Stainless steel foil and method for manufacturing same

A stainless steel foil and stainless steel technology, applied in the field of stainless steel foil, can solve the problems of not being able to apply the battery case, etc., and achieve the effects of good electrolyte resistance, good stamping processability, and high plate thickness accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

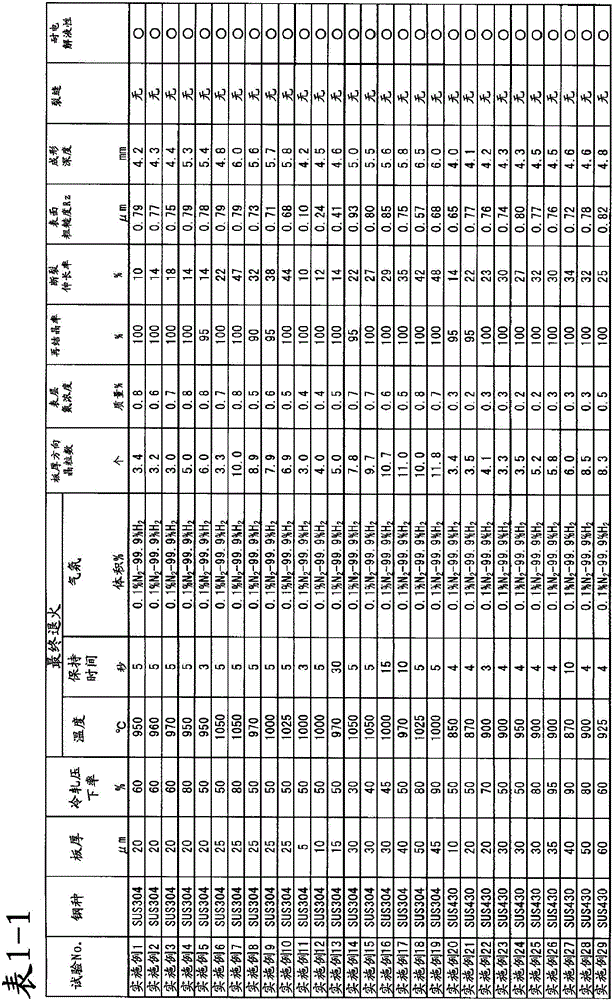

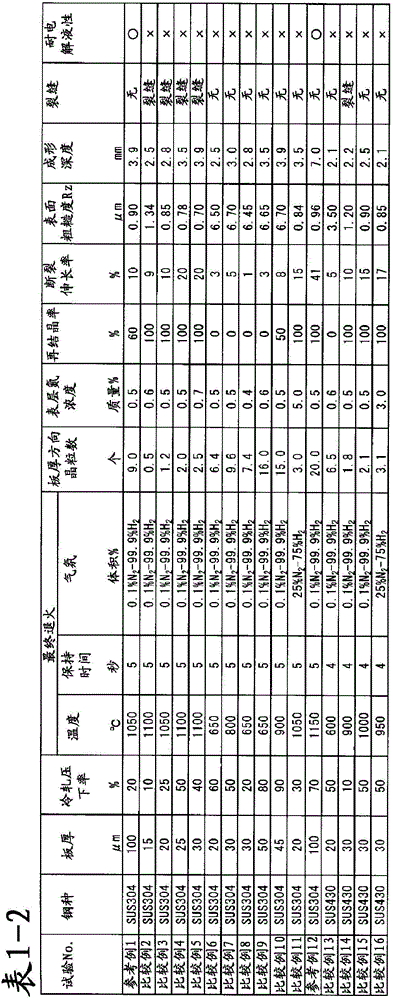

[0109] [Example]

[0110] As an example of the ultra-thin stainless steel foil according to the present invention, commercially available SUS304 (austenitic stainless steel) and SUS430 (ferritic stainless steel) were rolled by a foil rolling mill under the rolling conditions described in Table 1. An ultra-thin stainless steel foil having the thickness described in Table 1 was manufactured.

[0111] Here, the cold rolling reduction represents the reduction in the foil rolling process immediately before the final annealing, the final annealing temperature represents the temperature in the final annealing process performed after the rolling process is completed, and the holding time represents the temperature at the final annealing temperature. time to keep the stainless steel foil under.

[0112] The annealing atmosphere is set as 0.1 vol% nitrogen-99.9 vol% hydrogen mixed gas or 25 vol% nitrogen-75 vol% hydrogen mixed gas.

[0113] The recrystallization rate is observed by mirr...

reference example 1

[0123] Reference examples 1 and 12 are examples of stainless steel foils with a plate thickness of 100 μm. In Reference Example 1, although the annealing temperature was relatively high, the sheet thickness was thick and recrystallization did not proceed. However, since the plate thickness is thick, the number of crystal grains in the cross section is 9, and the elongation at break and the forming depth are secured to some extent. Reference Example 11 is an example in which both the elongation at break and the depth of forming are very good because the recrystallization rate is 100%. Thus, it can be seen that, when the plate thickness is thick like the conventional stainless steel foil, the elongation at break becomes good and the plastic deformability is ensured, so that the subject of the present invention is not conspicuous.

[0124] In addition, Examples 20-29 and Comparative Examples 13-16 are the examples which used SUS430. In comparing SUS304 and SUS430, it was confir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com