Modified polyurethane and preparation method and application thereof

A polyurethane and polyurethane coating technology, applied in the field of adhesive materials, can solve the problems of polyurethane coating surface pulverization, poor aging resistance, low strength, etc., to ensure elongation at break, increase tensile strength, and improve aging resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] An embodiment of the present invention provides a method for preparing modified polyurethane, which includes the following steps S110-S130.

[0030] S110: In parts by mass, 10 parts of pentaerythritol triacrylate and 30-70 parts of polydimethylmethylhydrogensiloxane are mixed, heated and reacted under catalytic conditions, and reaction products are separated to prepare hydroxyl-containing silicone oil.

[0031] Further, in parts by mass, 10 parts of pentaerythritol triacrylate and 40-60 parts of polydimethylmethylhydrogensiloxane are mixed, heated and reacted under catalytic conditions, and reaction products are separated to prepare hydroxyl-containing silicone oil. Pentaerythritol triacrylate and polydimethylmethylhydrogensiloxane can be fully added to form a specific multi-branched siloxane structure.

[0032] Further, the hydrogen content of polydimethylmethylhydrogensiloxane is 0.5%-2%. Furthermore, the hydrogen content of polydimethylmethylhydrogensiloxane is 0.8%...

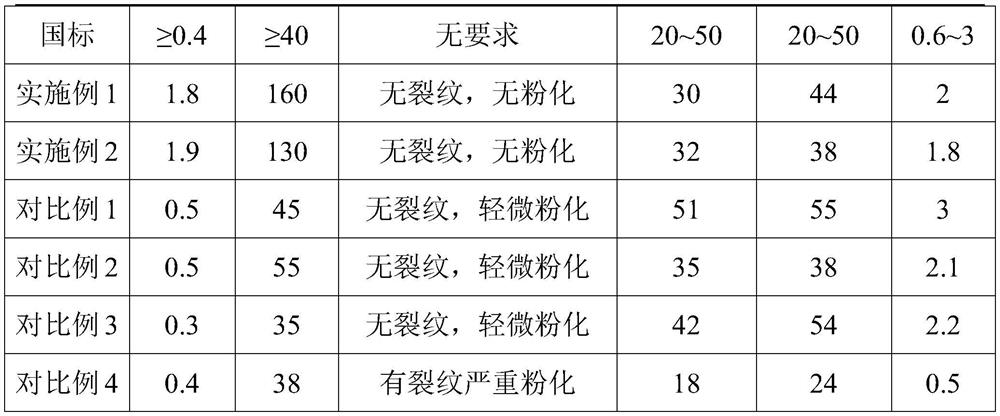

Embodiment 1

[0059] (1) Preparation of hydroxyl-containing silicone oil:

[0060] In terms of parts by mass, first add 10 parts of pentaerythritol triacrylate and 60 parts of polydimethylmethylhydrogensiloxane (hydrogen content 0.95%-1.05%) to the reactor under stirring conditions, and then add 0.2 Parts of chloroplatinic acid, heated to 80 ° C for 8 hours. After the reaction was completed, the temperature was raised to 120° C., and the reaction product was separated by vacuum distillation for 30 minutes under a negative pressure of 0.095 MPa to obtain a hydroxyl-containing silicone oil.

[0061] (2) Preparation of modified polyurethane:

[0062] In terms of parts by mass, add 100 parts of polyoxypropylene diol (Mn=2000g / mol) to the reactor, raise the temperature to 100°C, dehydrate for 2 hours under the condition of negative pressure 0.095MPa, add 40 parts of 4,4'-diol Phenylmethane diisocyanate (pure MDI), reacted at 80°C for 2 hours, lowered to 70°C, added 4 parts of trimethylolpropan...

Embodiment 2

[0068] (1) Preparation of hydroxyl-containing silicone oil:

[0069] In terms of parts by mass, first add 10 parts of pentaerythritol triacrylate and 40 parts of polydimethylmethylhydrogensiloxane (hydrogen content 0.95%-1.05%) to the reactor under stirring conditions, and then add 0.2 Parts of chloroplatinic acid, heated to 70 ° C for 7 hours. After the reaction was completed, the temperature was raised to 120° C., and the reaction product was separated by vacuum distillation for 30 minutes under a negative pressure of 0.095 MPa to obtain a hydroxyl-containing silicone oil.

[0070] (2) Preparation of modified polyurethane:

[0071] In terms of parts by mass, add 100 parts of polyoxypropylene diol (Mn=2000g / mol) to the reactor, raise the temperature to 100°C, dehydrate for 2 hours under the condition of negative pressure 0.095MPa, add 55 parts of 4,4'-diol Phenylmethane diisocyanate (pure MDI), reacted at 85°C for 2 hours, lowered to 65°C, added 5 parts of trimethylolpropan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com