A kind of preparation method of high-volume fraction sip/al composite material high temperature resistant gold coating

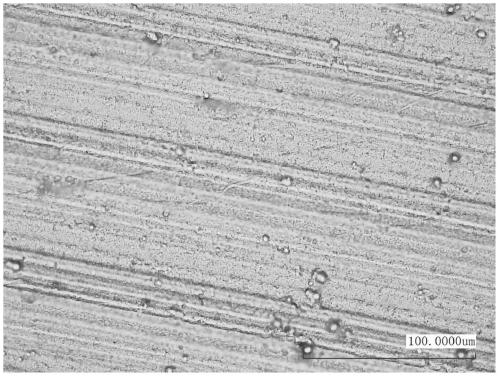

A composite material and high-temperature-resistant technology, which is applied in the coating process of metal materials, plating of superimposed layers, coating, etc., can solve the problems of reduced contact area between the coating and the substrate, poor bonding of the coating, and peeling, etc., to achieve Uniform appearance, low porosity, fine crystallization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The method for preparing a high temperature-resistant gold coating on the surface of a high-volume Sip / Al composite material of the present invention is to coat the surface of an aluminum-based composite material with a silicon particle component of 50% to 60% by volume, and the specific steps are as follows: :

[0042] (1) Wipe the surface of the high-volume Sip / Al composite material, so that the surface of the high-volume Sip / Al composite material is completely wetted by water and the water film is continuous within 30s; the silicon particle group in the high-volume fraction Sip / Al composite material The volume percentage of the centrifuge is 50% to 60%;

[0043] (2) the surface of the high volume fraction Sip / Al composite material obtained in step (1) is sandblasted, and the sandblasting operating conditions are as follows:

[0044]

[0045] After sandblasting, use oil-free compressed air to dry the surface of the high-volume Sip / Al composite material;

[0046] ...

Embodiment 1

[0094] A preparation method for high temperature resistant gold coating of Sip / Al composite material with high volume fraction, the method comprises the following steps:

[0095] 1) Wipe the surface of the high-volume Sip / Al composite material, so that the surface of the high-volume Sip / Al composite material is completely wetted by water and the water film is continuous within 30s; the silicon particle component in the high-volume fraction Sip / Al composite material The volume percentage of 60%;

[0096] 2) sandblasting the surface of the high-volume Sip / Al composite material obtained in step 1), and the sandblasting operating conditions are as follows:

[0097]

[0098] After sandblasting, use oil-free compressed air to dry the surface of the high-volume Sip / Al composite material;

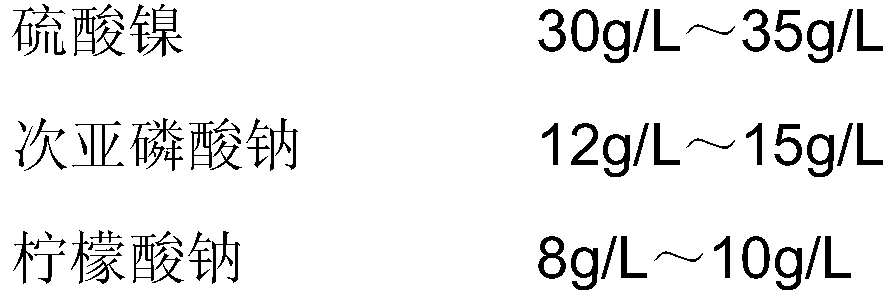

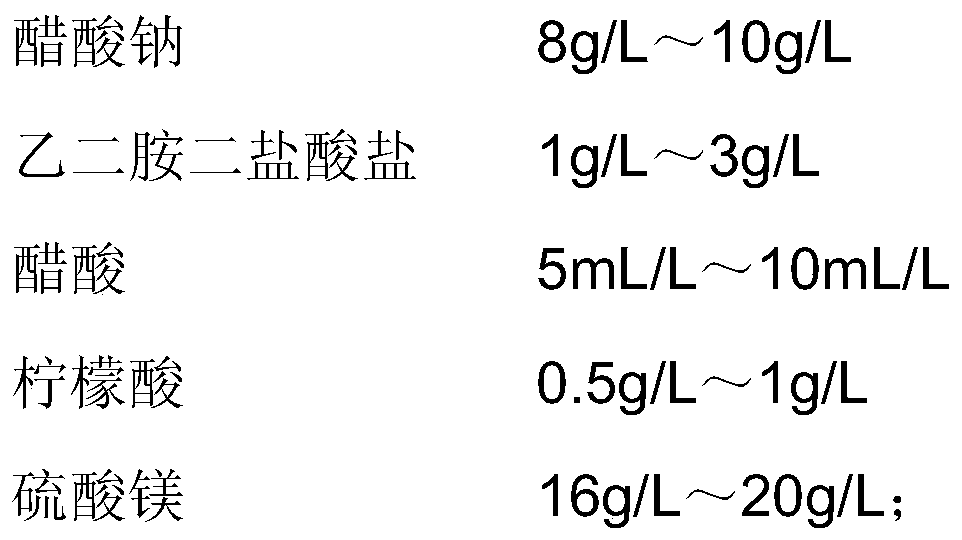

[0099] 3) chemically degreasing the surface of the high-body fraction Sip / Al composite material obtained in step 2), and the chemical degreasing solution formula and operating conditions are as...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com