Chloroethylene suspension polymerization terminator and preparation method and use method thereof

A technology of suspension polymerization and terminator, applied in the field of vinyl chloride suspension polymerization terminator, can solve the problems of low polymerization termination efficiency, difficulty in preparing dispersion solution, toxicity, etc., and achieve excellent termination effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

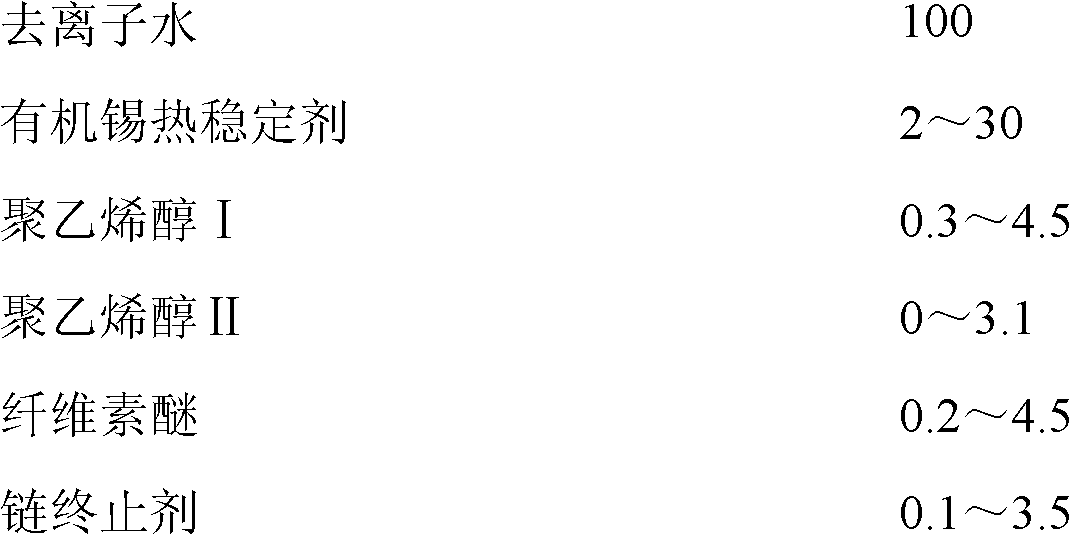

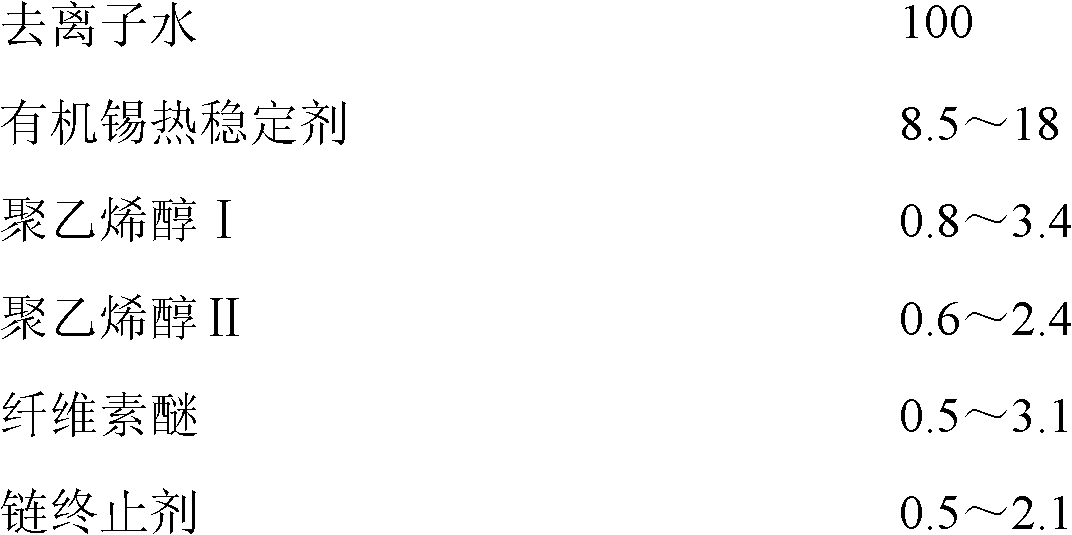

[0069] Vinyl chloride suspension polymerization terminator components:

[0070]

[0071] Preparation of vinyl chloride suspension polymerization terminator: Dissolve 0.83 parts of polyvinyl alcohol I (PVA80), 0.50 parts of polyvinyl alcohol II (PVA55) and 1.67 parts of hydroxypropyl methylcellulose into 75 parts of deionized water, stir at high speed Form an aqueous dispersant emulsion in 0.25 hours; add 11.1 parts of organotin S, S'-bis(isooctyl thioacetate)-bis(n-octyl)tin to the above aqueous emulsion, and stir for 0.5 hour to form an organotin emulsion; Add aqueous solution of sodium dimethyldithiocarbamate (25 parts of desalted water in this aqueous solution, 2.33 parts of sodium dimethyldithiocarbamate) into the above-mentioned aqueous emulsion, and stir for 0.35 hours to obtain the vinyl chloride suspension polymerization termination solution of the present invention. agent. (The above operations are all carried out under normal temperature and pressure, and the sti...

Embodiment 2

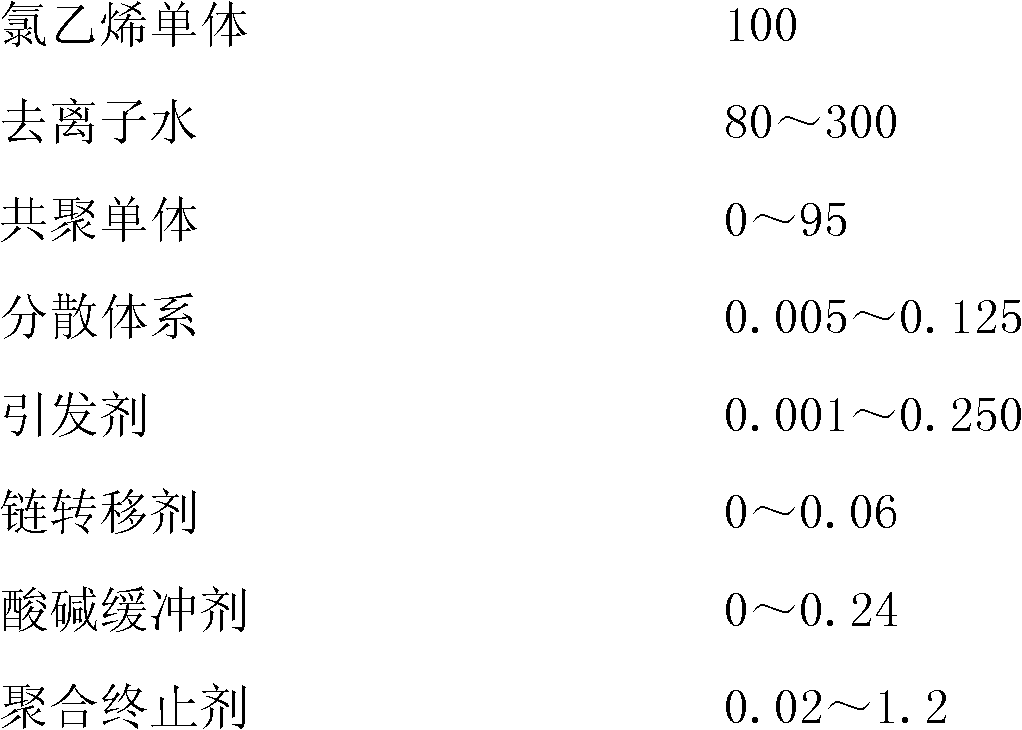

[0084] The polymerization formula is as follows:

[0085]

[0086] Note:

[0087] PVA80: polyvinyl alcohol with an alcoholysis degree of 80%

[0088] PVA55: polyvinyl alcohol with a degree of alcoholysis of 55%

[0089] E50: Hydroxypropylmethylcellulose

[0090] TAPP: pivalate peroxypivalate

[0091] TBPND: tert-butyl peroxyneodecanoate

[0092] NG: 2-Mercaptoethanol

[0094] Vinyl chloride suspension polymerization terminator is the same as embodiment 1

[0095] Operation method:

[0096] Wash the polymerization reactor with deionized water, add deionized water, PVA80, PVA55, E50, NaOH, TAPP, TBPND in the formula amount at room temperature, close the reactor, start stirring, the speed is 450rpm, vacuumize to -0.095MPa, Add VCM, stir for 10 minutes, then raise the temperature to the reaction temperature of 61°C, then add the formulated amount of NG, and complete the addition within 20 minutes. Control the reaction at 57°C. When the pr...

Embodiment 3

[0098] The polymerization formula is as follows:

[0099]

[0100] Note:

[0101] PVA80: polyvinyl alcohol with an alcoholysis degree of 80%

[0102] E50: Hydroxypropylmethylcellulose

[0103] LE: azobisisoheptanonitrile

[0104] NG: 2-Mercaptoethanol

[0105] NaOH: sodium hydroxide

[0106] Vinyl chloride suspension polymerization terminator is the same as embodiment 1

[0107] Operation method:

[0108] Wash the polymerization reactor with deionized water, add deionized water, PVA80, E50, NaOH, LE at normal temperature, close the reactor, start stirring, rotate at 450rpm, vacuumize to -0.095MPa, add VCM,

[0109] Stir for 10 minutes, then raise the temperature to the reaction temperature of 62.2°C, and add NG within 30 minutes. When the reaction pressure is reduced by about 0.21 MPa from the constant pressure state, add the emulsion, keep the reaction conditions unchanged, observe and record the change of the polymerization reaction pressure, release the pressure a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com