Silicon-free rubber outsole and preparation method thereof

A silicone rubber and outsole technology, applied in the field of shoe soles and outsoles, can solve problems such as shoe material damage and affect the normal movement of staff, and achieve the effects of low production cost, convenient control and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

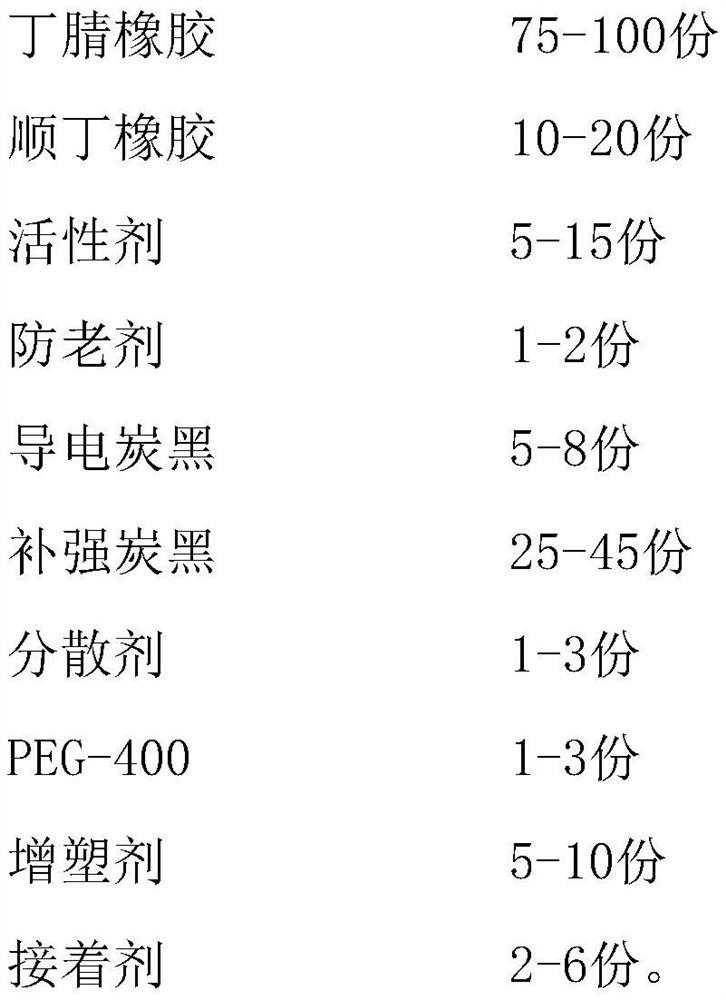

[0035] A kind of non-silicone rubber outsole, comprises the raw material of following parts by weight:

[0036]

[0037] The preparation method of described nitrile rubber comprises the steps:

[0038] (R1), 70 parts by weight of butadiene, 30 parts of acrylonitrile, 8 parts of fluorine-containing acrylate monomer, 0.8 part of coupling agent, 4 parts of emulsifier, 0.5 part of dodecyl mercaptan, 0.15 part Ferrous sulfate, 0.15 part of 1,3-diketone, 0.15 part of initiator, 0.15 part of polymerization inhibitor sodium nitrite and 250 parts of water, set aside;

[0039] (R2), add fluorine-containing acrylate monomer and coupling agent to acrylonitrile and mix, then add butadiene, water, emulsifier, dodecyl mercaptan, ferrous sulfate and 1,3-diketone in sequence , pre-emulsified for 40min to obtain a pre-emulsion;

[0040] (R3) Add hydrogen peroxide to the pre-emulsion, copolymerize at 10° C. for 2 hours, then add 0.5 part of polymerization inhibitor sodium nitrite and mix to...

Embodiment 2

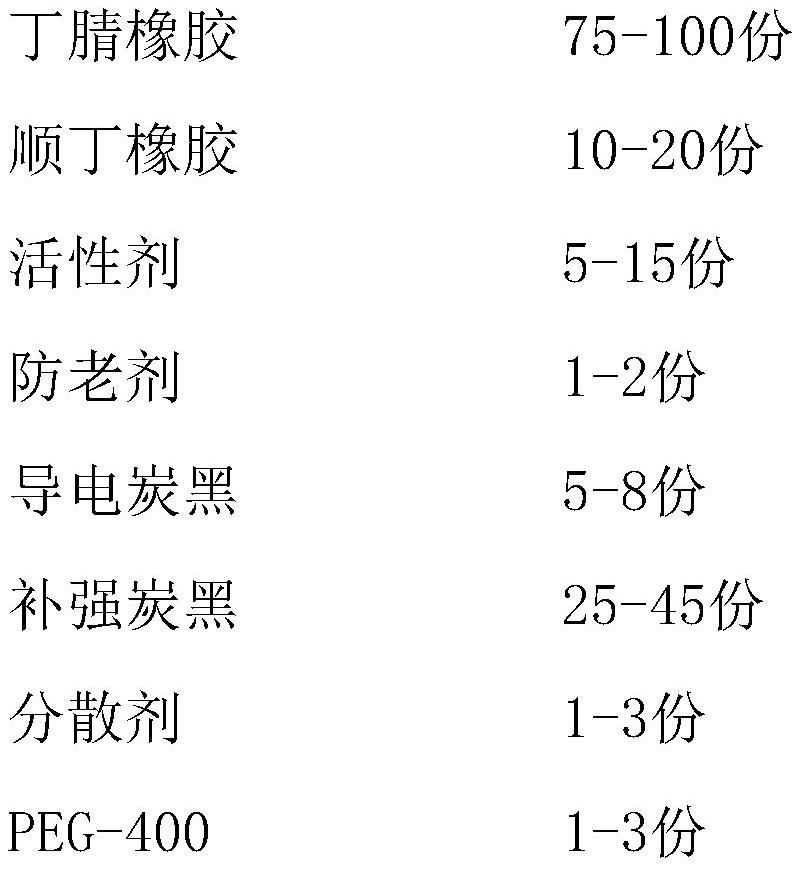

[0051] A kind of non-silicone rubber outsole, comprises the raw material of following parts by weight:

[0052]

[0053] The preparation method of described nitrile rubber comprises the steps:

[0054] (R1), 60 parts by weight of butadiene, 20 parts of acrylonitrile, 5 parts of fluorine-containing acrylate monomer, 0.5 part of coupling agent, 2 parts of emulsifier, 0.1 part of dodecyl mercaptan, 0.1 part Ferrous sulfate, 0.1 part of 1,3-diketone, 0.1 part of initiator, 0.1 part of polymerization inhibitor sodium nitrite and 200 parts of water, set aside;

[0055] (R2), add fluorine-containing acrylate monomer and coupling agent to acrylonitrile and mix, then add butadiene, water, emulsifier, dodecyl mercaptan, ferrous sulfate and 1,3-diketone in sequence , pre-emulsified for 30 minutes to obtain a pre-emulsion;

[0056] (R3) Add hydrogen peroxide to the pre-emulsion, copolymerize at 1° C. for 1 hour, then add 0.1 part of polymerization inhibitor sodium nitrite and mix to ob...

Embodiment 3

[0067] A kind of non-silicone rubber outsole, comprises the raw material of following parts by weight:

[0068]

[0069] The preparation method of described nitrile rubber comprises the steps:

[0070] (R1), 80 parts by weight of butadiene, 40 parts of acrylonitrile, 10 parts of fluorine-containing acrylate monomer, 1 part of coupling agent, 5 parts of emulsifier, 0.8 part of dodecyl mercaptan, 0.2 part Ferrous sulfate, 0.2 part of 1,3-diketone, 0.2 part of initiator, 0.2 part of polymerization inhibitor sodium nitrite and 300 parts of water, set aside;

[0071] (R2), add fluorine-containing acrylate monomer and coupling agent to acrylonitrile and mix, then add butadiene, water, emulsifier, dodecyl mercaptan, ferrous sulfate and 1,3-diketone in sequence , pre-emulsified for 60 minutes to obtain a pre-emulsion;

[0072] (R3) Add hydrogen peroxide to the pre-emulsion, copolymerize at 15° C. for 3 hours, then add 1 part of polymerization inhibitor sodium nitrite and mix to o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com