Method for treating abrasive particle-containing waste

A technology of abrasive grains and waste materials, which is applied in the field of waste materials containing abrasive grains, can solve problems such as waste, and achieve the effect of purifying and optimizing the surface state of abrasive grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] A method of processing abrasive-containing waste, the method comprising the steps of:

[0062] S1 every 7 days, the upper sand waste slurry (which contains diamond micropowder) is taken out of the upper sand tank, which is a waste solution containing abrasive particles, and the abrasive particles are used to fix the surface of the wire saw to prepare the diamond wire saw. First put it into a container for settling, settling statically for 1 hour, then pour out the upper layer liquid, add water 3 times its volume to the residue, and stir at a speed of 600r / min for 5 minutes to obtain a mixed solution;

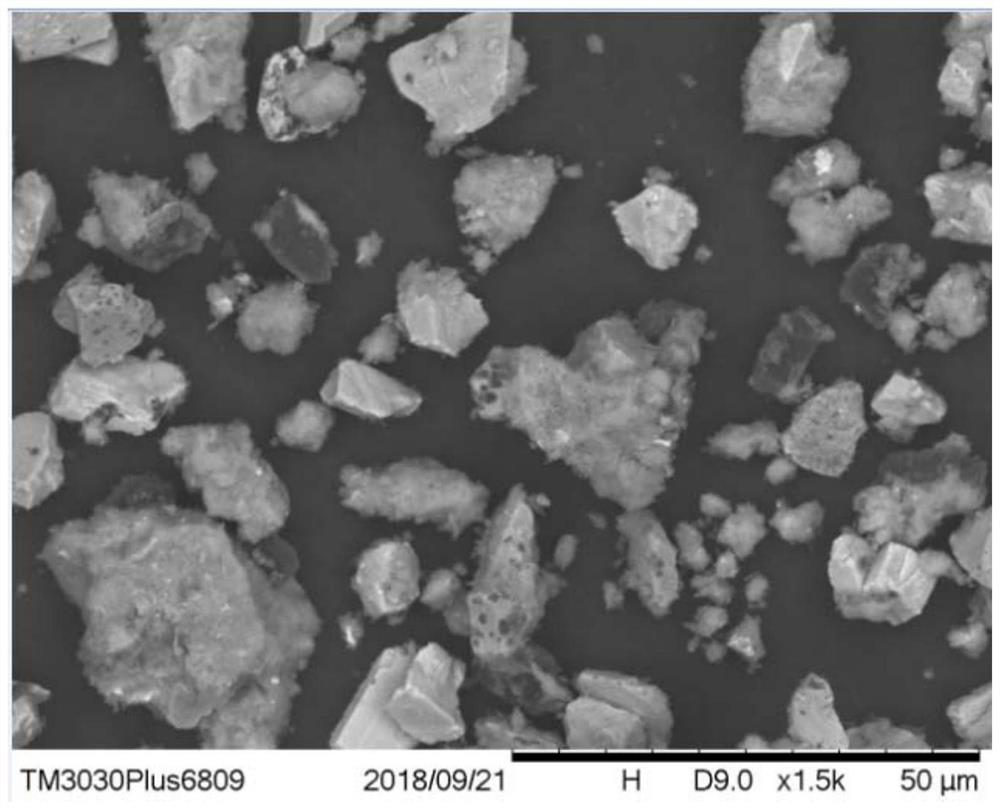

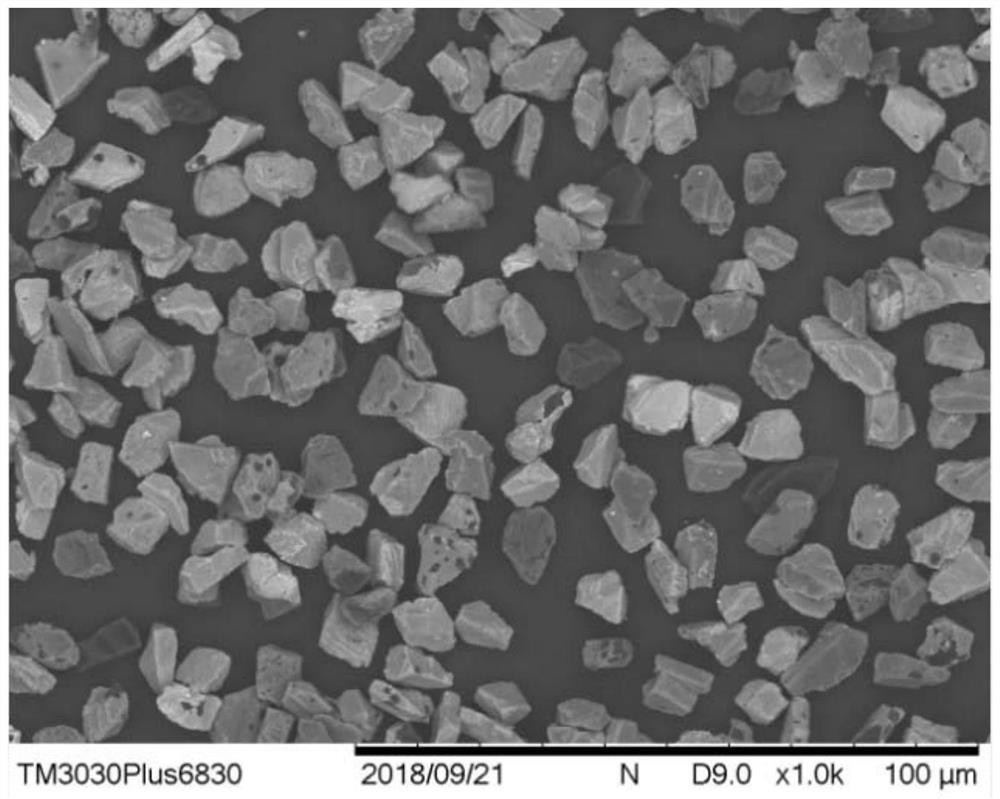

[0063] The minimum particle size of the diamond micropowder used for sanding in the upper sand tank is 6 μm, and the maximum particle size is 14 μm. The electroplating conditions carried out in the upper sand tank are: the main salt of the plating solution is nickel sulfamate, and the secondary salt is Nickel chloride, temperature 55 ℃, using sulfamic acid to adjust pH at...

Embodiment 2

[0069] A method for recovering diamond micropowder from the waste of electroplating for preparing diamond wire saw, characterized in that the method comprises the following steps:

[0070] S1 Every 10 days, take out the upper sand waste slurry (which contains diamond micro-powder) from the upper sand tank, put it into a container for settling before use, settling statically for 0.5 hours, then pour out the upper layer liquid and add it to the residue. 5 times its volume of water was stirred at a speed of 500 r / min for 8 minutes to obtain a mixed solution;

[0071] The minimum particle size of the diamond micropowder used for sanding in the upper sand tank is 6 μm, and the maximum particle size is 14 μm. The electroplating conditions carried out in the upper sand tank are: the main salt of the plating solution is nickel sulfamate, and the secondary salt is Nickel chloride, temperature 50 ℃, using sulfamic acid to adjust pH at 4;

[0072] S2 adopts the method of filtration to c...

Embodiment 3

[0081] A method of processing abrasive-containing waste, the method comprising the steps of:

[0082] S1 every 8 days, the upper sand waste slurry (which contains diamond micropowder) is taken out of the upper sand tank, which is a waste solution containing abrasive particles, and the abrasive particles are used to fix the surface of the wire saw to prepare the diamond wire saw. Put it into a container for settling before, settling statically for 0.8 hours, then pour out the upper layer liquid, add water 4 times its volume into the residue, and stir at a speed of 550r / min for 10 minutes to obtain a mixed solution;

[0083] The minimum particle size of the diamond micropowder used for sanding in the upper sand tank is 6 μm, and the maximum particle size is 14 μm. The electroplating conditions carried out in the upper sand tank are: the main salt of the plating solution is nickel sulfamate, and the secondary salt is Nickel chloride, temperature 60 ℃, using sulfamic acid to adjus...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com