Polyurethane composite-type waterproof thermal-insulation decorative board, and production method

A production method and technology of decorative panels, applied in the field of wall insulation materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0117] A. Raw material ratio of polyurethane adhesive

[0118] The raw material ratio of the foamed polyurethane adhesive used for the insulation layer is as follows:

[0119] 1. Polyester polyol 89.8 parts by weight

[0120] 2. Triethylenediamine 0.1 parts by weight

[0121] 3. Polyoxyethylene sorbitan monooleate 3.5 parts by weight

[0122] 4. Diethylethanolamine 0.3 parts by weight

[0123] 5.4.4 Bis(2.2-dimethylbenzyl)diphenylamine 0.5 parts by weight

[0124] 6. Melamine polyphosphate (MPP) 3.0 parts by weight

[0125] 7. Deionized water 2.8 parts by weight

[0126] B. Inorganic material ratio

[0127] The proportion of inorganic mineral materials used in the insulation layer is as follows:

[0128] 1. Expanded perlite 50.0 parts by weight

[0129] 2. Glass beads 28.0 parts by weight

[0130] 3. Fly ash 13.0 parts by weight

[0131] 4. Ash calcium powder 9.0 parts by weight

[0132] C. Production method

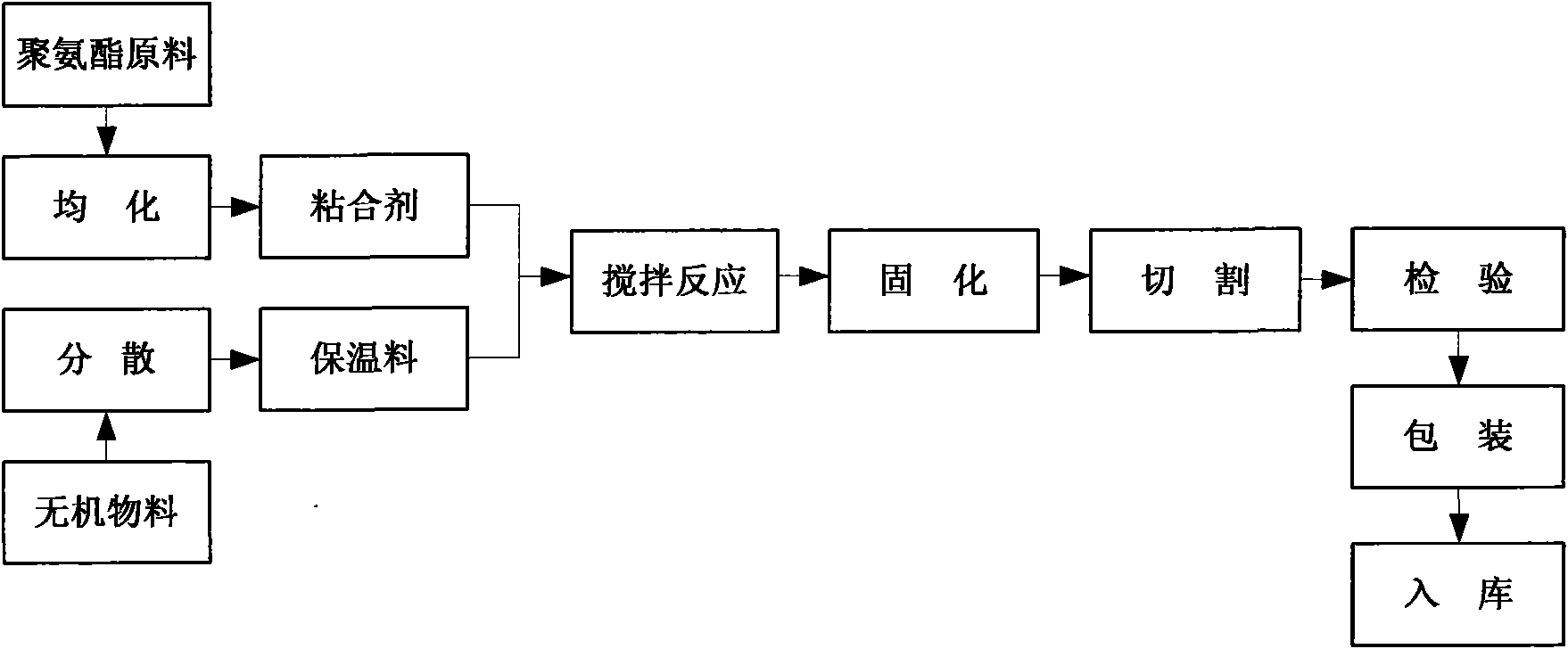

[0133] A kind of production method of polyurethane comp...

Embodiment 2

[0140] A. Raw material ratio of polyurethane adhesive

[0141] The raw material ratio of the foamed polyurethane adhesive used for the insulation layer is as follows:

[0142] 1. 92.8 parts by weight of polyester polyol

[0143] 2. Triethylenediamine 0.2 parts by weight

[0144] 3. Polyoxyethylene sorbitan monooleate 3.0 parts by weight

[0145] 4. Diethylethanolamine 0.2 parts by weight

[0146] 5.4.4 Bis(2.2-dimethylbenzyl)diphenylamine 0.2 parts by weight

[0147] 6. 0.1 parts by weight of 6-ethoxy-2,2,4-trimethyl-1,2-dihydroquinoline

[0148] 7. 0.5 parts by weight of melamine polyphosphate (MPP)

[0149] 8. Tris(2-chloropropyl) phosphate (TCPP) 0.5 parts by weight

[0150] 9. Deionized water 2.5 parts by weight

[0151] B. Inorganic material ratio

[0152] The proportion of inorganic mineral materials used in the insulation layer is as follows:

[0153] 1. Expanded perlite 45.0 parts by weight

[0154] 2. Glass beads 35.0 parts by weight

[0155] 3. Fly ash 15....

Embodiment 3

[0165] A. Raw material ratio of polyurethane adhesive

[0166] The raw material ratio of the foamed polyurethane adhesive used for the insulation layer is as follows:

[0167] 1. Polyester polyol 91.0 parts by weight

[0168] 2. Triethylenediamine 0.2 parts by weight

[0169] 3. Polyoxyethylene sorbitan monooleate 3.2 parts by weight

[0170] 4. Diethylethanolamine 0.4 parts by weight

[0171] 5.4.4 Bis(2.2-dimethylbenzyl)diphenylamine 0.2 parts by weight

[0172] 6. Melamine polyphosphate (MPP) 2.0 parts by weight

[0173] 7. Deionized water 3.0 parts by weight

[0174] B. Inorganic material ratio

[0175] The proportion of inorganic mineral materials used in the insulation layer is as follows:

[0176] 1. Expanded perlite 55.0 parts by weight

[0177] 2. Glass beads 30.0 parts by weight

[0178] 3. Fly ash 10.0 parts by weight

[0179] 4. Ash calcium powder 5.0 parts by weight

[0180] C. Production method

[0181] A kind of production method of polyurethane comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com