Separation type intercooling control method of cooling water system of diesel locomotive engine

A technology for cooling water systems and internal combustion locomotives, which is applied to the control of coolant flow, engine cooling, internal combustion piston engines, etc. It can solve the problems that the design method cannot meet the requirements, and achieve the effect of improving environmental protection requirements and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

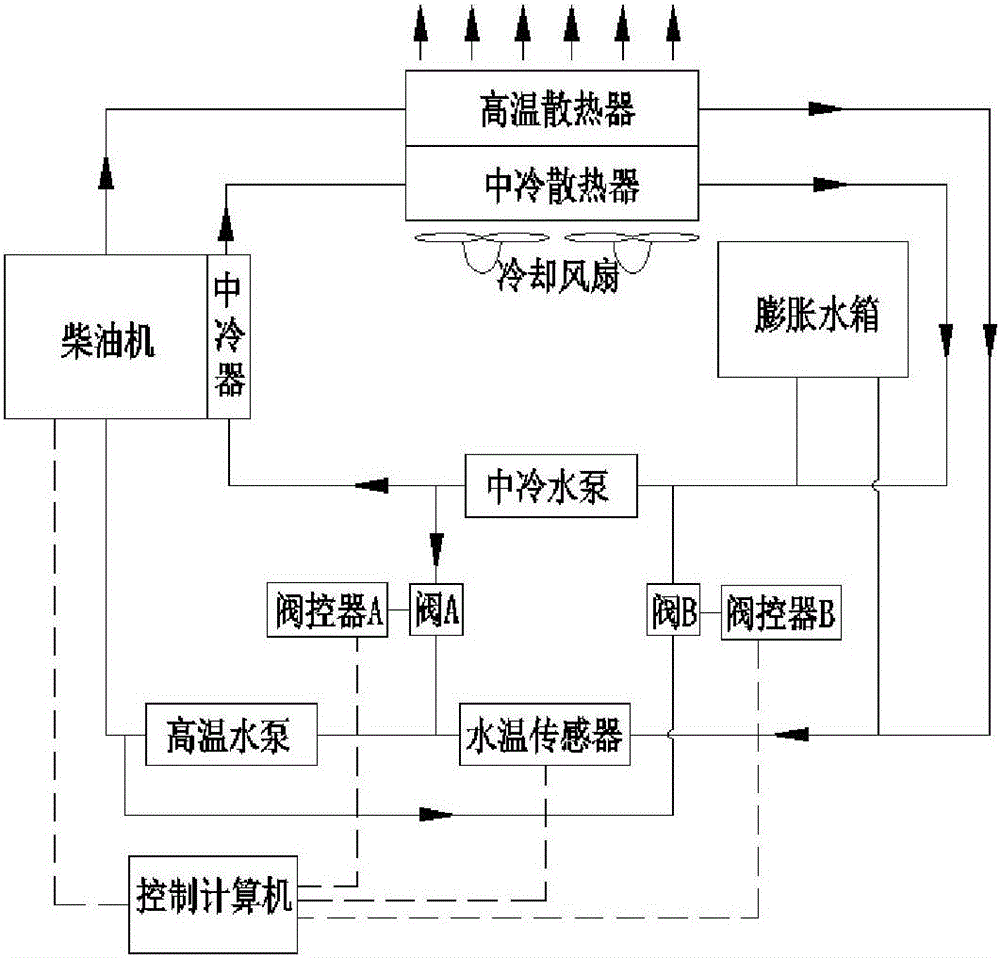

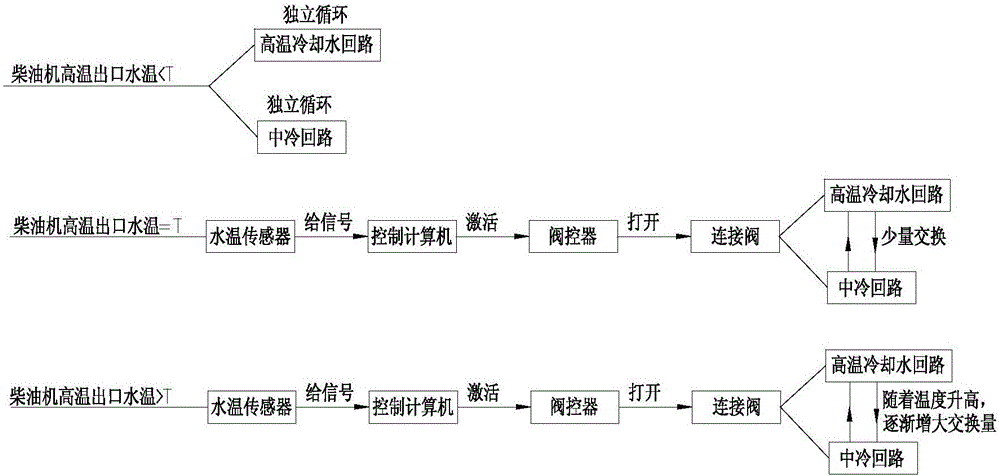

[0014] Now combined with figure 1 And figure 2 To further explain the invention, the highest ambient temperature rarely occurs in the actual use of locomotives and the locomotive is not always working under full load. The lower the ambient temperature or the lower the power of the locomotive, the heat dissipation capacity of the high-temperature radiator and the inter-cooling radiator The greater the margin. At this time, the heat dissipation capacity of the high-temperature cooling water is obviously excessive. If this excess heat dissipation capacity can be applied to the intercooling water system, it will obviously play a positive role in improving the performance of the diesel engine and reducing emissions.

[0015] The invention is applied to the cooling water system of a turbocharged diesel engine, and defines a cooling water system that has the ability to use a part of the cooling capacity to enhance the intake air of the intercooler when the cooling capacity of the cooli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com