Permeable reactive waterproof anticorrosion additive and mortar combination containing additive

An osmotic reaction type and additive technology, which is applied in the field of osmotic reaction type waterproof and anti-corrosion additives and mortar compositions containing the additive, can solve problems such as no anti-corrosion and rust-inhibiting functions, and achieves reducing construction difficulty, improving waterproof and anti-corrosion, and improving comprehensive durability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

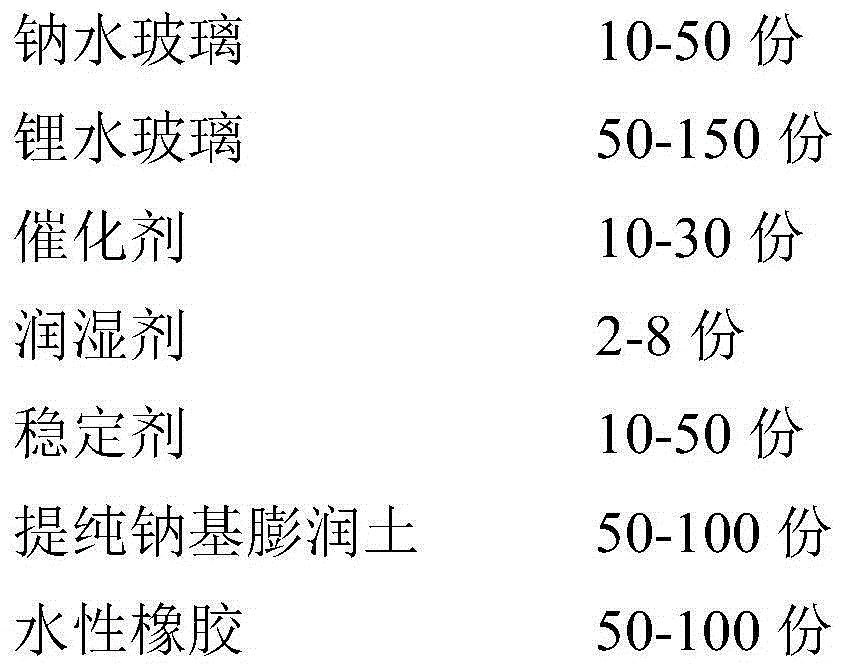

[0048] Preparation of Purified Sodium Bentonite

[0049]The preparation process of purified sodium-based bentonite is as follows: Naturally dry and crush the raw sodium-based bentonite, then dry it by airflow, and then grind it by Raymond mill, and then obtain purified sodium-based bentonite by wind selection and classification by airflow classifier, performance index for E Na+ / CEC×100%≥50%.

[0050] Preparation Example

[0051] Step a: Weigh 15g of aluminum metaphosphate, 30g of NaOH, 10g of sodium molybdate, and 30g of deionized water, and add them into a reactor at 90°C, stir and keep the temperature constant for 10 minutes.

[0052] Step b: Put 300g of deionized water in the above-mentioned reactor and mechanically stir at 100-300rpm at room temperature.

[0053] Step c: Weigh 1161g of deionized water and put it in another larger reactor at room temperature, add 4g of surfactant H140 and stir slowly at 30-50rpm, add the catalyst prepared in the above step b until mixed...

Embodiment 1

[0060] Prepare waterproof and anti-corrosion mortar according to the following ratio:

[0061] 42.5R ordinary Portland cement: sand: water: osmotic reaction type waterproof and anticorrosion additive = 1000g: 2000g: 250g: 300g

[0062] Mix the above-mentioned mortar evenly to prepare the mortar test piece, standardize it for 7 days, and test its waterproof and anti-corrosion performance after 21 days of natural curing. The performance is shown in Table 1.

[0063] Table 1 Main performance requirements of waterproof and anticorrosion mortar

[0064]

Embodiment 2

[0066] Prepare waterproof and anti-corrosion mortar according to the following ratio:

[0067] 42.5 Aluminate cement: sand: water: osmotic reaction type waterproof and anticorrosion additive = 1000g: 2000g: 250g: 300g

[0068] Mix the above-mentioned mortar evenly to prepare the mortar test piece, standardize it for 7 days, and test its waterproof and anti-corrosion performance after 21 days of natural curing. The performance is shown in Table 2.

[0069] Table 2 Main performance requirements of waterproof and anticorrosion mortar

[0070]

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com