Method for strengthening and toughening lithium disilicate glass ceramic and activating surface of lithium disilicate glass ceramic by utilizing ion exchange

A technology of lithium disilicate and glass ceramics, which is applied in the field of biomedical materials, can solve the problems of maintaining the mechanical properties of glass ceramics, such as greater risks, to meet the requirements of strengthening and toughening and biological activation treatment, expand the scope of application, mechanical The effect of performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] This embodiment comprises the steps of:

[0038] A step to prepare the total mass of NaNO 40g 3 And KNO 3 The mixed salt; the salt mixture NaNO 3 And KNO 3 It is the molar proportion of 50%, NaNO 3 And KNO 3 They were of analytical grade, quality and purity of greater than 99%;

[0039] Step two, step a mixed salt obtained in high purity alumina placed in a cylindrical crucible, and then heated in a tube furnace to 380 deg.] C for 30min and the mixed salt is completely melted to a liquid state, the molten steel is stirred during heating using intermittent stirring bar, and intermittently stirred intermittent interval of 3min ~ 5min, to give a mixed bath salts;

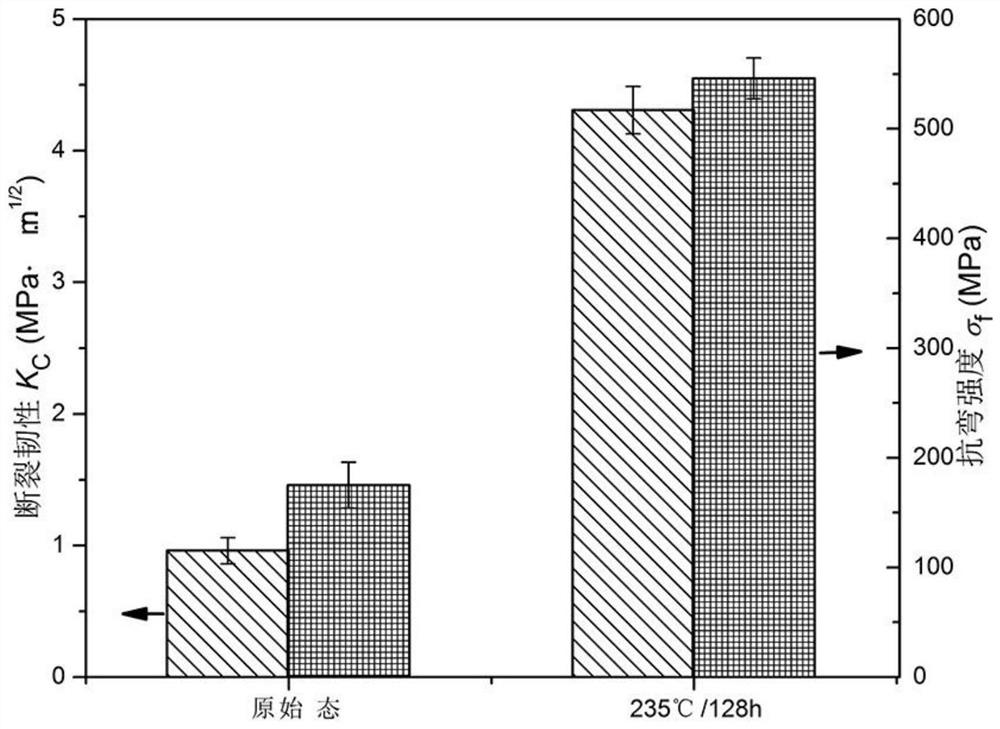

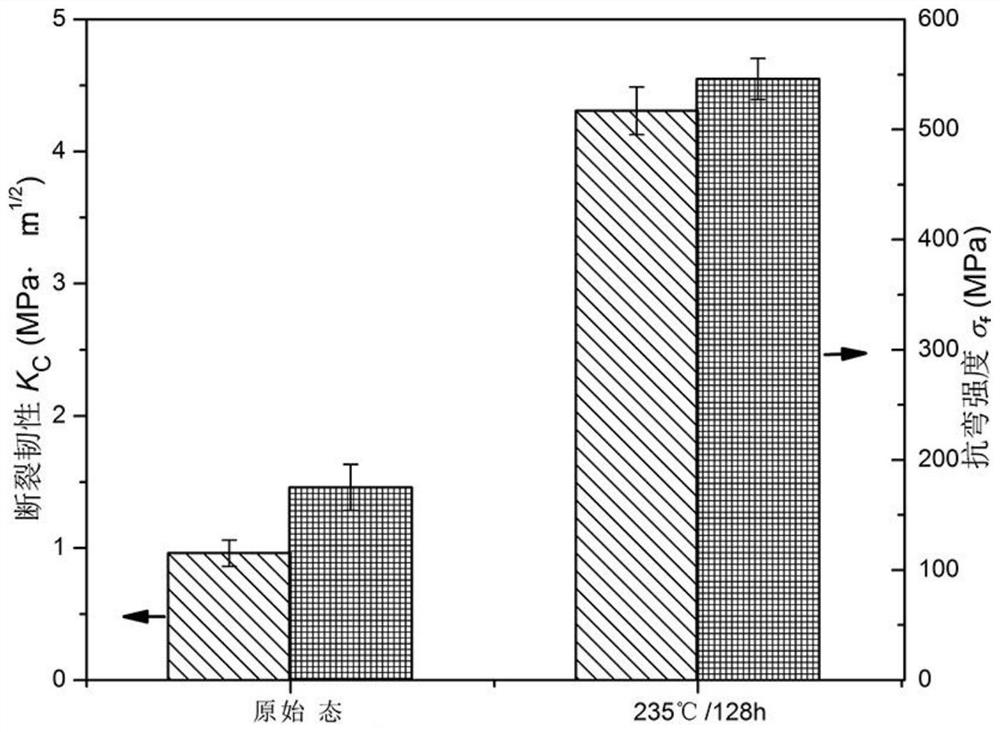

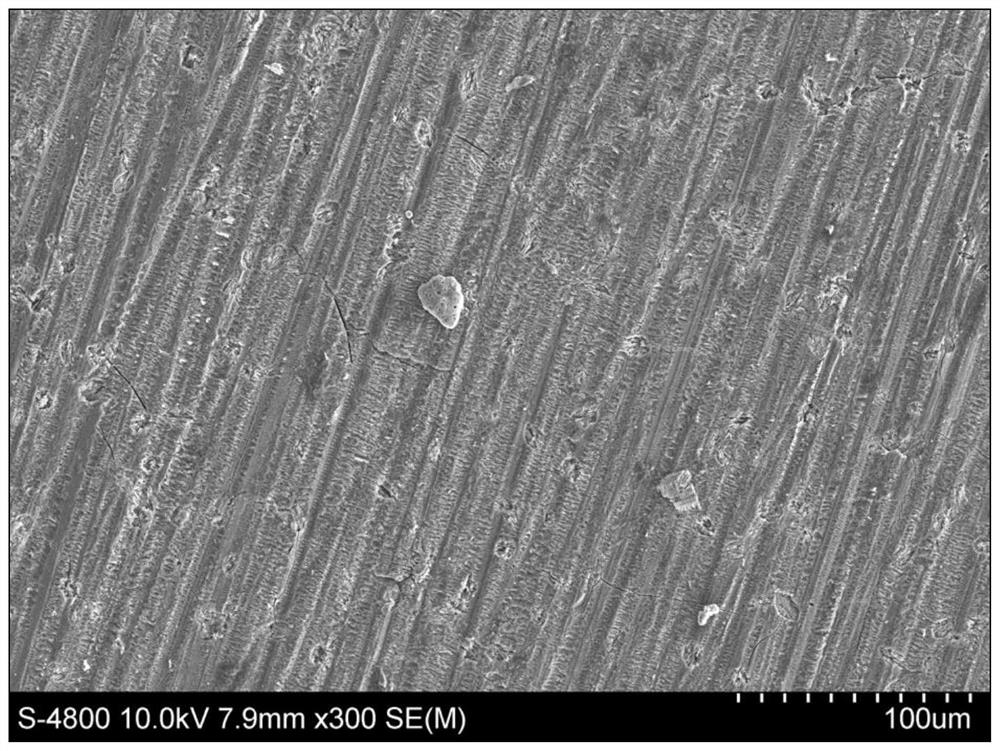

[0040] Step three, the mixture obtained in step two bath salts furnace cooling to 235 deg.] C and kept constant, and the lithium disilicate glass ceramic into the mixing bath salts molybdenum mesh basket is immersed in a constant temperature ion exchange treatment for 16 h, cooled to room temperature, lithium disili...

Embodiment 2

[0044] This embodiment of Example 1 except that: the time the ion exchange treatment step 3 is 32h.

Embodiment 3

[0046] This embodiment of Example 1 except that: the time the ion exchange treatment step 3 is 64h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com