Microwave dielectric ceramics and preparation method thereof

A technology of microwave dielectric ceramics and high quality, applied in the field of ceramic materials, can solve the problems of restricting development and utilization, increasing industrial production costs, etc., and achieve the effect of raw material acquisition, easy raw material and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

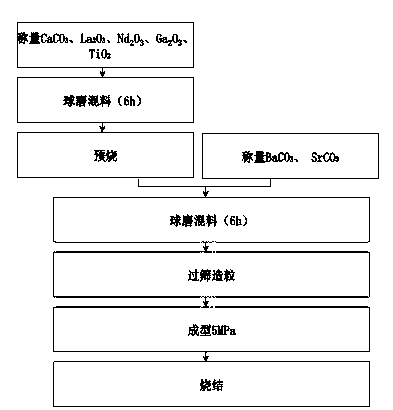

[0033] Embodiment 1-5 according to general formula (1-x) CaTiO 3 -x(La y Nd (1-y) )GaO 3 The microwave dielectric ceramics of this patent are prepared through the following steps:

[0034] The specific raw material manufacturers are as follows:

[0035]

[0036]1) Weigh CaCO according to the main crystal phase ratio in Table 1 3 ,TiO 2 , La 2 o 3 , Ga 2 o 3 ,Nd 2 o 3 , after mixing, ball mill on a planetary ball mill for 6 hours with deionized water and zirconium balls;

[0037] 2) After drying, heat it at 1400°C for 6 hours, and pre-calcine to prepare (1-x)CaTiO 3 -x(La y Nd (1-y) )GaO 3 (0.3≤x≤0.5, 0.3≤y≤0.6) powder;

[0038] 3) Take BaCO according to the doping content 3 and SrCO 3 , mixed with the pre-fired powder, and then added deionized water and zirconium balls according to the mass ratio of material: deionized water: zirconium balls = 1:1.2:5, and ball milled on a planetary ball mill for 6 hours;

[0039] 4) Dry the ball-milled slurry and pass i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| resonant frequency temperature coefficient | aaaaa | aaaaa |

| relative permittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com