A system for energy-saving environment friendly integrated flue gas treatment in a coking production process and a method thereof

An energy-saving, environmental-friendly, and production-process technology, applied in the field of flue gas treatment, can solve the problems of uneconomical and reliable application of catalytic denitrification process, low temperature, etc., and achieve the effects of reducing operating costs, increasing concentration, and good economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

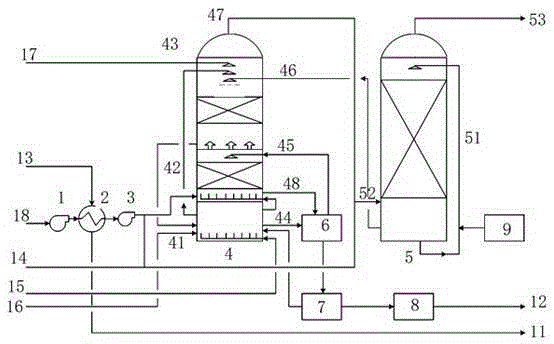

[0027] Embodiment 1: An integrated method for energy-saving and environmental protection treatment of flue gas in the coking production process, which includes the following implementation process: in the waste heat recovery process, the coking production flue gas from the coke oven flue is sent to the waste heat recovery boiler through the induced draft fan, and the The temperature of the flue gas is reduced from 300°C to about 160°C, and the waste heat of the flue gas is recovered to produce low-pressure steam, which enters the steam pipe network; the flue gas after waste heat recovery passes through the booster fan 3, passes through the flue gas input pipeline, and before entering the desulfurization tower 4 Confluence with the ozone input pipe, part of the flue gas Reacts quickly with ozone to generate , the flue gas is mixed with ozone and sent to the concentration section 42 of the desulfurization tower.

[0028] In the desulfurization process, in the concentration se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com