Method for preparing bismuth yellow hybrid pigment for polymer coloring and reinforcing from mixed-dimension attapulgite clay

A technology of attapulgite clay and attapulgite, applied in chemical instruments and methods, vanadium compounds, fibrous fillers, etc., can solve the problems of high preparation cost, high energy consumption, low pigment yield, etc., and achieve high yield , the effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

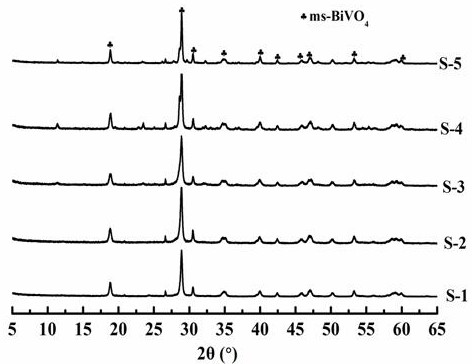

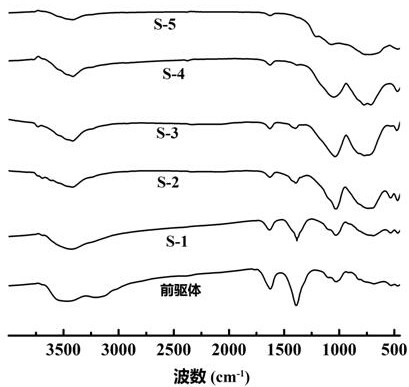

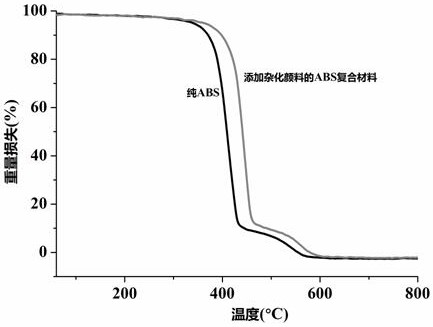

[0036] 60 g of natural mixed-dimensional attapulgite clay, 53.90 g of bismuth nitrate and 13.00 g of ammonium metavanadate were extruded into a differential-speed co-rotating twin-screw extruder to obtain a precursor. After crystallization at 700 °C for 120 min, Pulverize the base bismuth yellow hybrid pigment. On this basis, 1 mL of vinyl tris (2-methoxyethoxy) silane was diluted with 5 mL of absolute ethanol, then mixed with bismuth yellow hybrid pigment and dried to constant weight to obtain polymeric Mixed-dimensional attapulgite clay-based bismuth yellow hybrid pigment for coloring and reinforcement of materials. The corresponding samples are respectively marked as S-1, which L * , a * , b * See Table 1 for color parameters.

Embodiment 2

[0038] 70 g of mixed-dimensional attapulgite clay, 48.8 g of bismuth nitrate, 31.2 g of bismuth chloride, 23.4 g of ammonium metavanadate and 12.1 g Sodium molybdate was put into a co-rotating twin-screw extruder to extrude the precursor to obtain the precursor, and after crystallization at 500°C for 90 min, it was pulverized to obtain the bismuth yellow hybrid pigment. On this basis, 0.8 mL of vinyltris(2-methoxyethoxy)silane and 0.7 mL of 3-glycidyloxypropyltrimethoxysilane were mixed and diluted with 8 mL of absolute ethanol, and then Mixed with bismuth yellow hybrid pigment and dried to constant weight to prepare mixed-dimensional attapulgite clay-based bismuth yellow hybrid pigment for polymer coloring and reinforcement. The corresponding samples are respectively marked as S-2, which L * , a * , b * See Table 1 for color values.

Embodiment 3

[0040] Mixed dimensional attapulgite clay 50 g, 64.1 g bismuth ammonium citrate, 70.61 bismuth sulfate, 17.55 1 g of ammonium metavanadate and 12.10 g of sodium molybdate were put into a double-stage twin-screw extruder to extrude the precursor to obtain the precursor, and after crystallization at 500 °C for 180 min, the bismuth yellow hybrid pigment was obtained by crushing. On this basis, 3 mL of vinyl tris (2-methoxyethoxy) silane was diluted with 10 mL of absolute ethanol, then mixed with bismuth yellow hybrid pigment and dried to constant weight to obtain a polymer Mixed-dimensional attapulgite clay-based bismuth yellow hybrid pigment for coloring and reinforcement of materials. The corresponding samples are respectively marked as S-3, which L * , a * , b * See Table 1 for color values.

PUM

| Property | Measurement | Unit |

|---|---|---|

| draft ratio | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com