Pressure-resistant lightweight heat-insulating brick and preparation method thereof

A kind of insulation brick, light-weight technology, applied in ceramic products, other household appliances, applications, etc., can solve the problems that affect the reliability and safety of construction projects, high sintering temperature of refractory insulation bricks, increase processing costs, etc., to achieve suitable promotion application, high compressive strength, and the effect of reducing the cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

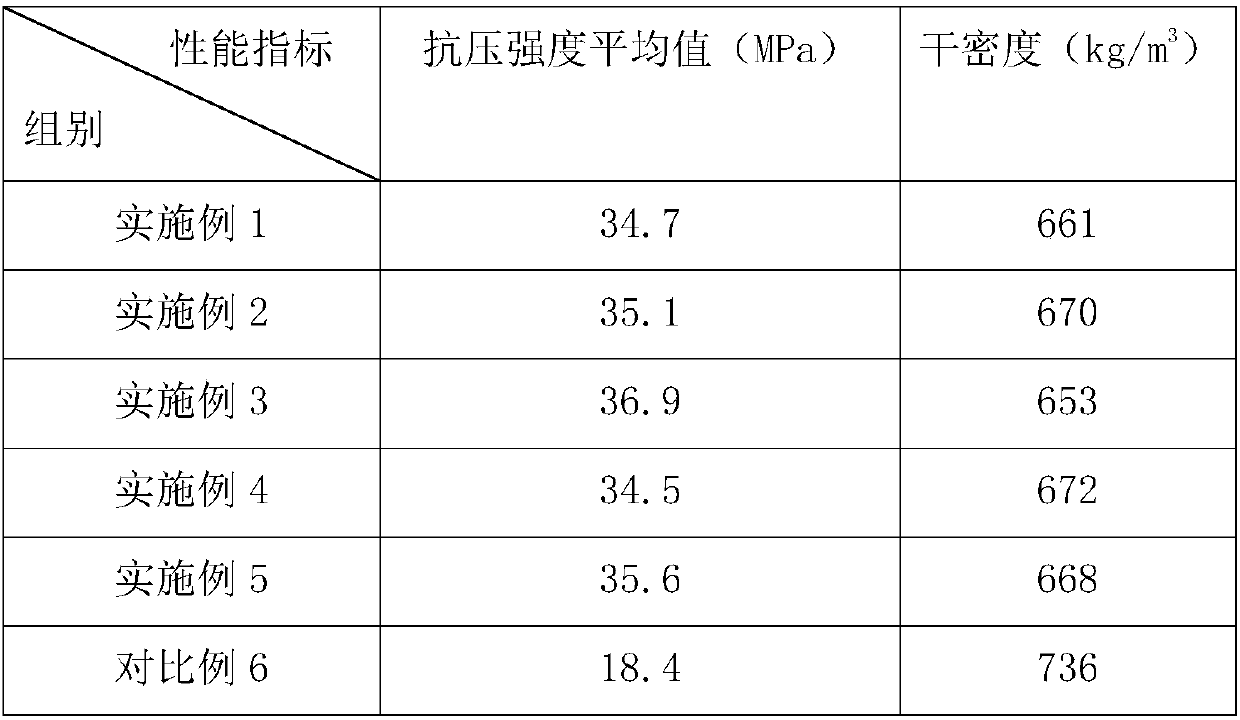

Examples

Embodiment 1

[0027] A kind of pressure-resistant light-weight insulation brick, the following raw materials are prepared: 70kg of dehydrated river mud, 50kg of tailings iron sand, 30kg of modified diatomite, 5kg of floating beads, 5kg of purple sand shale, 5kg of ceramic fiber, 5kg of shell carbon powder, peroxidized Calcium 4kg, hydroxyethyl methylcellulose 4kg, methyl methacrylate 3kg, dry strength agent 1kg and blowing agent 1kg.

[0028] Among them, the water content of the dehydrated river mud is controlled at 15%, and the tailings iron sand, floating beads and purple sand shale are crushed to a particle size of 1-2mm by a jaw crusher;

[0029] In addition, the above-mentioned shell charcoal powder only uses coconut shell charcoal; the above-mentioned dry strength agent uses cationic polyacrylamide; the above-mentioned foaming agent uses triethoxybutane.

[0030] The preparation process of the above-mentioned compression-resistant lightweight insulation brick is carried out according ...

Embodiment 2

[0036] A kind of pressure-resistant light-weight insulation brick, prepare the following raw materials: dehydrated river mud 80kg, tailings iron sand 60kg, modified diatomite 40kg, floating beads 10kg, purple sand shale 10kg, ceramic fiber 8kg, shell carbon powder 8kg, peroxidized Calcium 6kg, hydroxyethyl methylcellulose 5kg, methyl methacrylate 4kg, dry strength agent 2kg and blowing agent 2kg.

[0037] Among them, the water content of the dehydrated river mud is controlled at 20%, and the tailings iron sand, floating beads and purple sand shale are crushed to a particle size of 1-2mm by a jaw crusher;

[0038] In addition, the above-mentioned shell charcoal powder only uses rice husk powder; the above-mentioned dry strength agent uses chitosan; the above-mentioned foaming agent uses sodium silicate.

[0039] The preparation process of the above-mentioned compression-resistant lightweight insulation brick is carried out according to the following steps:

[0040] 1) First, a...

Embodiment 3

[0045] A kind of pressure-resistant light-weight insulation brick, the following raw materials are prepared: 100kg of dehydrated river mud, 80kg of tailings iron sand, 50kg of modified diatomite, 15kg of floating beads, 15kg of purple sand shale, 10kg of ceramic fiber, 10kg of shell carbon powder, peroxidized Calcium 8kg, hydroxyethyl methylcellulose 6kg, methyl methacrylate 5kg, dry strength agent 3kg and blowing agent 3kg.

[0046] Among them, the water content of the dehydrated river mud is controlled at 15%, and the tailings iron sand, floating beads and purple sand shale are crushed to a particle size of 1-2mm through a jaw crusher. The shell charcoal powder uses coconut shell charcoal, rice husk powder and straw powder a mixture of all three;

[0047] In addition, the above-mentioned shell charcoal powder only uses coconut shell charcoal; the above-mentioned dry strength agent uses chitosan; the above-mentioned foaming agent uses sodium silicate.

[0048] The preparatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com