Large-grain-diameter rubber block-modified asphalt mastic and gravel sealing layer and preparation method thereof

A technology of modified asphalt and a production method, which is applied to the coagulation pavement, roads, roads and other directions of on-site paving, can solve the problems of high cost, unstable quality, large energy consumption, etc., and achieves low production cost and reduced stress strength. factor, the effect of reducing energy consumption and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

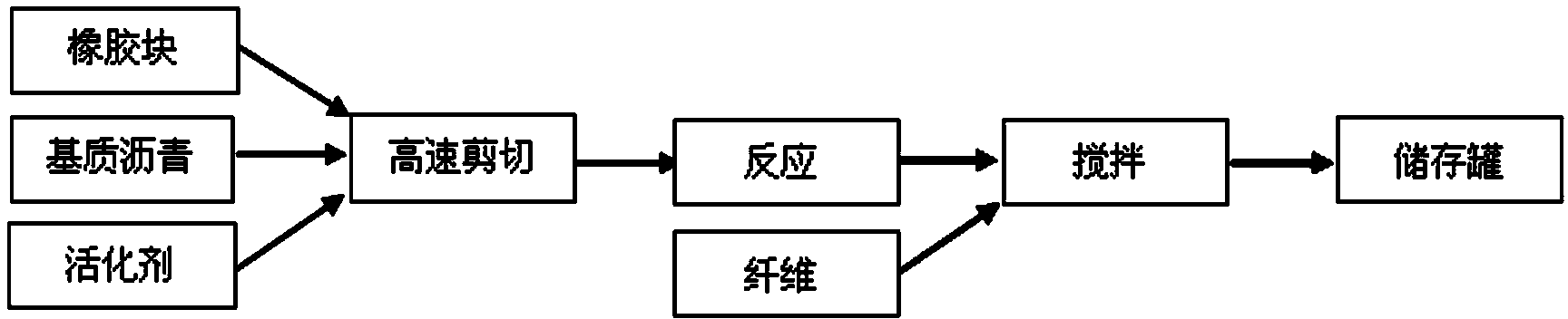

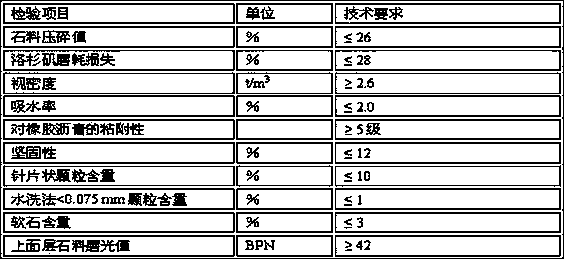

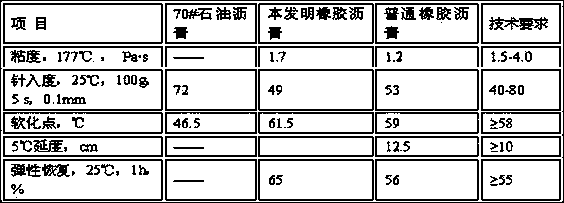

[0046] Refer to attached figure 1 , a large-diameter rubber block modified asphalt mastic macadam seal layer of the present invention is composed of aggregates, fibers and rubber block modified asphalt, and the aggregate is crushed stone with a particle size of 9.5 mm to 13.2 mm , according to the aggregate weight of 0.2 to 0.5% of the rubber block modified asphalt for pre-coating; the fibers are lignin flocculent fibers, and the mixing ratio of the fibers is 3% to 5% of the mass of the rubber block modified asphalt ;

[0047] The crushed stone material is hard stone, clean, free of weathered particles, and nearly cubic particles.

[0048] The crushed stone is rolled by impact crusher.

[0049]The temperature of the pre-wrapping is above 120°C, and the stacking time of the pre-wrapping aggregates should not exceed two weeks.

[0050] The preparation method of the large-diameter rubber block modified asphalt mastic gravel seal layer comprises the following steps,

[0051] (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com