Seamless steel pipe for ship and preparing method of seamless steel pipe

A technology for seamless steel pipes and ships. It is applied in the direction of pipes, rigid pipes, mechanical equipment, etc. It can solve the problems of reducing production efficiency, waste of raw materials, property losses, etc. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

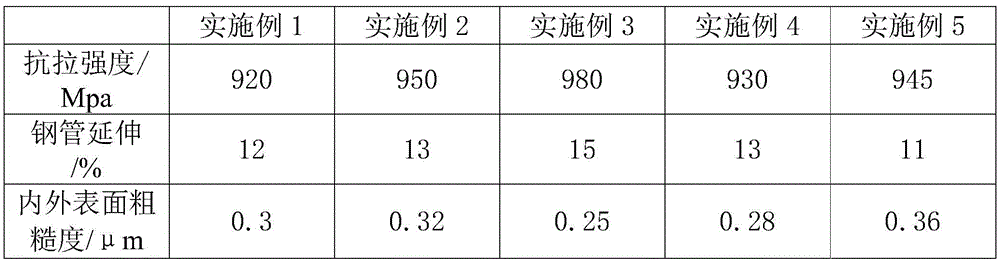

Examples

Embodiment 1

[0023] A seamless steel pipe for ships, the chemical composition of the seamless steel pipe is C: 0.12%, Si: 0.18%, Mn: 1.18%, Mo: 0.2%, Cr: 11.6%, Ti: 0.2% in weight percentage , V:0.45%, Re:0.32%, Al:0.02%, B:0.0008%, N:0.008%, P≤0.02%, S≤0.02%, O≤0.003%, the rest is Fe and unavoidable impurities, The total mass fraction of each component is 100%.

[0024] Preferably, the surface of the seamless steel pipe is sequentially coated with a first high-pressure resistant layer, a titanium nano-polymer alloy coating, and a modified epoxy ceramic coating layer from the inside to the position; the inner wall of the seamless steel pipe is coated with The second high-voltage resistant layer, the thickness of the first high-voltage resistant layer is 0.3mm, the thickness of the titanium nano-polymer alloy coating is 0.2mm, the thickness of the second high-voltage resistant layer is 0.4mm, and the modified The thickness of the permanent epoxy ceramic coating layer is 0.2mm.

[0025] Pr...

Embodiment 2

[0033] A seamless steel pipe for ships, the chemical composition of the seamless steel pipe is respectively C: 0.14%, Si: 0.22%, Mn: 1.24%, Mo: 0.24%, Cr: 11.8%, Ti: 0.24% according to weight percentage , V:0.46%, Re:0.35%, Al:0.025%, B:0.001%, N:0.009%, P≤0.02%, S≤0.02%, O≤0.003%, the rest is Fe and unavoidable impurities, The total mass fraction of each component is 100%.

[0034] Preferably, the surface of the seamless steel pipe is sequentially coated with a first high-pressure resistant layer, a titanium nano-polymer alloy coating, and a modified epoxy ceramic coating layer from the inside to the position; the inner wall of the seamless steel pipe is coated with The second high-voltage resistant layer, the thickness of the first high-voltage resistant layer is 0.4mm, the thickness of the titanium nano-polymer alloy coating is 0.25mm, the thickness of the second high-voltage resistant layer is 0.45mm, and the modified The thickness of the permanent epoxy ceramic coating l...

Embodiment 3

[0043] A seamless steel pipe for ships, the chemical composition of the seamless steel pipe is respectively C: 0.18%, Si: 0.28%, Mn: 1.6%, Mo: 0.3%, Cr: 11.8%, Ti: 0.25% in weight percentage , V:0.5%, Re:0.4%, Al:0.04%, B:0.0012%, N:0.009%, P≤0.02%, S≤0.02%, O≤0.003%, the rest is Fe and unavoidable impurities, The total mass fraction of each component is 100%.

[0044] Further, the surface of the seamless steel pipe is sequentially coated with a first high-pressure resistant layer, a titanium nano-polymer alloy coating, and a modified epoxy ceramic coating layer from the inside to the position; the inner wall of the seamless steel pipe is coated with The second high-voltage resistant layer, the thickness of the first high-voltage resistant layer is 0.5mm, the thickness of the titanium nano-polymer alloy coating is 0.3mm, the thickness of the second high-voltage resistant layer is 0.5mm, and the modified The thickness of the permanent epoxy ceramic coating layer is 0.4mm.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com