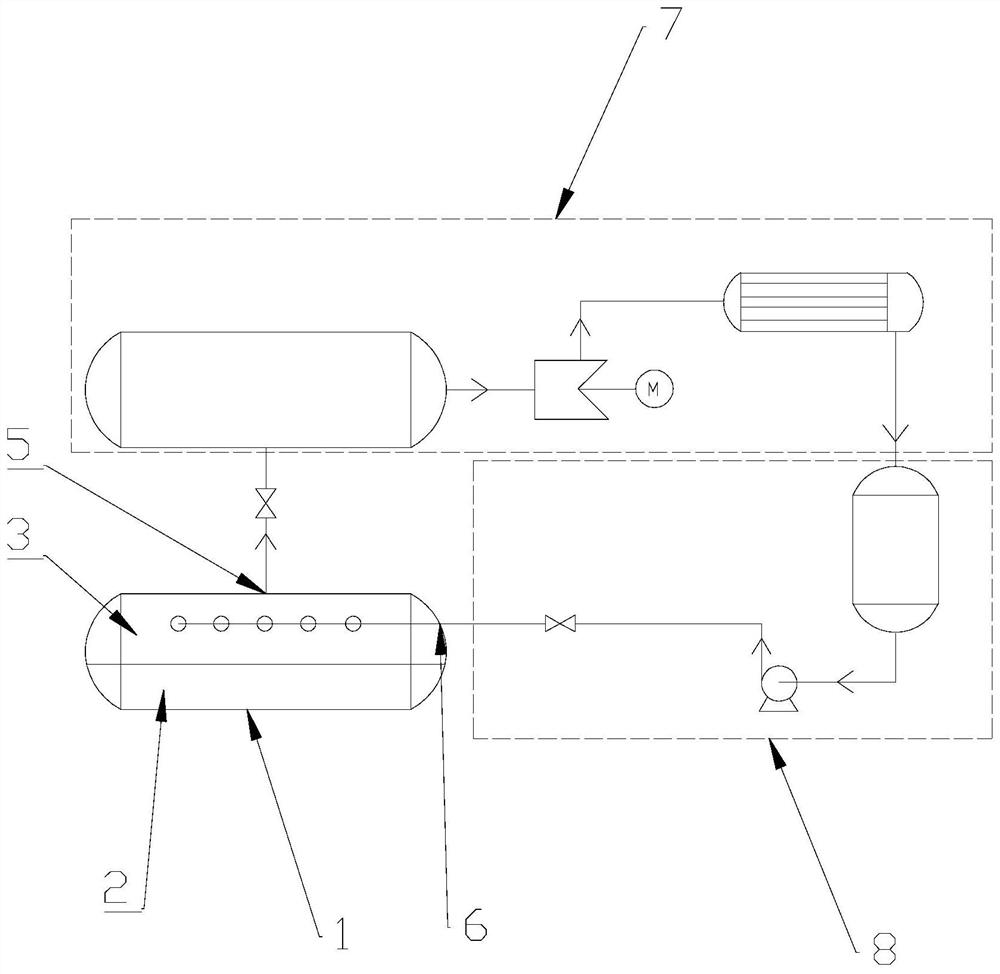

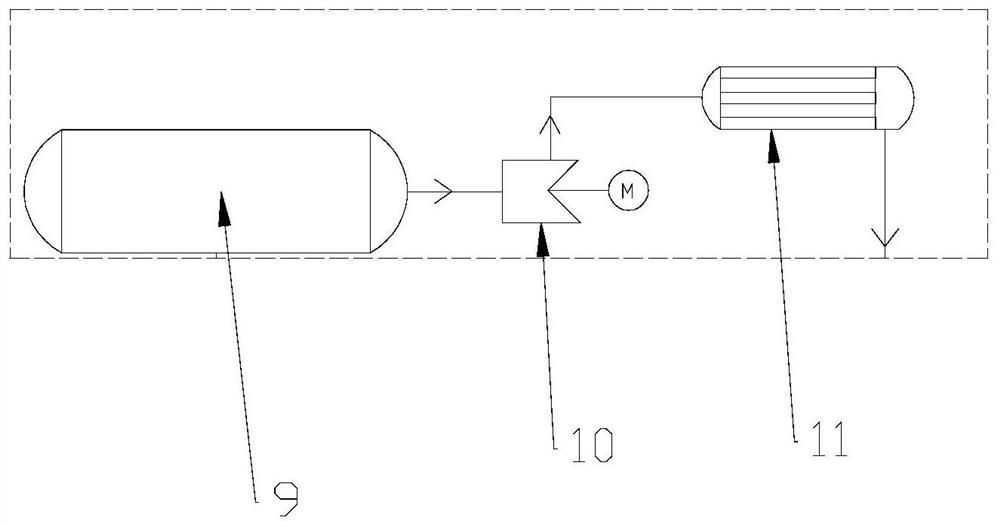

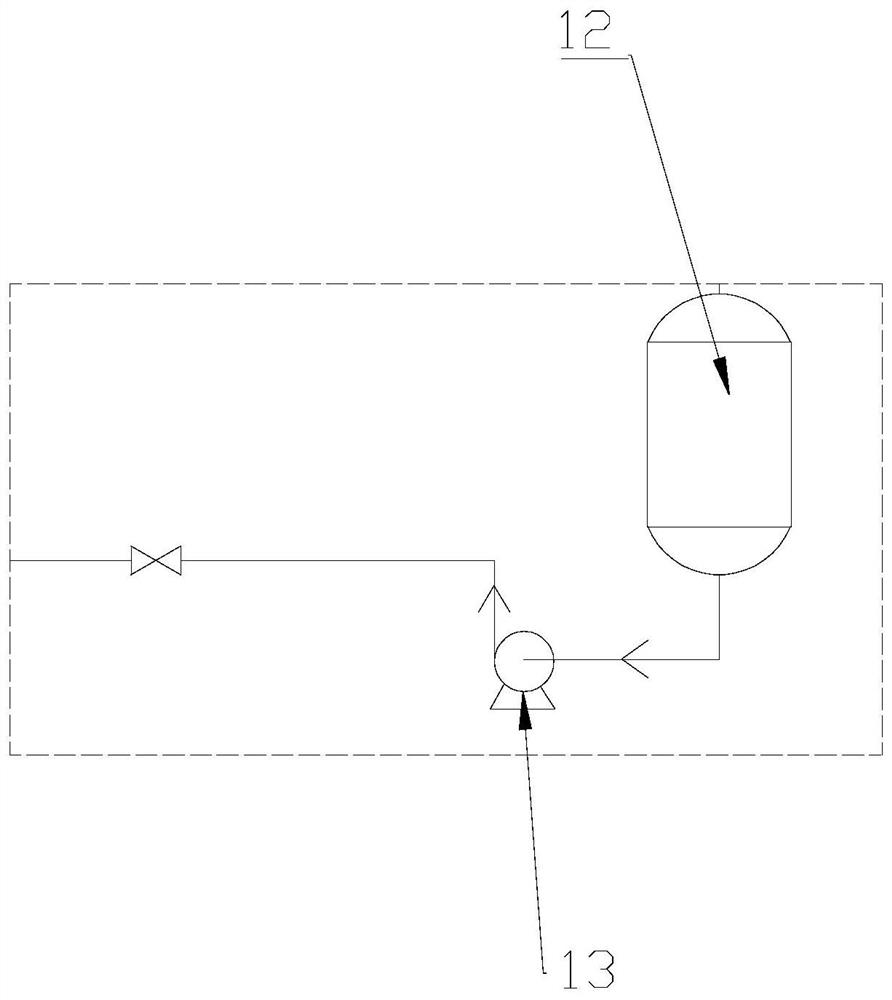

The invention relates to a method and a device for preparing modified cellulose, the device comprises a reaction kettle, the reaction kettle is internally provided with a solid-liquid space for reaction and a gas phase space for accommodating gas overflowing from the solid-liquid space, an outer circulation system is arranged outside the reaction kettle, the inlet end of the outer circulation system is communicated with the gas phase space in the reaction kettle, the inlet end of the outer circulation system is communicated with the gas phase space, and the outlet end of the outer circulatingsystem extends into the reaction kettle. The device is used for preparing hydroxypropyl methyl cellulose, hydroxyethyl methyl cellulose and other substances from cellulose, when cellulose etherification reaction is carried out, liquid in the solid-liquid space is heated and gasified, enters the gas-phase space firstly and then circularly enters the reaction kettle through the outer circulation system, so that the pressure in the kettle can be reduced, and the overall safety performance is guaranteed, the pressure resistance and sealing performance of the reaction kettle can be reduced, meanwhile, the liquid continuously passes through the outer circulation system and returns into the reaction kettle, so that the reaction liquid in the reaction kettle is always in an excessive state, the reaction speed is high, and the production efficiency is high.

Description

technical field [0001] The application relates to a method and device for preparing modified cellulose. Background technique [0002] Both hydroxypropyl methylcellulose (HPMC) and hydroxyethyl methylcellulose (HEMC) are non-ionic cellulose ethers, which are easy to dissolve in water and have good thickening, suspension, dispersion, emulsification, adhesion, Film-forming, water-retaining, and colloidal protection properties have been widely used in coatings, construction, medicine, food, textiles, papermaking, and polymer polymerization. [0003] The cellulose ether reactor is divided into horizontal reactor or vertical reactor, which can be used as a reaction device alone or with a cooler as a reaction device. [0004] The reactor used alone is suitable for the slurry process, the etherification agent is dissolved in an inert organic solvent, and the reaction pressure is generally low, below 0.6MPa. However, this kind of process reactor has a small amount of feed, long rea...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08B11/193C08B17/06C08B1/08C08B1/10B01J19/18

CPCC08B11/193C08B17/06C08B1/08C08B1/10B01J19/1881

Inventor 滕鲲李长胤刘涛张燕李同河李茂丰赵明

Owner SHANDONG YITENG NEW MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com