Container tilting concentrator

A tilting, concentrator technology, applied in laboratory containers, laboratory utensils, chemical instruments and methods, etc., can solve the problems of complicated work content, air pollution, reducing concentration efficiency, etc., and is conducive to rapid heating , save energy consumption, expand the effect of contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

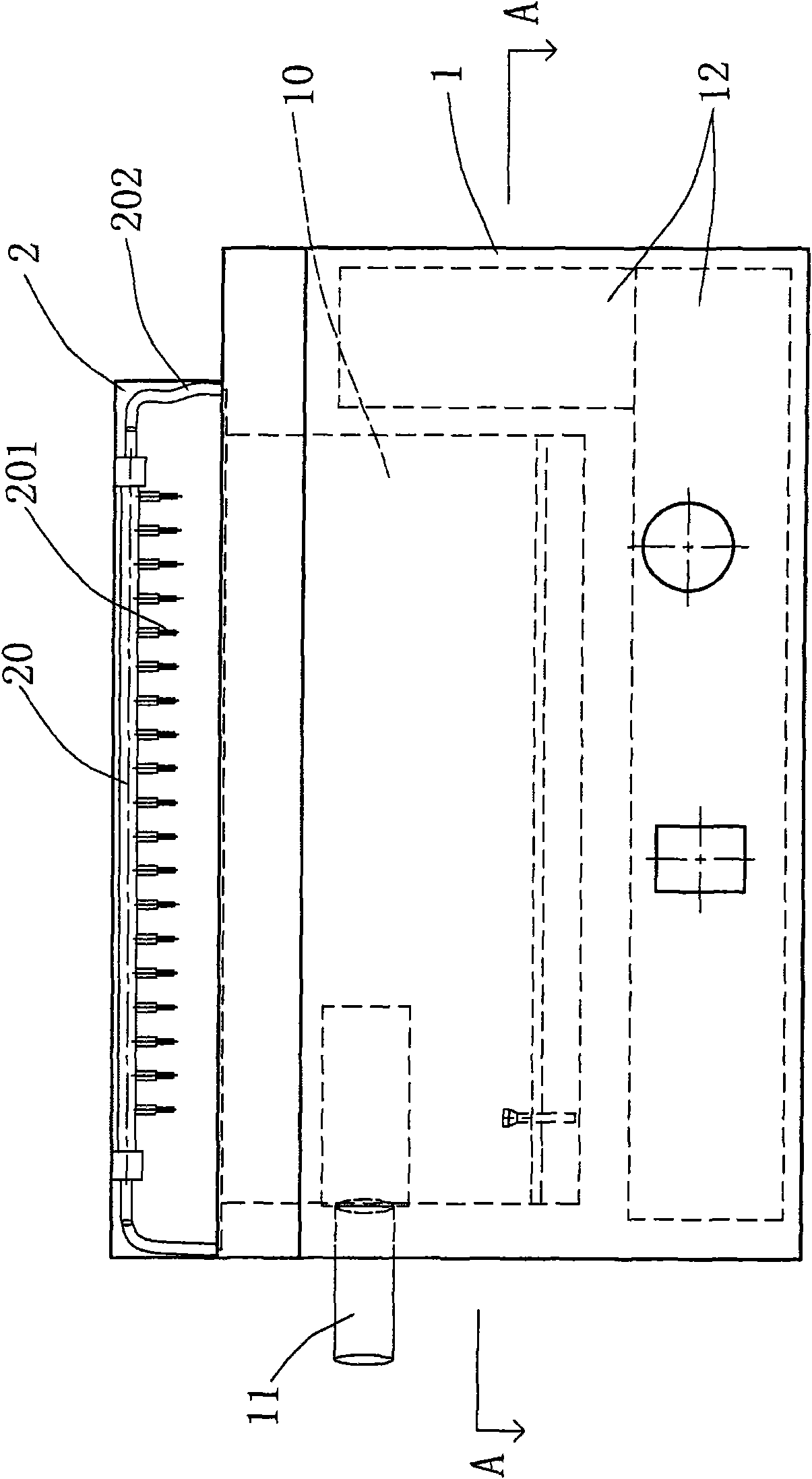

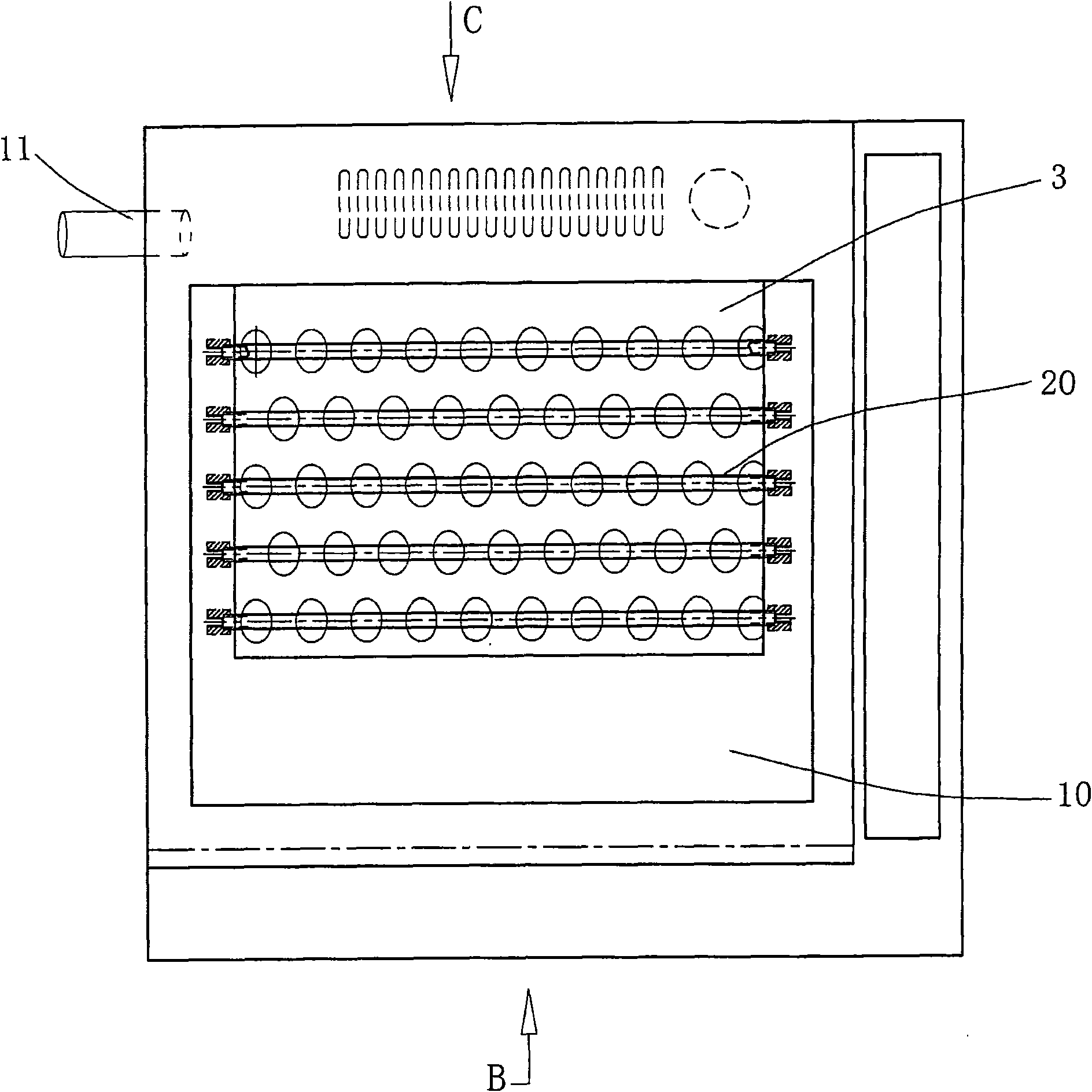

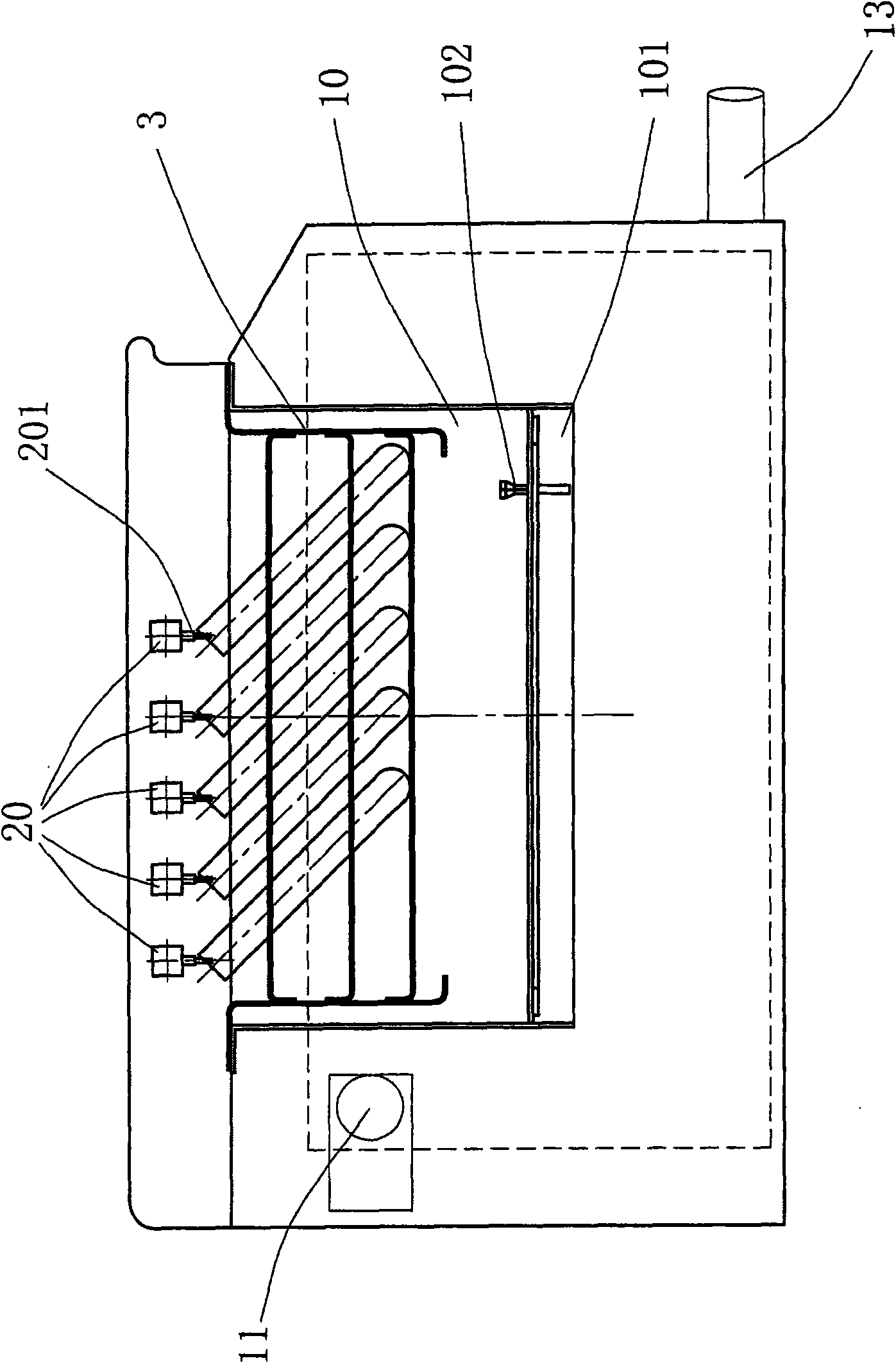

[0051] figure 1 It is a schematic diagram of the front view of Embodiment 1 of the container inclined concentrator of the present invention; figure 2 It is a top view schematic diagram of Embodiment 1 of the container inclined concentrator of the present invention; image 3 It is a schematic side view of Embodiment 1 of the container inclined concentrator of the present invention; Figure 4 is along figure 1 A schematic cross-sectional view of the A-A line. As shown in the figure, a container inclined concentrator proposed by the present invention has a closed container, and the closed container includes a housing 1 and a cover 2 capable of sealingly covering the housing. 1 is provided with an evaporation chamber 10, and the evaporation chamber 10 is provided with a container placement rack 3. The casing 1 is provided with an exhaust port 11, and the cover body 2 is provided with multiple rows of spray pipes 20. The positions and structures of the exhaust ports and the sp...

Embodiment 2

[0063] Figure 9 It is a schematic front view of Embodiment 2 of the container inclined concentrator of the present invention; Figure 10 It is a schematic top view of Embodiment 2 of the container inclined concentrator of the present invention; Figure 11 It is a schematic side view of Embodiment 2 of the container inclined concentrator of the present invention; Figure 12 is along Figure 9 Schematic cross-sectional view of line B-B in middle.

[0064] As shown in the figure, in this embodiment, the exhaust port 11 is connected to a reagent recovery device 5 . The reagent recovery device 5 and the airtight container composed of the housing 1 and the cover 2 can be provided separately or integrally. Such as Figure 9 , 10 , Shown in 12, have represented the structure that is arranged as a whole. Wherein, the reagent recovery device 5 is arranged on one side of the evaporation chamber 10 in the casing, and an exhaust fan 51 arranged in the casing transports the evaporat...

Embodiment 3

[0068] In order to facilitate the evaporation of reagents, infrared heaters or microwave heaters (not shown) may be arranged around and on the bottom surface of the evaporation chamber 10 . Alternatively, an electromagnetic heater or a heating sheet may also be provided on the bottom surface of the evaporation chamber. Wherein, the heating sheet is a sheet-shaped resistance wire heater.

[0069] The use of infrared heating, electromagnetic heating or microwave heating is more conducive to the rapid heating of the evaporation environment. Among them, infrared heating and microwave heating can make the environment in the evaporation chamber reach the preset temperature in a very short time, thereby saving energy consumption. .

[0070] Other structures, working principles and beneficial effects of this embodiment are the same as those of Embodiments 1 and 2, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com