Modified hydroxyethyl methyl cellulose for enhanced ceramic tile adhesive and preparation method and application thereof

A technology of hydroxyethyl methyl and cellulose, applied in the direction of adhesive additives, polymer adhesive additives, etc., can solve the problems of small production capacity, low pressure, low labor intensity, etc., to improve the ability to maintain moisture, Effect of improving tensile bond strength and enhancing tensile bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

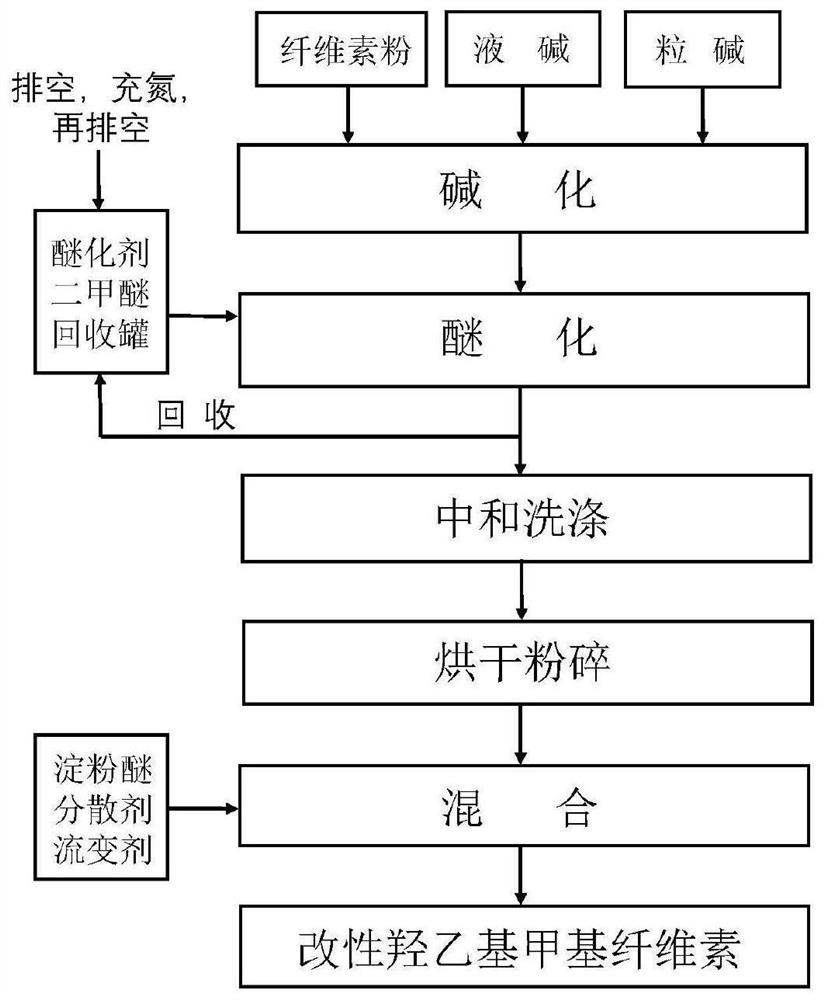

Method used

Image

Examples

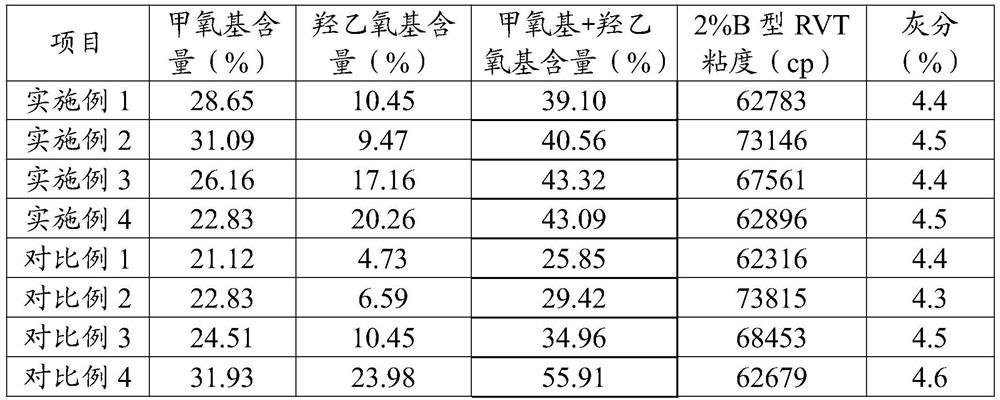

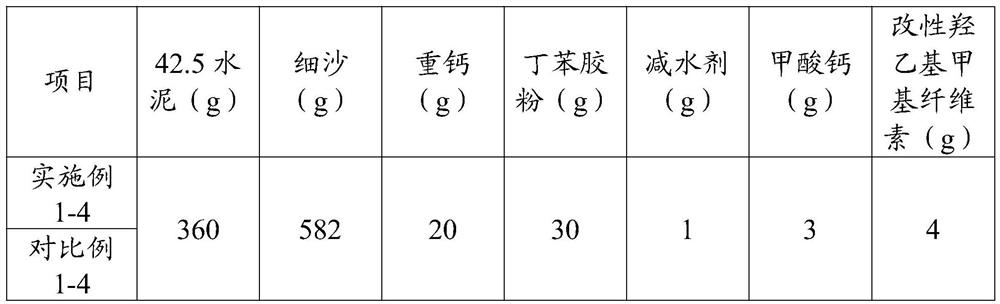

Embodiment 1

[0051] Modified hydroxyethyl methylcellulose for reinforced tile adhesive, made from the following quality raw materials: 74kg of hydroxyethylmethylcellulose, hydroxypropyl starch (19.5% hydroxypropoxy content, 5% type B LVT viscosity 1950cp, ash content 7.5%, produced by Shandong Yiteng New Material Co., Ltd.) 20kg, anionic polyacrylamide 3kg and guar gum 3kg;

[0052] Among them, hydroxyethyl methylcellulose is made of cotton cellulose powder (average degree of polymerization is 2638, particle diameter is 0.230mm, bulk density is 175g / L) 100kg, granular sodium hydroxide (particle diameter is 0.7mm) 27kg, hydrogen Prepared from 63kg of sodium oxide aqueous solution (50% mass concentration), 74kg of methyl chloride and 13kg of ethylene oxide.

[0053] The preparation method specifically comprises the following steps:

[0054] (1) Take each raw material by the above-mentioned quality;

[0055] (2) Add cotton cellulose powder, granular sodium hydroxide and aqueous sodium hydro...

Embodiment 2

[0058] Modified hydroxyethyl methyl cellulose for reinforced tile adhesive, made from raw materials of the following quality: hydroxyethyl methyl cellulose 66kg, hydroxypropyl starch (hydroxypropoxy content is 19.5%, 5% type B LVT viscosity 1950cp, ash content 7.5%, produced by Shandong Yiteng New Material Co., Ltd.) 30kg, nonionic polyacrylamide 2kg and gum arabic 2kg;

[0059] Among them, hydroxyethyl methylcellulose consists of 100kg of wood cellulose powder (average degree of polymerization is 2873, particle size is 0.230mm, bulk density is 175g / L), granular sodium hydroxide (particle size is 0.7mm) 35kg, hydrogen Prepared from 52kg of sodium oxide aqueous solution (50% mass concentration), 81kg of methyl chloride and 12kg of ethylene oxide.

[0060] The preparation method specifically comprises the following steps:

[0061] (1) Take each raw material by the above-mentioned quality;

[0062] (2) Add wood cellulose powder, granular sodium hydroxide and aqueous sodium hydr...

Embodiment 3

[0065] Modified hydroxyethyl methyl cellulose for reinforced tile adhesive, made from raw materials of the following quality: 71 kg of hydroxyethyl methyl cellulose, hydroxypropyl starch (19.5% hydroxypropoxy content, 5% type B LVT viscosity 1950cp, ash content 7.5%, produced by Shandong Yiteng New Material Co., Ltd.) 25kg, polyvinyl alcohol 2kg and carrageenan 2kg;

[0066] Wherein, hydroxyethyl methylcellulose is made of bamboo cellulose powder (average degree of polymerization is 1050, particle diameter is 0.18mm, bulk density is 150g / L) 20kg, wood cellulose powder (average degree of polymerization is 2520, particle diameter is 0.18mm, bulk density 150g / L) 60kg, cotton cellulose powder (average degree of polymerization 5010, particle size 0.18mm, bulk density 150g / L) 20kg, granular potassium hydroxide (particle size 0.3mm) 66kg 100kg of potassium hydroxide aqueous solution (mass concentration is 40%), 168kg of methyl chloride and 53kg of ethylene oxide.

[0067] The prepar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com