A kind of anti-graphite adsorption composite coil and its preparation method

A composite roll and graphite technology, applied in chemical instruments and methods, antifouling/underwater coatings, synthetic resin layered products, etc., can solve the problems of difficult cleaning of ground materials, easy adsorption of graphite powder, and difficulty in meeting requirements, etc. Achieve the effect of smooth and smooth surface, simplified production process and good high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

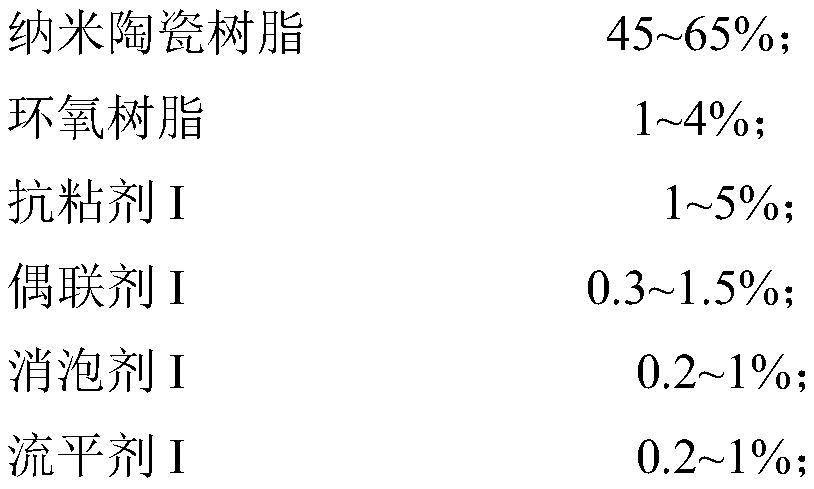

[0066] 1. Preparation of nanometer anti-graphite coating

[0067] 60 parts of nano-ceramic resin TJ-185 with a solid content of 55% and a light transmittance of 92%, 2 parts of epoxy resin NPEL-128 with a viscosity of 15000cps; 5 parts of anti-sticking agent I BYK3700, 1 part of coupling agent I KH792 , 0.5 part of defoamer I BYK066N, 0.5 part of leveling agent I BYK333, after 20 parts of butyl acetate and 11 parts of ethylene glycol monobutyl ether are stirred evenly, obtain the nano anti-graphite coating;

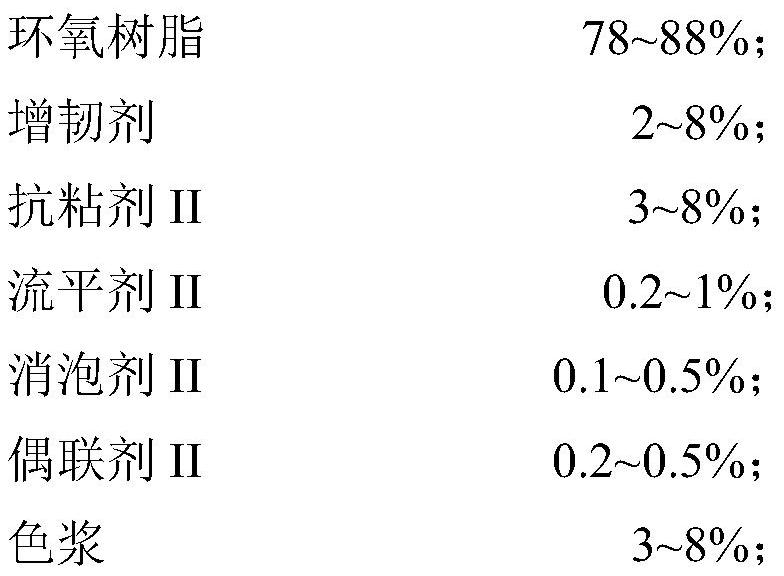

[0068] Second, the preparation of epoxy resin coating

[0069] Preparation of component A: 80 parts of epoxy resin NPEL-170, 6 parts of toughening agent ZR-05, 6 parts of anti-sticking agent II polytetrafluoroethylene micro-powder wax powder, 0.5 parts of leveling agent II BYK354, 0.2 parts of defoamer II BYK054, 0.3 parts of coupling agent II KH560, 7 parts of color paste E-50, mixed and stirred evenly to obtain component A of epoxy resin coating;

[0070] B component ...

Embodiment 2

[0091] 1. Preparation of nanometer anti-graphite coating

[0092] 55 parts of nano-ceramic resin SJ-2200 with a solid content of 60% and a light transmittance of 95%, 4 parts of epoxy resin NPEL-170 with a viscosity of 15000cps; 4 parts of anti-sticking agent I SJ5800, 0.5 parts of coupling agent I KH792, 0.2 parts of defoamer IBYK066N, 0.3 parts of leveling agent I BYK333, 20 parts of propylene glycol methyl ether and 16 parts of ethylene glycol are stirred evenly to obtain nano-graphite-resistant coatings;

[0093] Second, the preparation of epoxy resin coating

[0094] Preparation of component A: 83 parts of epoxy resin NPEL-128, 5 parts of toughening agent ZR-05, 5 parts of anti-sticking agent II polytetrafluoroethylene wax modified polyethylene wax micropowder, 0.3 parts of leveling agent II BYK354, 0.2 1 part of defoamer II BYK054, 0.5 part of coupling agent IIKH560, 6 parts of color paste E-50, mixed and stirred evenly to obtain component A of epoxy resin coating;

[...

Embodiment 3

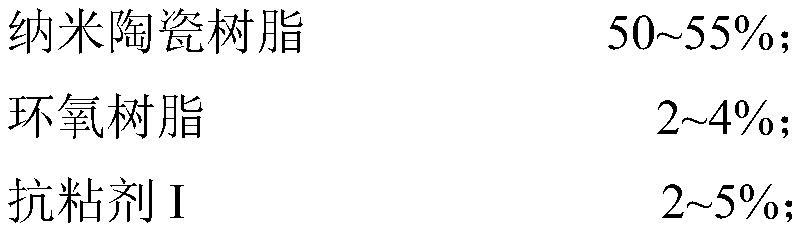

[0104] 1. Preparation of nanometer anti-graphite coating

[0105] 50 parts of nano-ceramic resin SJ-2200 with a solid content of 60% and a light transmittance of 95%, 3 parts of epoxy resin NPEL-128 with a viscosity of 15000cps; 2 parts of anti-sticking agent I SJ5800, 1 part of coupling agent I KH792 , 0.6 part of defoamer I BYK066N, 0.4 part of leveling agent I BYK333, 28 parts of isopropanol and 15 parts of ether acetate were stirred evenly to obtain nanometer anti-graphite coating;

[0106] Second, the preparation of epoxy resin coating

[0107] Preparation of component A: 50 parts of epoxy resin NPEL-128, 35 parts of epoxy resin NPEL-170, 4 parts of toughening agent ZR-05, 5 parts of anti-sticking agent II polypropylene wax powder, 0.5 parts of leveling agent II BYK354 , 0.2 parts of defoamer II BYK054, 0.3 parts of coupling agent IIKH560, 5 parts of color paste E-50, mixed and stirred evenly to obtain component A of epoxy resin coating;

[0108] B component is: 100 par...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com