Patents

Literature

32results about How to "Meet toughness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing flame-retardant waterborne polyurethane containing phosphaphenanthrene and/or phenyl phosphate groups

InactiveCN104592475ANon-corrosive generationEvenly distributedGroup 5/15 element organic compoundsPolymer scienceAlcohol

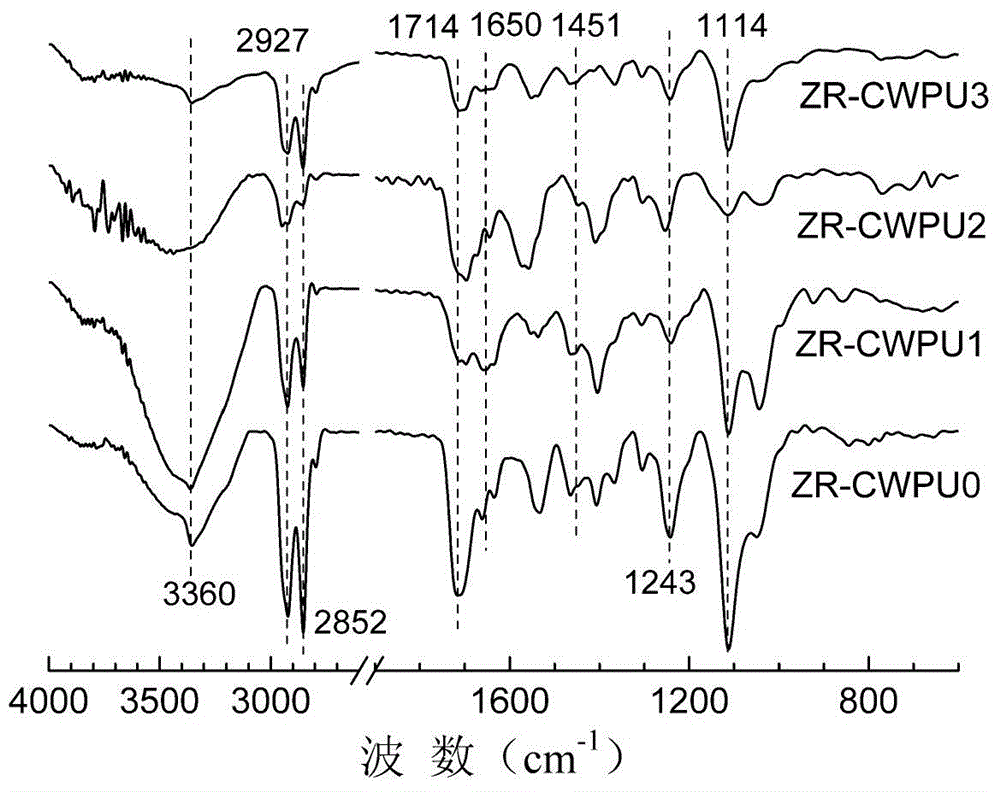

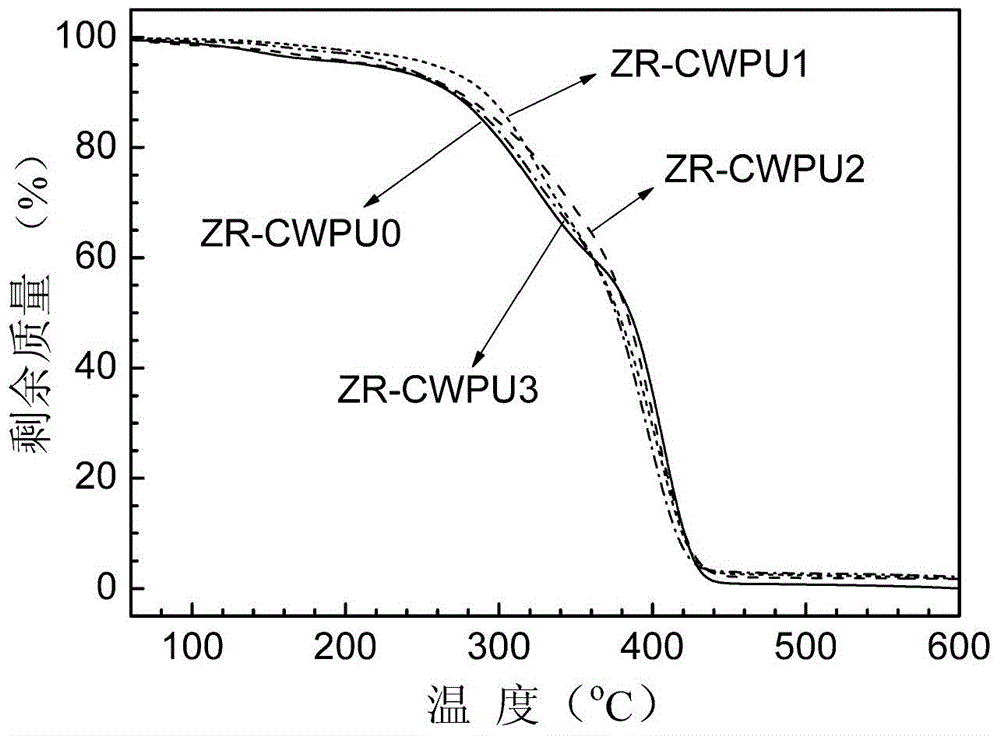

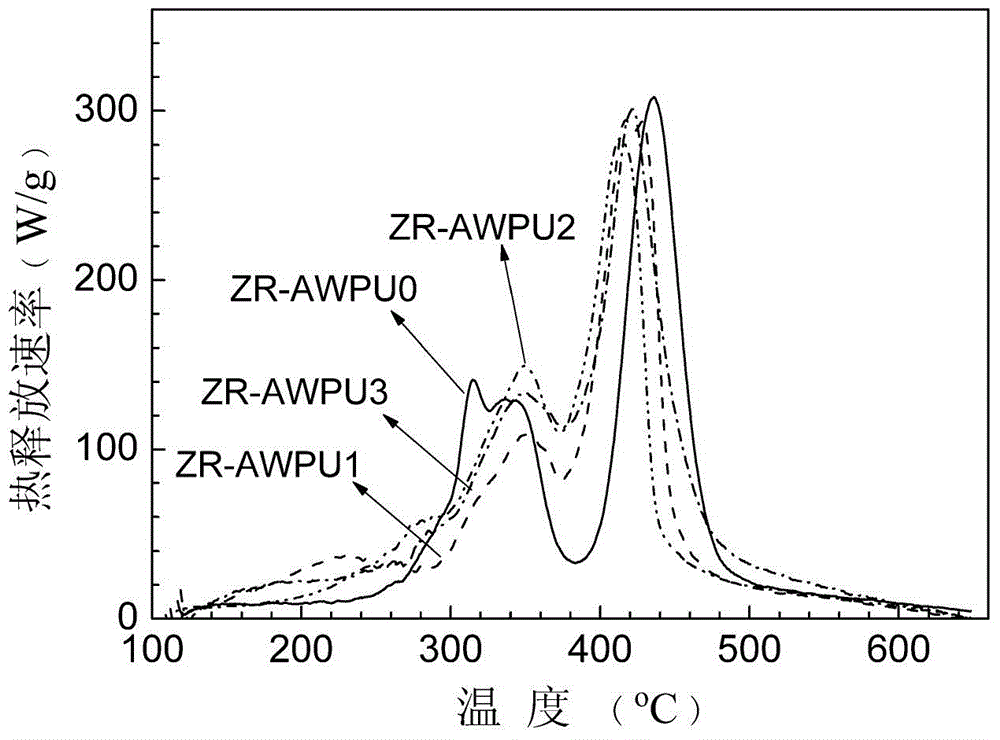

The invention discloses a method for preparing flame-retardant waterborne polyurethane containing phosphaphenanthrene and / or phenyl phosphate groups. The method is characterized by comprising the following step of reacting dihydric alcohol as a reactant which contains phosphaphenanthrene and / or phenyl phosphate groups and of which the hydroxyl groups are symmetric with diisocyanate, macromolecular dihydric alcohol, anionic or cationic hydrophilic chain extender and the like to synthesize flame-retardant waterborne polyurethane. According to the method, since flame-retardant dihydric alcohol is used as one of chain extenders, flame-retardant dihydric alcohol ca partially or totally substitute other small molecular chain extenders, phosphorus-containing flame-retardant groups are controllable in content and difficult to migrate and are evenly distributed, and the flame-retardant property of waterborne polyurethane can be enduringly retained. According to the structural characteristics of selected flame-retardant dihydric alcohol, by virtue of one and a combination of two or more of flame-retardant groups, phosphorus in the flame-retardant groups can be alone located at a main chain, side chains or simultaneously located at the main chain and the side chains of the polyurethane molecule chain as desired so as to meet the requirements of different flame-retardant properties or other properties such as mechanics, toughness and plasticity.

Owner:UNIV OF SCI & TECH OF CHINA

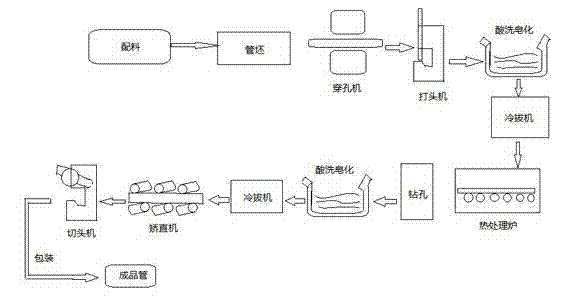

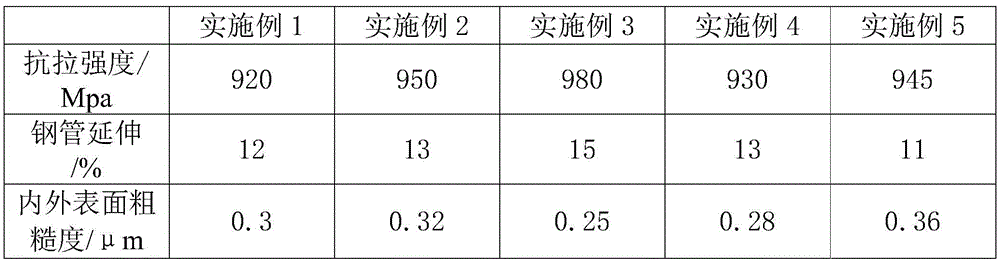

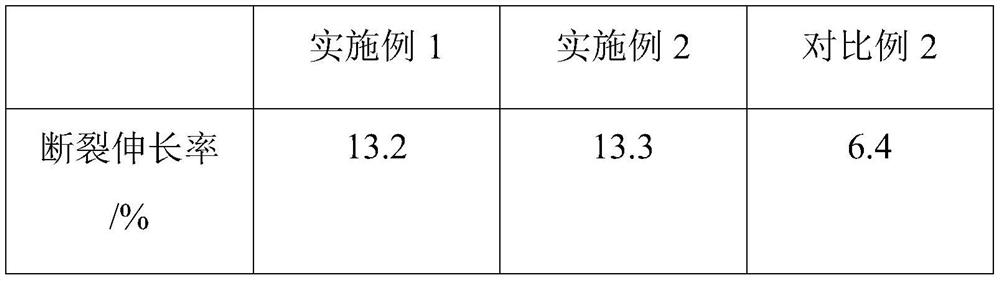

Manufacturing method of vehicle seamless steel tubes

The invention relates to a manufacturing method of vehicle seamless steel tubes. Surface quality of finished products can be improved through twice phosphorus acid saponification processing and secondary cold drawing processing; during manufacturing, external and internal quality of the products can be guaranteed through twice test, performance index of the steel tubes with the tensile strength larger than or equal to 500Mpa and extension larger then or equal to 10% and internal and external surface roughness smaller than or equal to 0.4 micrometers can be achieved by directly using saw cutting without heat treatment and mechanical machining, requirements of the steel tubes of vehicle parts on strength, toughness and surface quality are met, and meanwhile, technical requirement of processing-free steel tube parent materials of the vehicle parts can be met.

Owner:泰州双马节能科技有限公司

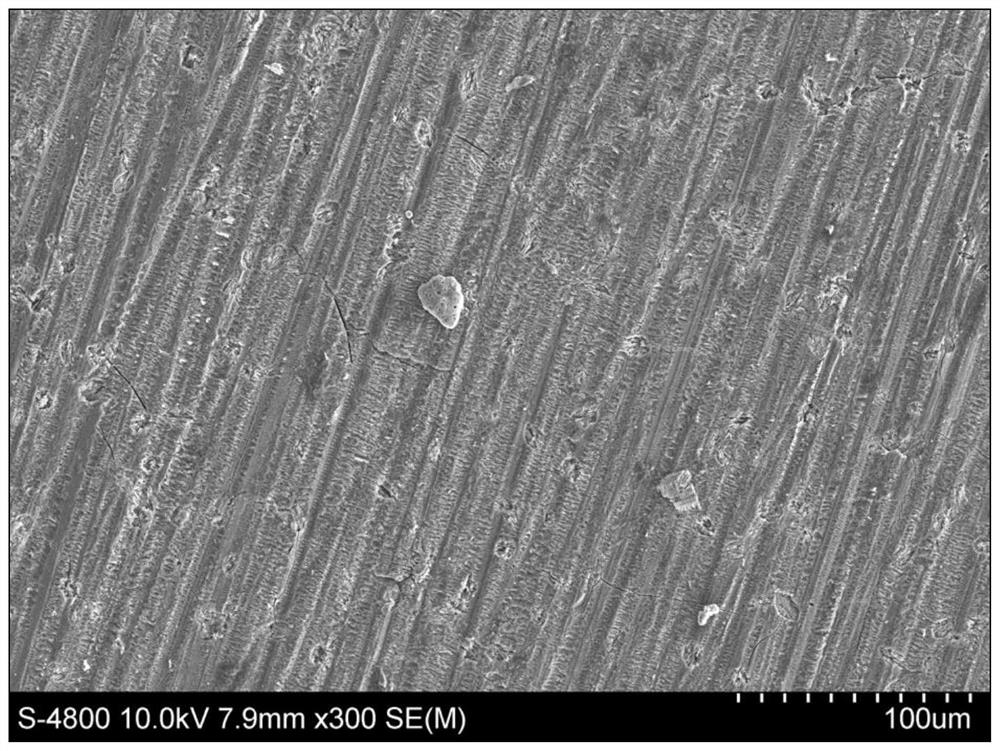

Melt spinning method for high-strength high-modulus polyvinyl alcohol fiber

InactiveCN102797050AMeet toughnessMeet the needs of crack resistanceArtificial filament washing/dryingArtificial filament heat treatmentHot air ovenPolyvinyl alcohol

The invention relates to a melt spinning method for a high-strength high-modulus polyvinyl alcohol fiber, comprising the following steps: uniformly mixing polyvinyl alcohol, water and an amide compound, and then, sufficiently swelling; adding the sufficiently swelled polyvinyl alcohol into a twin screw extruder, sufficiently melting, then extruding, and cooling the melt trickle through air blowing to form a nascent fiber; and drying the prepared nascent fiber through a hot-air oven, and then carrying out multistage stretching and tension heat setting to form the polyvinyl alcohol fiber. By using the preparation method of the polyvinyl alcohol fiber provided by the invention, melt spinning and high stretching of the polyvinyl alcohol are realized through hydrogen bond compounding among molecules of the water, the amide compound and the polyvinyl alcohol, and the prepared polyvinyl alcohol fiber has excellent mechanical property; and the melt spinning method is simple in production process, little in environment pollution and low in production cost; and the polyvinyl alcohol fiber prepared by using the method has the advantages of controllable fineness, high strength and high modulus so as to be widely applied to the field of civil engineering concrete.

Owner:SHANGHAI LUOYANG NEW MATERIAL TECH

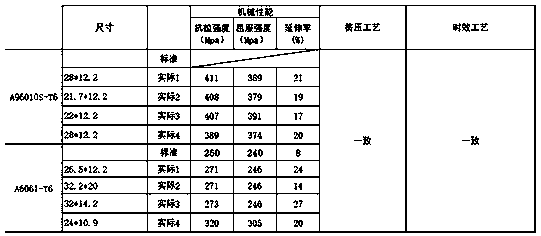

Novel aluminum alloy material and production process thereof

The invention relates to the technical field of aluminum alloy production, in particular to a novel aluminum alloy material and a production process thereof. The novel aluminum alloy material comprises, by mass percentage, 0.05-0.22 wt% of nickel, 0.8-1.6 wt% of chromium, 0.024-0.032 wt% of manganese, 0.78-1.5 wt% of magnesium, 0.66-1.65 wt% of silicon, 0.45-1.2 wt% of iron, 3.5-5.8 wt% of copper, 4.8-6.5 wt% of zinc, and the balance aluminum and other inevitable impurities. The mechanical property and mechanics property of the novel aluminum alloy material are excellent, and the surface of an aluminum alloy profile can be effectively protected against scratches; and in addition, the process is simple and reasonable, and the production efficiency is high.

Owner:ANHUI HENGXING DECORATION ENG CO LTD

B-grade anti-acid pipeline steel plate and production process

ActiveCN109811263AReduce manufacturing costMeet the requirements of acid and corrosion resistanceChemical compositionMetallurgy

The invention discloses a B-grade anti-acid pipeline steel plate. The chemical composition of the B-grade anti-acid pipeline steel plate comprise the following in mass percentage: 0.010-0.040% of C, 0.10-0.30% of Si, 0.80-0.90% of Mn, no more than 0.015% of P, no more than 0.0010% of S, 0.10-0.20% of Ni, 0.10-0.20% of Cu, 0.020-0.040% of Nb, 0.08-0.15% of Mo, 0.010-0.020% of Ti, 0.001-0.003% of Ca, 0.010-0.040% of Al, the balance Fe, inevitable impurities, 0.16-0.23% of Ceq, and 0.07-0.13% of Pcm. The invention uses a small amount of Nb alloy element, the tax refund treatment is conducted on the Mo element, the production cost is effectively reduced, and the product anti-acid corrosion resistance requirements are met.

Owner:NANJING IRON & STEEL CO LTD

Economical 900MPa-grade ultrahigh-strength quenched and tempered steel plate and production method thereof

InactiveCN110952020AImprove low temperature impact toughnessImprove tensile propertiesFurnace typesHeat treatment furnacesHeating timeHeating furnace

The invention relates to an economical 900MPa-grade ultrahigh-strength quenched and tempered steel plate. The steel plate comprises the following chemical components in percentage by mass: 0.155-0.175% of C, 0.10-0.30% of Si; 1.20-1.40% of Mn, less than or equal to 0.013% of P, less than or equal to 0.003% of S, 0.020-0.030% of Nb, 0.010-0.020% of Ti, 0.20-0.40% of Cr, 0.30-0.40% of Mo, 0.0010-0.0020% of B, 0.015-0.050% of Als, and the balance of Fe and other inevitable impurities. The invention further relates to a production method of the economical 900MPa-grade ultrahigh-strength quenched and tempered steel plate. In the heating process, a continuous casting billet is heated in a heating furnace, a high-temperature rolling and heating process is adopted, it is ensured that all alloy elements are completely dissolved, the temperature of a heating section is 1230-1270 DEG C, the temperature of a soaking section is 1210-1250 DEG C, and the total heating time coefficient is 9-10 min / cm.By optimizing the component design and improving the process, the 900MPa-grade ultrahigh-strength quenched and tempered steel plate which is excellent in strength and toughness, uniform in internal structure, good in welding performance and low in cost is produced.

Owner:HANDAN IRON & STEEL GROUP +1

Seamless steel pipe for ship and preparing method of seamless steel pipe

InactiveCN105546228AGood mechanical propertiesImprove corrosion resistanceRigid pipesMicrometerSurface roughness

The invention relates to the technical field of seamless steel pipes, in particular to a seamless steel pipe for a ship and a preparing method of the seamless steel pipe. Chemical components of the seamless steel pipe comprise, by weight percentage, 0.12% to 0.2% of C, 0.18% to 0.32% of Si, 1.18% to 1.8% of Mn, 0.2% to 0.4% of Mo, 11.6% to 12.2% of Cr, 0.2% to 0.3% of Ti, 0.45% to 0.58% of V, 0.32% to 0.48% of Re, 0.02% to 0.05% of Al, 0.0008% to 0.018% of B, 0.008% to 0.01% of N, not larger than 0.02% of P, not larger than 0.02% of S, not larger than 0.003% of O and the balance Fe and inevitable impurities. The sum of mass percentages of all components is 100; the steel pipe tensile strength of the seamless steel pipe is larger than or equal to 900 Mpa, the steel pipe elongation is larger than or equal to 10%, the inner and outer surface roughness is smaller than or equal to 0.4 micrometer, and the requirements of the steel pipe special for the ship on strength, toughness and surface quality are met; and the experiment shows that compared with a conventional seamless steel pipe, the seamless steel pipe for the ship has the beneficial effects that the production efficiency is improved, and the production cost is reduced.

Owner:ZHEJIANG OCEAN UNIV

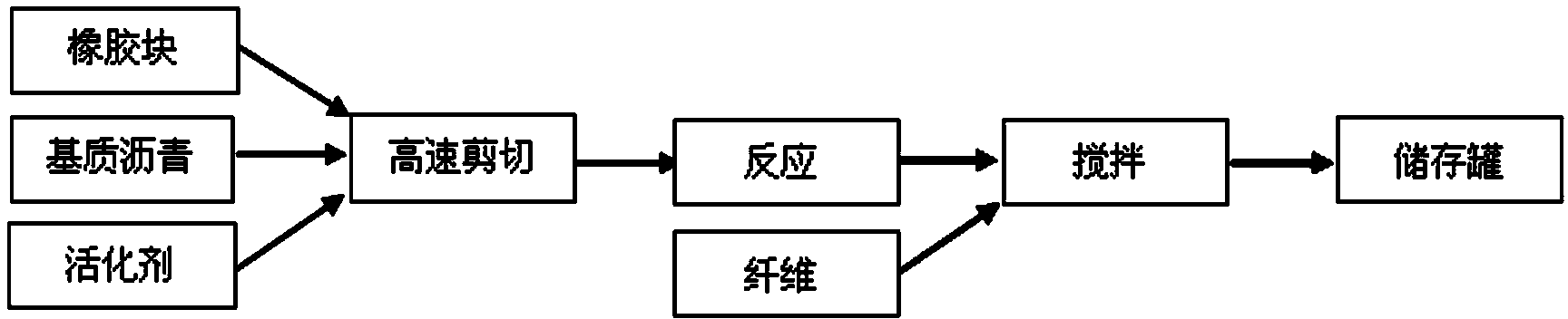

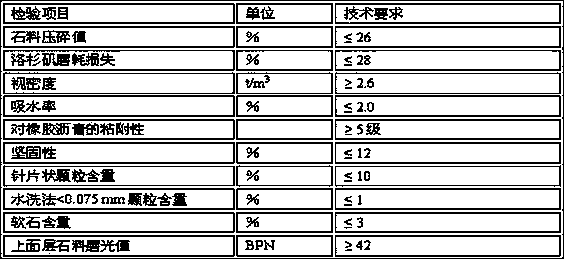

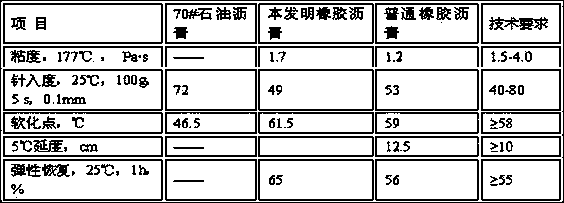

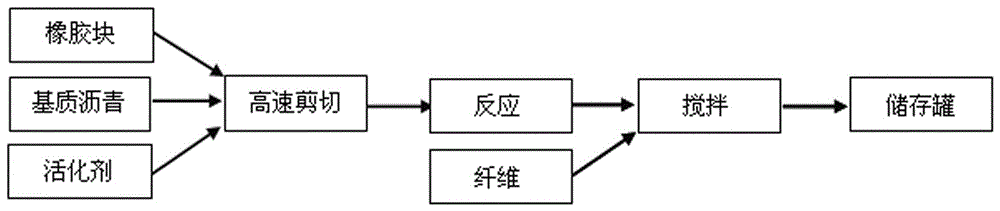

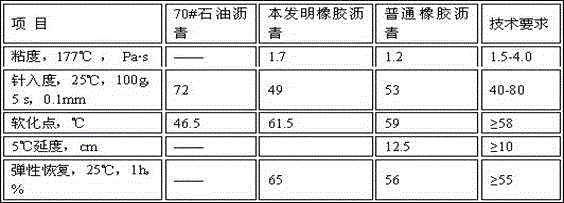

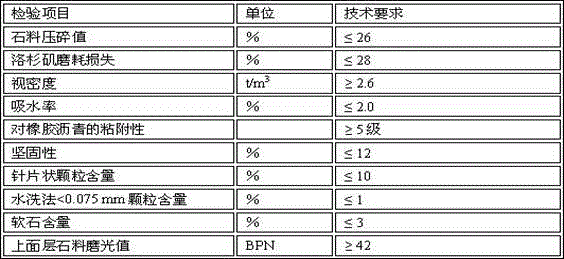

Large-grain-diameter rubber block-modified asphalt mastic and gravel sealing layer and preparation method thereof

The invention discloses a large-grain-diameter rubber block-modified asphalt mastic and gravel sealing layer and a preparation method thereof, and relates to a pavement structure layer consisting of large-grain-diameter rubber block-modified asphalt and fiber together with single-grain-diameter gravels, and a preparation method thereof. The large-grain-diameter rubber block-modified asphalt mastic and gravel sealing layer consists of aggregate, fiber and rubber block-modified asphalt. The preparation method comprises the following steps: 1) sweeping, blowing dust and cleaning an underlayer; 2) preparing the rubber block-modified asphalt; 3) preparing the rubber block-modified asphalt mastic; 4) before sprinkling the rubber asphalt mastic, inspecting various indexes; 5) sprinkling the rubber block-modified asphalt mastic; 6) scattering and paving the gravels; 7) performing rolling compaction; 8) sweeping the large-grain-diameter rubber block-modified asphalt mastic and gravel sealing layer. The large-grain-diameter rubber block-modified asphalt mastic and gravel sealing layer is low in production cost, low in energy consumption, free of pollution and high in storage stability. The preparation method is convenient in construction, simple and feasible, and can be easily applied to industrial production.

Owner:NANJING TONGAN ROAD ENG +2

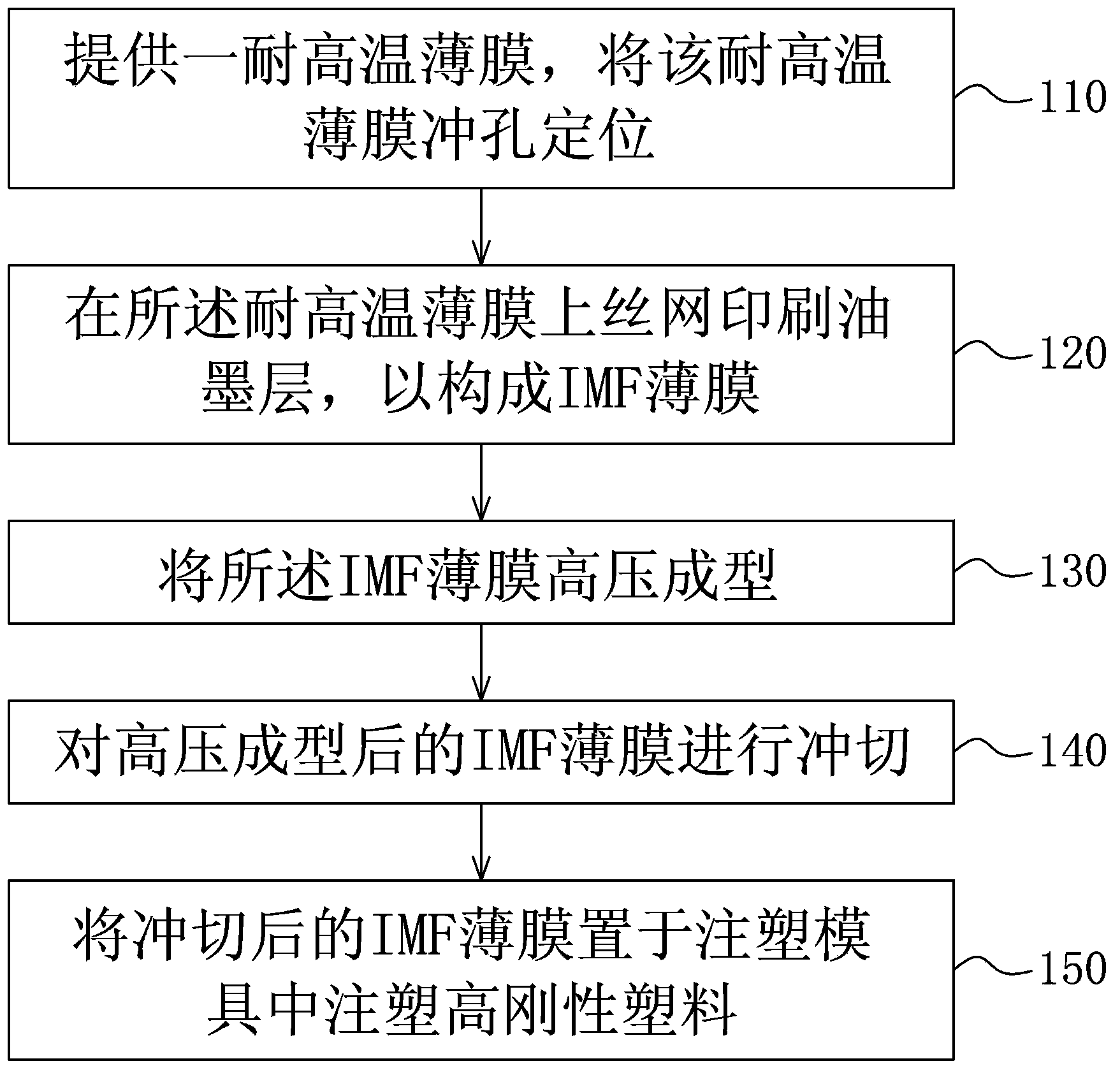

Plastic housing manufacturing method and product thereof

InactiveCN104057576AGuaranteed hardnessGuarantee that the product has hardnessCoatingsScreen printingPrinting ink

A plastic housing manufacturing method and a product thereof. The method comprises the following steps: (1) providing a high temperature resistant film, performing punching positioning of the high temperature resistant film; (2) performing silk-screen printing of a printing ink layer on the high temperature resistant film to form an IMF film; (3) performing high-pressure molding of the IMF film; (4) punching the IMF film after high-pressure molding; (5) putting the punched IMF film in an injection mold, performing injection molding of high-rigidity plastics, and allowing the IMF film to be subjected to transfer printing to the surface of the high-rigidity plastic product during injection molding. The plastic housing product is a product manufactured by the plastic housing manufacturing method.

Owner:MITAC PRECISION TECH(KUNSHAN) CORP

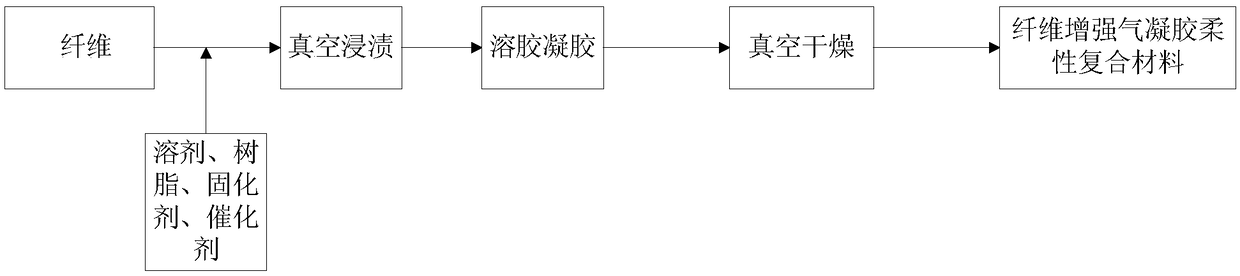

Fiber reinforced flexible aerogel composite material and preparation method thereof

InactiveCN109337380AStrong shape-dimensional abilityImprove machinabilityMaterials preparationResin-Based Composite

The invention relates to a fiber reinforced flexible aerogel composite material and a preparation method thereof, and belongs to the technical field of composite material preparation. According to thecomposite material, fiber-reinforced flexible aerogel which has the advantages of being high in strength, good in toughness, strong in shape retention ability and good in processing ability when being compared with existing resin-based composite materials is adopted, so that the problems that the traditional fiber-reinforced aerogel composite materials are limited in shaping size, poor in toughness and difficult to process are solved, and the application field of the fiber-reinforced aerogel is greatly expanded.

Owner:BEIJING SATELLITE MFG FACTORY

Alloy material and production process thereof

The invention discloses an alloy material and a production process thereof. According to the technical scheme, the alloy material comprises the following components including, by weight, 0.8-1.2% of Si, 0-0.5% of Fe, 0.15-0.6% of Cu, 0.2-0.8% of Mn, 0.6-0.1% of Mg, 0-0.1% of Cr, 0-0.25% of Zn, 0-0.1% of Ti and the balance Al, wherein the content of Si is 1.11%, and the content of Mn is 0.69%. Theproduction process of the alloy material comprises the following steps that (1) the components of raw materials are weighed according to mass percentages; (2) the raw materials are placed into a smelting furnace and smelted into alloy liquid, the alloy liquid temperature is made to reach 705-750 DEG C, and heat preservation is performed for 45-60 min; (3) the alloy liquid temperature is decreasedto 520-580 DEG C, a refining agent is added, the temperature is increased to 670-710 DEG C, and component testing is performed; and (4) the alloy liquid is subjected to standing and is cooled to 650-660 DEG C, mould filling is performed, and the alloy liquid is cooled into bars. According to the scheme provided by the invention, the tensile strength and the yield strength are high.

Owner:CHANGSHU SYNERGY AUTOMOBILE PARTS CO LTD

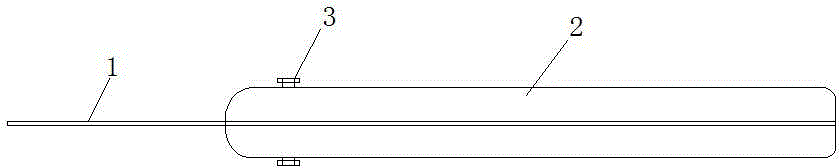

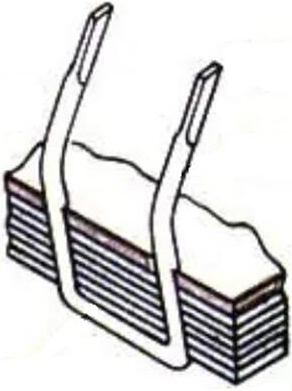

Special tool for cleaning special-shaped spinneret orifice

The invention discloses a special tool for cleaning a special-shaped spinneret orifice. The tool comprises a through needle (1) and an operation rod (2), wherein one end of the through needle (1) stretches into an end of the operation rod (2) and is fixed through a screw. The thickness of the through needle (1) is 0.06 mm, the width of the through needle is 0.12 mm, and the length of the through needle is 25 mm. The length of the operation rod (2) is 70 mm. The through needle (1) is a silver needle. When the tool is used, the yarn outlet face of a spinneret plate faces upwards, the operation rod is held by hand, the miniature through needle is lightly inserted into the spinneret orifice and moves upward, downward, frontward and backward, and therefore sundries attached to the inner wall of the spinneret orifice can be cleaned out.

Owner:扬州天富龙科技纤维有限公司

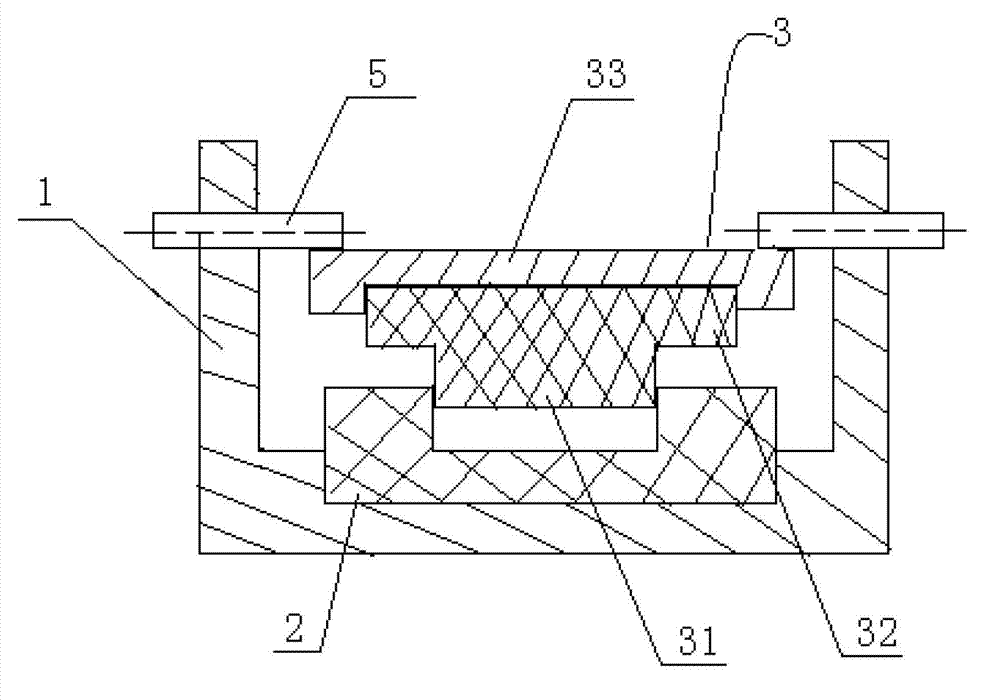

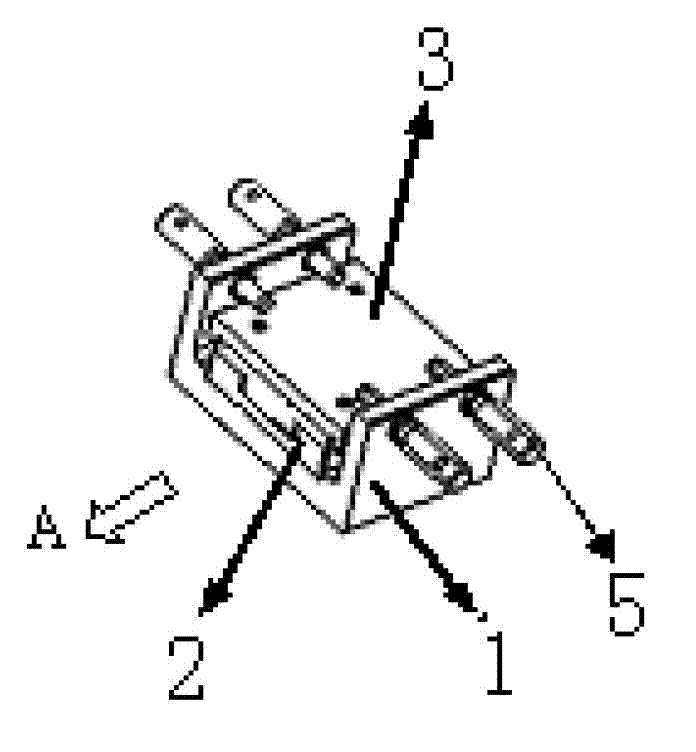

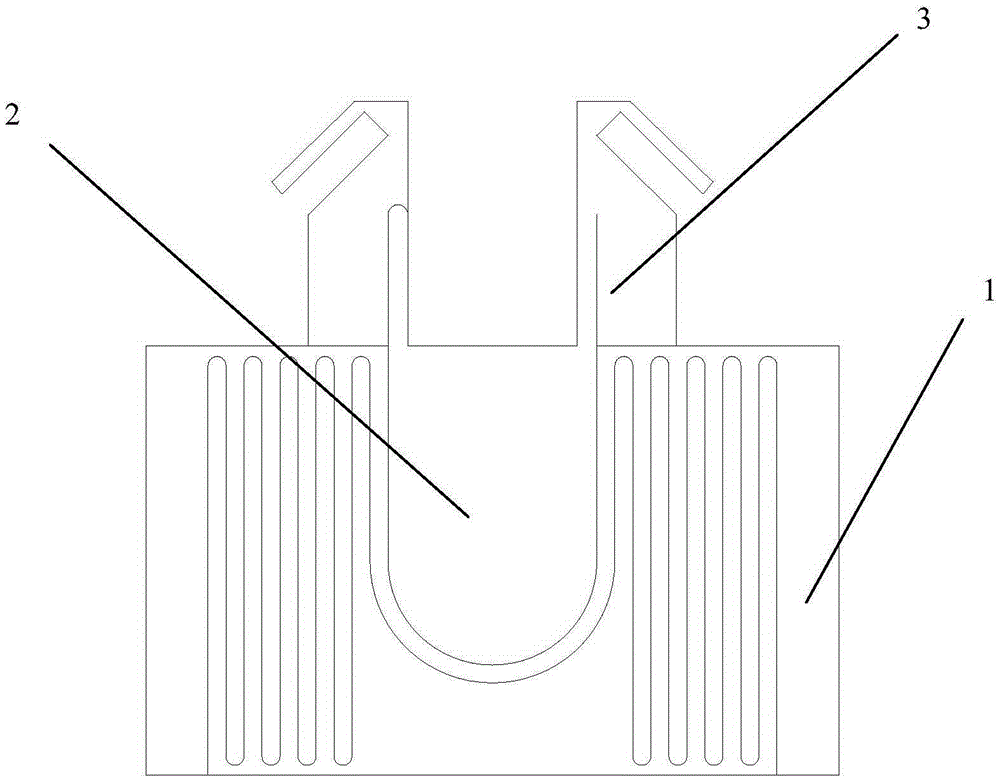

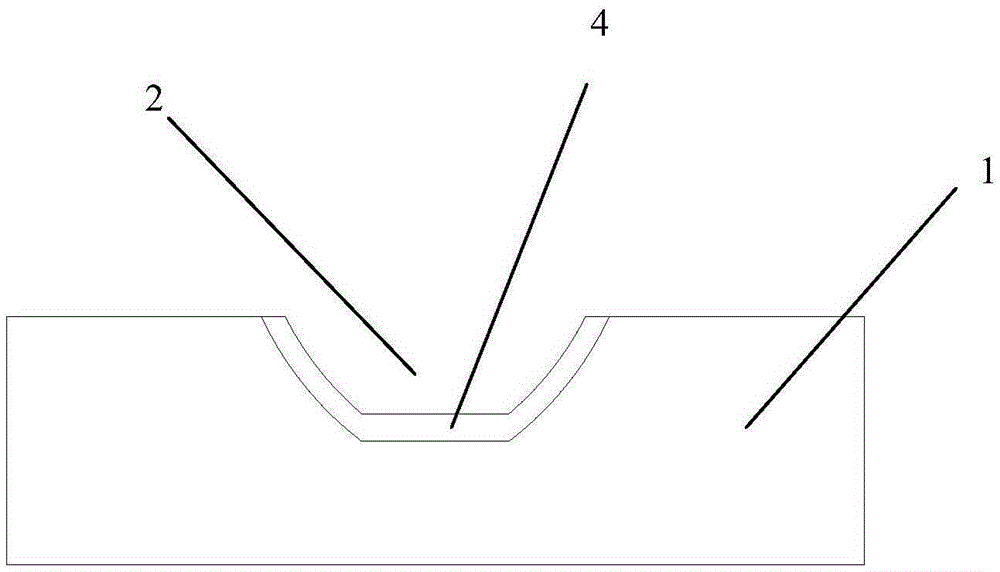

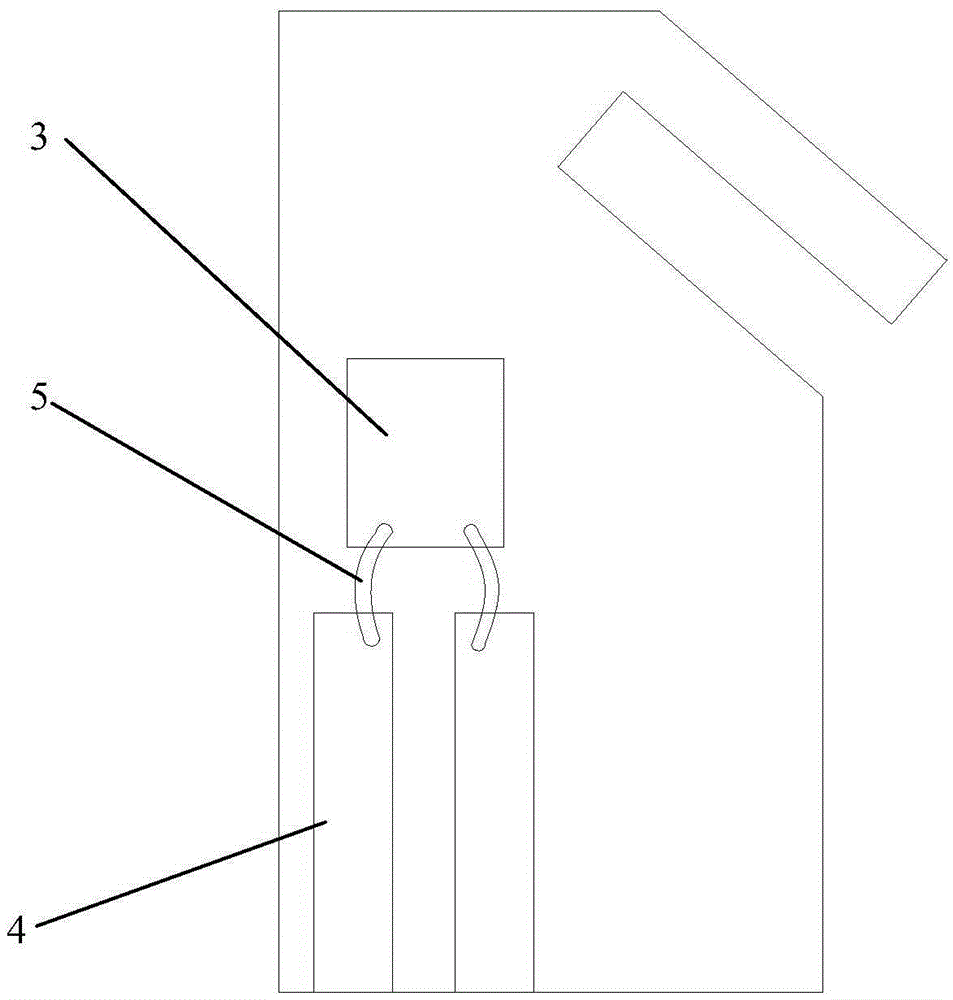

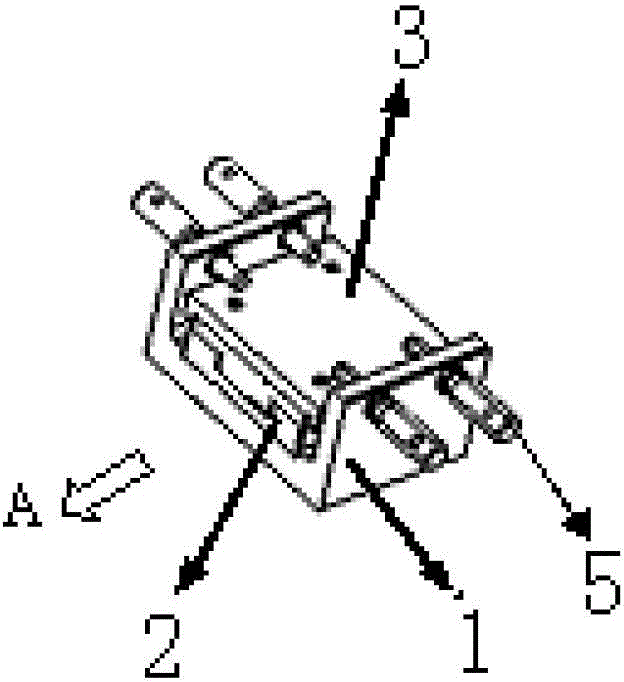

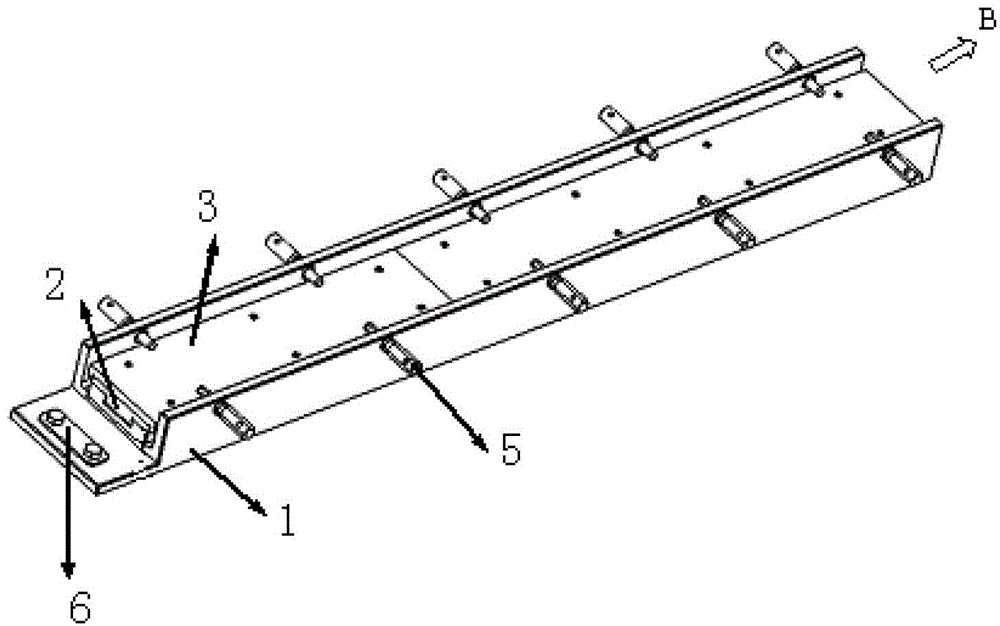

Cable three-dimensional forming method and cable three-dimensional forming device

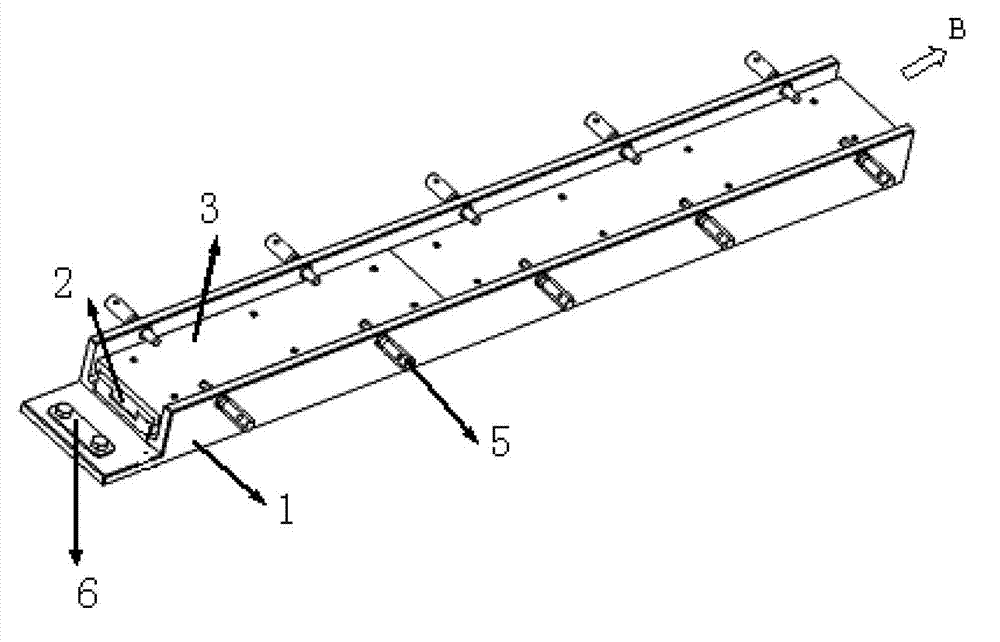

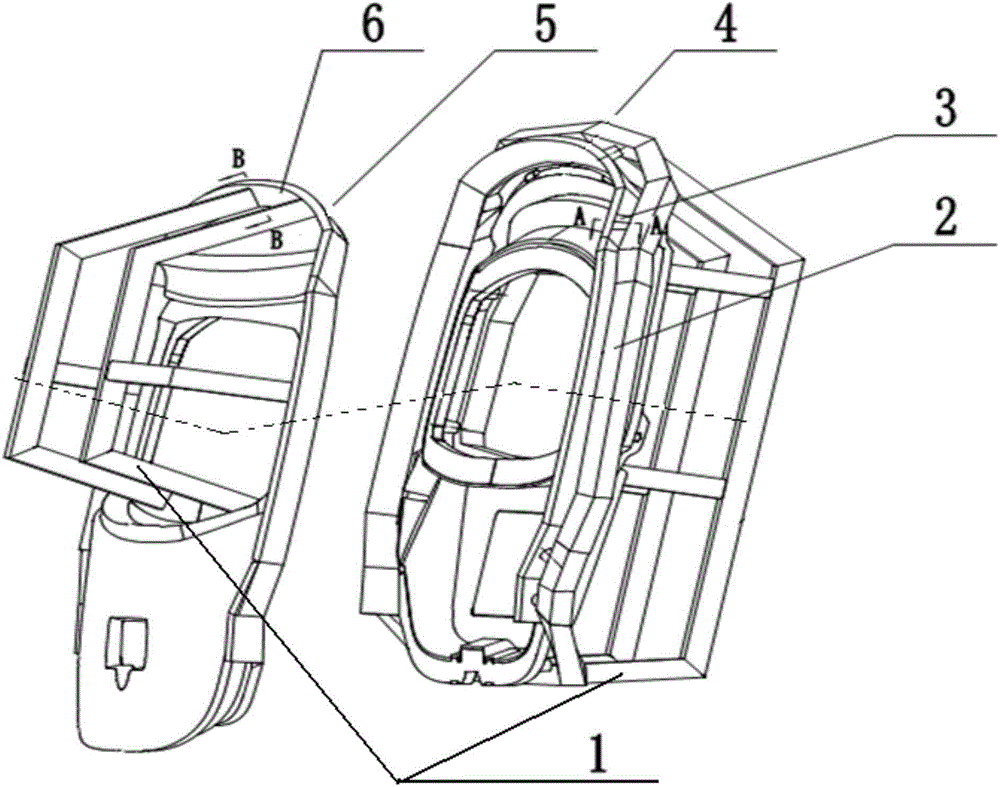

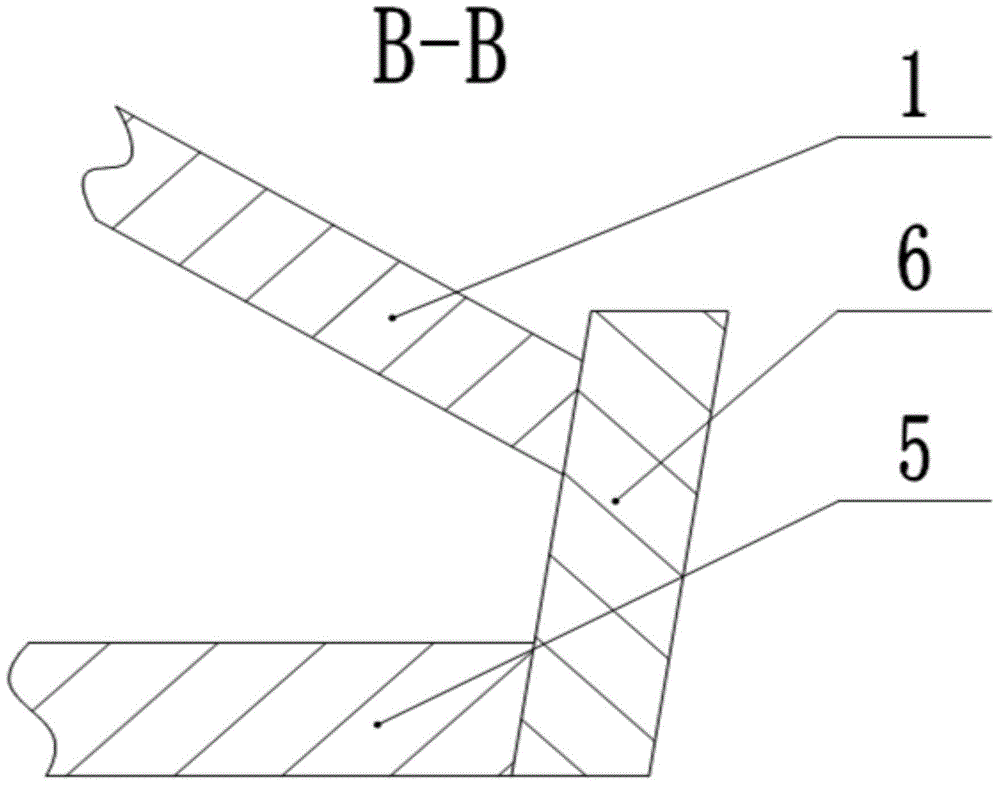

ActiveCN102904186AAssembly time savingFirmly assembledApparatus for joining/termination cablesEngineeringMechanical engineering

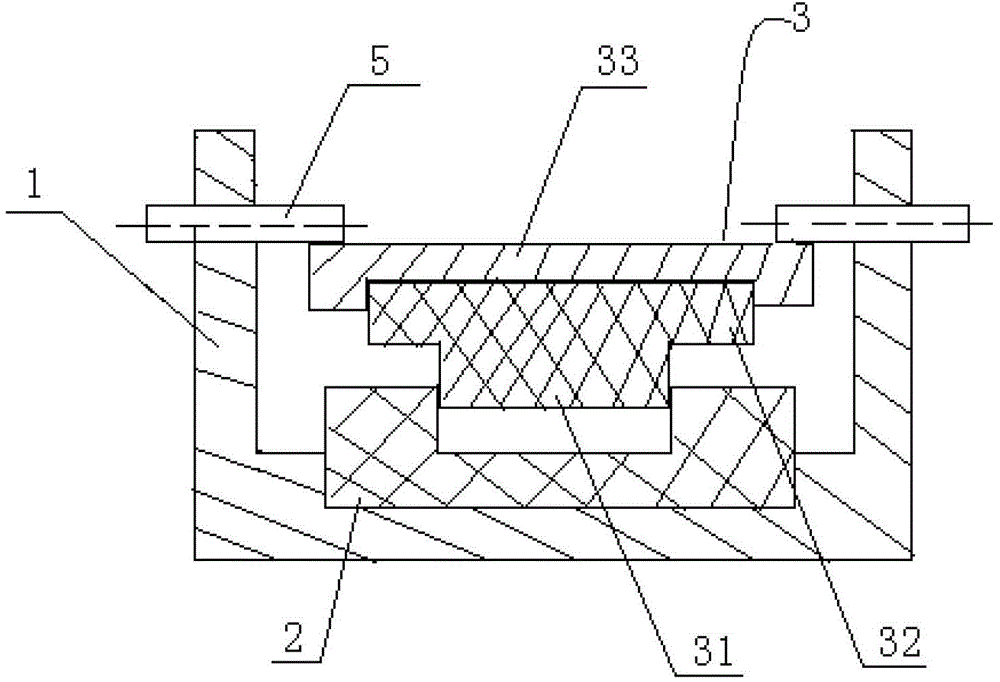

The invention discloses a cable three-dimensional forming method and a cable three-dimensional forming device. The method comprises the following steps of: 1, fixing the terminal of a wire bundle, coating a glue solution and curing; 2, carding the wire bundle so as to flatten the wire bundle; and 3, uniformly coating the glue solution on the to-be-cured part of the wire bundle so as to cure the wire bundle. The device comprises a base, a locating slot, a press plate, a locating hole and a locating pin, wherein the locating slot is fixed on the base; the press plate is arranged on the locating slot and can move in the locating slot; the locating hole is formed at the side face of the base and positioned above the press plate; the locating pin is matched with the locating hole; and the press plate is fixed by the locating pin. By utilizing the method and the device, flexible wires with multiple diameter specifications can be realized; by virtue of three-dimensional forming on the basis of the structural size and spatial shape of a cable slot, the wires are effectively protected from being damaged during the assembly process; and the cable is time-saving and reliable in assembly.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

Cereals alcohol-soluble protein conduit and preparation method thereof

ActiveCN101757692AGood mechanical propertiesImprove mechanical propertiesCatheterProsthesisProtein solutionBiocompatibility Testing

The invention relates to a cereals alcohol-soluble protein conduit and a preparation method thereof in the field of biomedical technology; the method comprises the following steps: cereals alcohol-soluble protein and organic solvents are mixed to obtain protein solution; after the protein solution is extracted by a mold, drying treatment is carried out and the protein pipe is demoulded from the mold; secondary extraction is carried out to the protein pipe, so as to form a nanoscale spherical structure surface outside, and then form fixation is carried out; finally, conducting polymer is deposited on the protein conduit surface, so as to prepare the conductive cereals alcohol-soluble protein conduit. In the invention, the cereals alcohol-soluble protein is used as raw materials, and the protein conduit has good biocompatibility and degradation, is suitable for preparing tissue engineering conduits and is helpful for regeneration and functional rehabilitation of damaged tubular shaped soft tissues.

Owner:SHANGHAI JIAO TONG UNIV

Integral molding method of plasticizing trunk lid of automobile

The invention relates to an integral molding method of a plasticizing trunk lid of an automobile, and belongs to the technical field of molding. The molding method comprises the following steps: cleaning the inner surface of a die, and coating the inner surface with a die releasing agent; adding raw materials for the plasticizing trunk lid of the automobile to the die, performing die assembly, locking the die so as to form a die cavity, and exerting 0.08-0.12MPa of pressure to the die cavity; mounting the die in a screw plastic molding machine which drives the die to rotate, rotating the die and shifting the rotating die to a heating furnace, and heating the shifted die until the raw materials in the die are heated to be melted and uniformly coated on the inner surface of the die cavity so as to form a trunk lid blank of the automobile; cooling the die, performing die sinking and die release, and taking out the blank after die release so as to obtain the trunk lid finished product of the automobile. The molding method performs an integral molding at a time in the die; the processing technology is simple and feasible; the production efficiency is high; and the production cost is low. The trunk lid is made from a fiber reinforcement modified material, so that the molding method meets the requirements for the strength and the toughness of the trunk lid, and achieves the purpose of light weight of the trunk.

Owner:NINGBO GMF TECH

Electronic tag inserting piece

InactiveCN105404919AEase of mass productionMeet fragileRecord carriers used with machinesMilling cutterFragility

The present invention provides an electronic tag inserting piece. The electronic tag inserting piece comprises a substrate, a chip and a connecting line, wherein an upper surface of the substrate is provided with an inner groove, a surface of the inner groove is provided with a conductive layer, and the chip is disposed on the substrate and is connected to the conductive layer on the surface of the inner groove via the connecting line. The substrate of the electronic tag inserting piece is manufactured by a splicing method of injection molding and is detected; the conductive layer of the electronic tag inserting piece is an aluminum layer; and after plating a film on the substrate of the electronic tag inserting piec, removing the conductive layer, such as the aluminium layer, on the upper surface of the substrate, and leaving the conductive layer on the inner grove as an antenna. According to the texture and composition of the substrate, the tag inserting piece can easily meet various requirements, such as fragility, high temperature resistance, high tenacity, high strength and the like; batch production of tags can be easily achieved; and not only performance of the tags can be guaranteed, but also techniques such as PCB production, milling cutter cutting, etching and the like are not required, thereby simplifying the technique process.

Owner:天津市盘石纳新科技股份有限公司

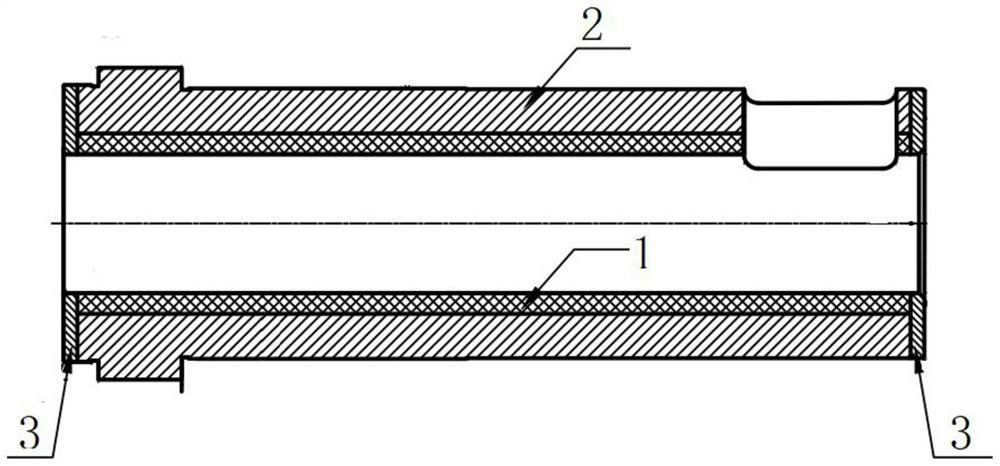

Production process of high-temperature structural ceramic/metal composite material tube for aluminum alloy die casting machine

ActiveCN113649772AExtended service lifeSimple production processFurnace typesHeat treatment furnacesDie castingCeramic metal

The invention relates to a production process of a high-temperature structural ceramic / metal composite material tube for an aluminum alloy die casting machine. The composite material tube comprises a ceramic lining, a metal jacket and an end cover. The production process of the composite material tube comprises the steps of machining the ceramic lining, machining the metal jacket and the end cover, and assembling and matching the ceramic lining, the metal jacket and the end cover. A ceramic lining machining process comprises the steps of raw material preparation, grinding and pulping, workpiece forming, green body drying, high-temperature firing and inner and outer circle machining. A metal jacket and end cover machining process comprises the steps of metal tube and end cover cutting and blanking, metal tube and end cover inner and outer circle rough machining, heat treatment and metal tube and end cover inner and outer circle finish machining. A ceramic lining, metal jacket and end cover assembling and matching process includes the steps of measurement inspection, combined assembly and thermal adaptation testing. A metal tube and a ceramic tube are compounded, so that the alloy melt corrosion resistance and the wear resistance of the material tube are greatly improved, and the service life is long; the composite material tube is low in heat conductivity coefficient, and energy consumption is reduced; and strength and toughness are good, the manufacturing cost is low, and production period is short.

Owner:江苏三条鱼新材料科技有限公司 +1

3D printing metal powder for dental fixed-removable restoration and preparation method thereof

InactiveCN111054915AMeet the fixedFulfil requirementsAdditive manufacturing apparatusIncreasing energy efficiency3d printSelective laser melting

The invention discloses 3D printing metal powder for dental fixed-removable restoration and a preparation method thereof. The 3D printing metal powder for dental fixed-removable restoration comprises,by mass, 20-30% of Cr, 1-5% of Mo, 5-10% of W, less than or equal to 1% of Fe, less than or equal to 1% of Mn, less than or equal to 2% of Si, less than or equal to 0.1% of Ni, less than or equal to1% of C, less than or equal to 0.1% of Be, less than or equal to 0.1% of Cd, and Co as a matrix. The preparation method of the 3D printing metal powder for dental fixed-removable restoration comprisesthe specific steps of (1) conducting smelting, specifically, mixing prepared chemical components, preparing a master alloy ingot through vacuum induction smelting and cutting off the shrinkage cavitydefect at the head; and conducting homogenizing heat treatment on the master alloy ingot through a vacuum heat treatment furnace; (2) conducting atomization pulverizing; (3) conducting screening to obtain spherical alloy powder; (4) conducting selective laser melting forming; and (5) conducting heat treatment. Through the 3D printing metal powder for dental fixed-removable restoration and the preparation method thereof, the requirements for properties of a fixed-removable restoration body can be met.

Owner:NANTONG JINYUAN INTELLIGENT TECH CO LTD

Inorganic aggregate polyurethane millstone floor as well as preparation method and application thereof

PendingCN114319779ADoes not affect product qualityImprove physicsPolyurea/polyurethane coatingsFlooringPolymer sciencePolyol

The invention discloses an inorganic aggregate polyurethane millstone floor as well as a preparation method and application thereof. The millstone floor sequentially comprises a polyurethane substrate layer, an inorganic aggregate polyurethane millstone layer and a polyurethane transparent surface layer from inside to outside, the inorganic aggregate polyurethane millstone layer is formed by paving a polyol polyurethane self-leveling coating, a diisocyanate curing agent and an inorganic aggregate according to the mass ratio of 1: 1.25: 6, and the inorganic aggregate is selected from recycled glass, marble powder or stone with regular shapes. The polyol polyurethane self-leveling coating is composed of polyol polyurethane resin and a functional aid in a mass ratio of 19: 1. The inorganic aggregate polyurethane millstone terrace belongs to a noise reduction terrace system which is soundproof, seamless and ergonomic, is attractive and comfortable in visual effect, meets the use requirements of high strength, toughness and difficulty in cracking, is convenient to construct and maintain in the later period, is environment-friendly and safe, and can be applied to the ground of public places such as exhibition halls, medical treatment, education, office, entertainment or retail.

Owner:SHANGHAI YANHUANG ENVIRONMENTAL TECH CO LTD

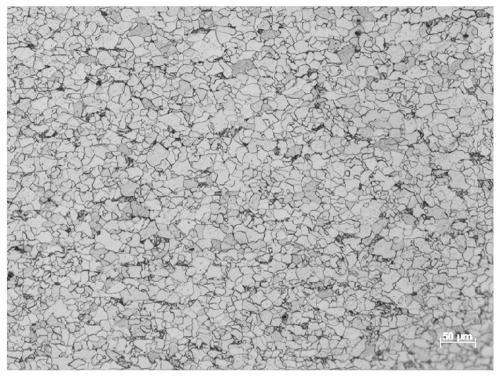

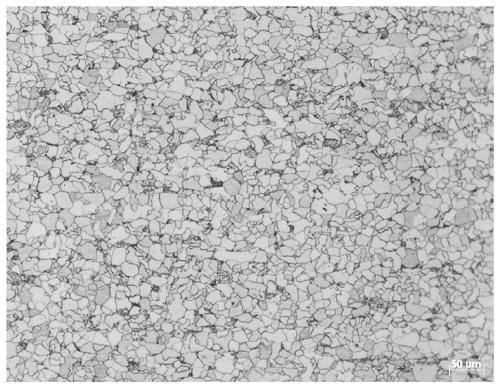

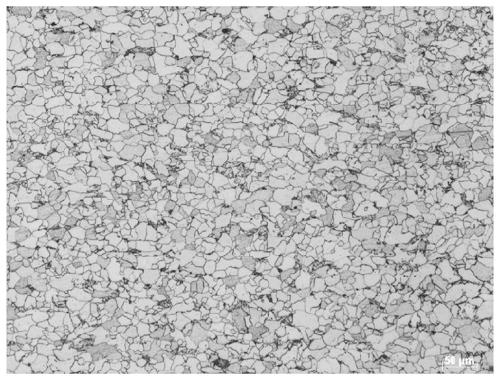

355MPa-grade maritime work steel plate for polar region and preparation method of 355MPa-grade maritime work steel plate

PendingCN114836607AMeet performance needsFine grainTemperature control deviceFurnace typesSlow coolingUltimate tensile strength

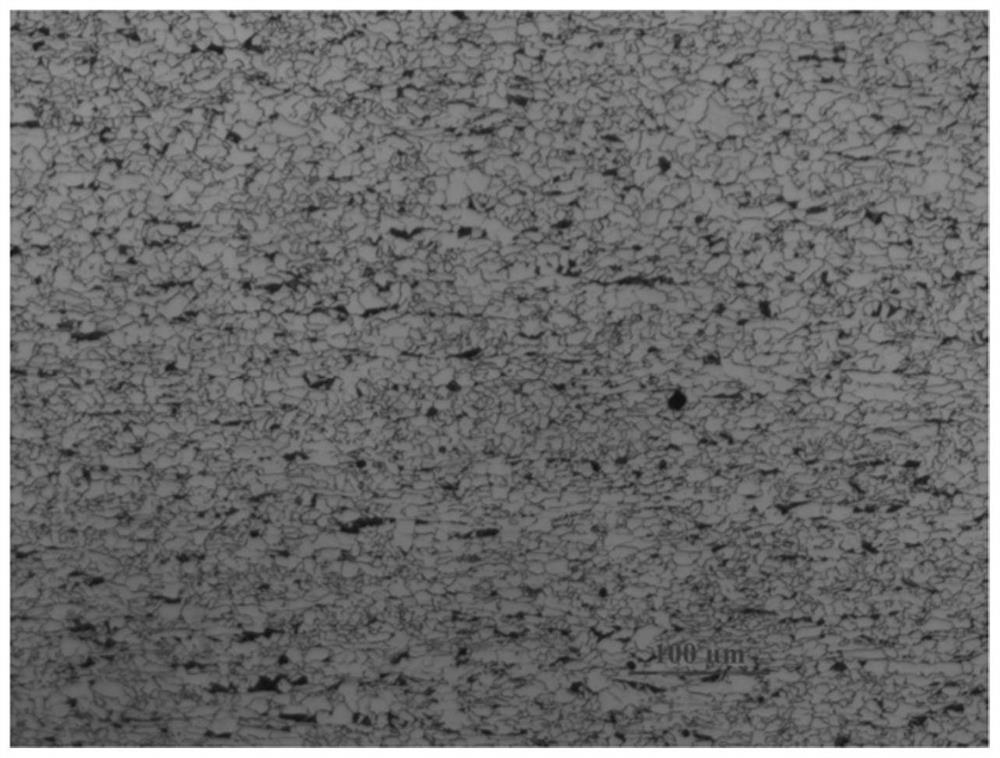

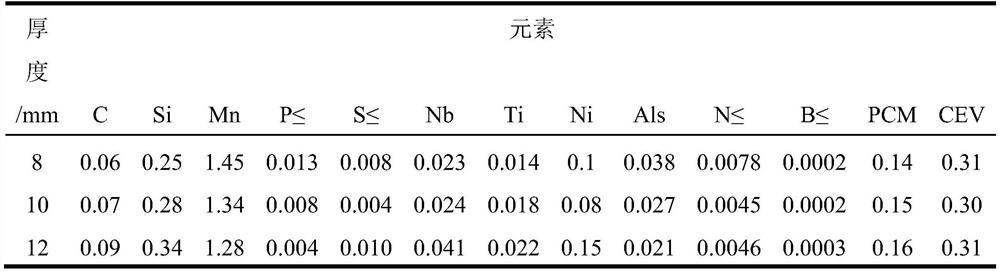

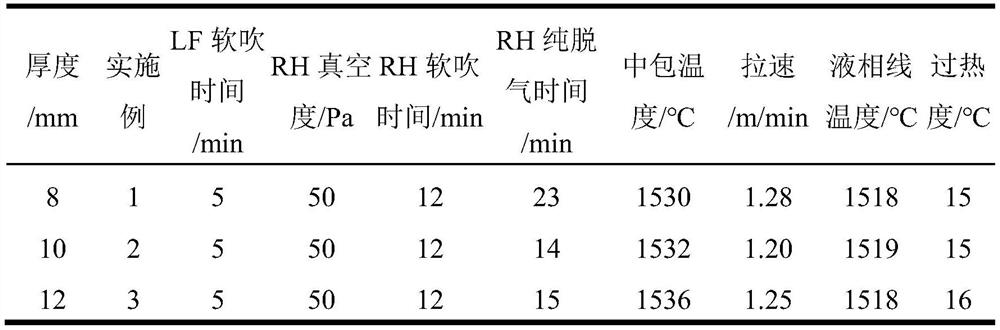

The invention discloses a 355MPa-grade maritime work steel plate for a polar region and a preparation method of the 355MPa-grade maritime work steel plate, and belongs to the technical field of microalloyed steel production, and the 355MPa-grade maritime work steel plate comprises the following components in percentage by mass: 0.06 to 0.014 percent of C, 0.20 to 0.50 percent of Si, 1.20 to 1.60 percent of Mn, 0.020 to 0.050 percent of Nb, 0.010 to 0.050 percent of Ti, 0.07 to 0.20 percent of Ni, 0.010 to 0.050 percent of Als, less than or equal to 0.025 percent of P and less than or equal to 0.020 percent of S. The preparation method of the steel plate comprises the steps of molten iron pretreatment, converter or electric furnace smelting, refining, continuous casting, casting blank cleaning and slow cooling. And heating the slowly cooled blank in a furnace, rolling, air-cooling the steel plate, and carrying out flaw detection to obtain the qualified steel plate. The microstructure of the obtained 355MPa-grade maritime work steel plate is ferrite and pearlite, grains are fine and uniform, the grain size is about 10 grades, the yield strength reaches 400-480MPa, the tensile strength reaches 480-530MPa, the percentage elongation after fracture reaches 25-35%, the impact energy at the temperature of-40 DEG C is larger than or equal to 160J, the impact energy at the temperature of-52 DEG C is larger than or equal to 100J, and the requirements of project construction such as oil and gas exploitation and ocean engineering in extremely cold areas for the performance of the steel plate are met.

Owner:LAIWU STEEL YINSHAN SECTION CO LTD

Tearable film thermoplastic acrylic resin and preparation method thereof

The invention belongs to the field of special films, and discloses a tearable film thermoplastic acrylic resin, which is prepared by carrying out a radical polymerization reaction on the following components by weight: 24-30% of a soft monomer, 10-15% of methyl methacrylate, 5-10% of styrene, 3-5% of C12-C18 alkyl methacrylate, 0.5-1.5% of an organosilicon monomer, and the balance of a solvent. According to the present invention, the resin exhibits excellent easy-peeling property at both high and low temperatures, and does not use a plasticizer, such that the problem of after tackiness of theresin at a high temperature is solved.

Owner:GUANGDONG RITOP FINE CHEM

Method and device for three-dimensional forming of cables

ActiveCN102904186BAssembly time savingFirmly assembledApparatus for joining/termination cablesEngineeringMechanical engineering

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

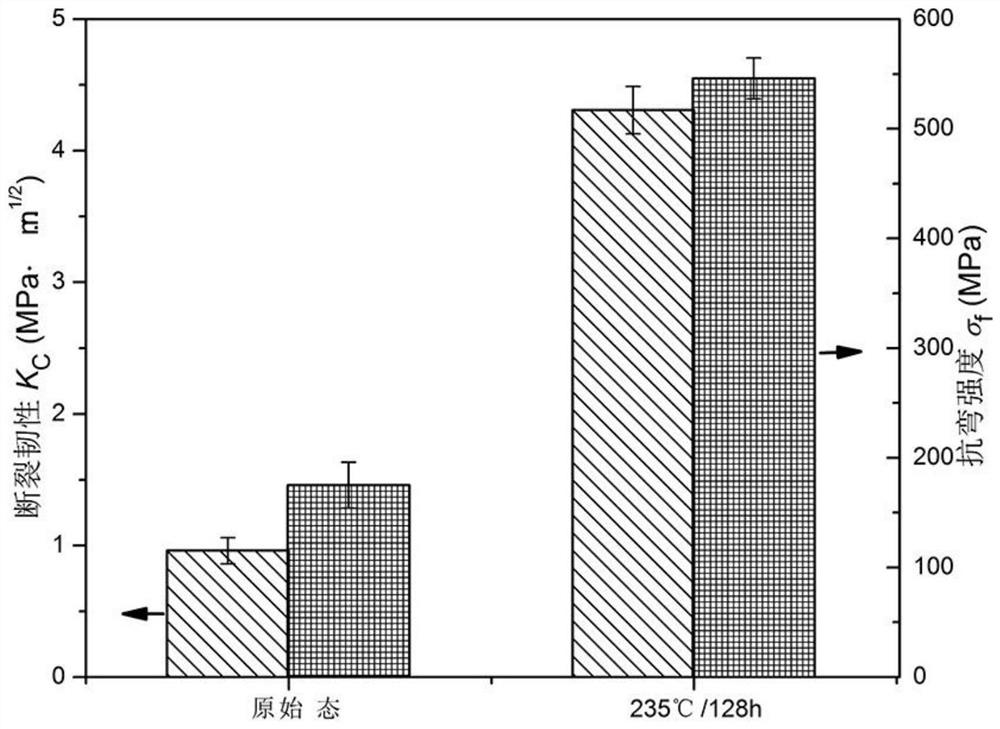

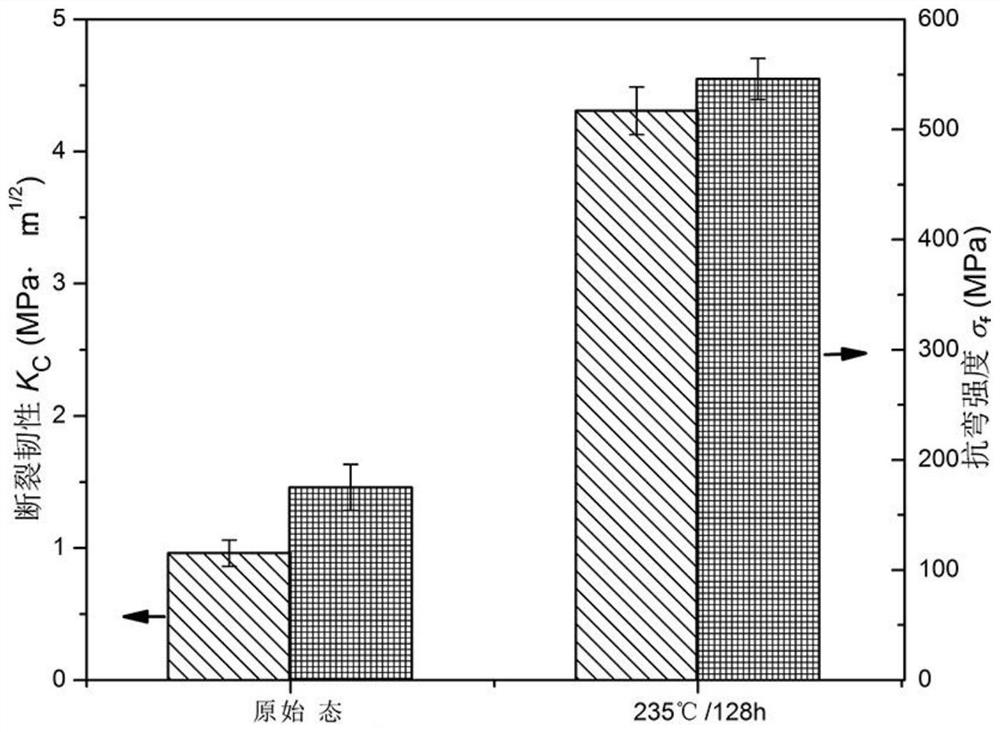

Method for strengthening and toughening lithium disilicate glass ceramic and activating surface of lithium disilicate glass ceramic by utilizing ion exchange

The invention discloses a method for strengthening and toughening lithium disilicate glass ceramic and activating the surface of the lithium disilicate glass ceramic by utilizing ion exchange. The method comprises the steps of 1, preparing mixed salt of NaNO3 and KNO3; 2, heating and melting to a liquid state to obtain mixed bath salt; 3, cooling along with the furnace, keeping the constant temperature, and immersing into lithium disilicate glass ceramic for ion exchange treatment; and 4, conducting ultrasonic cleaning after washing, and obtaining the toughened and surface-activated lithium disilicate glass ceramic. By adopting ion exchange treatment, Li < + > on the lithium disilicate glass ceramic surface layer and Na < + > in the mixed bath salt are exchanged due to chemical potential difference to generate residual compressive stress, so that the strengthening and toughening effect is realized, and the mechanical property is improved. Meanwhile, the composition and energy state of the lithium disilicate glass ceramic surface layer are changed, the exchanged Na < + > has a greater dissolution tendency in biological fluid, the surface activation effect on the lithium disilicate glass ceramic is realized, and the lithium disilicate glass ceramic has a wide application prospect in the field of bone repair.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

High-light-transmittance fabric and preparation method thereof

The invention discloses a high-light-transmittance fabric and a preparation method thereof. The high-light-transmittance fabric comprises modified fibers and a conditioner. The removal of polyvinylpyrrolidone enables a plurality of micropores to be formed in a fiber body, the formation of the micropores increases the specific surface area of the fiber material, restrains a large amount of air, and enhances the hydrophobic performance of the polyester fiber while transmitting light, so that the fabric is always kept in a dry and comfortable state, and the fabric is more convenient to clean. Intermolecular hydrogen bonds with relatively strong binding force can be formed between free hydroxyl groups and the polyester fibers and are combined with adjacent polyester fibers, and a hydrogen bond grid structure with high toughness is formed between the fibers, so that the mechanical strength of the pretreated polyester fibers is enhanced; and the catalytic action of a platinum-carbon mixture enables electrons in polyacrylamide molecules to gather with carbon atoms as the center, active sites on the polyacrylamide molecules are increased, the binding force between fibers is enhanced, the fabric keeps certain stability, and later deformation of the fabric is prevented.

Owner:张云

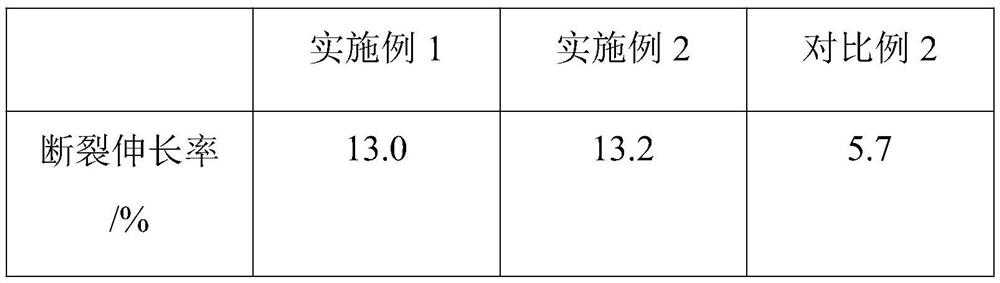

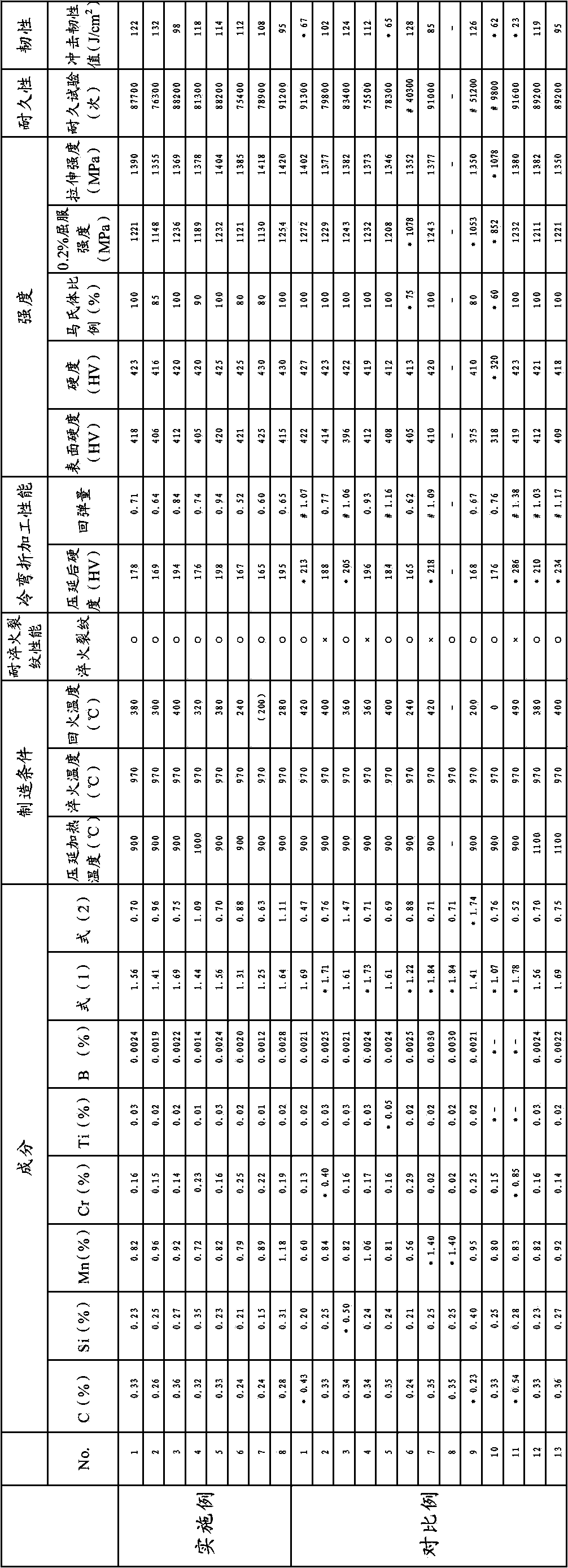

Solid stabilizer, steel material for solid stabilizer and method for producing solid stabilizer

InactiveCN102782172BMaintain quenching propertiesMaintain quenching crack resistanceFurnace typesInterconnection systemsTemperingCrack resistance

A steel material for a solid stabilizer which has high bendability, high hardenability, and high quenching crack resistance, a solid stabilizer having high strength, and a manufacturing method of the solid stabilizer. The steel material for the solid stabilizer contains, in mass %, 0.24 to 0.40% of C, 0.15 to 0.40% of Si, 0.50 to 1.20% of Mn, 0.03% or less of P, 0.30% or less of Cr, 0.01 to 0.03% of Ti, and 0.0010 to 0.0030% of B. The steel material for the solid stabilizer satisfies a condition of formula (1) below. Hardness in a radial center portion of the steel material for the solid stabilizer after tempering is 400 HV or more, and a martensite ratio in the radial center portion after the tempering is 80% or more. 1.24<(2C+0.1Si+0.4Mn+0.4Cr)×{1+(1.5B−300B2)×240}<1.7 (1) It is an object to provide a steel material for a solid stabilizer which has high bendability, high hardenability, and high quenching crack resistance, a solid stabilizer having high strength, and a manufacturing method of the solid stabilizer. The steel material for the solid stabilizer contains, in mass %, 0.24 to 0.40% of C, 0.15 to 0.40% of Si, 0.50 to 1.20% of Mn, 0.03% or less of P, 0.30% or less of Cr, 0.01 to 0.03% of Ti, and 0.0010 to 0.0030% of B. The steel material for the solid stabilizer satisfies a condition of formula (1) below. Hardness in a radial center portion of the steel material for the solid stabilizer after tempering is 400 HV or more, and a martensite ratio in the radial center portion after the tempering is 80% or more. 1.24<(2C+0.1Si+0.4Mn+0.4Cr)×{1+(1.5B−300B2)×240}<1.7 (1)

Owner:AICHI STEEL +1

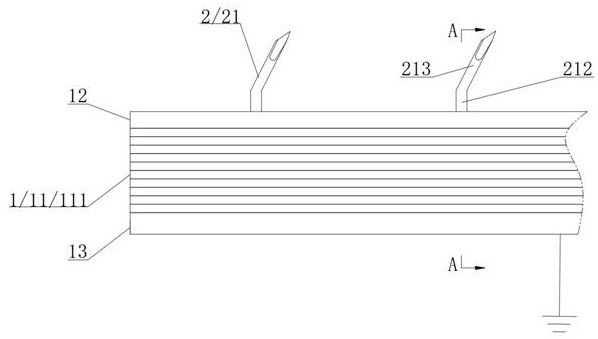

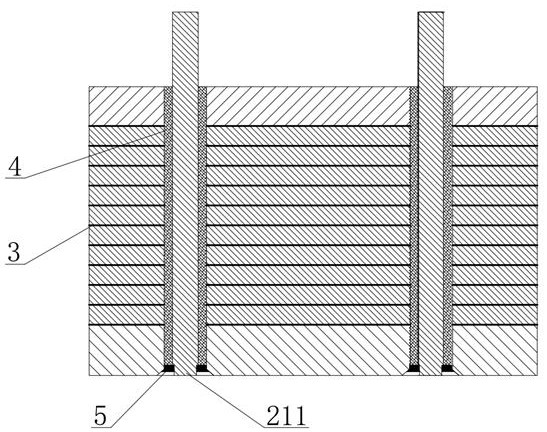

Anti-static high-holding-force elastic card clothing and forming process thereof

ActiveCN114836853AGood tensile propertiesResilientCarding machinesTextile/flexible product manufactureYarnMaterials science

The invention relates to anti-static high-holding-force elastic card clothing which comprises a plate-shaped base body and a carding assembly. The carding assembly is composed of a plurality of conductive metal card wires inserted into the plate-shaped base body in a matched mode. The plate-shaped base body comprises a fabric composite layer, an oil-resistant plate and a conductive metal plate. And the oil-resistant plate and the conductive metal plate are respectively glued on two sides of the fabric composite layer. And the conductive metal plate and the tail end of each conductive metal card wire are kept in an electric connection state. Thus, on one hand, it can be guaranteed that static charges gathered on the conductive metal card wires can be conducted out in time, and then the phenomenon that stripped fine yarn scraps are attached to the conductive metal card wires or fill installation gaps of the conductive metal card wires due to electrostatic induction is prevented; on the other hand, the oil-resistant plate and the conductive metal plate can synergistically play an auxiliary supporting role on the conductive metal card wires, and it is guaranteed that the conductive metal card wires are always kept in a correct posture in the yarn combing process. In addition, the invention further relates to a forming process for preparing the anti-static high-holding-force elastic card clothing.

Owner:金轮针布(江苏)有限公司

A kind of aluminum alloy material and its production process

Owner:ANHUI HENGXING DECORATION ENG CO LTD

A kind of large particle size rubber block modified asphalt mastic gravel seal layer and its preparation method

The invention discloses a large-grain-diameter rubber block-modified asphalt mastic and gravel sealing layer and a preparation method thereof, and relates to a pavement structure layer consisting of large-grain-diameter rubber block-modified asphalt and fiber together with single-grain-diameter gravels, and a preparation method thereof. The large-grain-diameter rubber block-modified asphalt mastic and gravel sealing layer consists of aggregate, fiber and rubber block-modified asphalt. The preparation method comprises the following steps: 1) sweeping, blowing dust and cleaning an underlayer; 2) preparing the rubber block-modified asphalt; 3) preparing the rubber block-modified asphalt mastic; 4) before sprinkling the rubber asphalt mastic, inspecting various indexes; 5) sprinkling the rubber block-modified asphalt mastic; 6) scattering and paving the gravels; 7) performing rolling compaction; 8) sweeping the large-grain-diameter rubber block-modified asphalt mastic and gravel sealing layer. The large-grain-diameter rubber block-modified asphalt mastic and gravel sealing layer is low in production cost, low in energy consumption, free of pollution and high in storage stability. The preparation method is convenient in construction, simple and feasible, and can be easily applied to industrial production.

Owner:NANJING TONGAN ROAD ENG +2

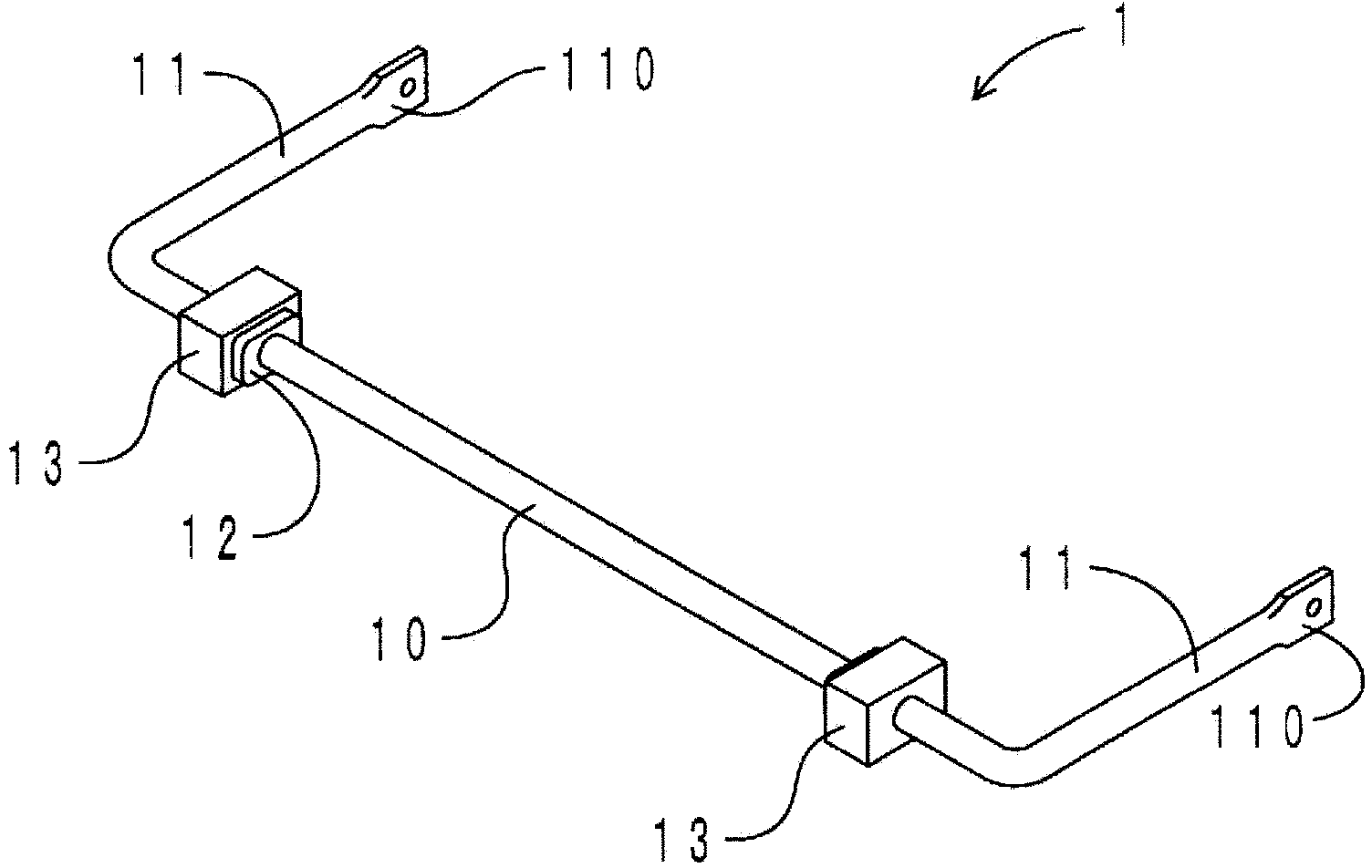

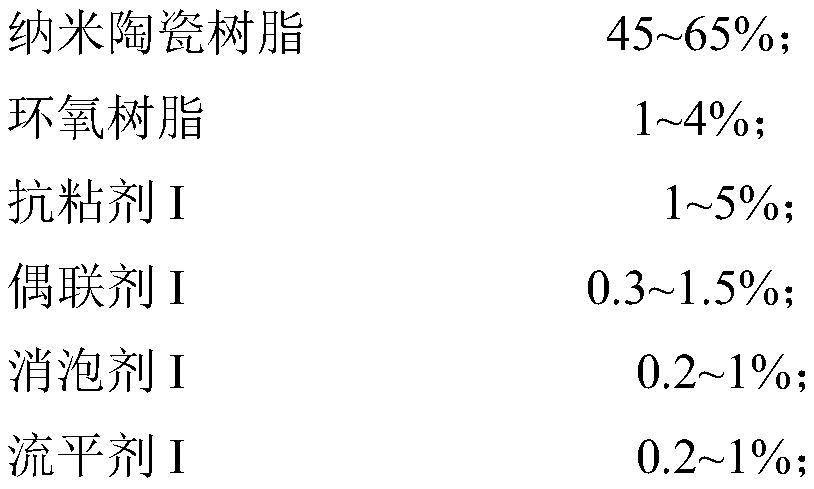

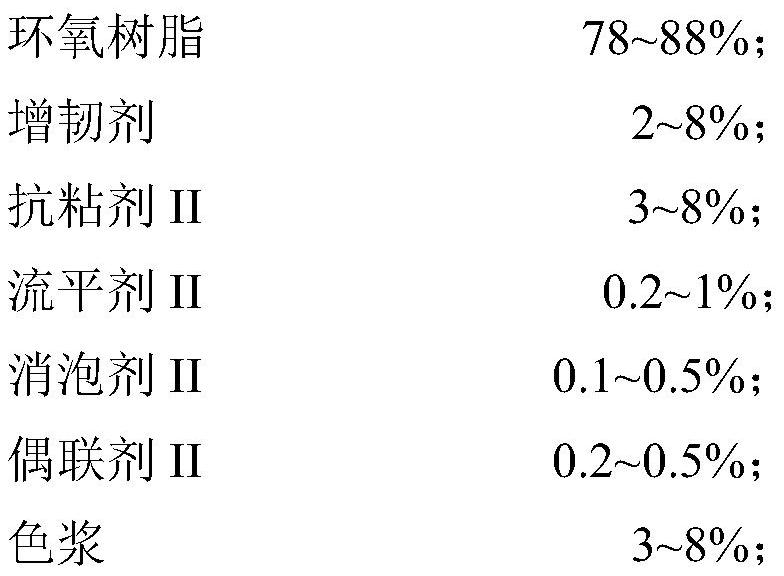

A kind of anti-graphite adsorption composite coil and its preparation method

ActiveCN110669404BMeet toughnessAdsorption wear-resistant and smoothAntifouling/underwater paintsSynthetic resin layered productsPolyesterGlass fiber

The invention discloses an anti-graphite adsorption composite roll material and a preparation method thereof. The anti-graphite adsorption composite roll material comprises a base layer of polyester fiber cloth, a fiber reinforcement layer, an anti-seepage layer and a nano-graphite-proof layer stacked in sequence from bottom to top ; The fiber-reinforced layer is formed by curing the anti-seepage and anti-adhesion coating coated on the polyester fiber cloth base layer and the glass fiber cloth placed on the anti-seepage and anti-adhesion coating; the anti-seepage layer is formed by curing the anti-seepage and anti-adhesion coating The coating is cured; the nano anti-graphite layer is formed by curing the nano anti-graphite coating, and the coating thickness is 10-30 μm. The present invention adopts nanometer anti-graphite coating and anti-seepage and anti-adhesion coating to prepare and obtain at least four-layer anti-graphite adsorption composite roll material having polyester fiber cloth base layer, fiber reinforced layer, anti-seepage layer and nano-anti-graphite layer. The surface hardness of the adsorption composite coil is above 7H. The surface is wear-resistant and smooth. It does not absorb graphite powder and can be removed by wiping with clean water. At the same time, it has the toughness that can satisfy the curling of the coil.

Owner:浙江港流高分子科技股份有限公司

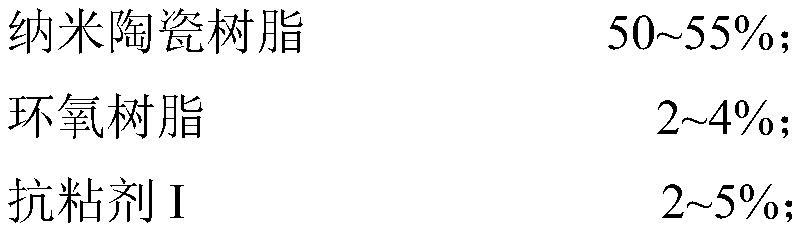

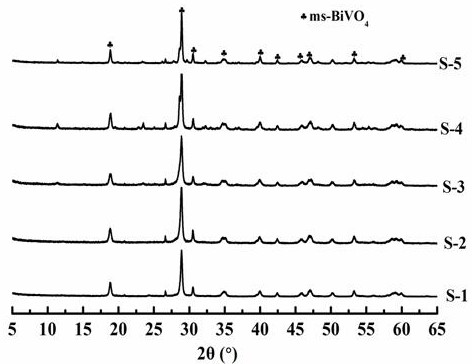

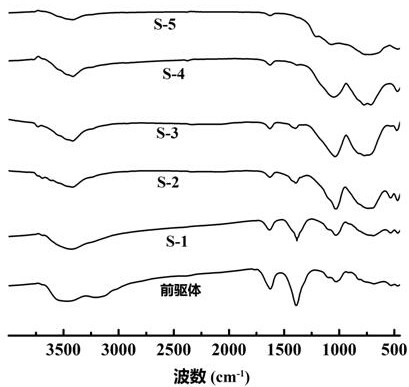

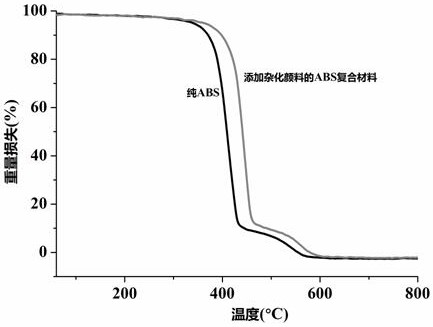

Method for preparing bismuth yellow hybrid pigment for polymer coloring and reinforcing from mixed-dimension attapulgite clay

PendingCN114381144ASolve productivitySolve the problem of high energy consumptionVanadium compoundsPigment treatment with organosilicon compoundsPolymer sciencePolymer chemistry

The invention provides a method for preparing a bismuth yellow hybrid pigment for polymer coloring and reinforcing by using mixed-dimension attapulgite clay, which comprises the following steps: adding the mixed-dimension attapulgite clay, a bismuth source and a vanadium source into a twin-screw extruder, extruding by using the twin-screw extruder without or after adding a molybdenum source to obtain a precursor, and crystallizing at a high temperature of 500-900 DEG C for 30-180 minutes to obtain the bismuth yellow hybrid pigment. The preparation method comprises the following steps: diluting a silane coupling agent with absolute ethyl alcohol, mixing the diluted silane coupling agent with the bismuth yellow hybrid pigment, and drying to constant weight, thereby obtaining the mixed-dimension attapulgite clay-based bismuth yellow hybrid pigment for polymer coloring and reinforcing. The mixed-dimension attapulgite clay-based bismuth yellow hybrid pigment is prepared by adopting a double-screw extruder, so that the technical problems of intermittent production and high energy consumption of a traditional solid-phase method are solved, and the defects of low yield, more wastes and complicated steps of a liquid-phase method are also avoided. The method disclosed by the invention is low in energy consumption, high in yield, green, clean, low in production cost and suitable for industrial continuous production.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com