Solid stabilizer, steel material for solid stabilizer and method for producing solid stabilizer

A manufacturing method and stabilizer bar technology, applied in the direction of manufacturing tools, transportation and packaging, furnace types, etc., can solve the problem of difficult to obtain characteristics, unsatisfactory bending processing performance, quenching performance, quenching crack resistance, strength, and reduce bending processing Performance or quenching crack resistance and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

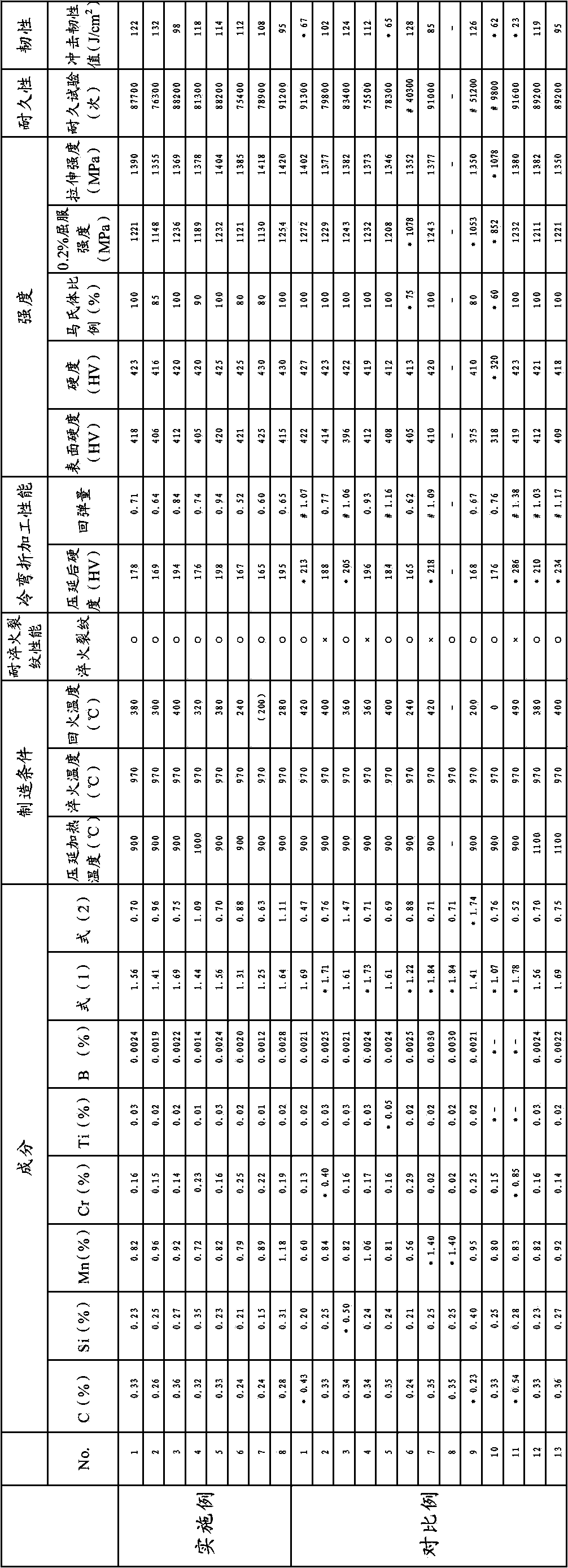

[0076] The evaluation tests for quenching crack resistance, cold bending performance, strength, durability, toughness, etc. performed on stabilizer bars and steel materials for stabilizer bars will be described below.

[0077]

[0078] First, the manufacturing method of the samples (Examples 1-8, Comparative Examples 1-7, 9-13) is demonstrated. The manufacturing method of the sample includes a hot forging process, a quenching process, a tempering process, and a finishing process.

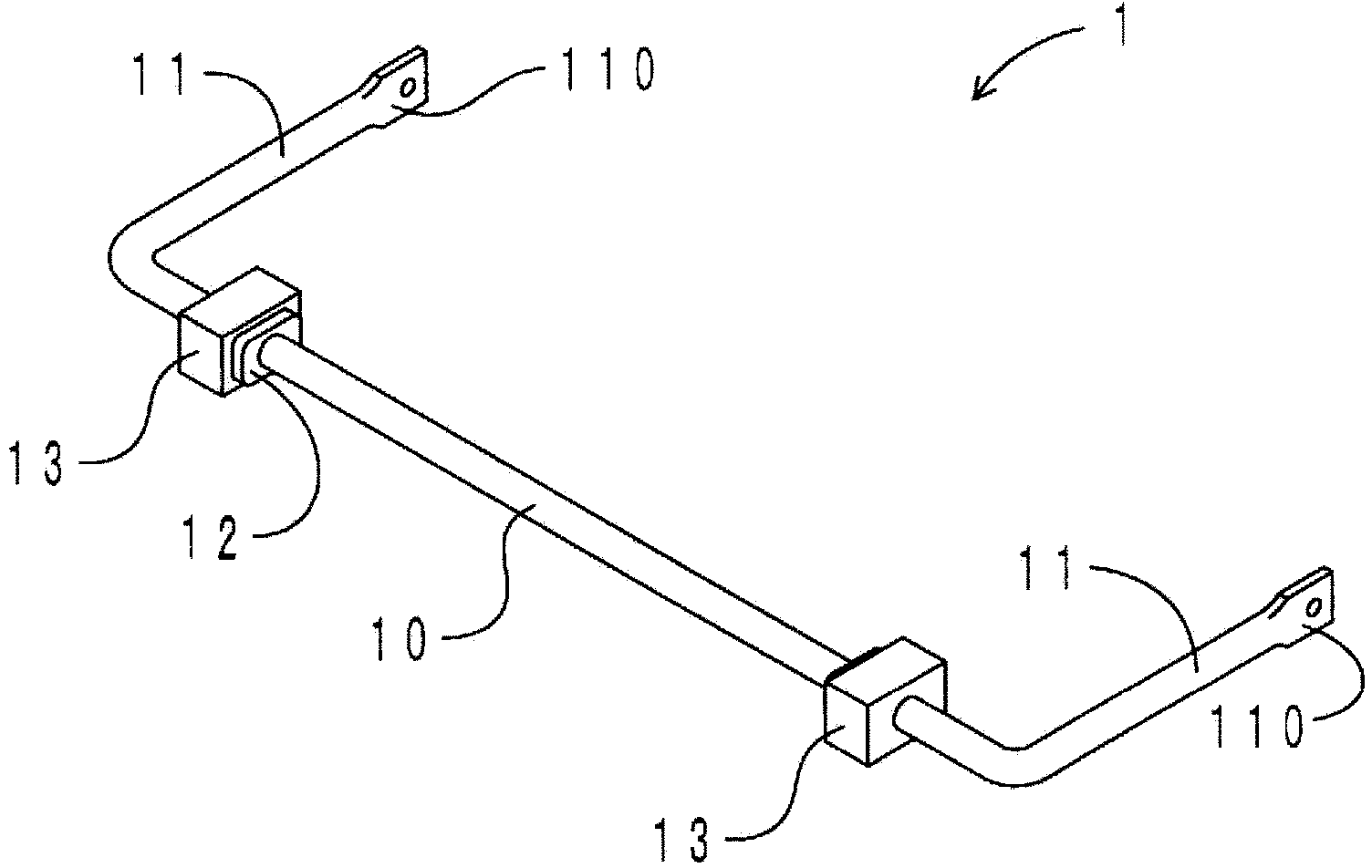

[0079] In the hot forging process, steel is first cut to a predetermined length. Next, both ends in the axial direction of the cut steel material are heated, hot forged, and pierced. like this, such as figure 1 As shown, a pair of hole portions 110 are formed at both ends in the axial direction of the steel material.

[0080] In the quenching step, first, the pair of hole portions 110 of the steel material are clamped. Next, electric heating was performed by passing electricity between the pair ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com