High plasticity, high tenacity and ultra-high tensile steel, and manufacturing method thereof

A technology of ultra-high-strength steel and high toughness, which is applied in the field of ultra-high-strength steel manufacturing, and can solve problems such as the plastic index requirements for ultra-high-strength steel, the plastic index requirements, and the lack of low-temperature impact toughness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

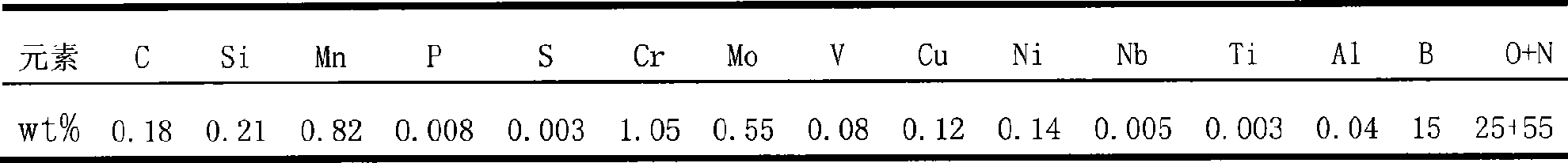

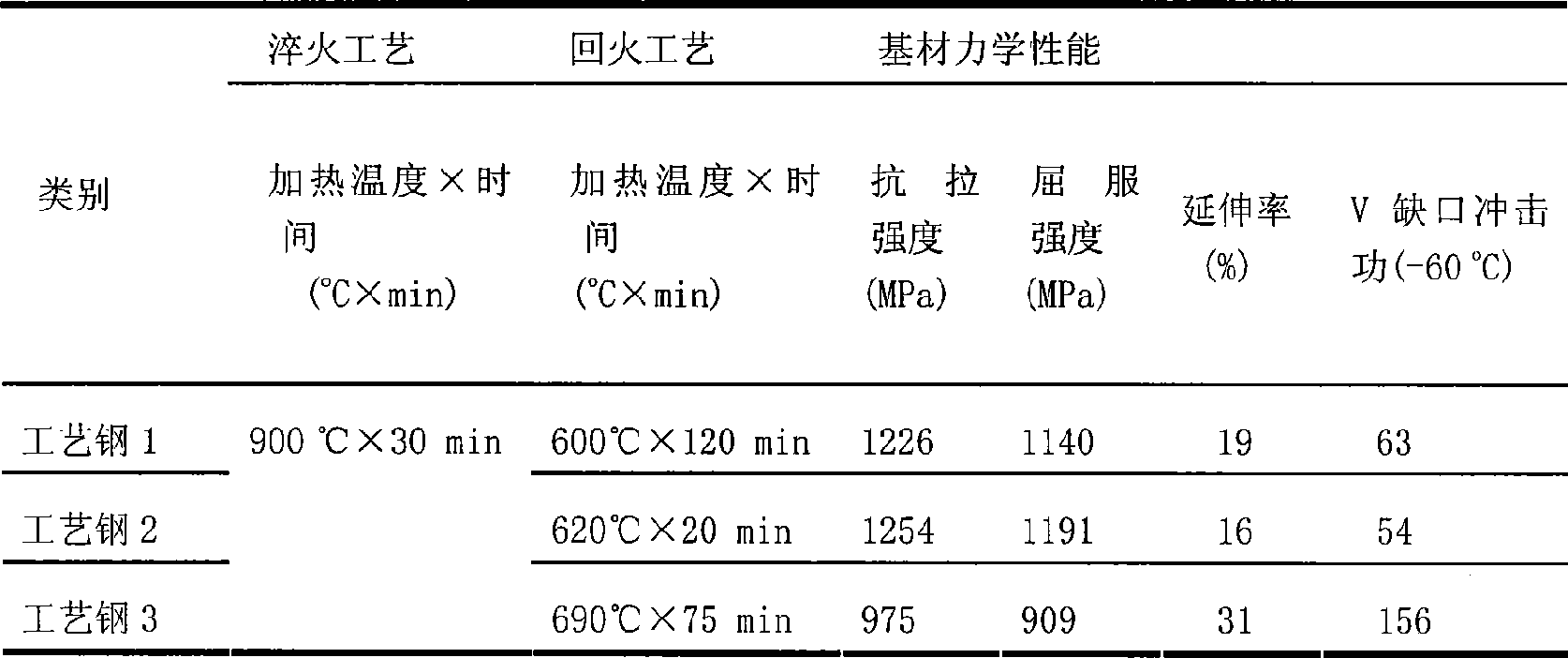

Embodiment 1

[0040] Embodiment 1 of the present invention selects raw materials with low sulfur and phosphorus content, and adopts 50Kg vacuum furnace to smelt, so that the chemical composition in the steel meets the requirements of Table 1, and the balance is Fe and unavoidable impurity elements. Then use inert gas protection to cast, pour two ingots in each furnace, and the average diameter of the ingot is? 120mm. After the riser of the ingot was cut off, it was made into a hot-rolled plate with a plate thickness of 12 mm and a width of 200 mm on a 250 mm rolling mill. Among them, the main hot rolling process is: the slab heating temperature is 1200-1250°C, the initial rolling start temperature is 1150-1180°C, the rough rolling total reduction rate is 60-70%, and the rough rolling end temperature is 1020-1070°C . The start temperature of finish rolling is 930-980°C, the total reduction ratio of finish rolling is 30-40%, and the end temperature of finish rolling is 850-870°C. Cool in a...

Embodiment 2

[0046] Example 2 of the present invention selects high-quality steel scrap with pretreated molten iron + P and low S content as raw material, and uses a 150-ton electric furnace for smelting, and adopts out-of-furnace refining, vacuum degassing (VD), inclusion denaturation, and argon blowing and stirring, etc. Pure steel smelting process, so that the chemical composition in the steel meets the requirements in Table 1, and the level of inclusions meets the above requirements. Then the inventive steel was continuously cast into a round billet with an outer diameter of 310 mm. During piercing and continuous rolling of tube blanks, the temperature of each process is strictly controlled. The billet is heated to 1250°C, and after heat centering, it is cross-rolled and pierced at 1200-1250°C, with a deformation of 60-70%; the rolling temperature range is controlled at 1100-1150°C, and the deformation is 20-30%; The diameter temperature is controlled above Ar3, and the deformation is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com