Anti-fouling water-based paint and preparation method thereof

A water-based paint and anti-fouling technology, which is applied in the direction of anti-corrosion paint, coating, etc., can solve the problems of equipment surface corrosion damage, paint film can not be kept clean, frequent removal of pollutants, etc., to achieve toughened paint film increase, adjustment and Effect of antifouling agent bleed control, excellent adhesion and chalking resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

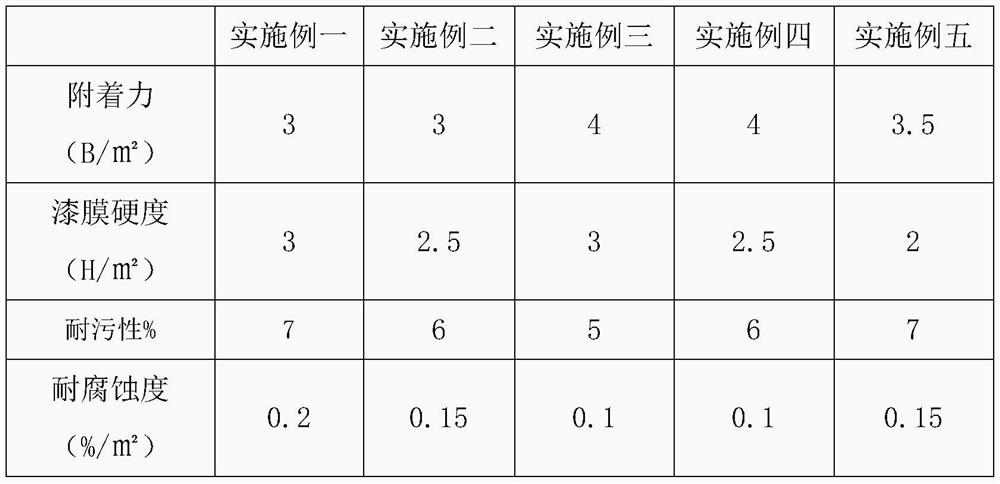

Examples

Embodiment 1

[0021] A kind of anti-fouling water-based paint and its preparation method proposed by the present invention include the following raw materials in parts by weight: 50 parts of water-based fluorocarbon emulsion, 30 parts of antifouling agent, 2 parts of additive, 3 parts of filler, 8 parts of solvent, auxiliary 1 dose;

[0022] Among them, the antifouling agent is prepared by the following method: titanium dioxide, copper naphthenate, dispersant, thickener, and solvent are mixed to obtain the antifouling agent, wherein the solvent is one of butyl acetate, ethyl acetate, and butanol or more, the mass ratio of titanium dioxide, copper naphthenate, dispersant, thickener, and solvent is 50:15:5:3:10

[0023] The present invention also proposes a preparation method of an antifouling type water-based paint and a preparation method thereof, comprising the following steps:

[0024] S1. In parts by weight, weigh 50 parts of water-based fluorocarbon emulsion, 30 parts of antifouling ag...

Embodiment 2

[0028] A kind of anti-fouling water-based paint and its preparation method proposed by the present invention include the following raw materials in parts by weight: 55 parts of water-based fluorocarbon emulsion, 35 parts of antifouling agent, 3 parts of additive, 4 parts of filler, 11 parts of solvent, auxiliary 2 doses;

[0029] Among them, the antifouling agent is prepared by the following method: titanium dioxide, copper naphthenate, dispersant, thickener, and solvent are mixed to obtain the antifouling agent, wherein the solvent is one of butyl acetate, ethyl acetate, and butanol or more, the mass ratio of titanium dioxide, copper naphthenate, dispersant, thickener, and solvent is 50:16:5.5:3.5:12

[0030] The present invention also proposes a preparation method of an antifouling type water-based paint and a preparation method thereof, comprising the following steps:

[0031] S1. In parts by weight, weigh 55 parts of water-based fluorocarbon emulsion, 35 parts of antifoul...

Embodiment 3

[0035] A kind of anti-fouling water-based paint and its preparation method proposed by the present invention include the following raw materials in parts by weight: 60 parts of water-based fluorocarbon emulsion, 40 parts of antifouling agent, 4 parts of additive, 5 parts of filler, 14 parts of solvent, auxiliary 3 doses;

[0036] Among them, the antifouling agent is prepared by the following method: titanium dioxide, copper naphthenate, dispersant, thickener, and solvent are mixed to obtain the antifouling agent, wherein the solvent is one of butyl acetate, ethyl acetate, and butanol or more, the mass ratio of titanium dioxide, copper naphthenate, dispersant, thickener, and solvent is 50:17:6.5:4:12.5

[0037] The present invention also proposes a preparation method of an antifouling type water-based paint and a preparation method thereof, comprising the following steps:

[0038] S1. In parts by weight, weigh 60 parts of water-based fluorocarbon emulsion, 40 parts of antifoul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com