Anti-static high-holding-force elastic card clothing and forming process thereof

A holding force and anti-static technology, applied in fiber processing, deburring devices, textiles and papermaking, etc., can solve the problems of reduced carding efficiency, influence of cloth quality, entanglement of yarn jitter amplitudes, etc., to avoid tilting or High frequency jitter, the effect of improving mating reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

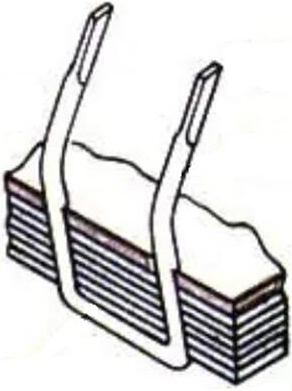

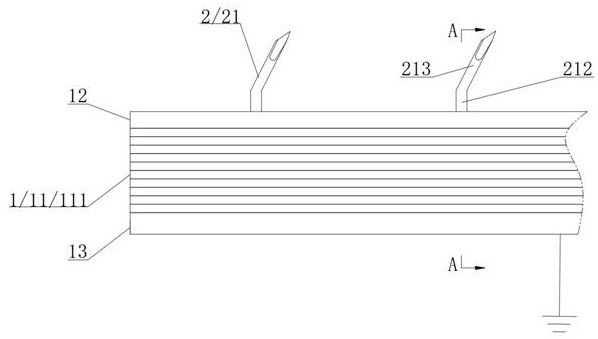

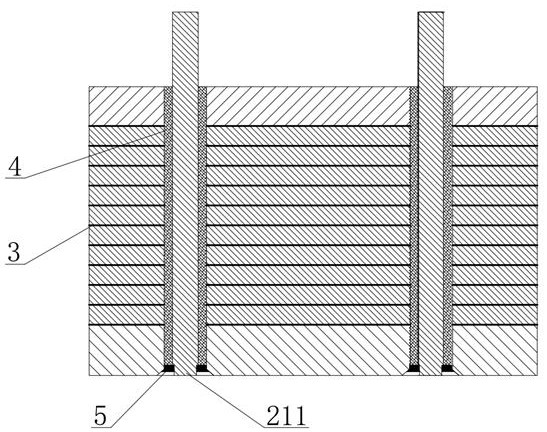

[0048] figure 2 , image 3 The schematic diagram of the structure of the first embodiment of the anti-static high-grip elastic card clothing in the present invention and its A-A cross-sectional view are respectively shown. It can be seen that it is mainly composed of a plate-shaped base 1, a carding component 2, A colloid layer 3, B glue The sleeve 4 and the solder joints 5 are composed of several parts. The combing assembly 2 is composed of a plurality of conductive metal comb needles 21 that are inserted into the plate-shaped base body 1 . The plate-shaped base body 1 includes a fabric composite layer 11 , an oil-resistant plate 12 and a conductive metal plate 13 . Wherein, the fabric composite layer 11 is formed by stacking 6 to 9 layers of burlap 111 . The oil-resistant plate 12 is glued to the upper side of the fabric composite layer 11 and is passed through by the conductive metal comb needles 21 . The conductive metal plate 13 is glued to the lower side of the fabr...

Embodiment 2

[0058] Figure 4 , Figure 5 The schematic diagram of the structure of the second embodiment of the anti-static high-holding force elastic card clothing in the present invention and its partial enlarged view are respectively shown. It can be seen that the difference between the second embodiment and the first embodiment is that the conductive metal The difference in soldering method between the comb pin 21 and the conductive metal plate 13 is specifically: the conductive pin 211 is in the shape of a flat strip, which is directly extended downward from the lower knee section 212 . A strip-shaped accommodating groove 131 that is adapted to the shape of the conductive pins 211 extends inward from the outer sidewall of the conductive metal plate 13 . After the conductive metal pins 21 are inserted in place relative to the mating holes, a 90° bending operation is performed on the conductive pins 211 to flatly press them in the strip-shaped receiving grooves 131 , and then along th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com