Large-section simply-supported box girder precasting and assembly process under conditions of strong wind and high altitude

A large-section, box-girder technology, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of complex operation, inconvenient control, poor concrete stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

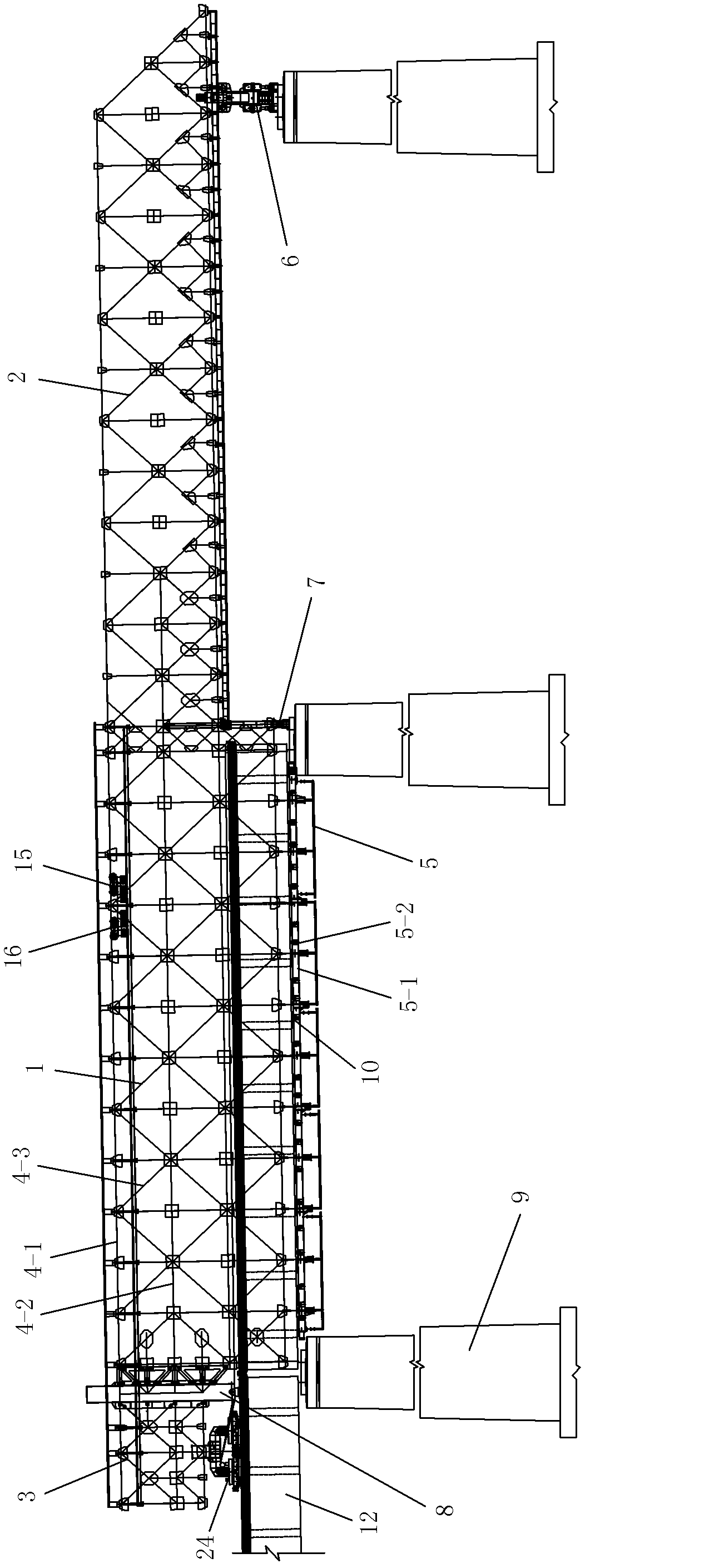

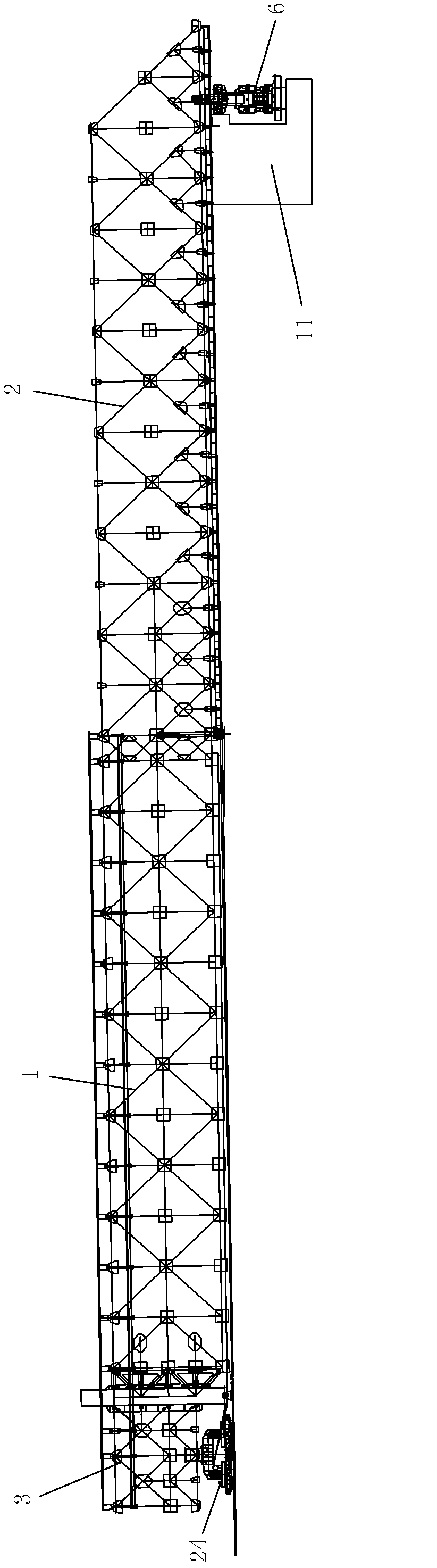

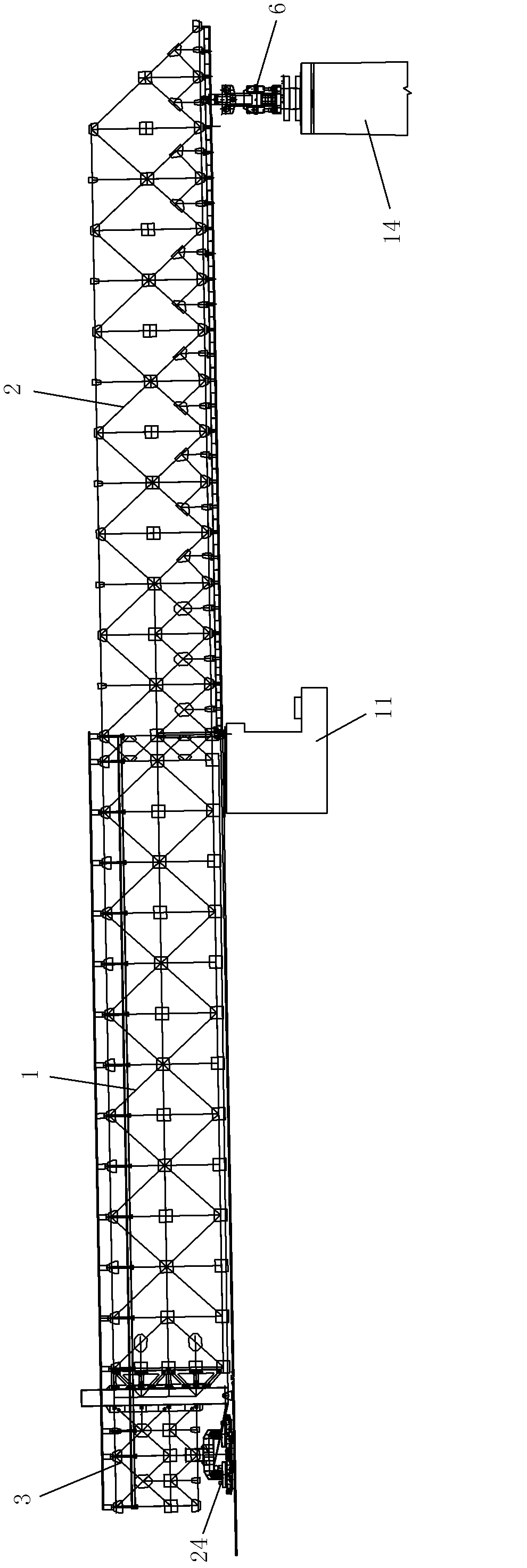

Image

Examples

Embodiment Construction

[0061] Such as Image 6 Shown is a prefabrication and assembly process of a large cross-section simply supported box girder under conditions of strong wind and high altitude. A box girder segment 13 is assembled, and each hole beam is supported and fixed by two bridge piers 9 at the bottom of its left and right ends, and it is characterized in that the process includes the following steps:

[0062] Step 1. Prefabrication of box girder segments: Centrally prefabricate all box girder segments 13 forming the simply supported box girder in the prefabrication field, the prefabrication methods of all box girder segments 13 are the same, and the box girder segments The prefabrication method of 13 comprises the following steps:

[0063] Step 101, fabrication and installation of reinforcement framework: according to the production and installation method of box girder reinforcement framework in the conventional box girder prefabrication process, fabricate and install the reinforcement...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com