Patents

Literature

86results about How to "Conducive to environmental requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

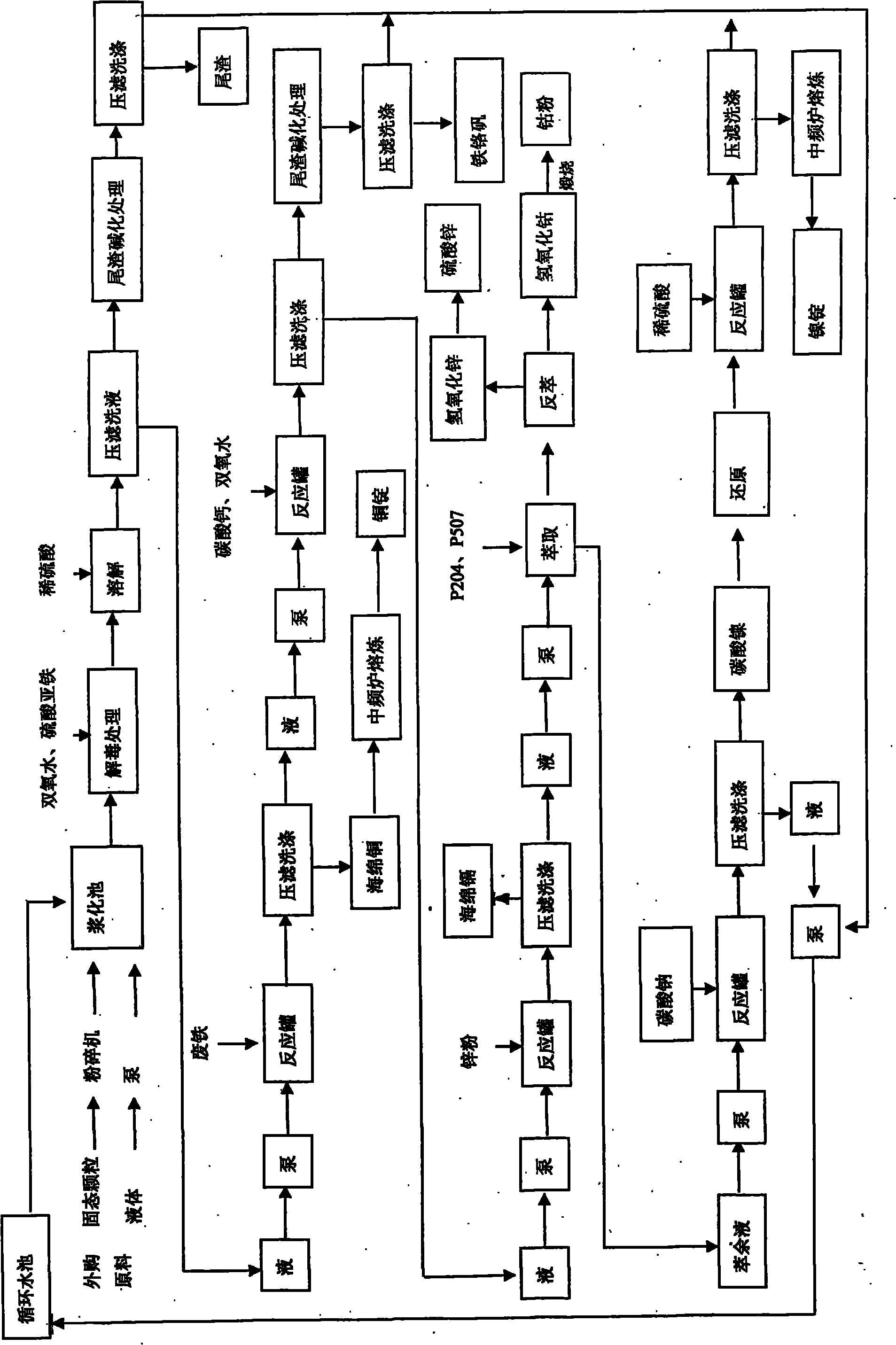

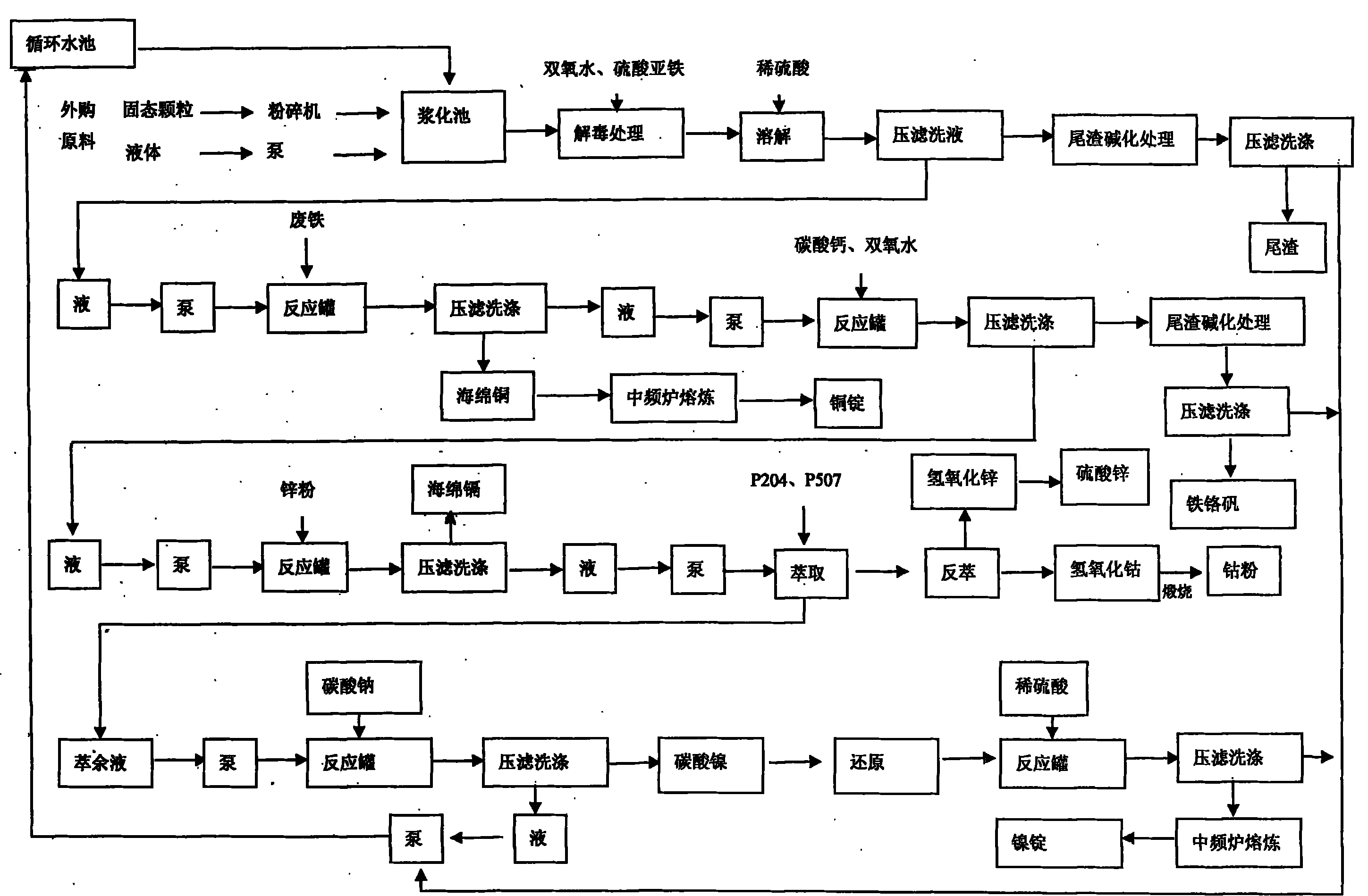

Method for recycling heavy metal pollution wastes

InactiveCN101871046AWide process adaptabilityRealize the purpose of resource utilizationProcess efficiency improvementChemistryCopper

The invention discloses a method for recycling heavy metal pollution wastes, which comprises the following steps of: 1) the pulping of raw materials; 2) acid leaching, namely, adding pulp obtained in the step 1 into a dilute sulphuric acid for filtration, and taking filter residues as the raw materials of bricks or cement; 3) copper displacement, namely, displacing copper out of filtrate in the step 2 with iron; 4) the preparation of ferrum-chrome-alum, namely, adding alkaline substances and an oxidant into the filtrate obtained in the step 3, adjusting a PH value, and precipitating and filter-pressing the mixed solution to obtain the ferrum-chrome-alum; and 5) the preparation of sponge cadmium, namely, displacing cadmium out of the filtrate obtained in the step 4 with zinc. The process has the advantages of suitability for the treatment of waste residues and waste liquor in a plurality of industries of electroplating, surface treatment, heavy metal smelting, chemical engineering and the like, no need of heating liquid-phase materials, the realization of closed cycle, and the capacity of extracting a plurality of valuable metals, such as Cu, Cr, Cd, Ni, Co, Zn and the like, directly taking the wastes obtained after the metal separation as the raw materials of the bricks or cement, and saving coal and electricity amounting to 20,000 T standard coal and 40,000-ton water per year for enterprises recycling 5,000-ton metals per year.

Owner:青川县天运金属开发有限公司

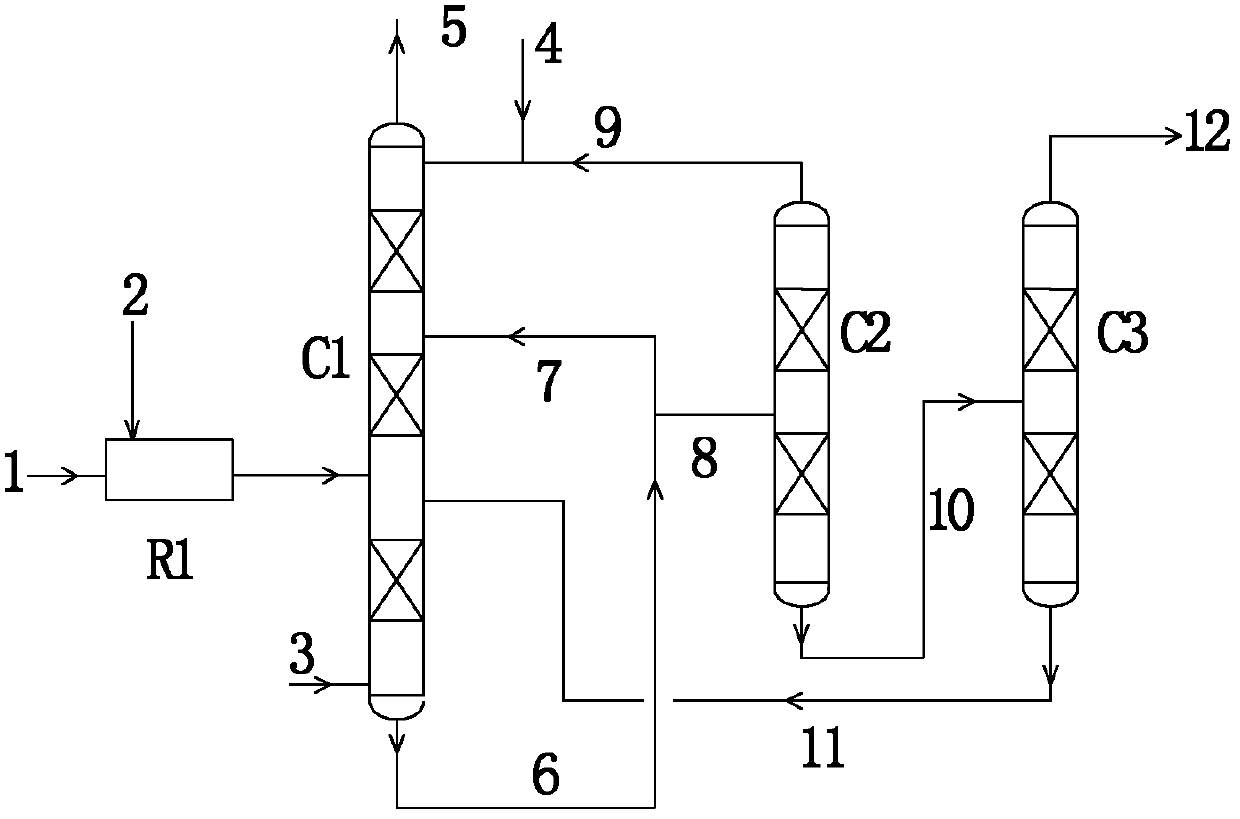

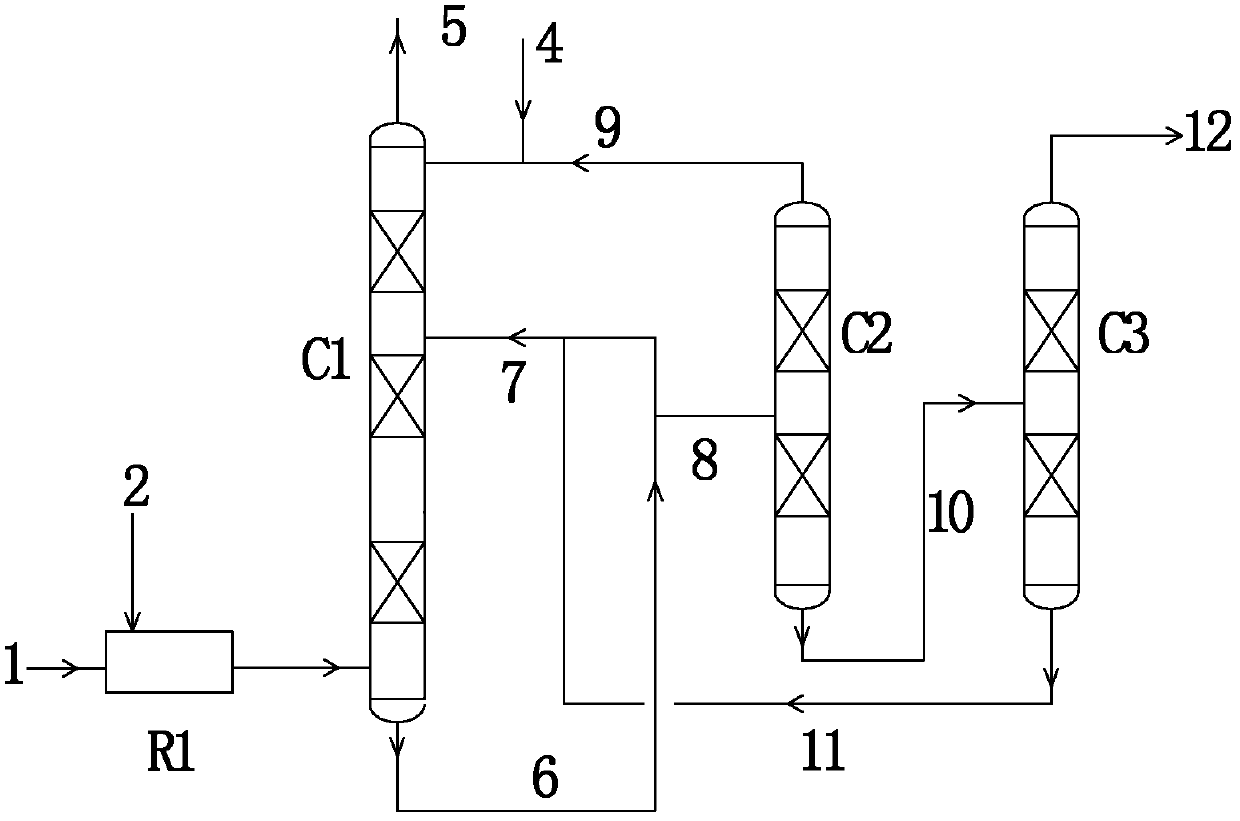

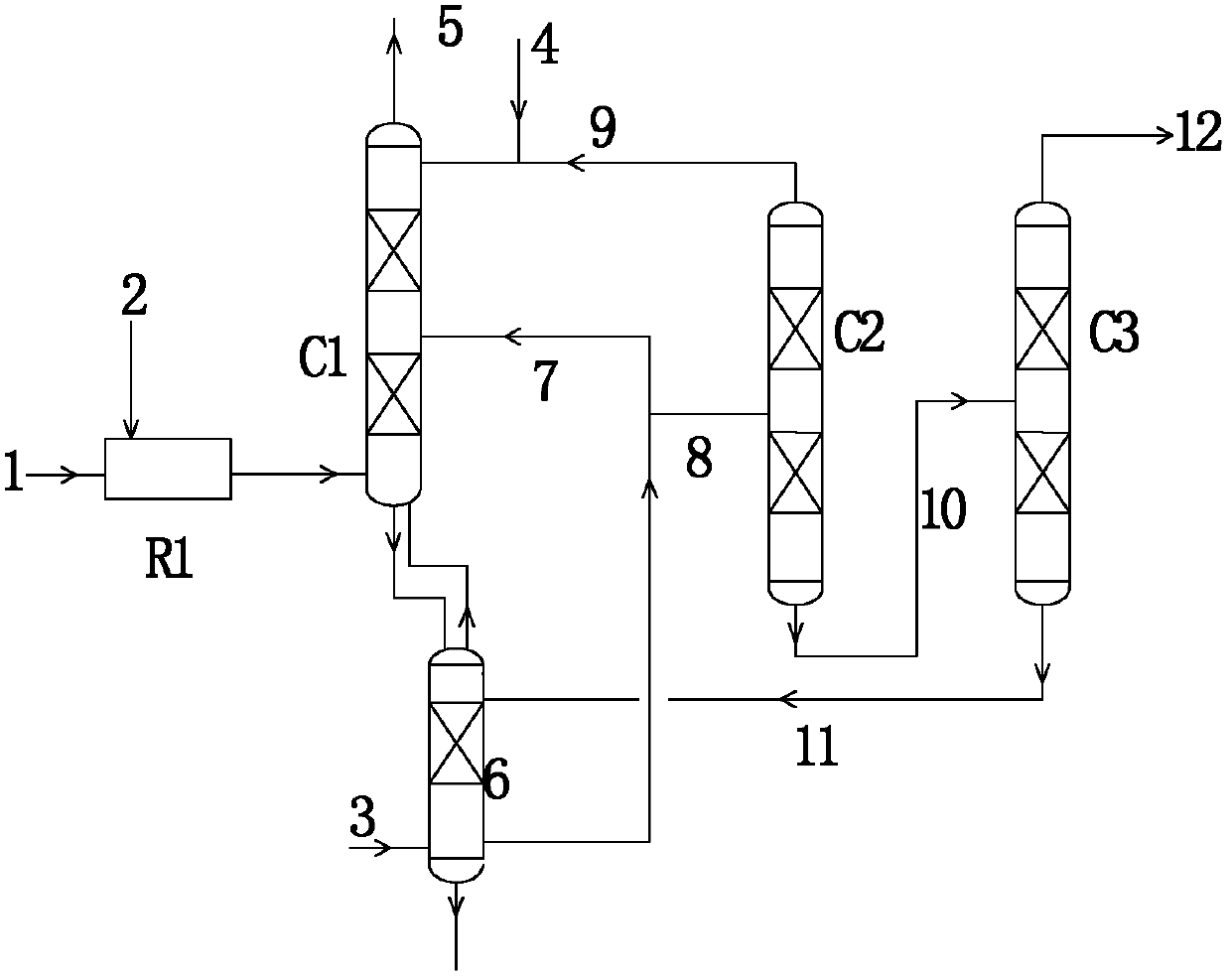

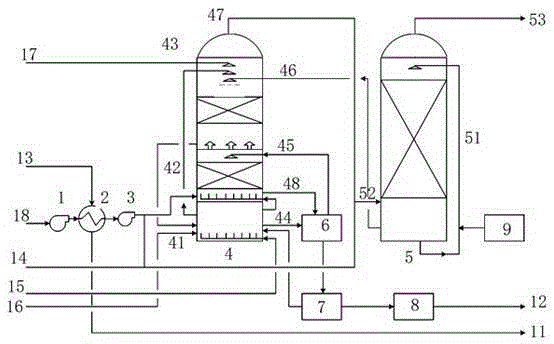

Preparation method for methyl nitrite

ActiveCN103373925AReduce heat supplyHigh yieldNitrous acid preparation ester preparationWastewaterNo conversion

The invention relates to a preparation method for methyl nitrite. The preparation method is characterized by comprising the following steps of: taking NO-containing gas, O2 and methanol as raw materials, inputting the NO-containing gas, the O2 and the methanol into at least one esterification column, reacting to obtain methyl nitrite, and recycling nitric acid and the residual methanol, wherein the residual methanol is recycled in at least one methanol recycling column, and the nitric acid is recycled in at least one nitric acid recycling column. Compared with the prior art, the preparation method for the methyl nitrite has the advantages that MN can be effectively generated, the NO conversion rate can be improved, the yield of the MN can be increased, the heating capacity of the bottom of the esterification column can be reduced, and the wastewater discharged from a system does not contain the nitric acid; the problem of the nitric acid wastewater generated in a process for generating methyl nitrite from NO is thoroughly solved, and the preparation method is beneficial to environmental protection and has a good practical application value and production significance.

Owner:PUJING CHEM IND SHA +1

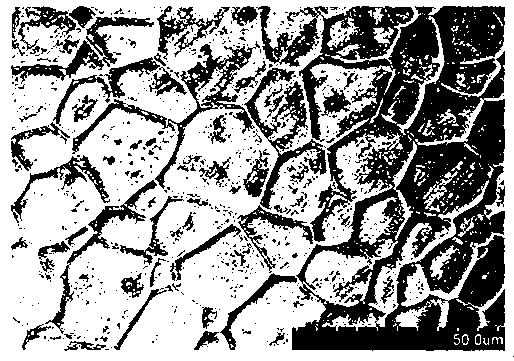

Process for preparing copper-indium-selenium sputtering target

InactiveCN101333645AReduce usageConducive to environmental requirementsVacuum evaporation coatingSputtering coatingIndiumNew energy

The invention belongs to the new energy technique field of photoelectric material, in particular to a process for preparing a copper indium selenide sputtering target. A Cu2Se powder and an In2Se3 powder prepared or purchased in the market are mixed in a planetary ball mill for ball milling and then cold-press molding so as to make a biscuit with mixed material of Cu2Se and In2Se3, the biscuit is positioned in a closed vacuum sintering furnace, and is sintered and cooled for de-molding in the H2 protective atmosphere, thereby obtaining the copper indium selenide target. The produced target has uniform copper indium selenide phase, and the relative density reaches over 95 percent. The process has the advantages of simple process, high efficiency, low cost and good stability, and conveniently and stably guarantees the preparation process of copper indium selenide absorption layer films.

Owner:TSINGHUA UNIV +1

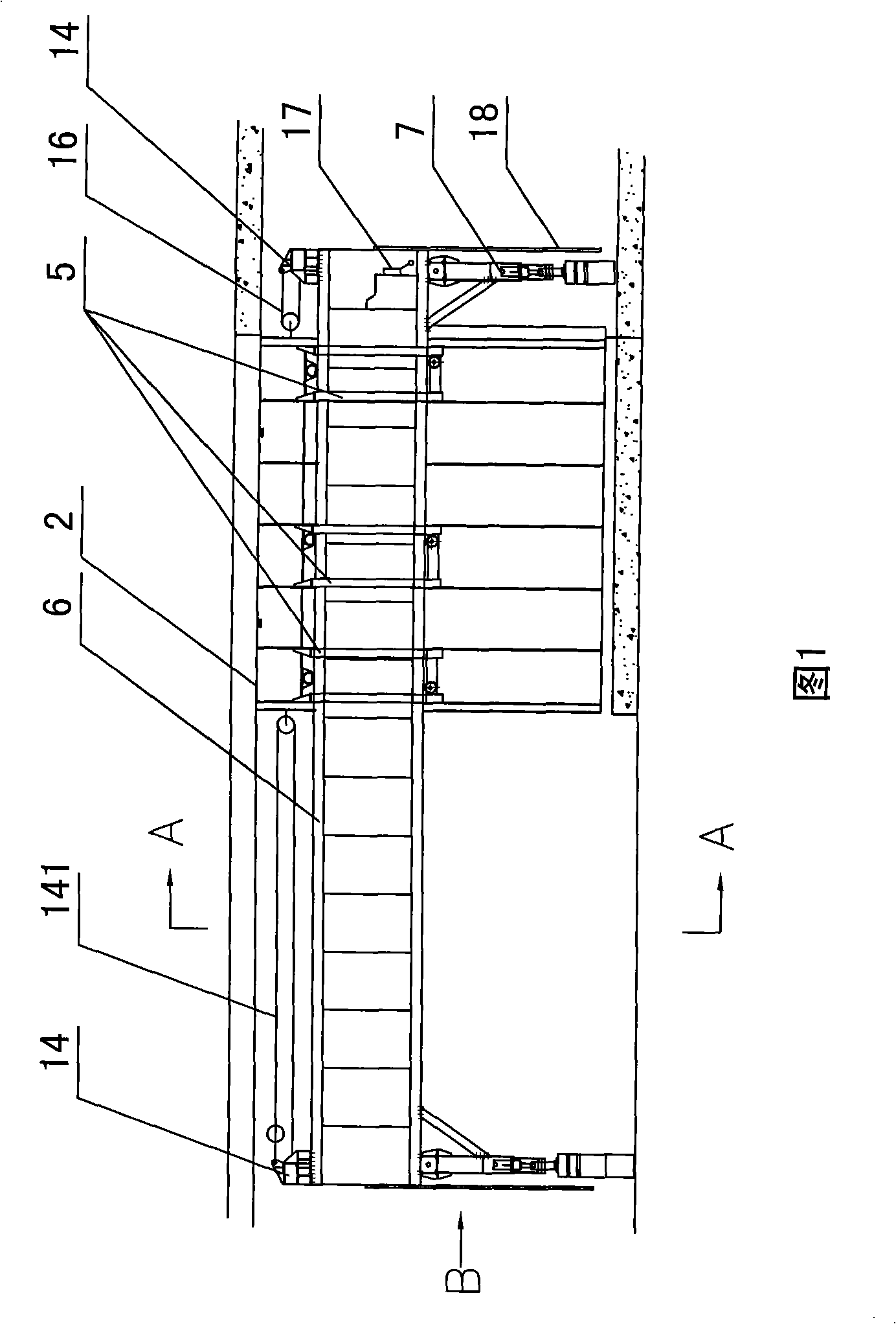

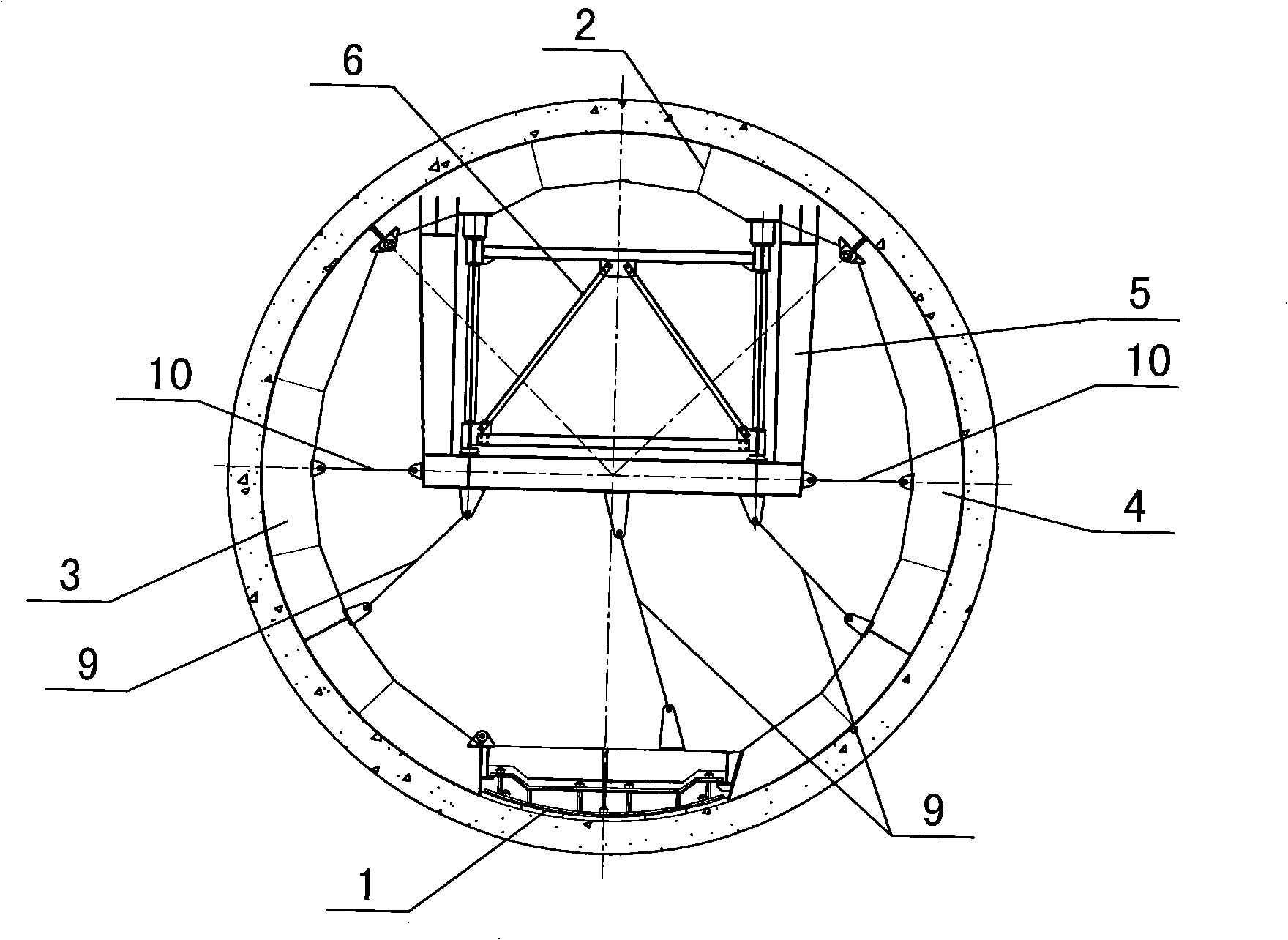

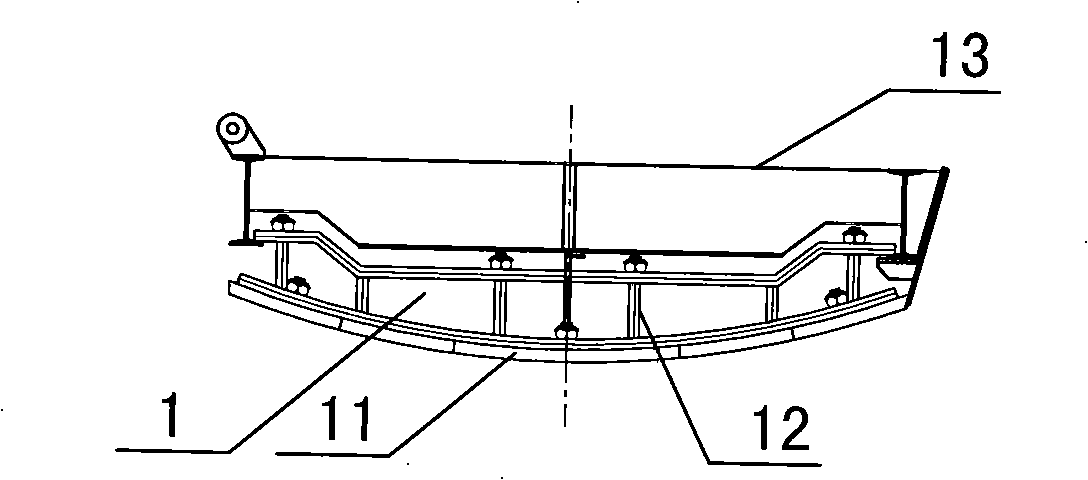

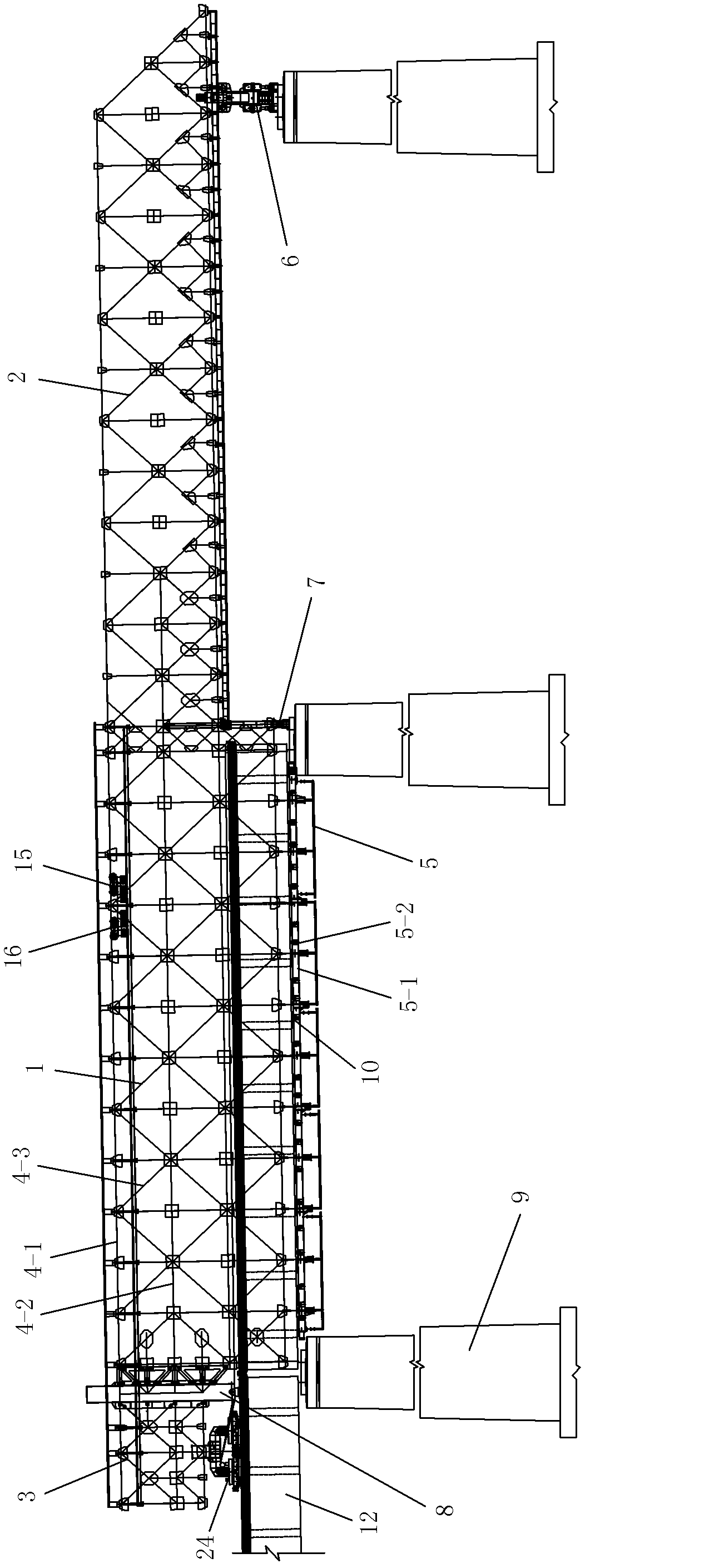

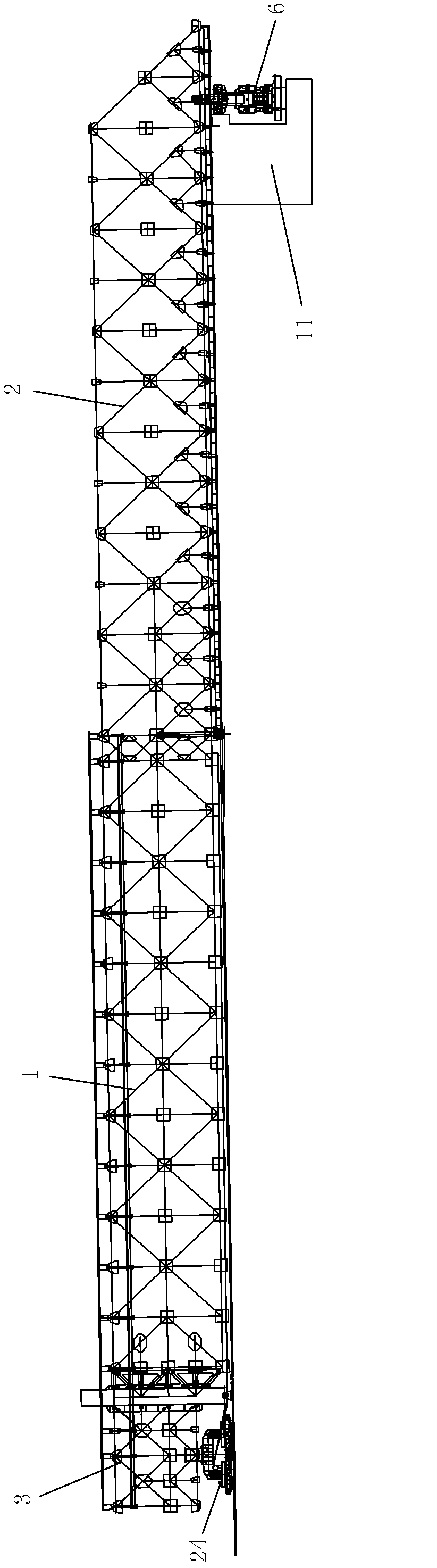

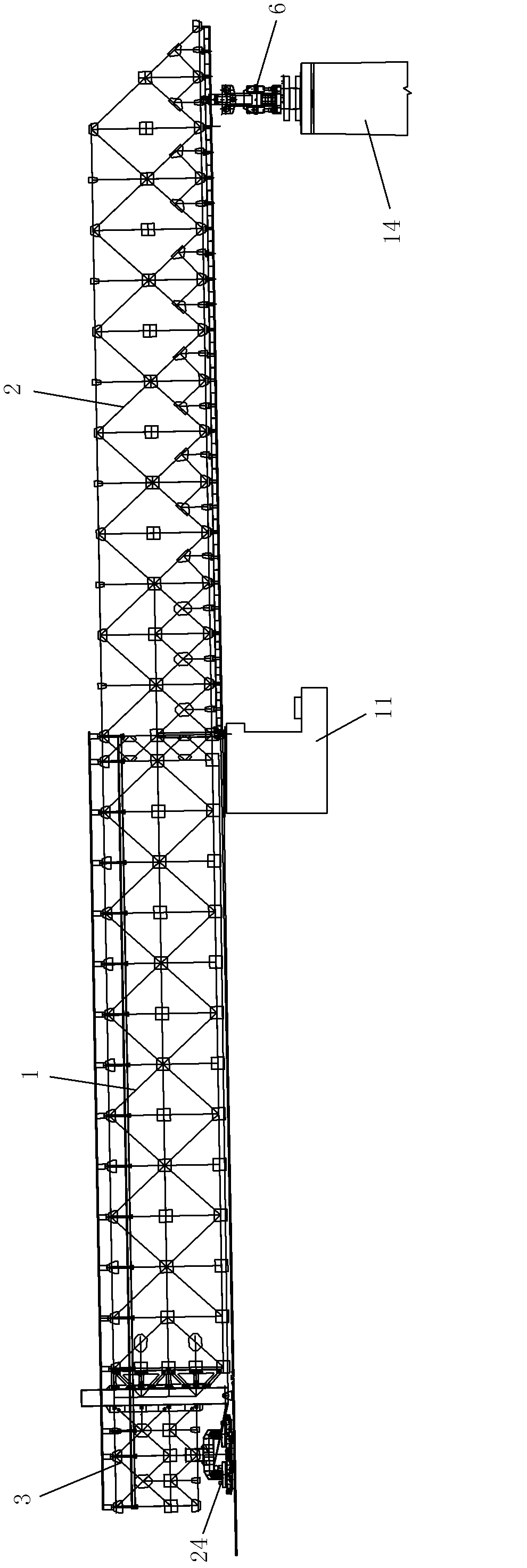

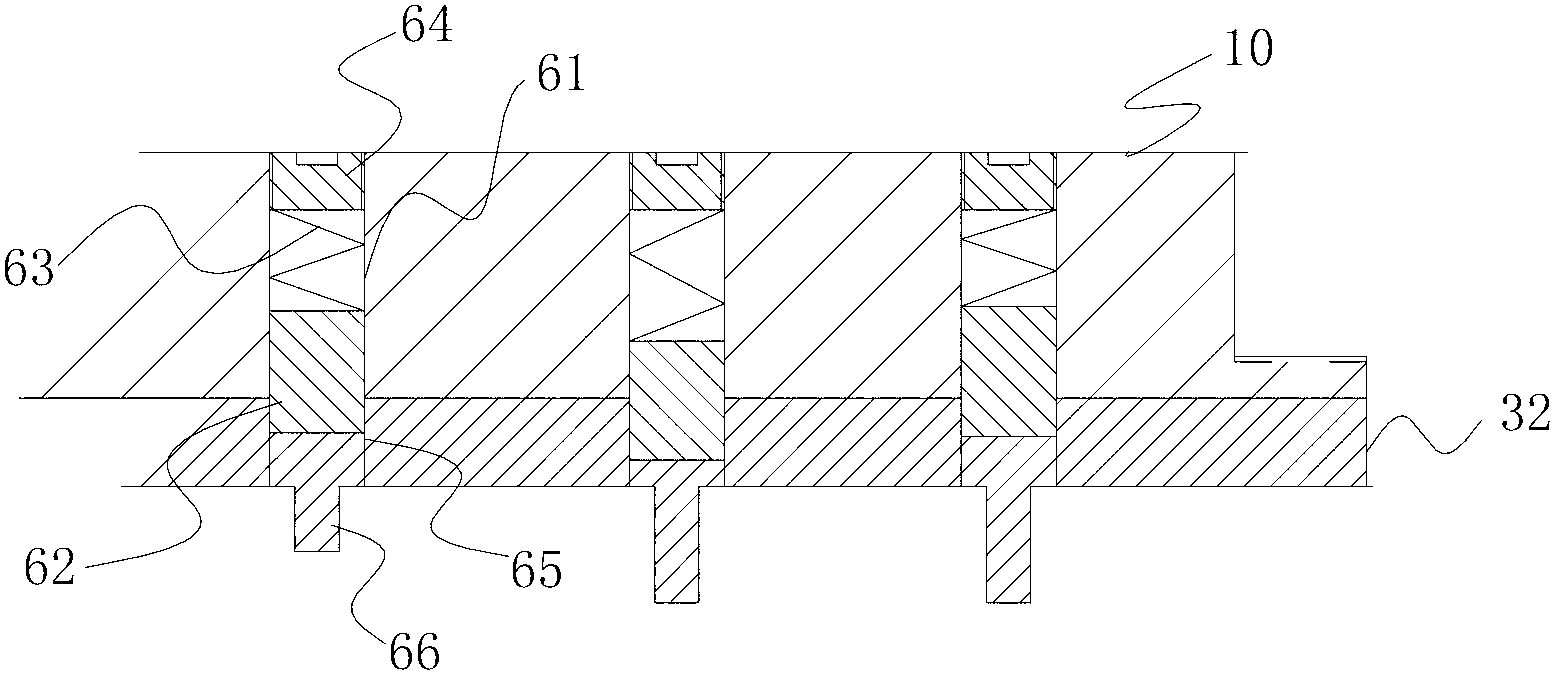

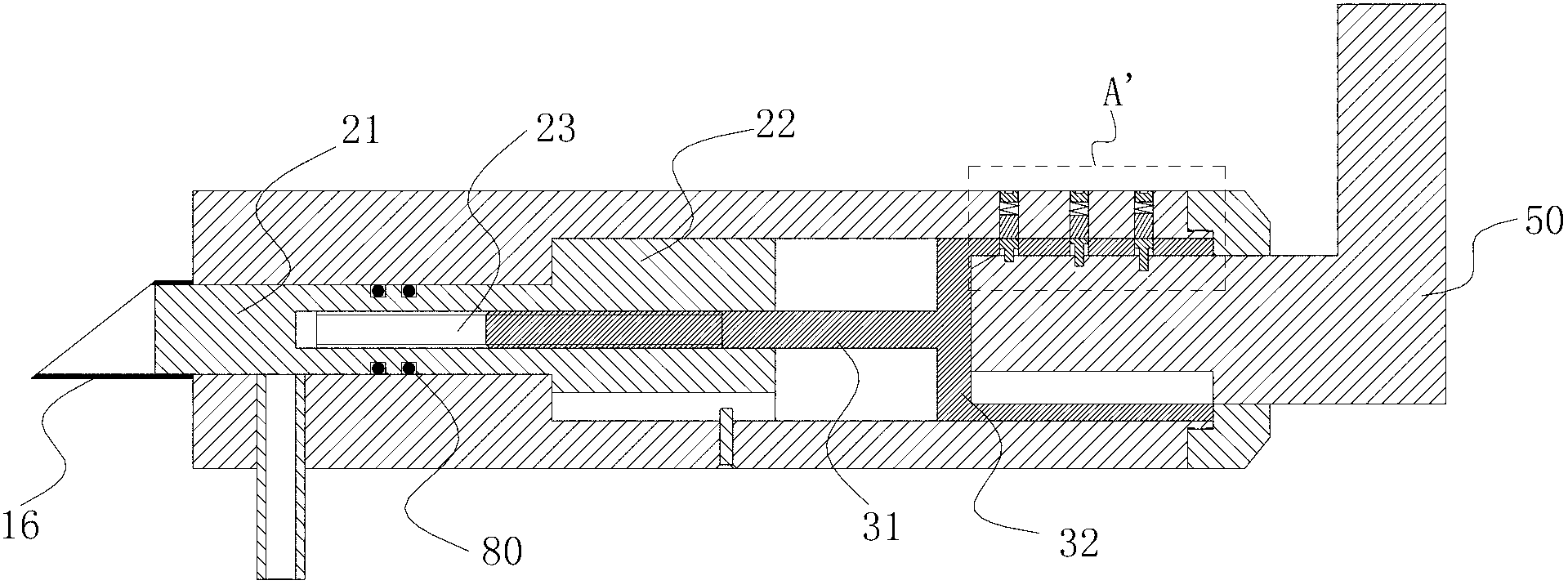

Tunnel concrete lining formwork apparatus

InactiveCN101298839AGood tunnel forming qualityImprove pouring qualityUnderground chambersTunnel liningEngineeringSliding contact

The present invention discloses a tunnel concrete lining template device comprising a template system and needle beam system for bearing; the template system comprises template assembly and template pylon; the template assembly comprises arced left die, right die, top die and bottom die; the left die, right die, top die and bottom die are correspondingly connected to form template assembly with round section; the template pylon is hung on the top die; and bottom of the template pylon is respectively installed with left die, right die and telescopic standing demoulding device connected by the bottom die; the needle beam system comprises bearing needle beam placed in the upper part of the tunnel and pre and post supporting leg device for supporting the bearing needle beam; upper end face of the bearing needle beam is in slide contact with the top die and the needle beam is placed on the template pylon; and the bottom die is in the detachable structure; the bottom die in the detachable structure is installed with opening part which is able to execute trowel-finishing on the surface of the tunnel bottom arch concrete after detaching or turning over when the concrete is initially set. The template device effectively removes the problem of foam of the traditional whole section template bottom arc foam and improves the internal appearance molding quality of the bottom arc concrete.

Owner:SINOHYDRO BUREAU 14 CO LTD

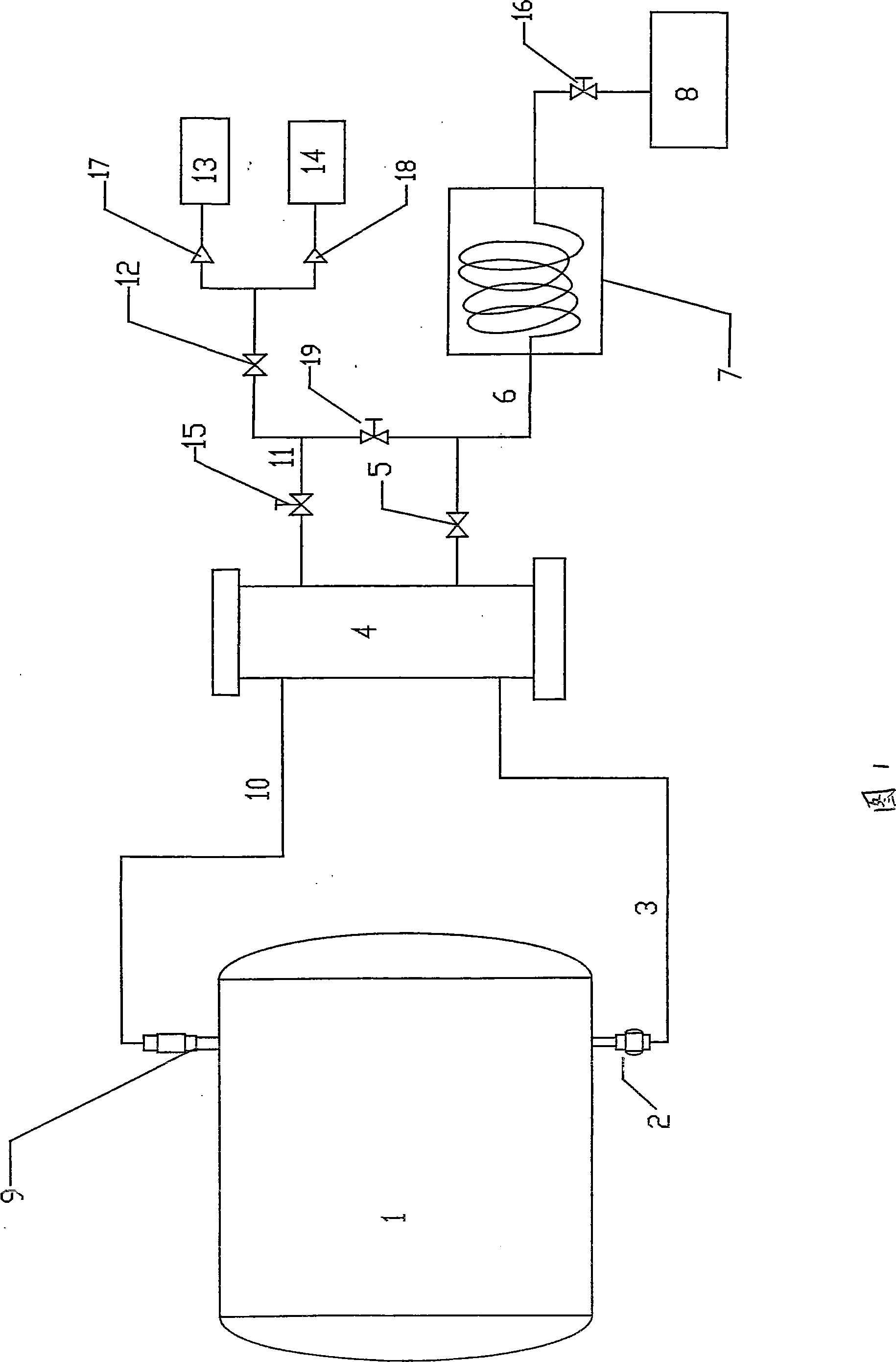

Pipe pile steam test maintenance residual heat utilization and reutilization sulfur dioxide desulfurization technology

ActiveCN101249694AEasy energyReduce loadEnergy industryCeramic shaping apparatusEconomic benefitsEnvironmental engineering

The invention discloses a sulfur dioxide desulfuration technology through utilizing and recycling the afterheat from tubular pile pressure steam maintenance, which includes the steps of conducting the high-temperature residual steam and high-temperature condensation water in a pressure steam boiler into a pressure gas tank for flash evaporation, conducting the flash-evaporated steam into a steaming pool or another pressure steam boiler to recycle the residual steam, preheating the boiler water by the recycled residual steam in the steaming pool and by the high-temperature condensation water through a heat exchange system, and conducting the preheated condensation water into the water-film de-duster of the boiler to recycle the counteraction between the sulfur dioxide in the fumes and condensation water. The technology makes reasonable use of the high-temperature condensation water and the residual steam, adopts flash evaporation technology and reasonable process, realizes high recycling rate, and after recycling the residual steam, carries out de-dusting and desulfurization of the fumes from a coal burning boiler by utilizing the high pH value of the condensation water, thus reducing environmental pollution, simplifying the equipment, lowering the cost and producing significant economic benefits and environmental protection effects.

Owner:FUJIAN DADI CONCRETE PILE

Large-section simply-supported box girder precasting and assembly process under conditions of strong wind and high altitude

InactiveCN102587282AQuality improvementGuarantee the quality of prefabricationBridge erection/assemblyAbutmentRebar

The invention discloses a large-section simply-supported box girder precasting and assembly process under the conditions of strong wind and high altitude, wherein construction simply-supported box girders are single-hole girders or porous girders, each hole girder in the simply-supported box girders is formed by assembling a plurality of box girder sections, and each hole girder is supported and fixed by two bridge abutments arranged at the bottoms of the left end and the right end of the hole girder. The process includes the following steps: 1. concentrated precasting for the box girder sections: including production and installation for frameworks of steel reinforcements, form erecting, concreting and closed girder section life preserving; 2. assembly construction for the first hole girders in the single-hole girders or the porous girders: including girder section transfer, linear adjustment and girder section assembly; 3. construction for the next hole girders; and 4. repetition ofthe step 3 for multiple times till all construction processes of the construction simply-supported box girders are completed. The process is reasonable in design, simple in the steps, convenient in implementation and good in construction effect, the construction shaped simply-supported box girders are high in quality, and therefore, the process is especially suitable for large-section simply-supported box girder precasting and section assembly construction under the conditions of strong wind and high altitude.

Owner:中铁二十局集团第二工程有限公司

Preparation method of photoinitiator TPO

InactiveCN103880882AReduce usageNo emissionsGroup 5/15 element organic compoundsBenzoyl chlorideAniline

The invention provides a preparation method of a photoinitiator TPO, comprises the following formula: 22.5% of diethyl aniline, 7.5% of absolute methanol, 34% of chlorodiphenylphosphine, and 36% of 2,4,6-trimethyl benzoyl chloride. The method comprises the following steps: 1, stirring and uniformly mixing diethyl aniline and absolute methanol; 2, warming to 20 DEG.C, slowly dropping chlorodiphenylphosphine, preserving heat for 2 hours; 3, pumping out the material, and filtering for later use; 4, uniformly mixing the 2,4,6-trimethyl benzoyl chloride; 5, warming to 80 DEG.C, slowly dropping the material for later use in the step 3, and then preserving for 1 hour; 6, carrying out suction filtering by using a suction filtering groove to obtain the photoinitiator TPO. The process is simple, the flammable and combustible solvent such as methylbenzene is unnecessary to use in the reaction process, the preparation method is safe, reliable and in favor of energy-saving and environment-protecting.

Owner:XIANGYANG KEMIN CHEM TECH CO LTD

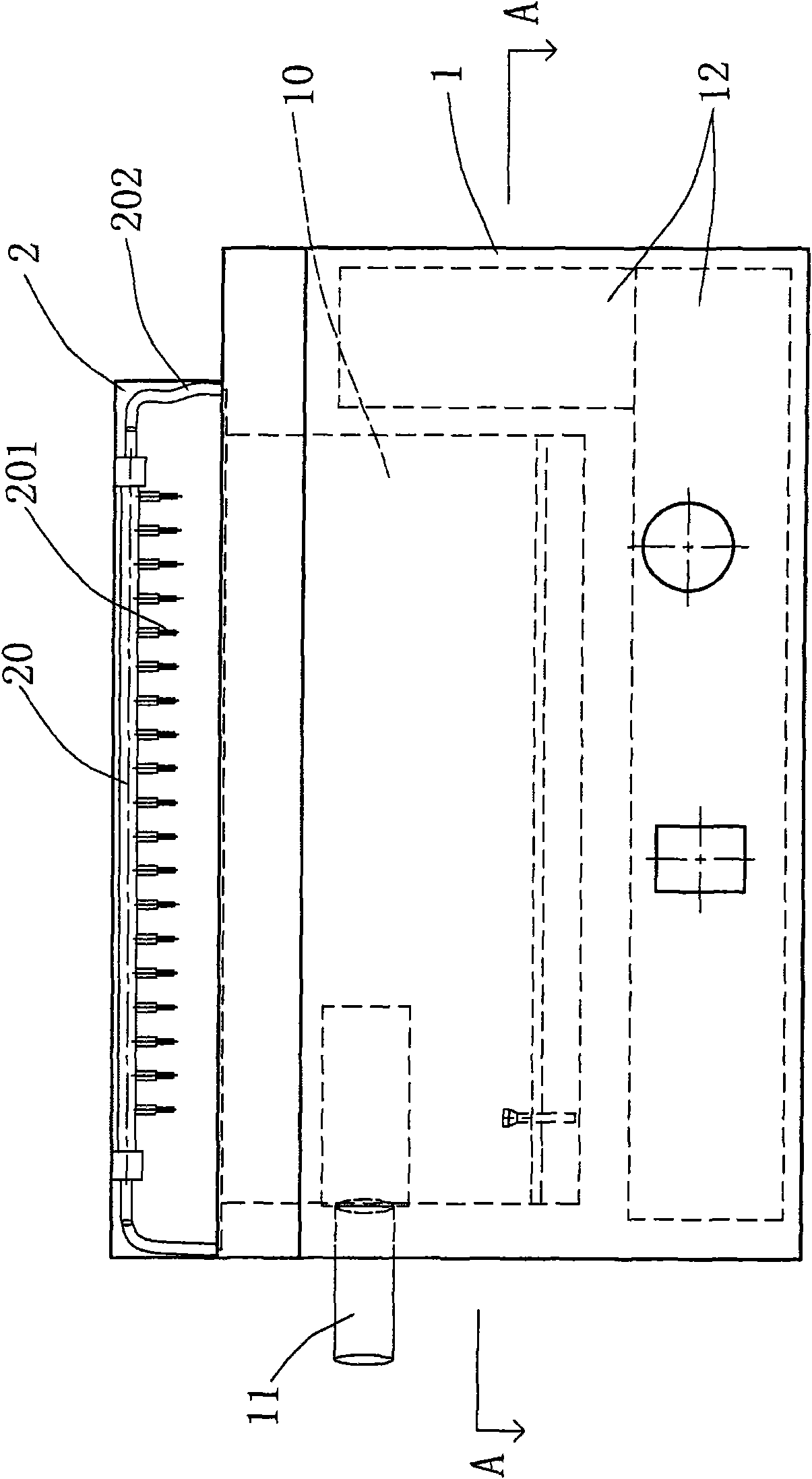

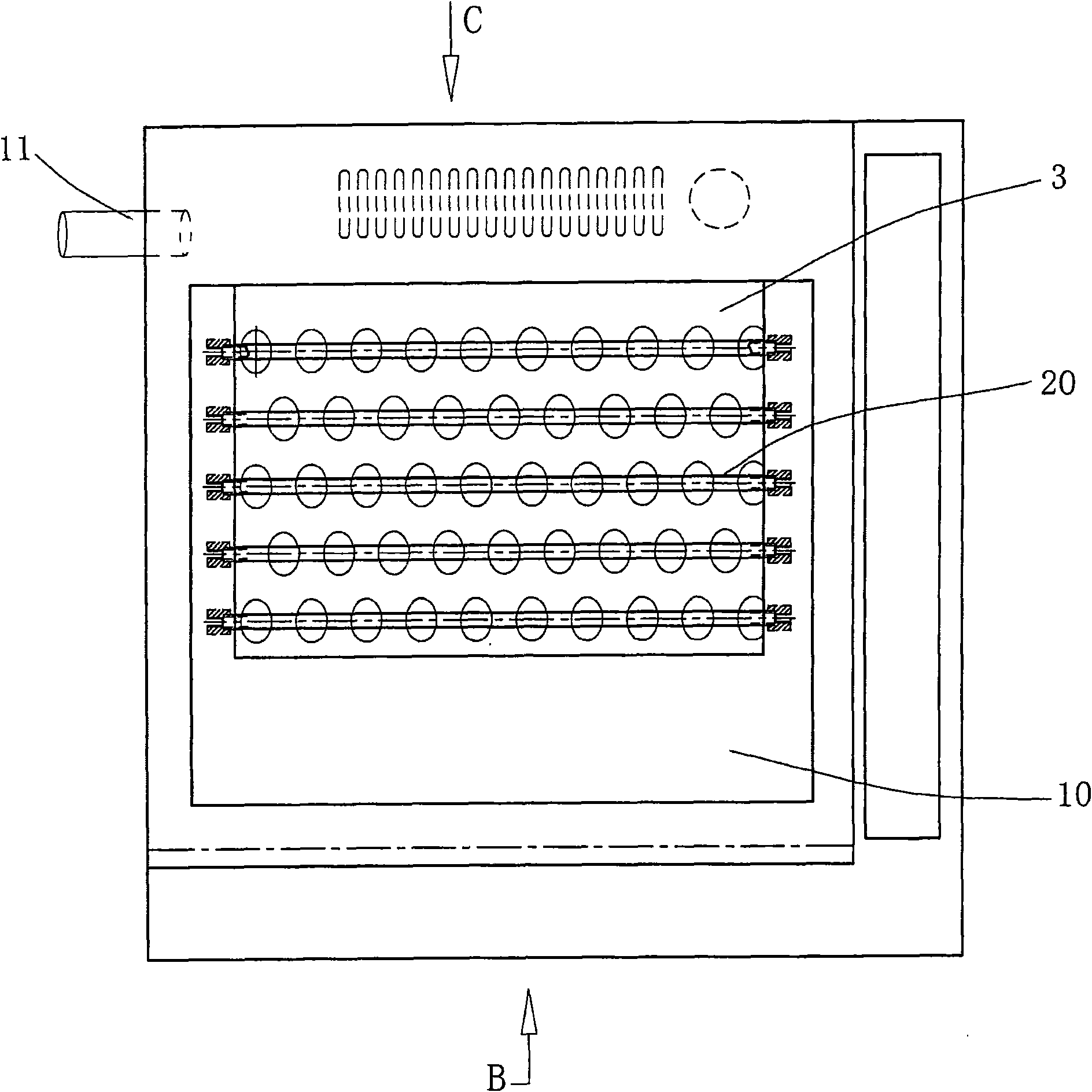

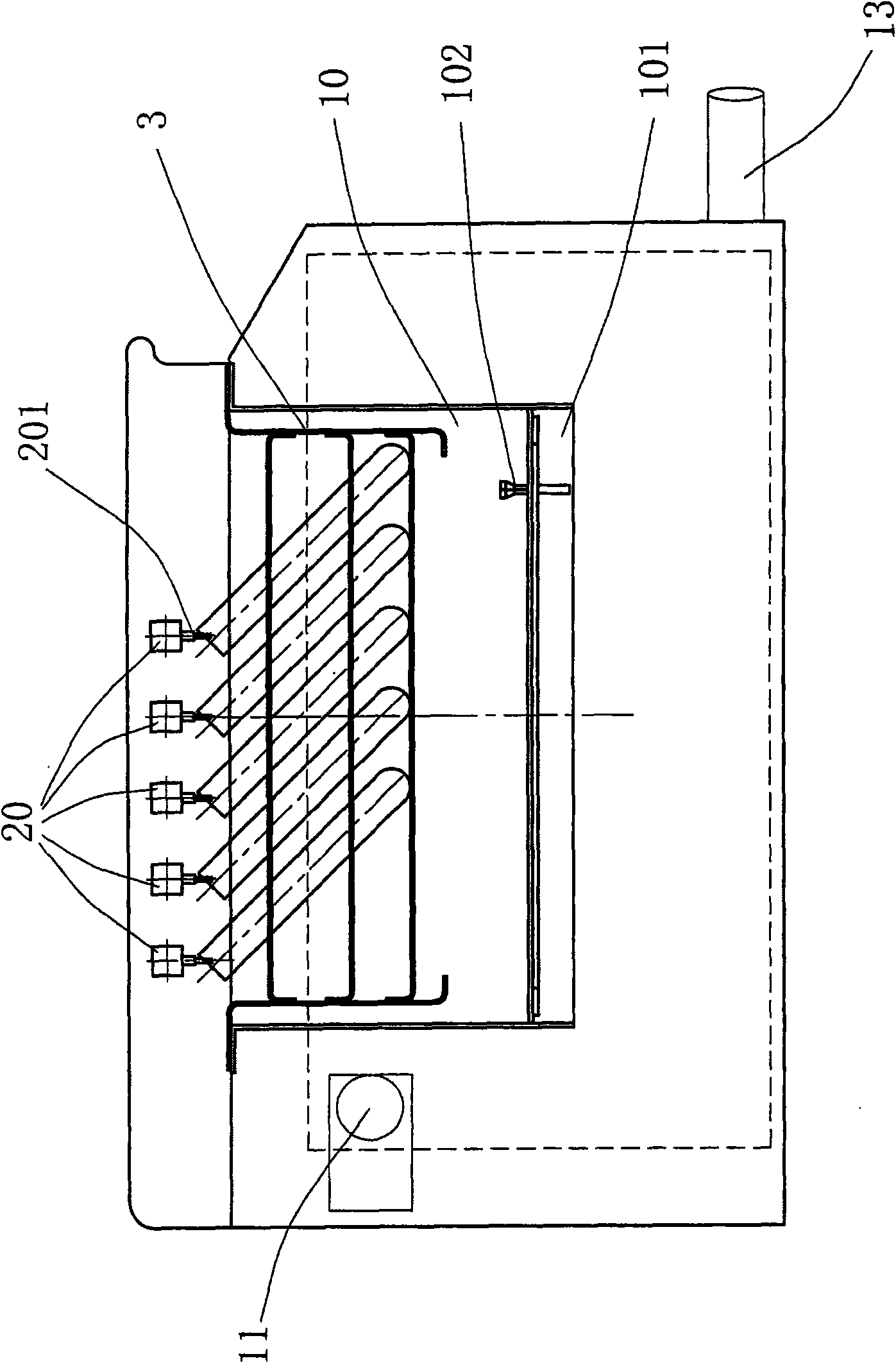

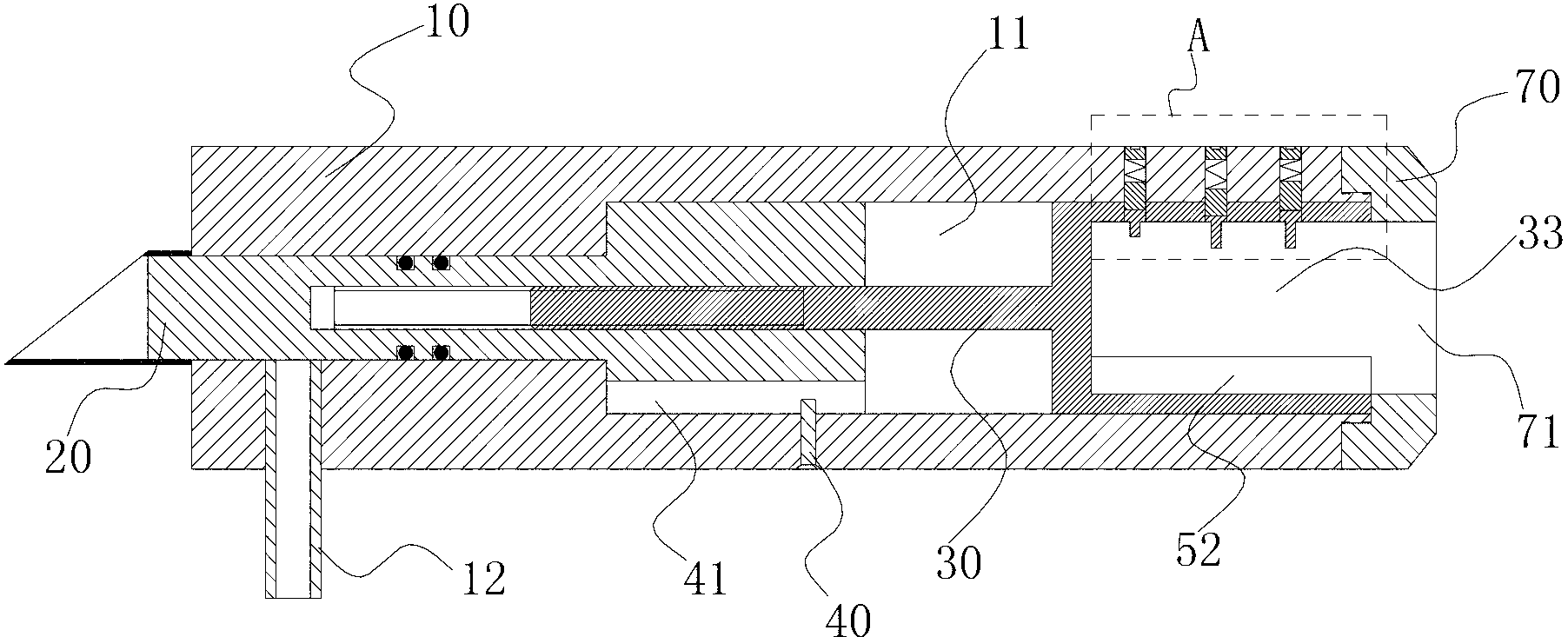

Container tilting concentrator

InactiveCN101988878AIncrease contact areaComplete efficientlyPreparing sample for investigationLaboratory glasswaresWater bathsEvaporation

The invention relates to a container tilting concentrator, which is provided with a sealed container, wherein the sealed container comprises a shell and a cover body which can be sealed and covered on the shell; an evaporating cabin is arranged in the shell, and a container-placing rack is arranged in the evaporating cabin; an air exhaust port is arranged on the shell, and multirow blowpipes are arranged on the cover body. The container tilting concentrator is characterized in that the container can be arranged on the placing rack in a tilting mode, a plurality of nozzles are arranged on each blowpipe, and each nozzle corresponds to the opening of the container, is vertically close to the side wall of the container and extends into the container. By using the concentrator of the invention, the liquid reagent evaporation and concentration efficiency can be effectively improved, the emission amount of harmful gases and environmental pollution are reduced, the operation safety for the operation personnel is guaranteed, and incorrect operation can be prevented through an inductive sensor under the condition of water bath heating.

Owner:BEIJING POLYTECH INSTR

Water soluable paint

A water-soluble paint is of low toxicity, non-inflammable, and non-explosive. It can be used for the metal flexible material. Its composition: acrylate 15-20%, melamine resin 6-9%, polyatomic alcohol polymer 5-10%, whiting 25-35%, ammonia liquor 3-7%, the rest is water. It also can be added into 0-5% leveling agent and 0.2-1.8% drier.

Owner:高国洁

Key needle tube type anti-theft anti-freezing sampling valve

InactiveCN103266866AAvoid stockpilingPrevent oil from freezingWell/borehole valve arrangementsSealing/packingReciprocating motionEnvironmental engineering

The invention discloses a key needle tube type anti-theft anti-freezing sampling valve, and relates to an anti-theft anti-freezing sampling valve used for the mouth of an oil-water well in the oil extraction field. The key needle tube type anti-theft anti-freezing sampling valve comprises a valve body, a valve core, a driving mechanism and an anti-theft mechanism; the valve core is contained in an inner cavity of the valve body in form of capable of moving along the axial direction; one port of the inner cavity is used as an oil inlet and the other port is provided with a gland; a sampling channel interconnected with the inner cavity is arranged on the valve body; the valve core, under the drive of the driving mechanism, controls the opening and closing of the sampling channel by the reciprocating motion; the end of the valve core facing the oil inlet can extends out of the oil inlet. By adopting the key needle tube type anti-theft anti-freezing sampling valve, the blind section in front of the valve in the prior art is eliminated, and therefore, the crude oil is prevented from being accumulated and stored in the valve body, the stored oil is prevented from freezing, meanwhile, the exhausting is not required, in this way, the labor intensity of the operators in the filed is reduced, the environmental protection is helped, the sampling veracity is ensured, and further, the accidents of crude oil leakage and environment pollution caused by the fact that the sampling valve is opened by an irrelevant person are effectively prevented.

Owner:PETROCHINA CO LTD

Method for preparing light absorption layer for CuInGaSe thin film solar cell

InactiveCN101771100AImprove performanceFulfil requirementsFinal product manufactureSemiconductor devicesToxic gasVulcanization

The invention relates to a method for preparing a light absorption layer for a CuInGaSe thin film solar cell. A Cu, In and Ga precast layer is sputtered on an Mo-plated substrate by adopting a vacuum magnetron sputtering method of the known technology. The method is characterized by comprising the preparation processes of packing, heating and cooling so as to prepare the absorption layer for the CuInCaSe thin film solar cell. Because of the adoption of a closed vacuum selenylation or vulcanization method, the solid selenium source or sulfur source is thoroughly, fully and uniformly selenylated or vulcanized; and the precast layer is transformed into the CuInGaSe or CuInGaS light absorption layer so as to effectively improve the thin film performance of the absorption layer, meet the requirement of the thin film solar cell, avoid using toxic gas such as H2Se or H2S and the like and facilitate environmental protection. The photoelectric conversion efficiency of the thin film solar cell prepared by adopting the absorption layer can reach 10.5 percent; and the equipment is simple, the consumption of reaction substances is low and the method is suitable for industrialized production.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST

Mould-proof and germproof water-soluble environmental-friendly nano activated carbon wall paint and preparation method thereof

InactiveCN103242726AConducive to environmental requirementsGood anti-mold and anti-bacterial effectAntifouling/underwater paintsPaints with biocidesCitrate sodiumActivated carbon

The invention discloses mould-proof and germproof water-soluble environmental-friendly nano activated carbon wall paint, which consists of the following ingredients in parts by mass according to the partial formula of raw materials: 20 parts of deionized water, 15 parts of water-soluble acrylic resin, 12 parts of sodium citrate, 8 parts of zinc oxide, 10 parts of zinc sulfate, 15 parts of nano activated carbon, 0.7 parts of talc powder and 0.3 parts of PH modifier; the wall paint also comprises an auxiliary material part consisting of dispersing agent, lubricating agent, biological preservative, mildew preventive and germicide, the auxiliary material part totally comprises 25 parts, wherein the volume rate of the mildew preventive to the germicide is 1:1, and the volume of the mildew preventive and the germicide are respectively 10% of the total volume of the auxiliary material; and the TVOC value of the mould-proof and germproof water-soluble environmental-friendly nano activated carbon wall paint is 0g / l, and the formaldehyde emission is 0g / l. The wall paint is non-toxic and tasteless, does not contain the general poisonous chemical organic solvent, is not added with poisonous wall paint preservative, meets the environmental protection requirement and can achieve good mould-proof and germproof effects.

Owner:HUNAN HUIBO CHEM TECH

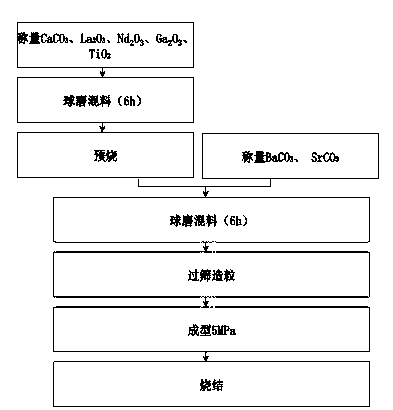

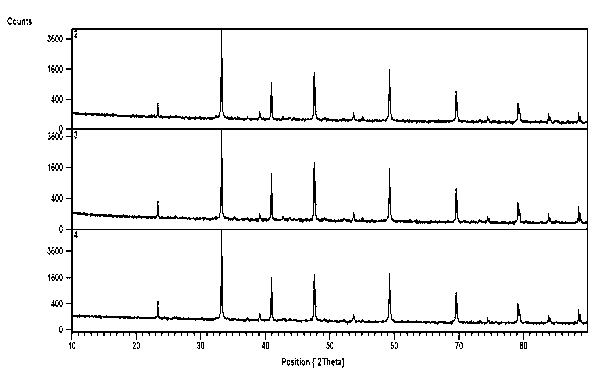

Microwave dielectric ceramics and preparation method thereof

The invention discloses a high-performance microwave dielectric ceramics and a preparation method thereof. The principal crystalline phase is (1-x)CaTiO3-x(LayNd(1-y))GaO3, CaCO3, TiO2, La2O3, Ga2O3 and Nd2O3 are taken as raw materials, and the modified doping agent comprises BaCO3 and SrCO3. The (1-x)CaTiO3-x(LayNd(1-y))GaO3 microwave dielectric ceramics is prepared according to the traditional solid-phase reaction method. The provided microwave dielectric ceramic material has excellent microwave dielectric performance, the relative dielectric constant epsilon r is adjustable between 40 and 45, Q*f is 40000-45000GHz, the resonant frequency temperature coefficient can be continuously adjusted, and the microwave dielectric ceramics can be widely applied to preparing dielectric resonators, filters, duplexers and other microwave devices in the modern communication base station.

Owner:WUHAN HONGXIN TELECOMM TECH CO LTD

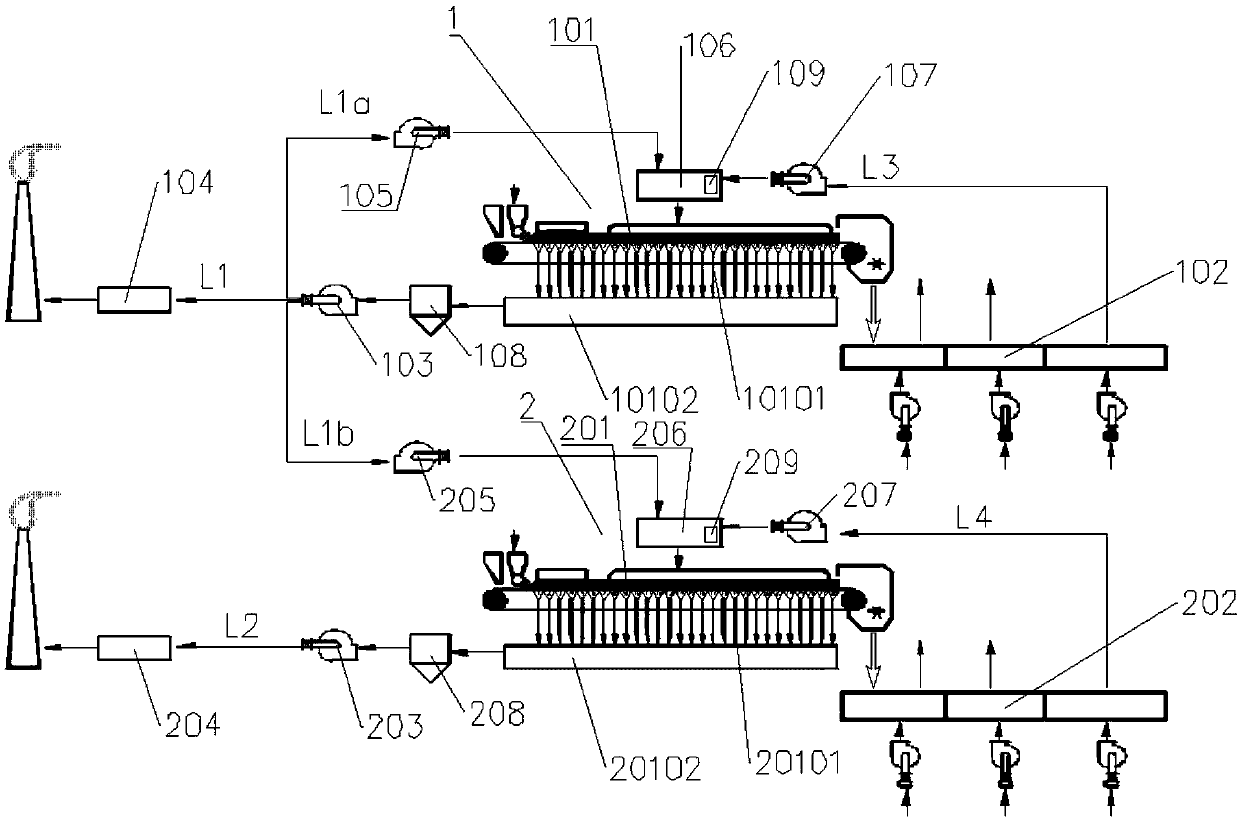

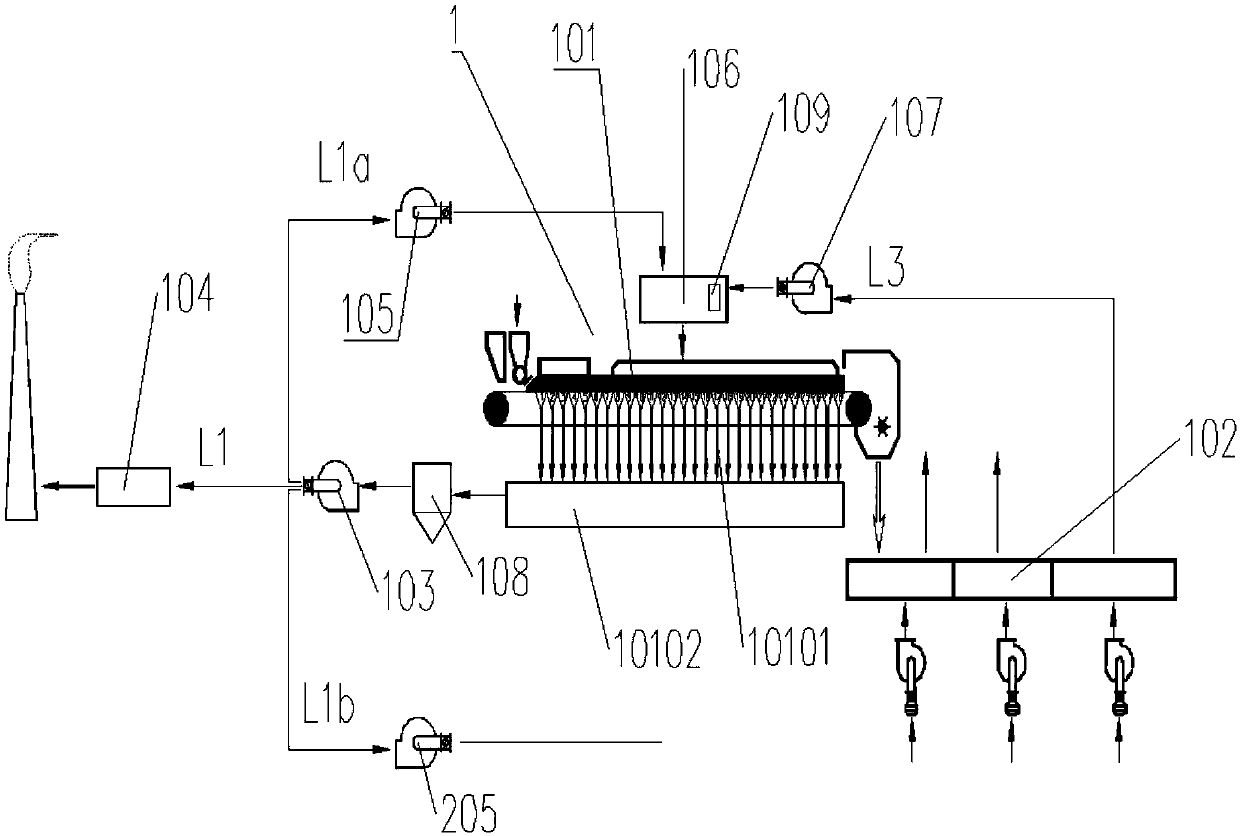

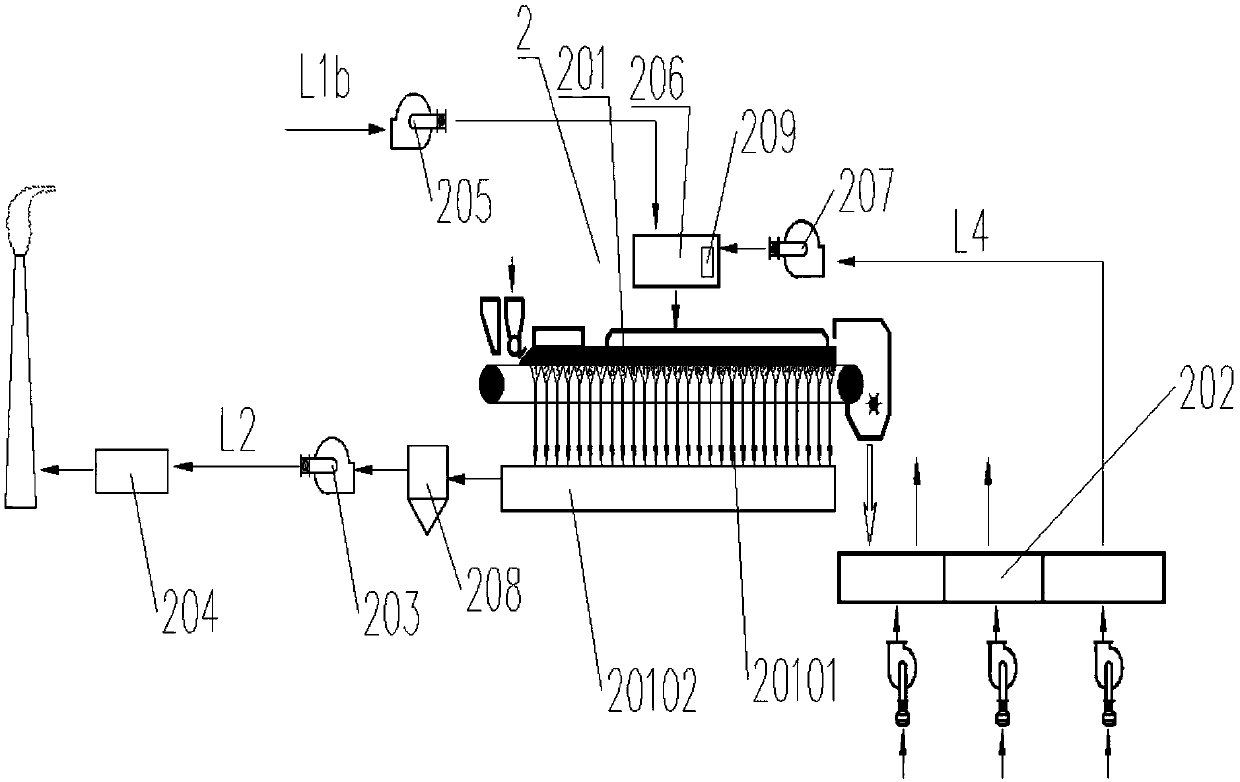

Flue gas comprehensive cyclic treatment method and treatment device for two series of sintering systems

ActiveCN109569183AEasy to transformGood desulfurization and denitrification effectGas treatmentLighting and heating apparatusActivated carbonFlue gas

A flue gas comprehensive cyclic treatment method for two series of sintering systems includes steps: 1) sintering, to be more specific, sintering raw materials in sintering machineS to generate sintering gas; 2) cooling, namely cooling the sintered raw materials in circular cooling machineS; 3) flue gas treatment, to be more specific, after the sintering gas passes through dedusting deviceS, entering a desulfurization and denitrification system to realize treatment, wherein a sintering system A is an activated carbon desulfurization and denitrification system, a system B is a wet desulfurization and denitrification system, and sintering flue gas of the sintering system A is fed into the sintering machine of the sintering system A and the sintering machine of the sintering system B throughtwo cyclic gas branch pipes respectively. In the dry desulfurization and denitrification system, the sulfide concentration is increased while the nitride concentration is reduced, and dry desulfurization and denitrification can be benefited; in the wet desulfurization and denitrification system, the sulfide concentration and the nitride concentration are reduced, and wet desulfurization and denitrification can be benefited. Therefore, energy consumption in industrial production is reduced, and production cost is saved.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

Anti-mosquito water-soluble environmental-friendly nanometer activated carbon wall paint and preparation method thereof

InactiveCN103242729AConducive to environmental requirementsAntifouling/underwater paintsPaints with biocidesAcrylic resinKaolin clay

The invention discloses anti-mosquito water-soluble environmental-friendly nanometer activated carbon wall paint, which is characterized in that the wall paint consists of the following ingredients in parts by mass according to the formula of a raw material part: 20 parts of deionized water, 15 parts of water-soluble acrylic resin, 12 parts of sodium citrate, 8 parts of zinc oxide, 10 parts of zinc sulfate, 15 parts of nanometer activated carbon, 5 parts of anti-mosquito essential oil, 0.3 parts of propylene glycol, 0.3 parts of kaolin and 0.4 parts of talcum powder; the wall paint also comprises an auxiliary material part consisting of dispersing agent, lubricating agent and biological preservative, and the auxiliary material part comprises 20 parts in total; and the TVOC(total volatile organic compound) value of the anti-mosquito water-soluble environmental-friendly nanometer activated carbon wall paint is 0g / l, and the formaldehyde emission is 0g / l. According to the wall paint, the anti-mosquito water-soluble environmental-friendly nanometer activated carbon wall paint is non-toxic and tasteless, does not contain the general poisonous chemical organic solvent, is not added with poisonous wall paint preservative and meets the environment protection requirement.

Owner:HUNAN HUIBO CHEM TECH

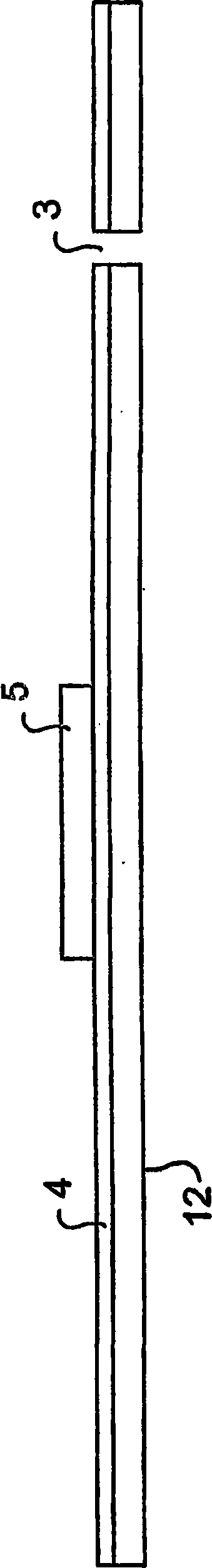

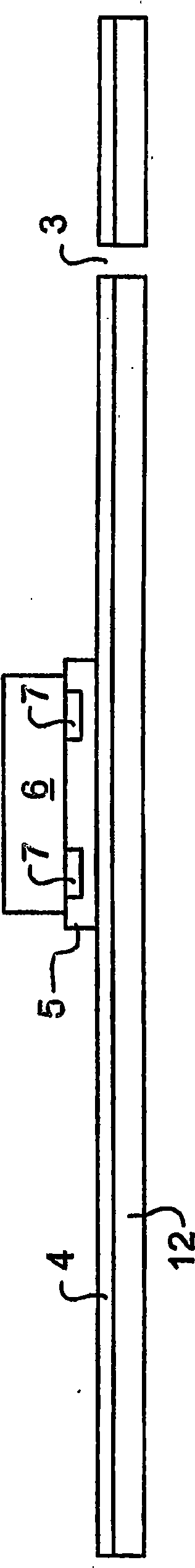

Method for manufacturing an electronic module and an electronic module

ActiveCN101546759ASimple and economical method of manufactureImprove featuresSemiconductor/solid-state device detailsSolid-state devicesContact zoneElectrical contacts

This application discloses an electronic module and a method for manufacturing an electronic module, in which a component (6) is glued (5) to the surface of a conductive layer, from which conductive layer conductive patterns (14) are later formed. After gluing the component (6), an insulating-material layer (1), which surrounds the component (6) attached to the conductive layer, is formed on, or attached to the surface of the conductive layer. After the gluing of the component (6), feed-throughs are also made, through which electrical contacts can be made between the conductive layer and the contact zones (7) of the component. After this, conductive patterns (14) are made from the conductive layer, to the surface of which the component (6) is glued.

Owner:IMBERATEK LLC

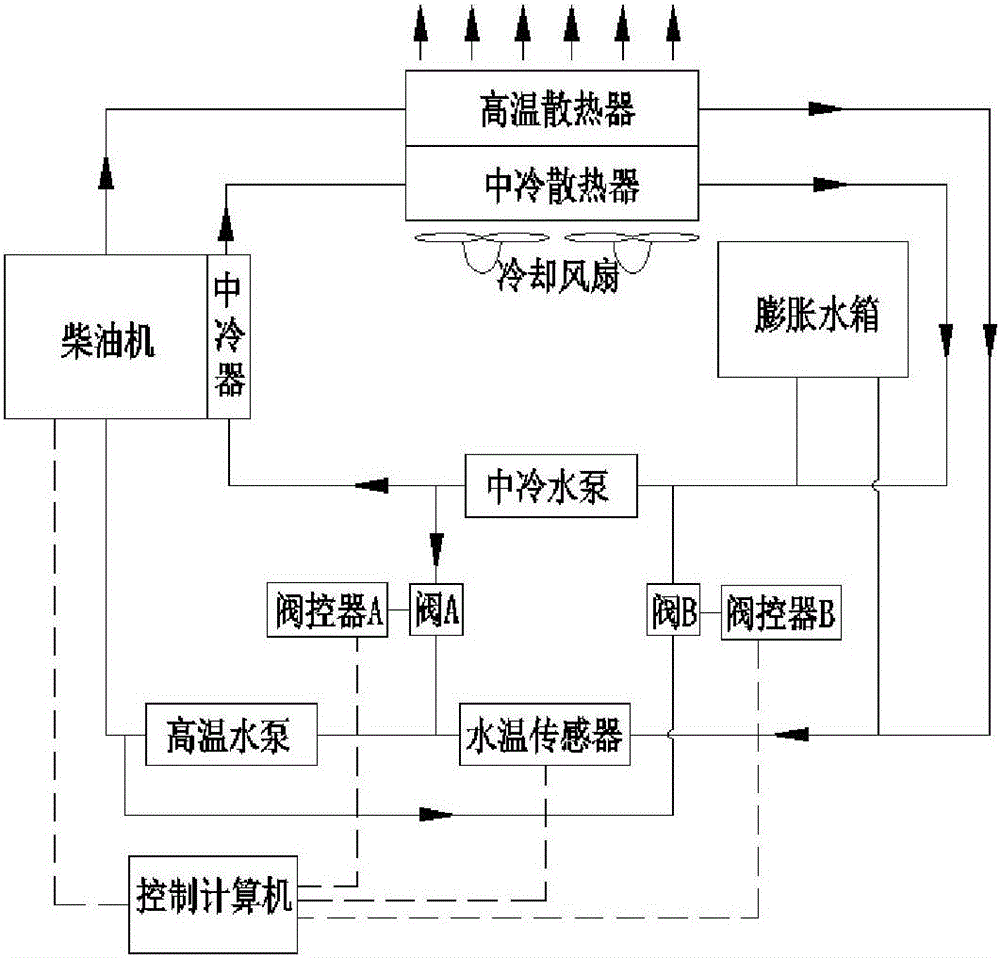

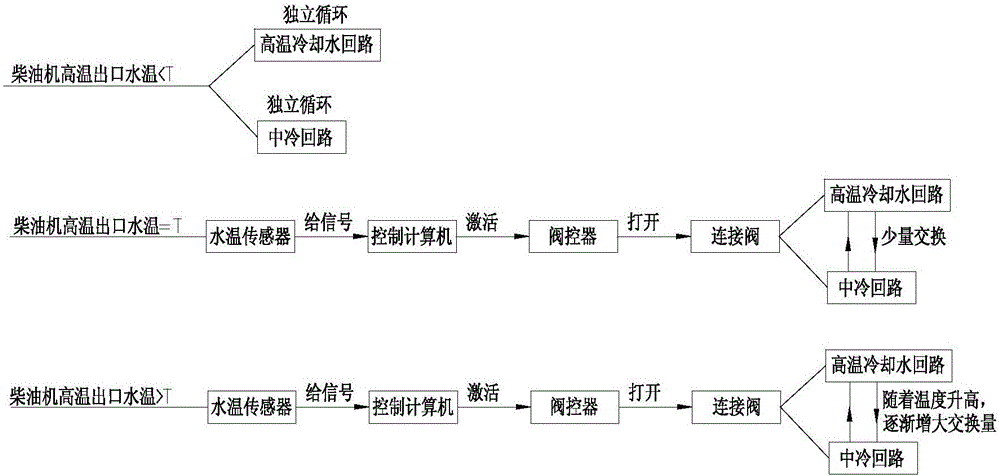

Separation type intercooling control method of cooling water system of diesel locomotive engine

InactiveCN106150658AConducive to environmental requirementsImprove performanceCoolant flow controlInternal combustion piston enginesDiesel locomotiveControl signal

The invention discloses a separation type intercooling control method of a cooling water system of a diesel locomotive engine. The separation type intercooling control method comprises two cooling water loops, namely a high-temperature cooling water loop and an intercooling water loop; the high-temperature cooling water loop comprises a high-temperature water pump, a diesel engine and a high-temperature heat radiator; the intercooling water loop comprises an intercooling water pump, an intercooling device and an intercooling heat radiator; the high-temperature cooling water loop and the intercooling water loop are connected through a valve A and a valve B; two ends of the valve A are connected with an outlet of the intercooling water pump and an inlet of the high-temperature water pump respectively; two ends of the valve B are connected with an outlet of the high-temperature water pump and an inlet of the intercooling water pump respectively; the valve A is controlled by a valve controller A and the valve B is controlled by a valve controller B; a control computer outputs a control signal to the valve controller A and the valve controller B; a temperature sensor is used for detecting a high-temperature outlet water temperature T of the diesel engine and transmitting a detected signal to the control computer; the separation type intercooling control method has an active effect on improvement of performances of the diesel engine and emission reduction.

Owner:CRRC DALIAN CO LTD

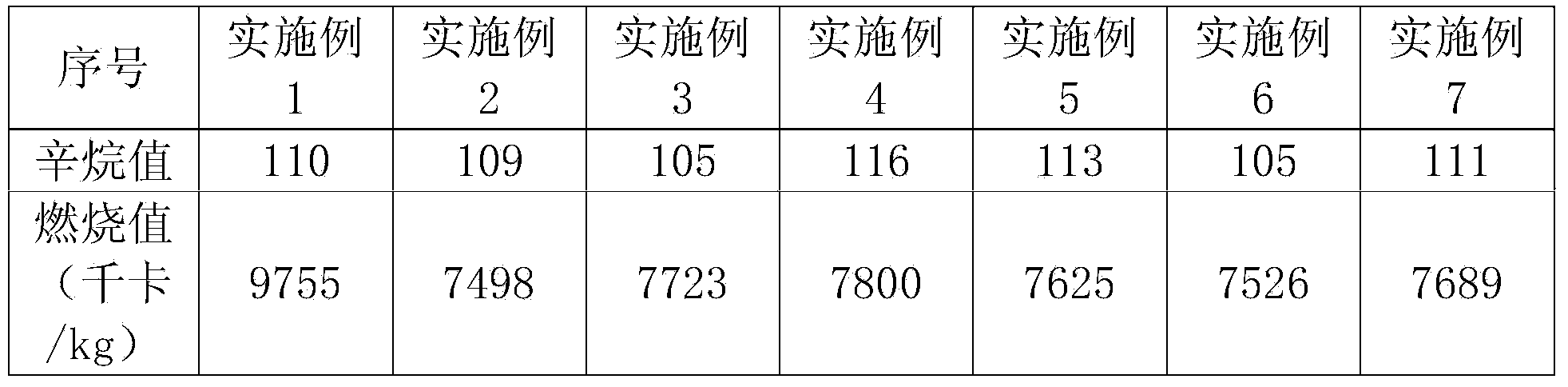

Alcohol ether petrol for vehicles

InactiveCN104263427ANo modification requiredEasy to useLiquid carbonaceous fuelsEthyl acetateMethyl benzoate

The invention discloses alcohol ether petrol for vehicles, and relates to the field of fuel. The alcohol ether petrol is prepared from the following components in parts by weight: 20-40 parts of petrol, 20-30 parts of methanol, 10-20 parts of ethyl alcohol, 10-25 parts of hydrocarbon, 1-7 parts of ethyl acetate, 2-8 parts of methyl benzoate, 3-10 parts of acetone, 5-15 parts of methyl tert-butyl ether, 1-8 parts of isopropyl ether, 1-5 parts of polytetrafluoroethylene, and 2-6 parts of isopropyl alcohol. Through the adoption of the alcohol ether petrol disclosed by the invention, the problems that the compounding ratio of ether alcohol is too low, cold booting is difficult, oil saving is inapparent and the like existing in the prior art can be solved, the tail gas emission is greatly reduced, the alcohol ether petrol is clean and environment-friendly, and the combustion performance and the safety performance of the fuel are improved.

Owner:东奇能源技术有限公司

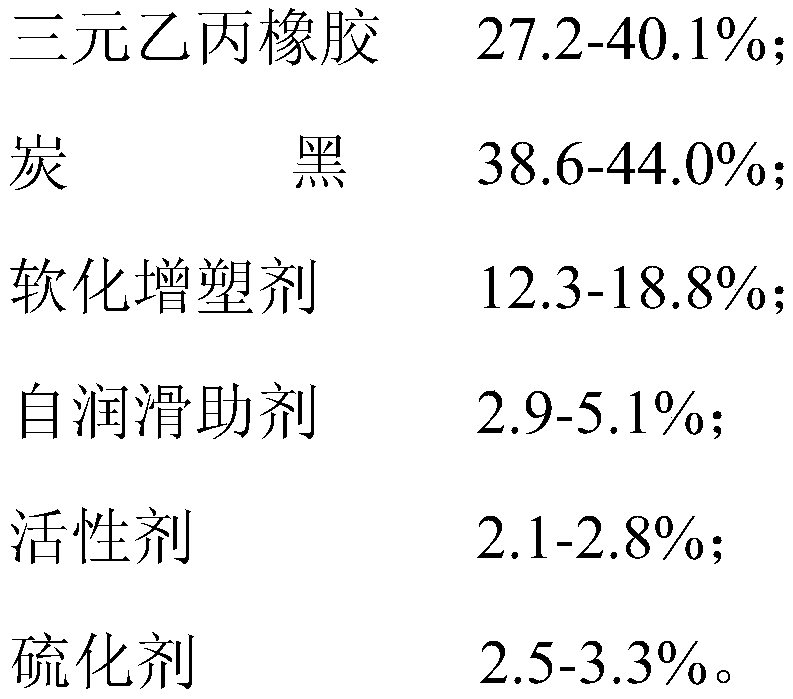

Environmentally-friendly self-lubricating wiring harness sheath EPDM and preparation method thereof

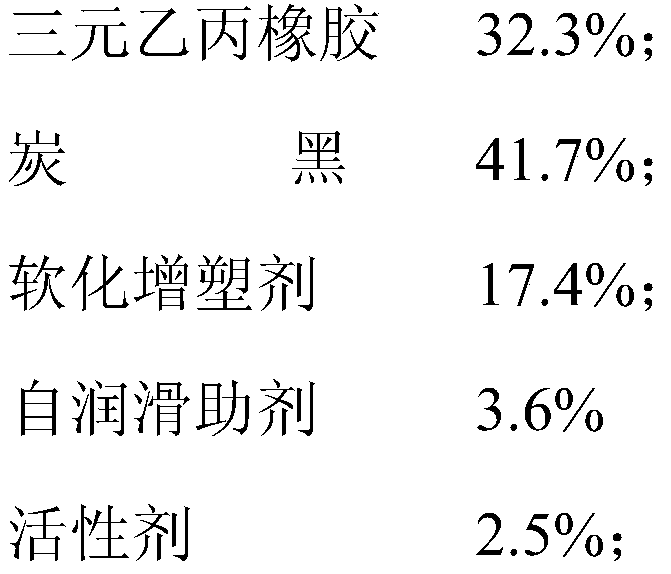

InactiveCN110591237AGood physical and mechanical propertiesMeet the performancePolymer scienceActive agent

The invention discloses environmentally-friendly self-lubricating wiring harness sheath EPDM, which comprises, by weight, 27.2-40.1% of ethylene propylene diene monomer rubber, 38.6-44.0% of carbon black, 12.3-18.8% of a softening plasticizer, 2.1-2.8% of an active agent, 2.9-5.1% of a self-lubricating auxiliary agent, and 2.5-3.3% of a vulcanizing agent. According to the present invention, the environmentally-friendly self-lubricating wiring harness sheath EPDM is an environmentally-friendly wiring harness sheath EPDM rubber material with excellent physical and mechanical properties and extremely low friction coefficient.

Owner:TAICANG GUANLIAN POLYMERIC MATERIAL

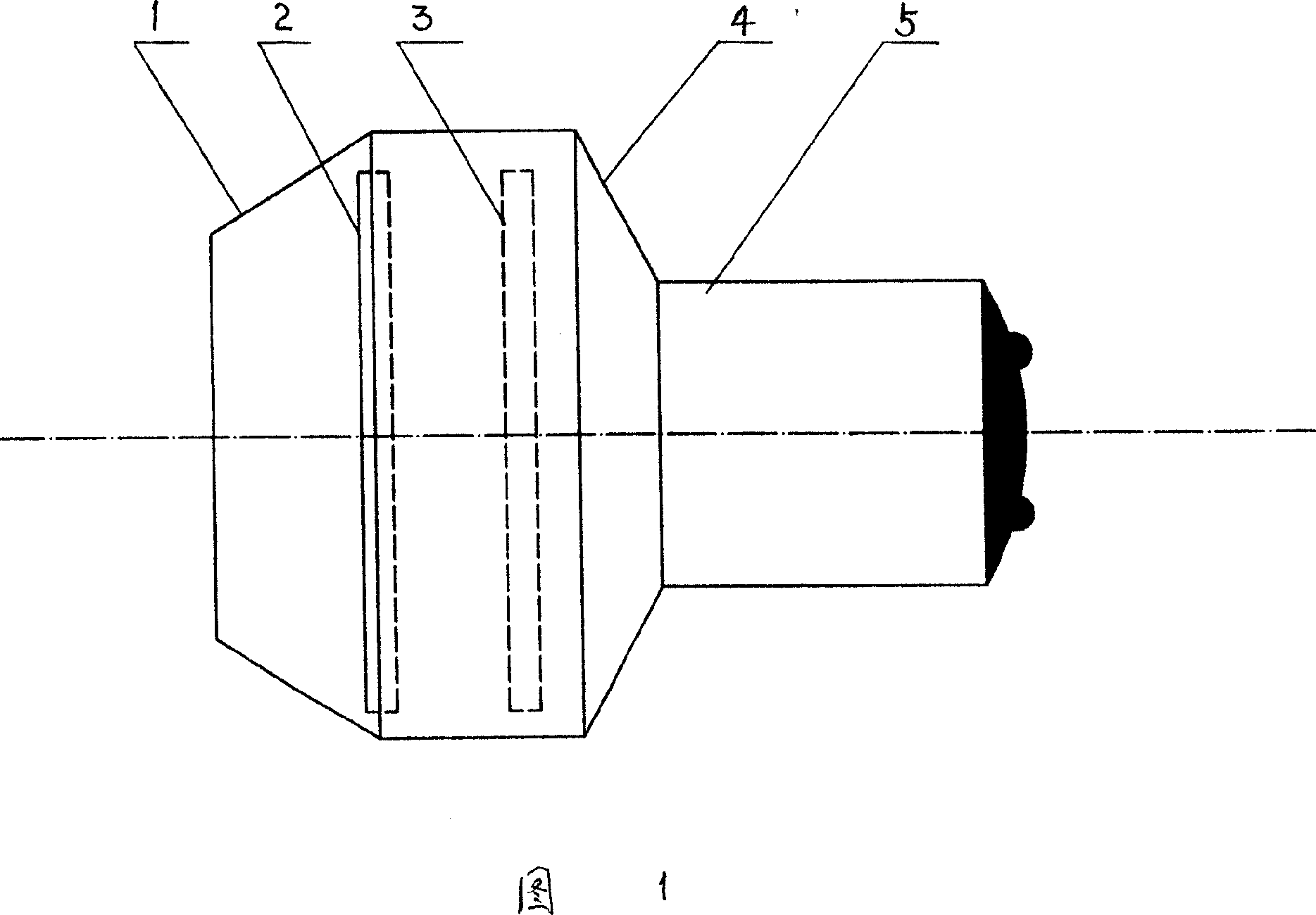

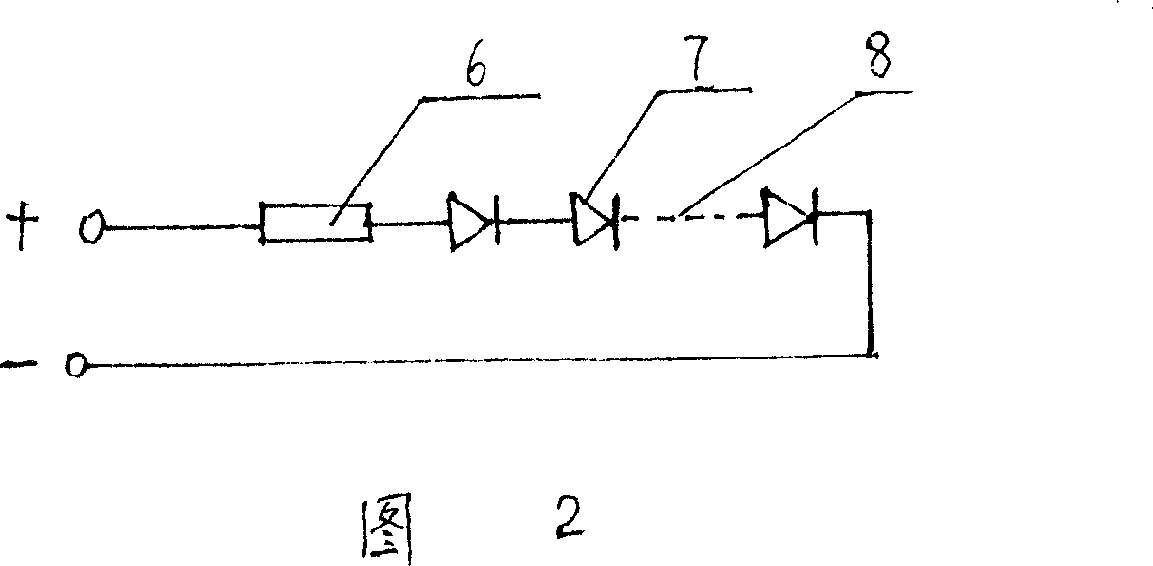

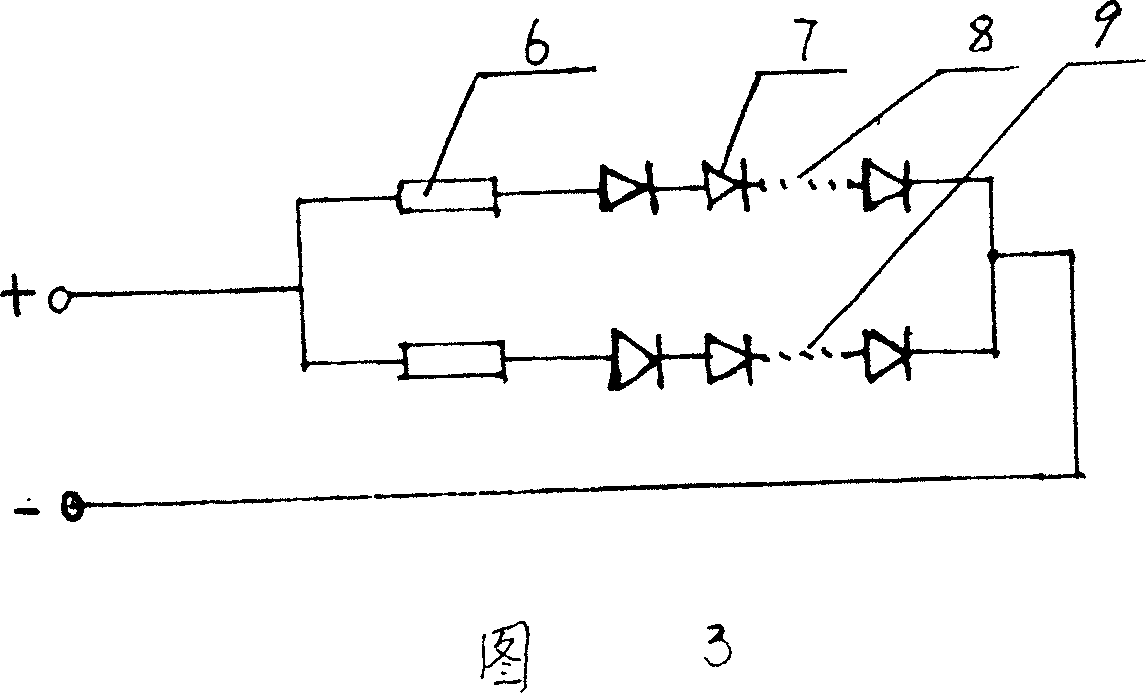

LED automobile indication lamp

InactiveCN101046285ALight stimulus response time is shortImprove responseLighting applicationsElectrical apparatusElectrical resistance and conductanceEngineering

The LED automobile indication lamp includes a lamp socket, a casing fixed onto the lamp socket, and a circuit board with resistors and a light emitting board comprising LED' s connected with wires and set inside the casing. The LED automobile indication lamp has high monochromaticity, high light emitting efficiency, high brightness, low power consumption, long service life, no contamination, high reliability, high safety and other features.

Owner:田仁德

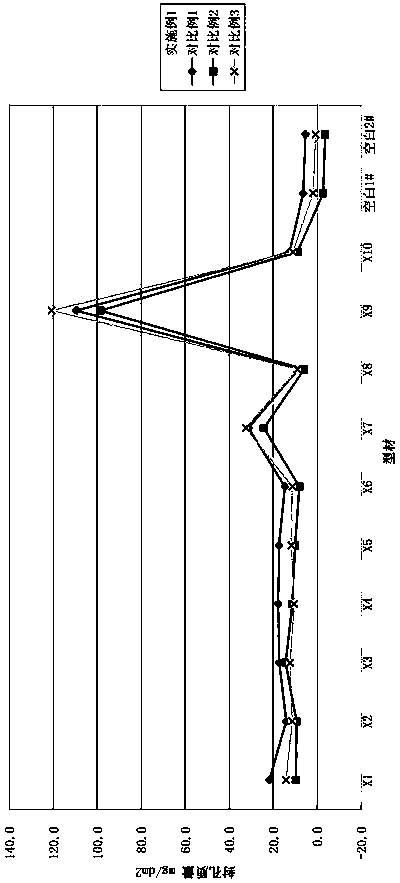

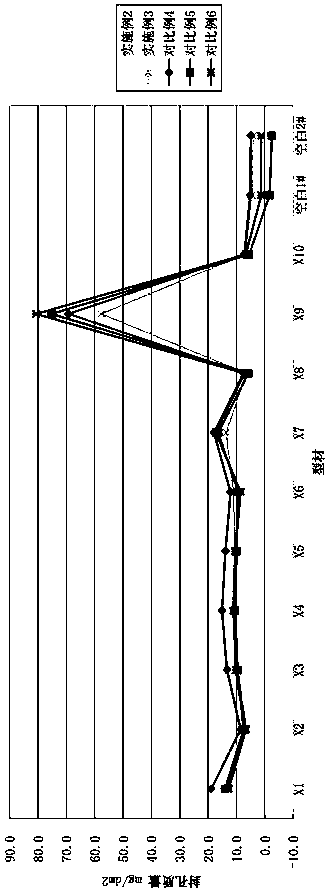

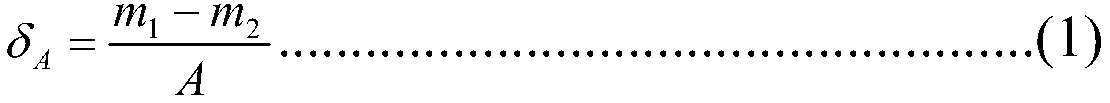

Method of evaluating hole sealing quality of anodic oxide film

ActiveCN108956367AGood correlationConducive to Occupational Health RequirementsWeighing by removing componentAnodic oxidationEnvironmental chemistry

The invention provides a method of evaluating the hole sealing quality of an anodic oxide film. The method comprises the following steps: measuring the anodic oxidation area of a test sample, degreasing, weighing, carrying out phosphorous magnesium acid process, and then calculating to obtain the weight loss per unit area of the test sample. The method for evaluating the hole sealing quality of the anodic oxide film is an environmentally friendly method of testing the hole sealing quality of anodic oxide films of aluminum and aluminum alloy, and has a strong correlation with a phosphoric chromium acid method which is a conventional test method.

Owner:GUANGDONG XINGFA ALUMINUM

Refining method of methylamino abamectin benzoate

ActiveCN108191935AHigh yieldHigh puritySugar derivativesSugar derivatives preparationFiltrationAbamectin

The invention discloses a refining method of methylamino abamectin benzoate, and belongs to the technical field of pesticides. The method comprises the steps that the methylamino abamectin benzoate isdissolved first, then the dissolved methylamino abamectin benzoate is cooled after being decolorized, and a solid is obtained with filtration, and the obtained solid is subjected to freeze crystallization treatment in a mixed solution of n-heptane, tetrahydrofuran and dichloromethane, and an obtained crystal is subjected to filtration, washing and drying to obtain a refined product of the methylamino abamectin benzoate. The method disclosed by the invention can obtain the high-yield and extremely high-purity refined product of the methylamino abamectin benzoate after one-time treatment, the yield can reach 80% to 85%, and the purity is not less than 99.0%.

Owner:武汉回盛生物科技股份有限公司

Water-soluble environment-friendly nanometer activated carbon wall paint with antifouling property and preparation method thereof

ActiveCN103242727BEasy to cleanConducive to environmental requirementsAntifouling/underwater paintsPaints with biocidesAcrylic resinOrganosolv

Owner:CHUZHOU HONGYUAN SPRAYING

Anti-freezing elastic water-soluble environmental-friendly nano activated carbon wall paint and preparation method thereof

ActiveCN103242728ALow TVOC valueConducive to environmental requirementsPolyester coatingsAcrylic resinCitrate sodium

The invention discloses anti-freezing elastic water-soluble environmental-friendly nano activated carbon wall paint, which is characterized in that the wall paint consists of the following ingredients in parts by mass according to the partial formula of raw materials: 20 parts of deionized water, 15 parts of water-soluble acrylic resin, 12 parts of sodium citrate, 8 parts of zinc oxide, 10 parts of zinc sulfate, 15 parts of nano activated carbon, 5 parts of dimethyl sulfoxide, 2 parts of elastic resin, 1 part of flatting agent and 2 parts of acrylic homopolymer emulsion; the wall paint also comprises an auxiliary material part consisting of dispersing agent, lubricating agent and biological preservative; and the TVOC value of the anti-freezing elastic water-soluble environmental-friendly nano activated carbon wall paint is 0g / l, and the formaldehyde emission is 0g / l. According to the wall paint and a preparation method thereof, the anti-freezing elastic water-soluble environmental-friendly nano activated carbon wall paint is non-toxic and tasteless, does not contain the general poisonous chemical organic solvent, is not added with poisonous wall paint preservative and meets the environment protection requirement.

Owner:CHUZHOU HONGYUAN SPRAYING

Technology for preparating boric acid, magnesium carbonate and sodium sulphate by combined method

InactiveCN1911801AHigh yieldSave mineral resourcesMagnesium carbonatesBoron-oxygen compoundsSodium carbonateCombined method

The process of co-producing boric acid, magnesium carbonate and sodium sulfate includes the first reaction step of reacting ascharite with 85 % concentration sulfuric acid to obtain wet boric acid and filtering to obtain filtrate; and the second reaction step of reacting the filtrate and sodium carbonate solution inside a reaction pond, filtering to obtain magnesium carbonate, concentrating the filtrate in a directly burning evaporator and hot filtering to obtain anhydrous sodium sulfate.

Owner:沙文斌

Rolling oil and preparation process thereof

InactiveCN102391908AGuaranteed smoothnessReduce dosageLubricant compositionMetalworkingPhosphoric acid

The invention belongs to the technical field of rolling oil, and discloses rolling oil used in the process of machining metals and a preparation process for the rolling oil. The rolling oil is technically characterized in that the rolling oil is prepared by stirring phosphoric acid, triethanolamine, a lubricant, a pH value regulator, sodium thiosulfate, Ninol, an antirusting agent, an emulsifier and water. The rolling oil does not contain mineral oil or aromatic hydrocarbon, so the rolling oil is favorable for the health of operators; and when the rolling oil is used for producing steel plates, friction force between rolled workpieces can be reduced effectively. The rolling oil has the characteristics of reducing calendaring loads effectively in the calendaring process, ensuring the glossiness of the rolled workpieces and relieving abrasion between the workpieces.

Owner:王占功

Sodium-free smokeless aluminum alloy environment-friendly refining agent and manufacturing method thereof

The invention discloses a sodium-free smokeless aluminum alloy environment-friendly refining agent and a manufacturing method thereof. The environment-friendly refining agent comprises the original compositions of, by weight, 40-49% of magnesium chloride, 20-29% of potassium chloride and 30-39% of aluminum fluoride, and then the environment-friendly refining agent is obtained finally through special melting treatment. Compared with the prior art, the sodium-free smokeless aluminum alloy environment-friendly refining agent is simple in proportion and does not contain sodium, flue gas is not generated in smelting, the industry blank is filled, and meanwhile, the great significance to environment-friendly modern metallurgy is achieved.

Owner:谢石华

Feed for egg-laying ducks and method for manufacturing feed

InactiveCN103494042APromote egg productionReduce manufacturing costAnimal feeding stuffChemistryAnimal Shells

The invention discloses feed for egg-laying ducks. The feed comprises, by mass, 35-38% of fermented dry beet pulp, 8-10% of fermented blood powder, 10-13% of animal shells, 0.8-1% of limestone powder, 1.2-1.5% of calcium phosphate, 0.2-0.5% of salt, 0.7-0.9% of nutritive additives, 2-3% of vegetable oil and the balance corn flour. The method for manufacturing the feed for the egg-laying ducks includes using the fermented dry beet pulp, the fermented blood powder and the corn flour as basic nutritive materials; crushing the animal shells; mixing the fermented dry beet pulp, the fermented blood powder, the corn flour and the crushed animal shells to obtain a mixture; adding a salt material into the mixture; adding the nutritive additives and the vegetable oil into the mixture and the salt material to obtain the feed. The feed for the egg-laying ducks and the method have the advantages that egg laying of the egg-laying ducks can be quickly promoted by the aid of the feed for the egg-laying ducks, and the production cost of the feed is lowered as compared with feed in an existing formula; the quality of the egg-laying ducks can be improved, and requirements on the food safety and environmental protection can be met advantageously.

Owner:DANYANG ZHENGDA OIL

Environment-friendly white linen hydrogen peroxide bleaching process

InactiveCN106120293AShort processEnergy savingBleaching apparatusVegetal fibresHydrogen peroxideChlorine

Owner:TUNGGA LINENANDCOTTON CO LTD

A system for energy-saving environment friendly integrated flue gas treatment in a coking production process and a method thereof

InactiveCN106552488ALow running costImprove economyDispersed particle separationEnergy inputAmmonium sulfateFlue gas

A system for energy-saving environment friendly integrated flue gas treatment in a coking production process and a method thereof are disclosed. The rear end of a coking flue gas pipeline is connected to a waste heat boiler through an induced draught fan. A pipeline after the waste heat boiler is connected to a flue gas inlet at the concentration segment at the middle of a desulfurization tower through a booster fan. An ozone pipeline is separately connected to a desulfurized flue gas inlet and a denitration tower flue gas inlet pipeline. An ammonia water supplementing pipeline is connected to the bottom of a liquid storage tank. The liquid storage tank is connected to an ammonium sulfate circulating tank through a pipeline. One pipeline after the ammonium sulfate circulating tank is communicated with the top of the concentration segment, and the other pipeline is connected to a solid liquid separator. A mother liquor after separation by the solid liquid separator is connected to the liquid storage tank through a pipeline. Ammonia is produced in a coking production high-temperature carbonization process in a coking enterprise, ammonia water is newly increased in subsequent chemical product production processes, and the residual ammonia water of the coking enterprise is utilized in the method to achieve desulfurization, and therefore the running cost is reduced, ammonium sulfate is produced as a byproduct, and the economical efficiency is higher.

Owner:JIANGXI YONGYUAN ENERGY SAVING ENVIRONMENTAL PROTECTION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com