Power assembly for two-shift motor vehicle

A powertrain, electric vehicle technology, applied in electric power units, power units, multi-transmission ratio transmissions, etc., can solve the problems of high motor output power requirements, poor flexibility, difficult assembly and maintenance, etc., and achieve easy assembly. and maintenance, derating, compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

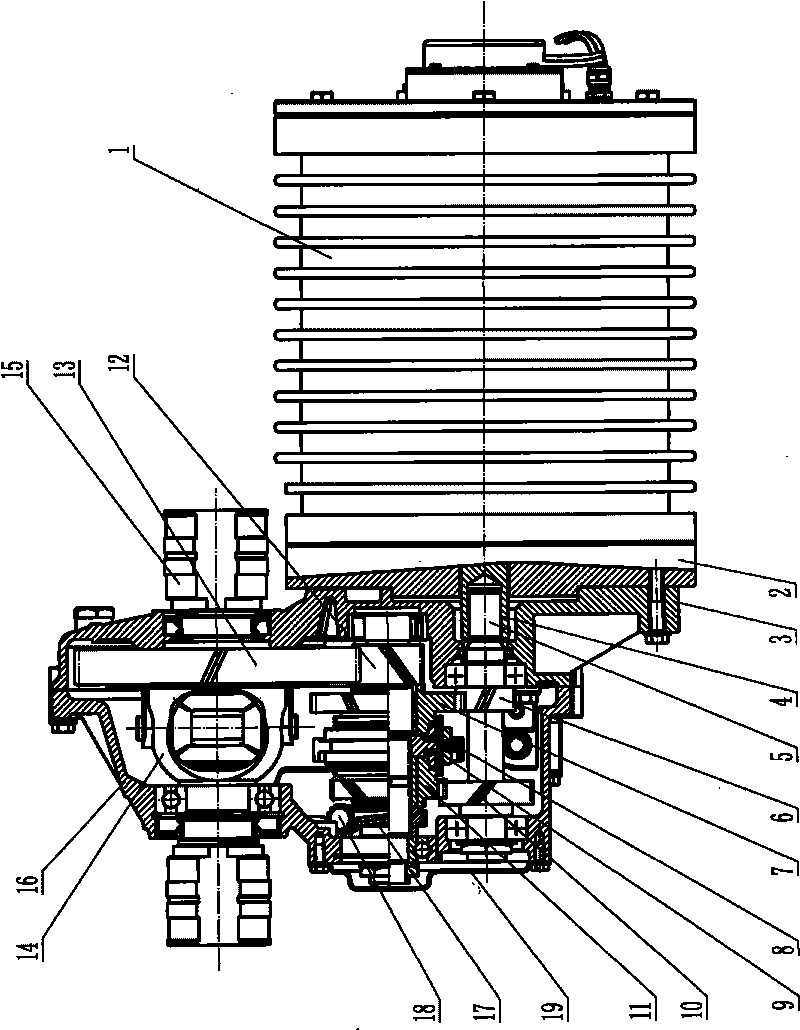

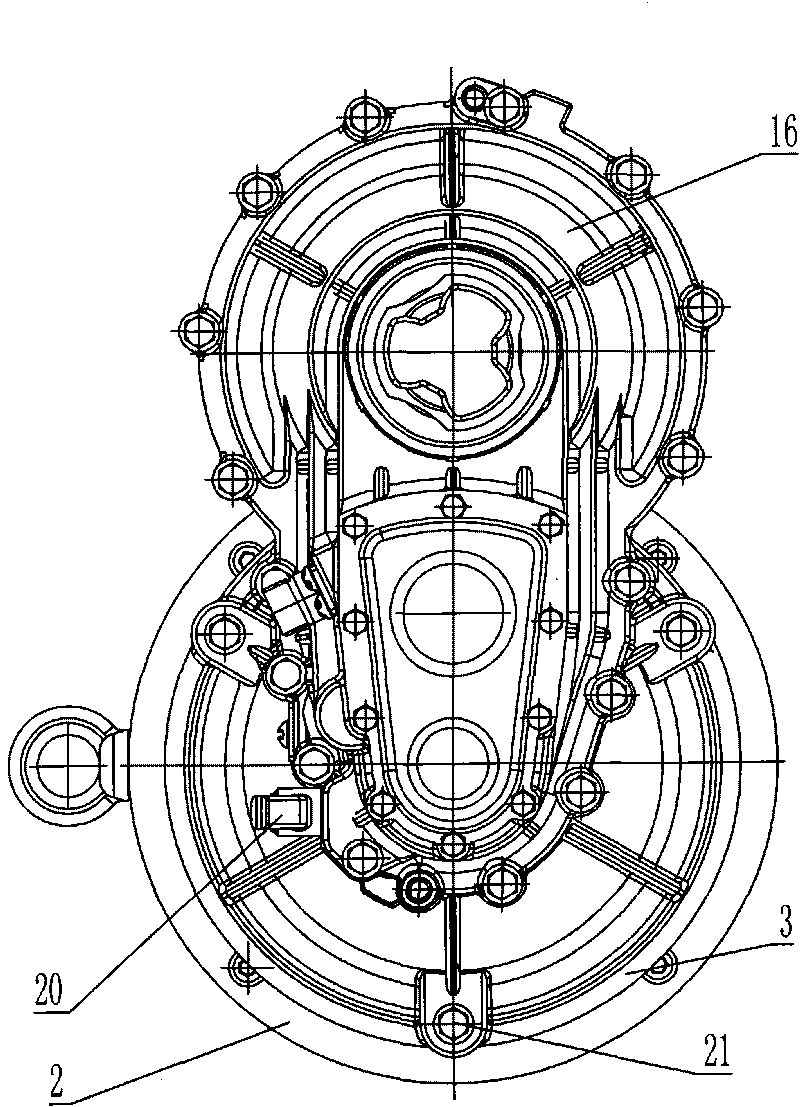

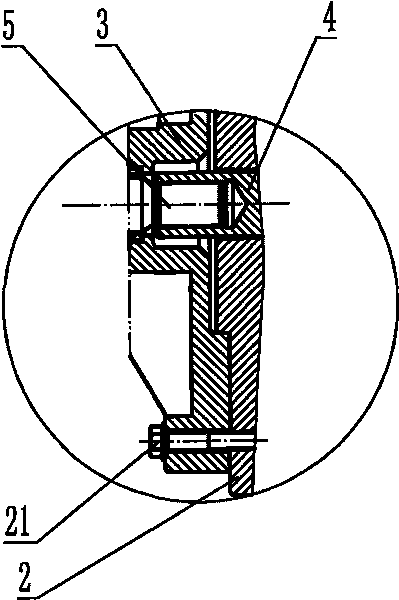

[0011] Describe in detail below in conjunction with accompanying drawing: figure 1 , figure 2 As shown, the drive motor 1 and the front end cover 3 of the transmission case are assembled by means of flange connection, that is, the notch boss of the drive motor end cover 2 is inserted into the notch groove of the transmission end cover 3, and the circumferentially evenly distributed bolts 21 are connected. .The assembly structure is simple and fast, which effectively improves the coaxiality of the assembly of the motor output shaft and the gearbox input shaft. The front end cover 3 and the rear end cover 16 of the transmission case are connected by bolts to form the transmission case, and the input shaft is installed through bearings 5. The output shaft 4 of the drive motor 1 and the transmission input shaft 5 are respectively connected by internal and external splines to transmit torque. The low-speed driving gear 6 and the high-speed driving gear 10 are installed on the inpu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com