Patents

Literature

41results about How to "To achieve toughening effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

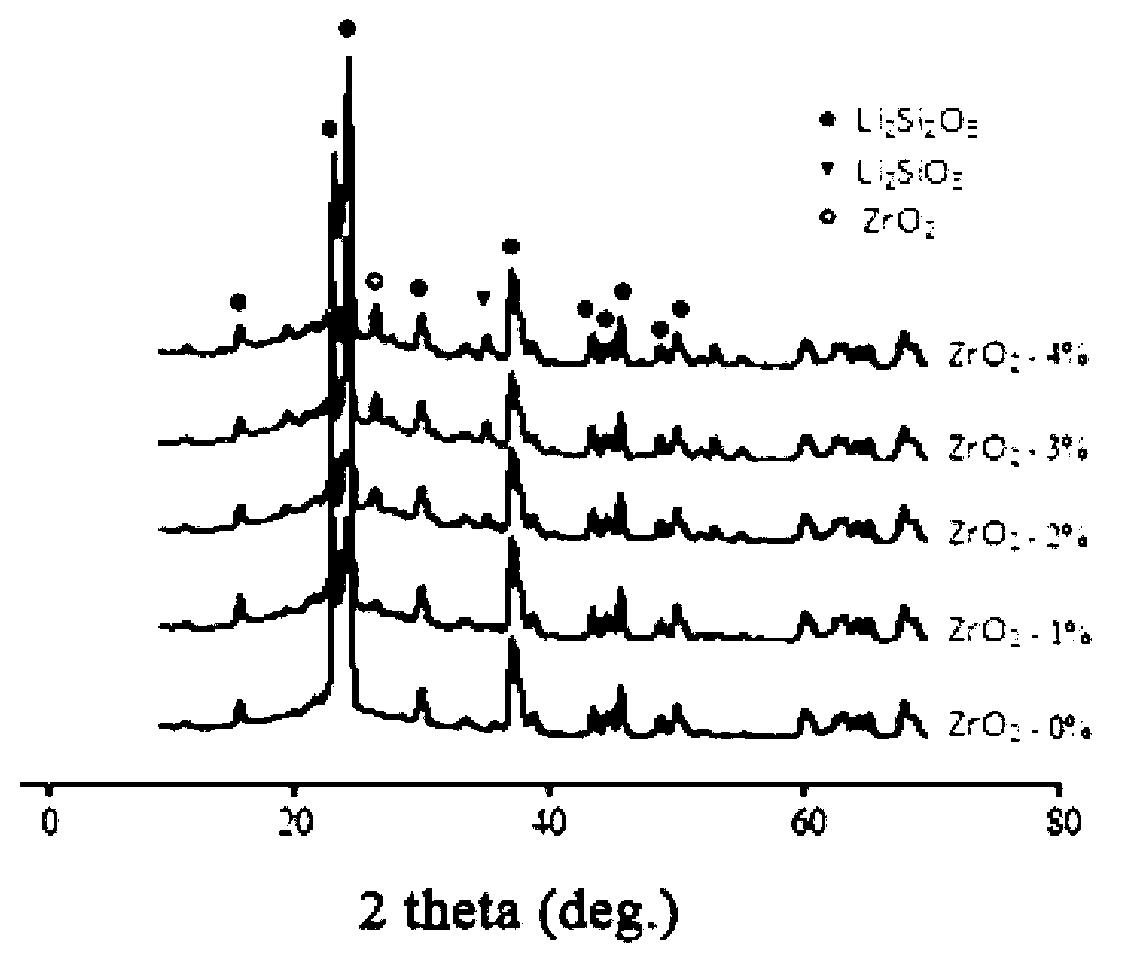

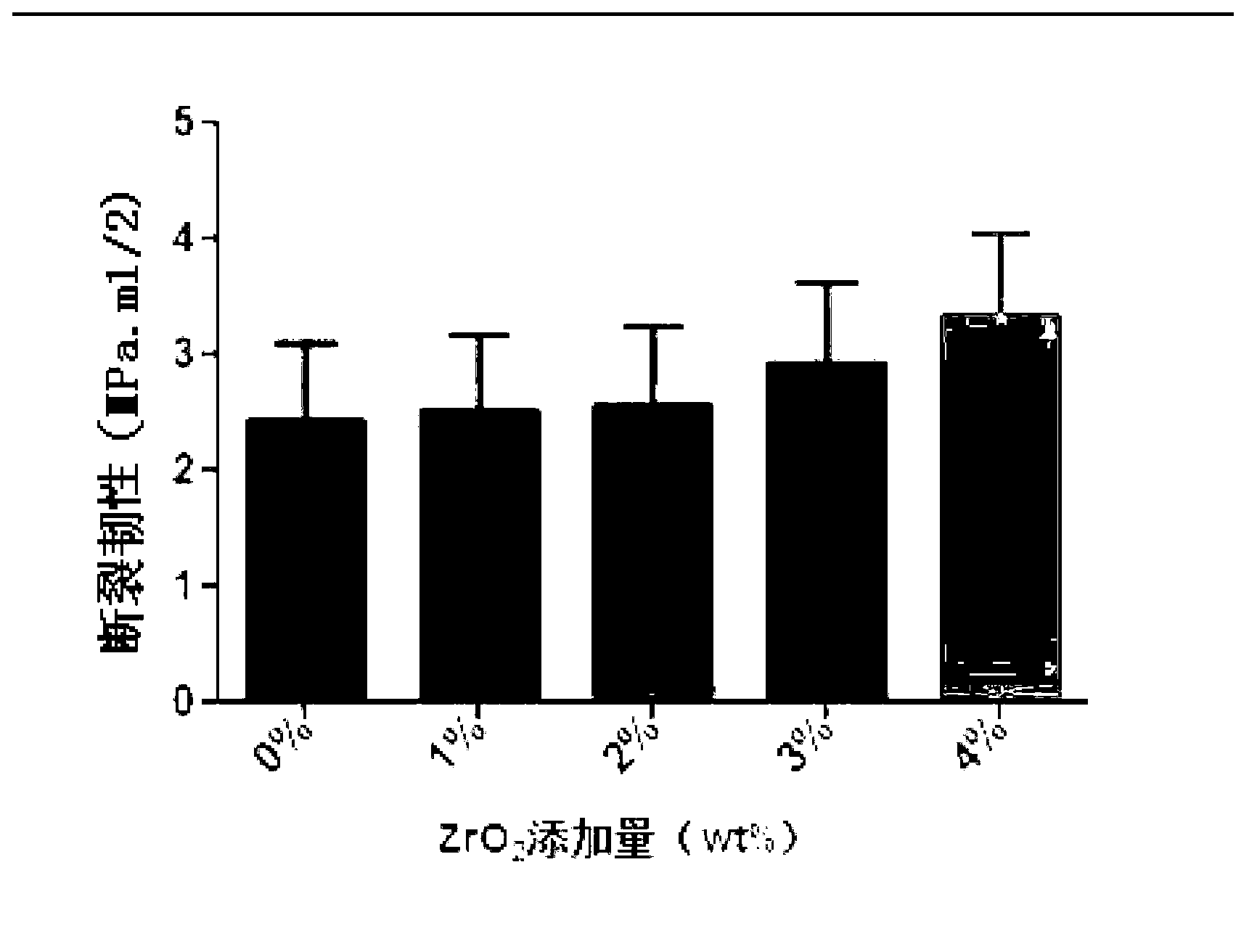

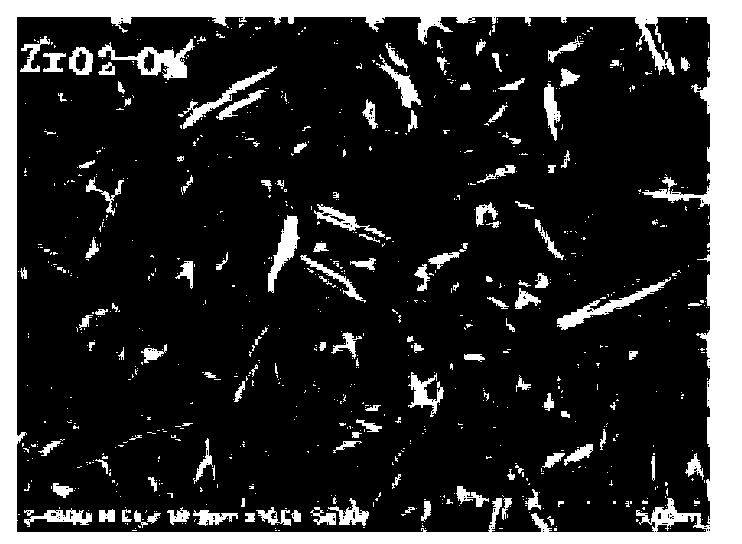

Strengthening-toughening glass ceramic and preparation method thereof

The invention belongs to the field of all-ceramics materials for the dentistry, and discloses a strengthening-toughening glass ceramic and a preparation method thereof. The strengthening-toughening glass ceramic comprises the following components in percentage by mass: 96 to 99% of basic component, and 1.0 to 4.0% of toughening component, wherein the basic component comprises the following components in percentage by mass: 58 to 62% of SiO2, 28 to 30% of Li2CO3, 3.5 to 4.0% of K2CO3, 2.5 to 3.0% of Al2O3, 11.4 to 1.6% of CeO2, and 2.6 to 3.0% of P2O5, and the toughening component is ZrO2.

Owner:FOURTH MILITARY MEDICAL UNIVERSITY

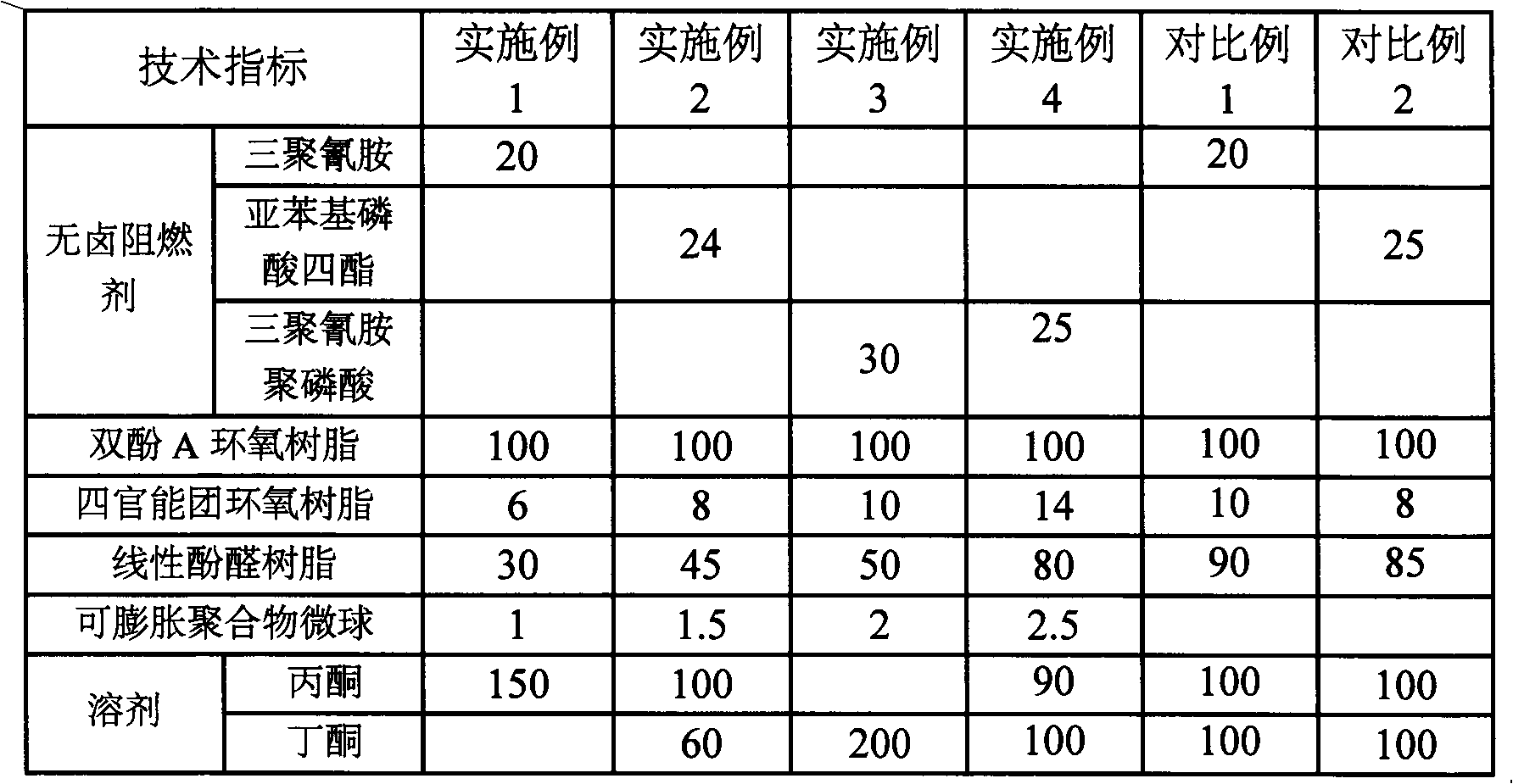

Environmentally-friendly underfill adhesive having low dielectric constant, and preparation method thereof

ActiveCN107828358ALow dielectric constantLow Halogen Environmental ProtectionNon-macromolecular adhesive additivesMacromolecular adhesive additivesEpoxyHalogen

The invention relates-an environmentally-friendly underfill adhesive having a low dielectric constant, and a preparation method thereof, and belongs to a one-component epoxy resin adhesive. The underfill adhesive comprises, by weight, 30-38 parts of epoxy resin, 8-20 parts of a curing agent, 33-46 parts of a filler, 2-5 parts of a diluent, 6-9 parts of a toughener, 0.3-0.5 part of a silane coupling agent, 0.3-0.5 part of an antifoaming agent and 0.2-0.8 part of a pigment. The underfill adhesive prepared in the invention has the advantages of low halogen content, low dielectric constant, high arc resistance, high weather resistance and the like, so packaging components have a high environmental protection property, a high electrical insulation property and a high reliability.

Owner:YANTAI DARBOND TECH

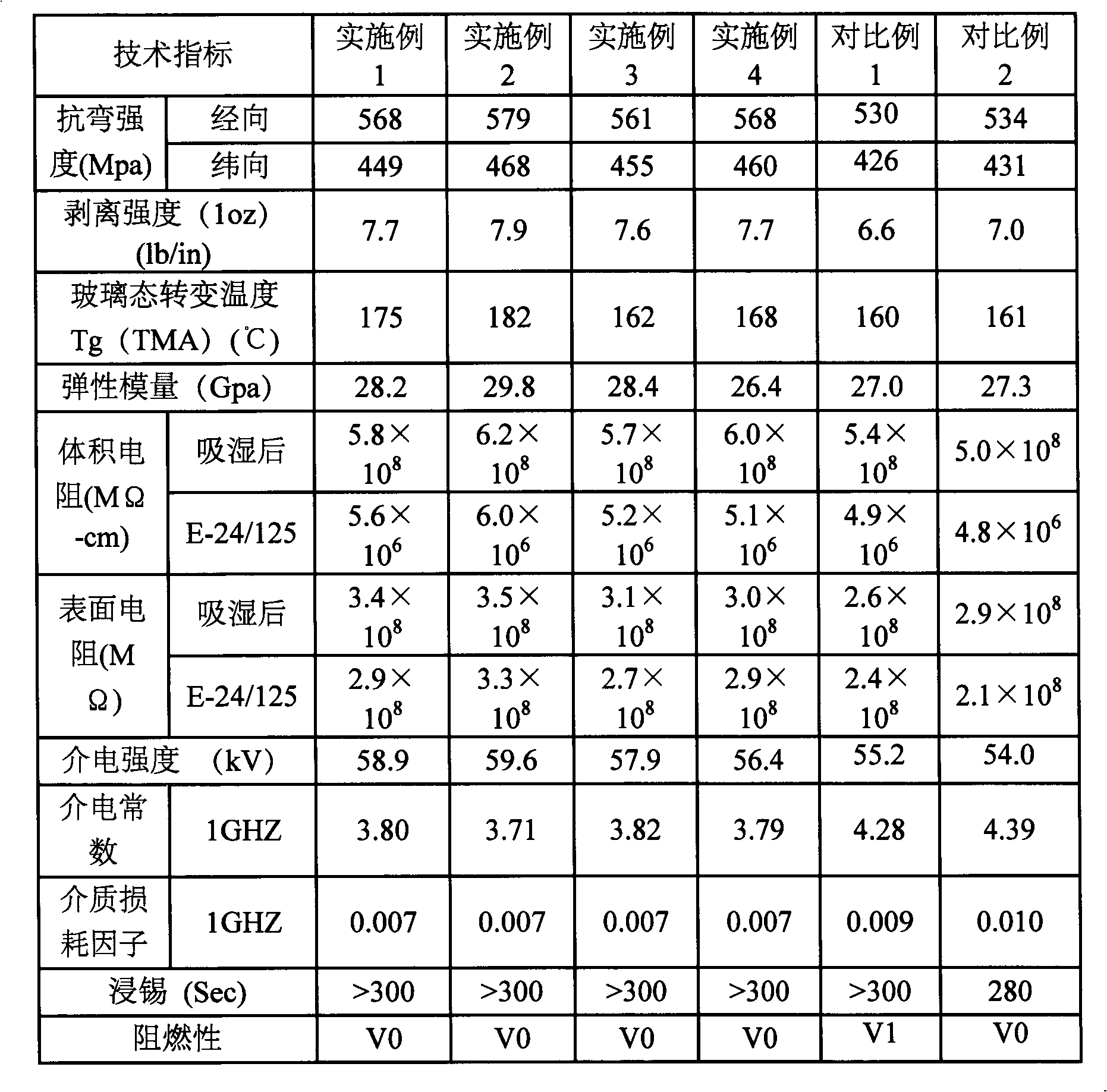

Toughening epoxy resin composition

InactiveCN102936396ALow dielectric constantFavorable denseMetal layered productsEpoxyDielectric loss

The invention relates to a toughening epoxy resin composition for copper-clad plate. Except for lower dielectric constant and dielectric loss, the toughening epoxy resin composition has excellent mechanical property, high heat resistance and flame retardant property, also has a more compact structure, and can meet the demand of the copper-clad plate for a high-frequency circuit board.

Owner:彭代信

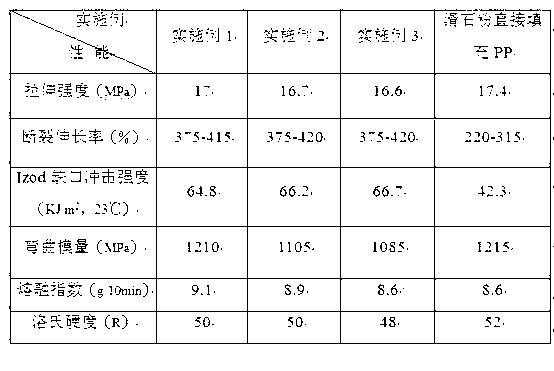

Talcum powder master batch and preparation method thereof

The invention relates to a talcum powder master batch and a preparation method thereof. The talcum powder master batch comprises the following components: 75-84% of talcum powder, 15-25% of ethylene-octene copolymer, 0.3-0.6% of antioxidant and 0.3-0.6% of lubricant. The preparation method of the talcum powder master batch comprises the following steps of: adding all the components to a banbury mixer for banburying according to the proportion, wherein the banburying time ranges from 5 to 7 min and the temperature ranges from 110 to 130 DEG C; next, adding the mixture to a double-screw extruder for mixing, wherein the extrusion temperatures of the first section and the second section of the double-screw extruder range from 150 to 170 DEG C, and the extrusion temperatures of other several sections range from 170 to 200 DEG C; and the total stay time of the mixture in the double-screw extruder ranges from 3 to 8 min; and finally, extruding the obtained material, and then cooling and the material and performing grain-sized cutting, thereby obtaining the desired talcum powder master batch. As the talcum powder master batch is used, the dust pollution caused in the use of the traditional talcum powder is solved, and the tenacity of a modified polypropylene material can be improved so that the modified polypropylene material can keep excellent rigidity.

Owner:SUZHOU HECHANG POLYMERIC MATERIALS

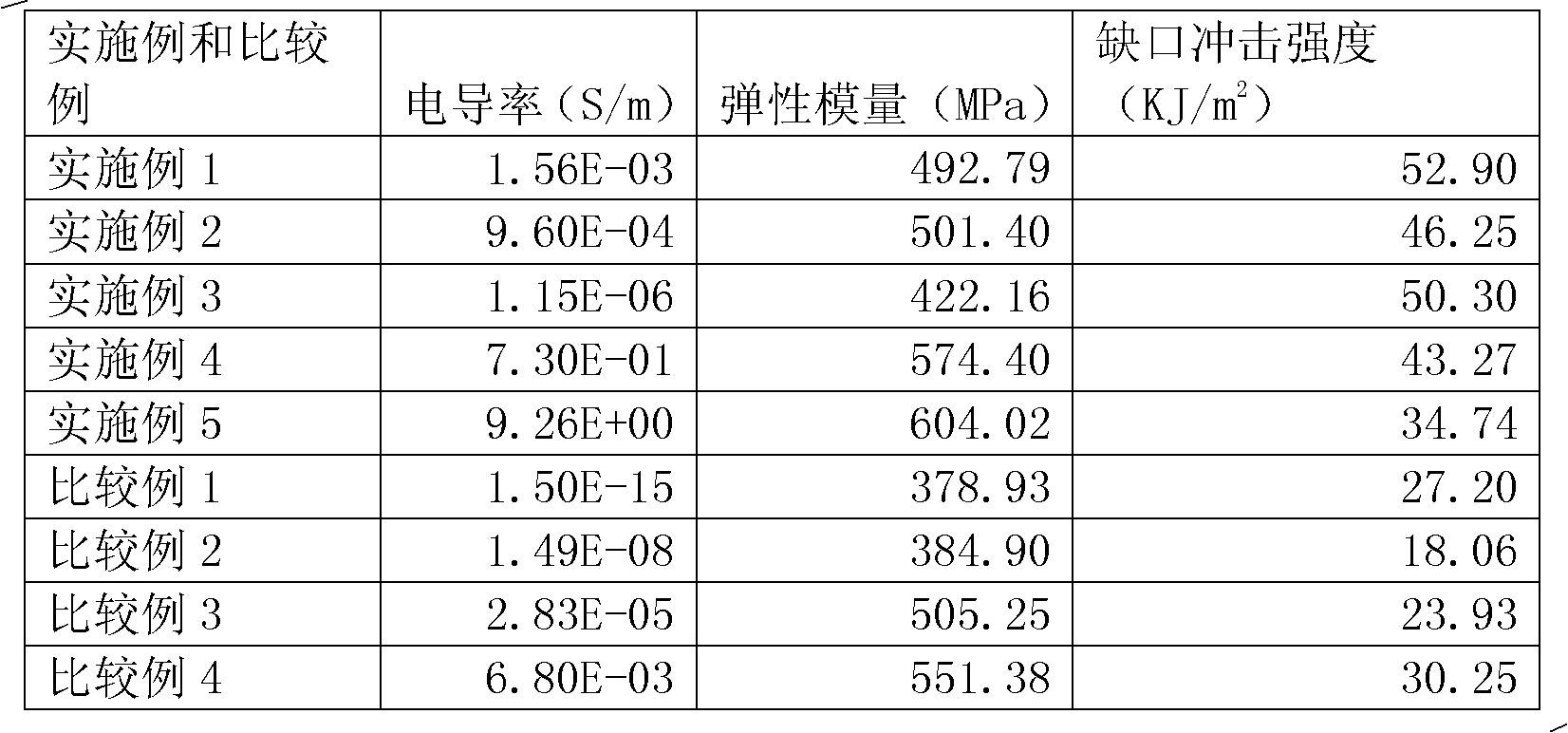

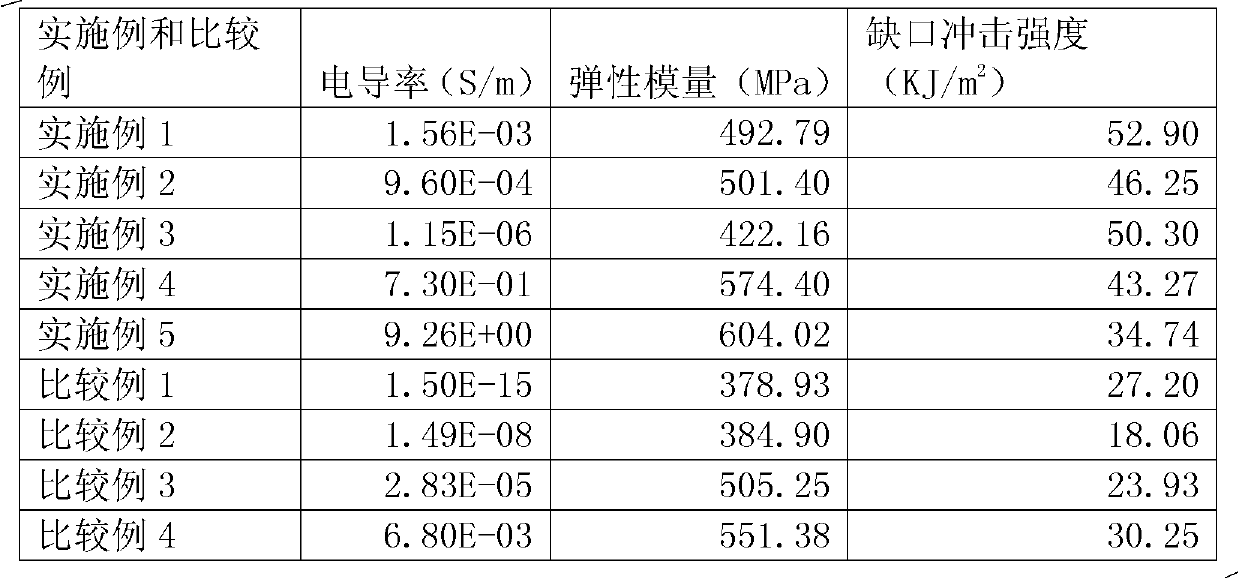

High-tenacity conducting nanocomposite material and preparation method thereof

ActiveCN102604186AGood electrical propertiesLarge aspect ratioCarbon nanotubeUltimate tensile strength

The invention relates to a high-tenacity conducting nanocomposite material and a preparation method thereof. The electrical conductivity of a polymer material is improved, at the same time, the mechanical properties, especially shock resistance, of the material is improved. The composite material uses carbon nanotubes as an electrically-conducting part, and is added with inorganic rigid calcium carbonate nano particles, further improves the electrical conductivity of the composite material by utilization of the volume exclusion effect of nano calcium carbonate, and at the same time, the inorganic toughening effect is achieved through the surface modification of nano calcium carbonate. The preparation method provided by the invention is simple and is suitable for industrial production; and the prepared composite material has high elastic modulus, impact strength and specific conductivity.

Owner:BEIJING UNIV OF CHEM TECH

Antistatic reinforced PP/ABS alloy material and preparation method thereof

The invention discloses an antistatic reinforced PP / ABS alloy material and a preparation method thereof. The antistatic reinforced PP / ABS alloy material comprises the following raw materials in parts by weight: 35-55 parts of PP, 15-30 parts of ABS, 2-5 parts of a compatilizer, 0.3-0.6 part of a coupling agent, 0.3-0.5 part of a compound antioxidant, 3-5 parts of a compound antistatic agent, 0.3-0.5 part of a lubricant and 15-30 parts of alkali-free glass fiber. The antistatic reinforced PP / ABS alloy material has the advantages of high heat-resistance temperature, low shrinking percentage, low surface impedance, good mechanical property, wide application range and the like.

Owner:佛山市东丽塑胶有限公司

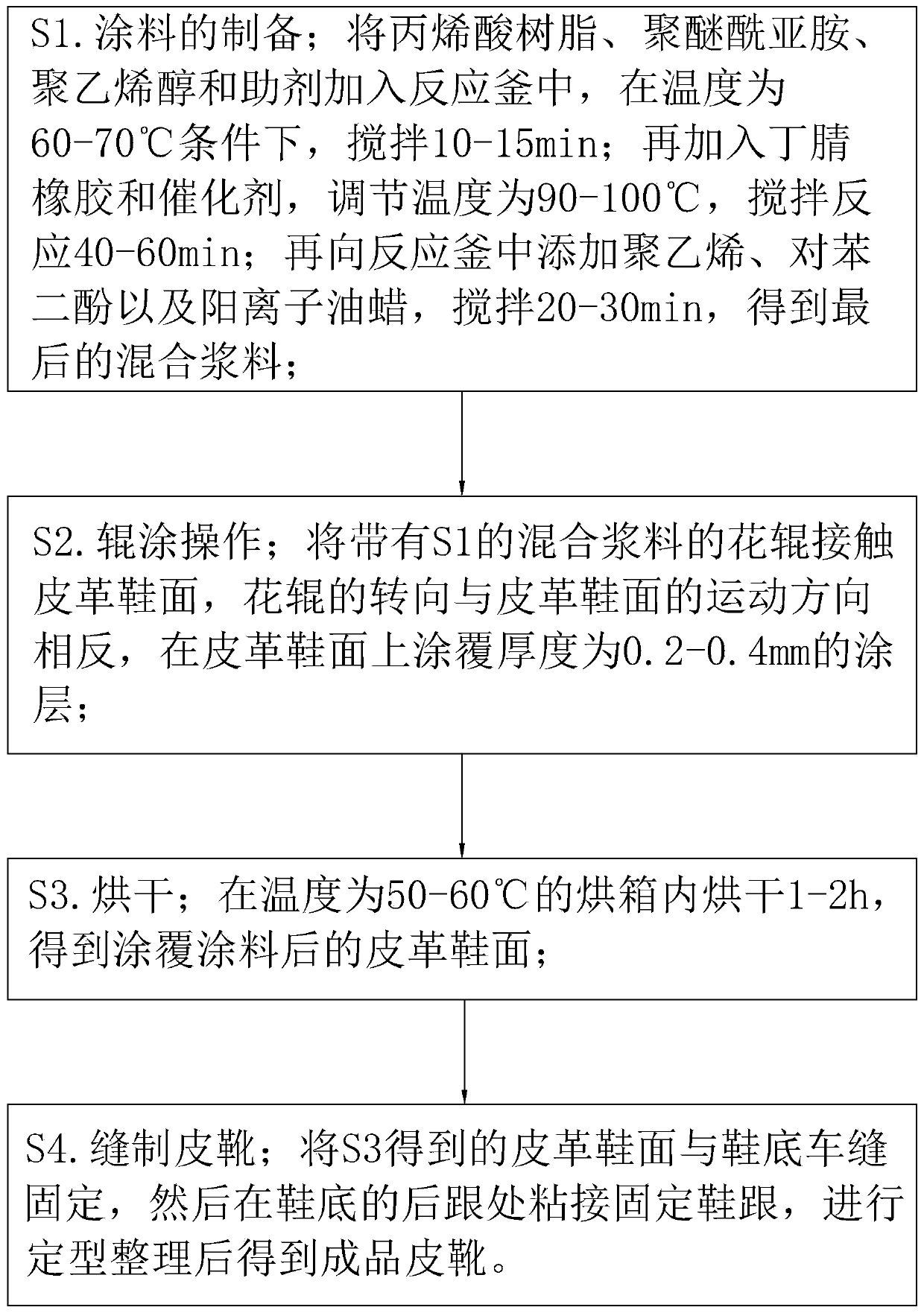

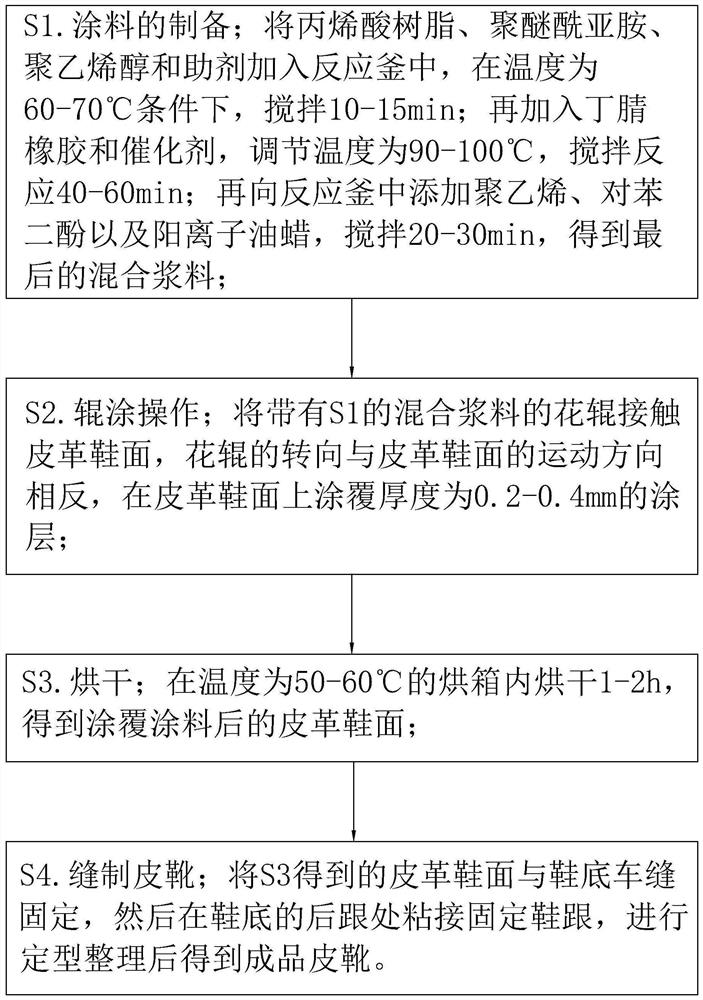

Leather boot and preparation method thereof

ActiveCN111213953AHigh modulusImprove heat resistanceFireproof paintsConjugated diene hydrocarbon coatingsImidePolymer science

The invention relates to the technical field of women's shoes, and discloses a leather boot. The leather boot comprises a leather vamp and a sole, wherein the leather vamp is coated with a coating, and the coating comprises the following components in parts by weight: 80-100 parts of acrylic resin, 10-15 parts of polyetherimide, 5-6 parts of nitrile rubber, 3-4 parts of a catalyst, 8-10 parts of polyvinyl alcohol, and 2-4 parts of an auxiliary agent. The leather boot has the following advantages and effects that: polyetherimide is added into the acrylic resin to form a particle dispersion phase, thereby enhancing the toughness of the acrylic resin; under the action of the catalyst, nitrile rubber and acrylic resin react to form an interpenetrating network, and a flexible section is introduced, so that the mobility of a network chain is improved, and the toughening effect is achieved; and the nitrile rubber changes acrylate into a proper net-shaped structure, so that the toughness and weather resistance of the acrylic resin are improved, the toughness and weather resistance of the leather vamp coated with the coating are improved, the situation that the leather vamp cracks in the storage process is avoided, and the service life of the leather vamp can be prolonged.

Owner:温州市丰盛鞋业有限公司

Anti-static polyvinyl chloride (PVC) plastic floor with double-layer structure

InactiveCN102373795AResilientMeet the protection requirementsFlooringHydroquinone CompoundCarbon black

The invention belongs to a polyvinyl chloride (PVC) floor, in particular to a double-layer anti-static PVC plastic floor. The anti-static PVC plastic floor with a double-layer structure is characterized by comprising the double-layer structure, wherein a surface layer is formed by auxiliary material, and a bottom layer is formed by main material; the formula of the main material of the anti-static PVC plastic floor contains the following components in parts by weight: 100-120 parts of PVC resin, 8-10 parts of lead sulfate tribasic, 200-250 parts of kaolin, 25-30 parts of dipentaerythritol, 5-10 parts of carbon black, 4-6 parts of dibutyl phthalate, 5-10 parts of ethoxylation aliphatic alkyl amine and 10 parts of paraffin; and the formula of the auxiliary material contains 100-120 parts of PVC resin, 10-12 parts of methacrylate-butadiene-styrene (MBS) resin, 3-5 parts of zinc stearate, 4-6 parts of dibutyl phthalate, 5-8 parts of lead sulfate tribasic and 2-4 parts of di-tert-butyl hydroquinone. In the anti-static PVC plastic floor with the double-layer structure, a high polymer plasticizing system is applied, so that the release of volatile organic compounds can be greatly reduced, and the anti-static PVC plastic floor meets the requirement of environmental protection; furthermore, the double-layer structure is adopted, and the surface-layer structure has good wear resistance and other excellent performance.

Owner:SUZHOU FUTONG NEW MATERIALS & HIGH TECH

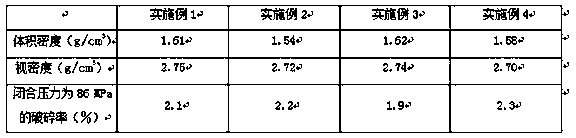

Halogen-free flame-retardant high-toughness bulk molding compound and method for preparing same

The invention provides a halogen-free flame-retardant high-toughness bulk molding compound and a method for preparing the same, and relates to the technical field of bulk molding compounds. The halogen-free flame-retardant high-toughness bulk molding compound comprises unsaturated polyester-polyurethane composite resin, curing agents, modified inorganic flame-retardant fillers, organic flame retardants, modified heavy calcium carbonate, release agents, reinforcement fibers, auxiliaries and toner. The method includes mixing raw materials for the halogen-free flame-retardant high-toughness bulkmolding compound with one another to form a compression molding or injection molding adhesive composite material 'in the shape of oil putty'; molding the compression molding or injection molding adhesive composite material by the aid of mold pressing processes to obtain the halogen-free flame-retardant high-toughness bulk molding compound. The halogen-free flame-retardant high-toughness bulk molding compound and the method have the advantages that unsaturated polyester and thermoset polyurethane interpenetrate network polymers, accordingly, the rigidity and the toughness of the halogen-free flame-retardant high-toughness bulk molding compound can be obviously improved, and the contraction ratio of the halogen-free flame-retardant high-toughness bulk molding compound can be reduced; multiple inorganic / organic composite halogen-free flame-retardant systems are used, synergistic effects can be realized by the multiple inorganic / organic composite halogen-free flame-retardant systems, accordingly, the halogen-free flame-retardant high-toughness bulk molding compound can be free of halogen and low in smoke and is nontoxic, environmental impact can be minimized, and the flame retardance of the halogen-free flame-retardant high-toughness bulk molding compound can be optimized.

Owner:ANHUI UNIVERSITY

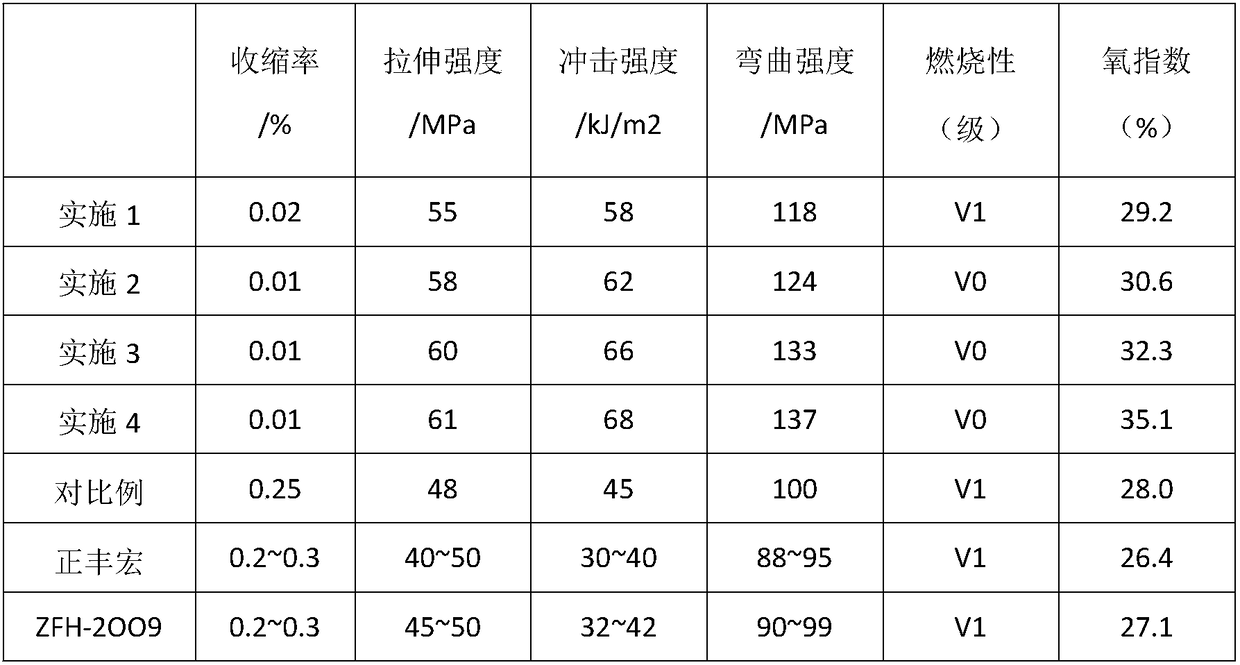

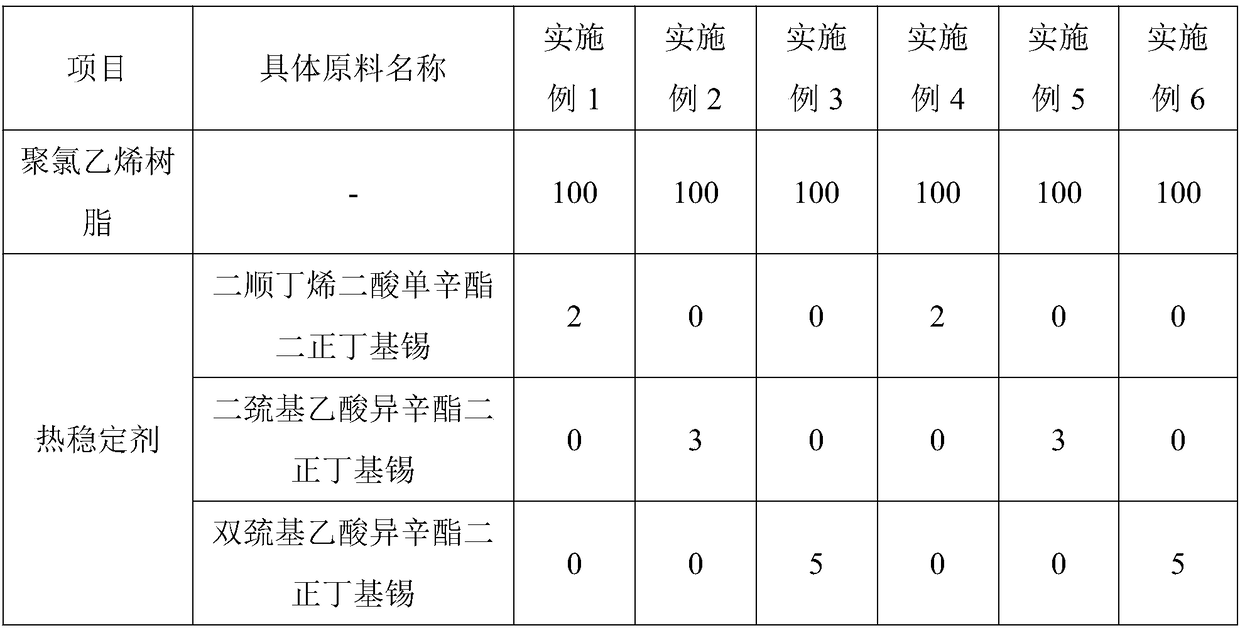

High-impact and high-fluidity polyvinyl chloride material and preparation method thereof

InactiveCN108084609ATo achieve toughening effectLarge specific surface areaPolyvinyl chlorideElectroplating

The invention discloses a high-impact and high-flow polyvinyl chloride material and preparation method thereof. The material has good high-low temperature impact resistance and excellent processing fluidity, and is a composite material which takes the polyvinyl ethylene as the base material and is blended and modified. The material is specifically prepared from the following components in parts byweight: 100 parts of polyvinyl chloride resin, 2-5 parts of heat stabilizer, 1-3 parts of lubricant, 0.5-2.5 parts of processing auxiliary, and 5-20 parts of composite impact modifier. The polyvinylchloride modified material provided by the invention can be used for preparing various pieces through an injection molding way, the traditional ABS material with expensive price is replaced, and the polyvinyl chloride material can be used for wine external package and decorative materials with an electroplating demand.

Owner:宜宾天亿新材料科技有限公司

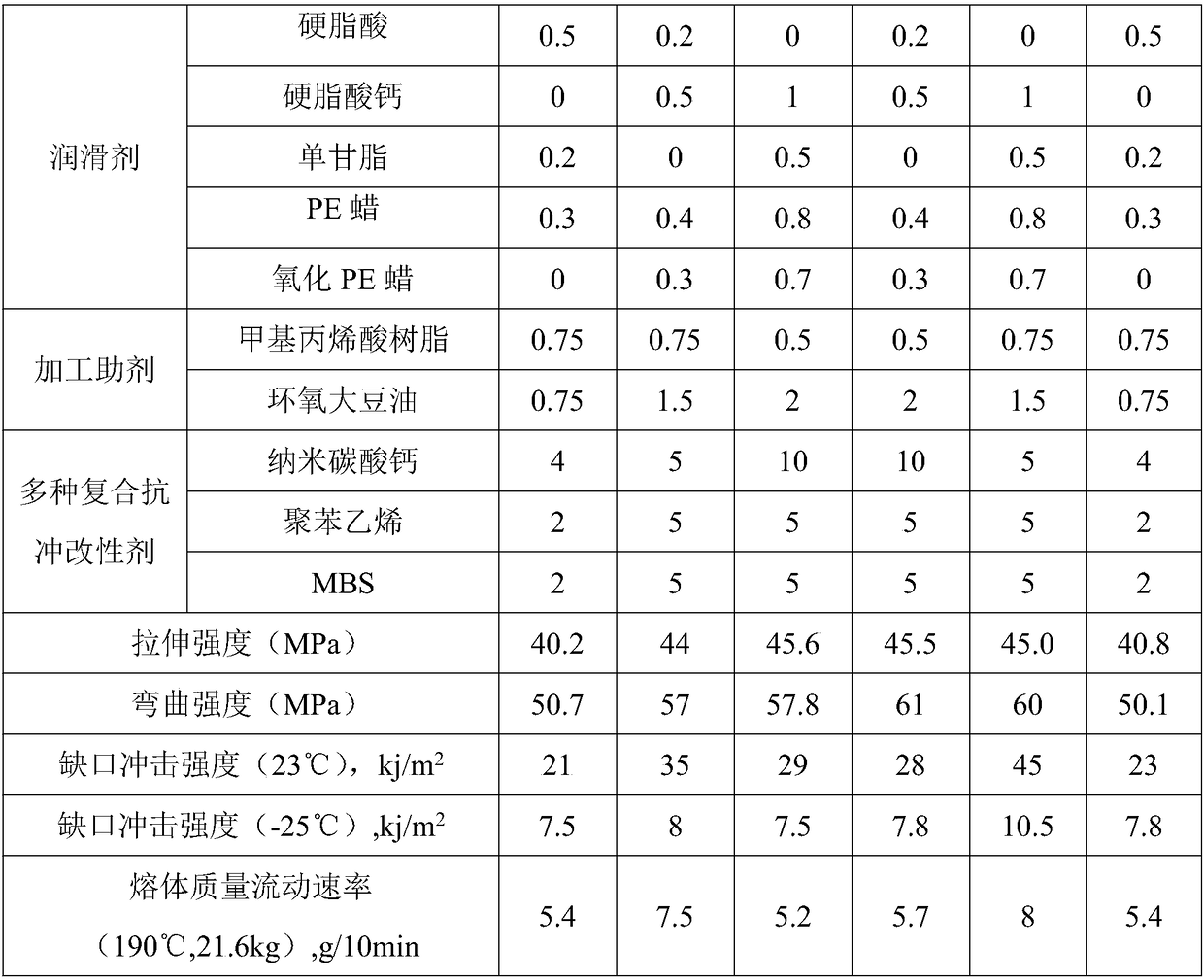

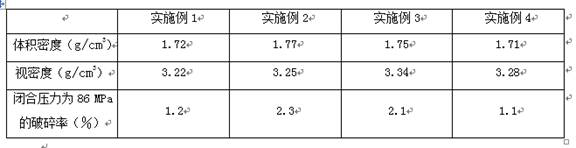

Sintering process of petroleum fracturing propping agent

ActiveCN111499344AGuaranteed performanceGuaranteed hardnessFluid removalDrilling compositionGraphitePotassium feldspar

The invention provides a sintering process of a petroleum fracturing propping agent, wherein the sintering process comprises the following steps: removing impurities from potassium feldspar, drying, and pulverizing to obtain potassium feldspar fine powder; uniformly mixing the potassium feldspar, graphite powder and magnesium powder, introducing protective gas, firing for 1-2 h at the temperatureof 600-700 DEG C, heating to 950-1100 DEG C, firing for 1-2 h, cooling, taking out, and crushing again to obtain secondary powder; and mixing the secondary powder with light calcined clay, sodium tripolyphosphate and tuff, carrying out spray mixing granulation and polishing to obtain ceramic primary particles, introducing protective gas, sintering the ceramic primary particles at the temperature of 1150-1210 DEG C for 0.5-1 h, continuously heating to 1250-1350 DEG C, and sintering for 1-2 h to obtain the petroleum fracturing propping agent. The method avoids the application of high-aluminum minerals, ensures the performance of the petroleum fracturing propping agent as much as possible, and has a great application prospect.

Owner:郑州市新郑梅久实业有限公司

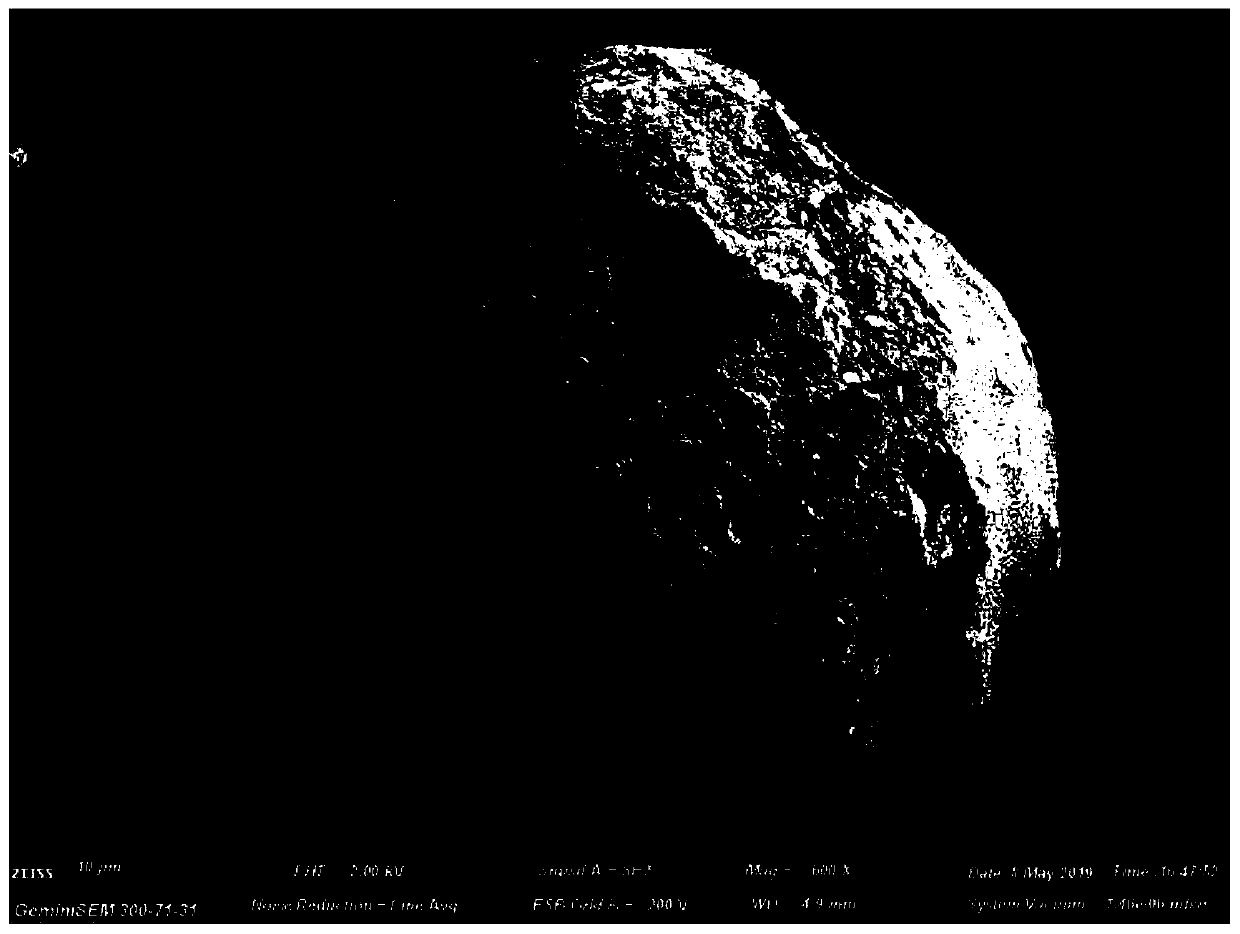

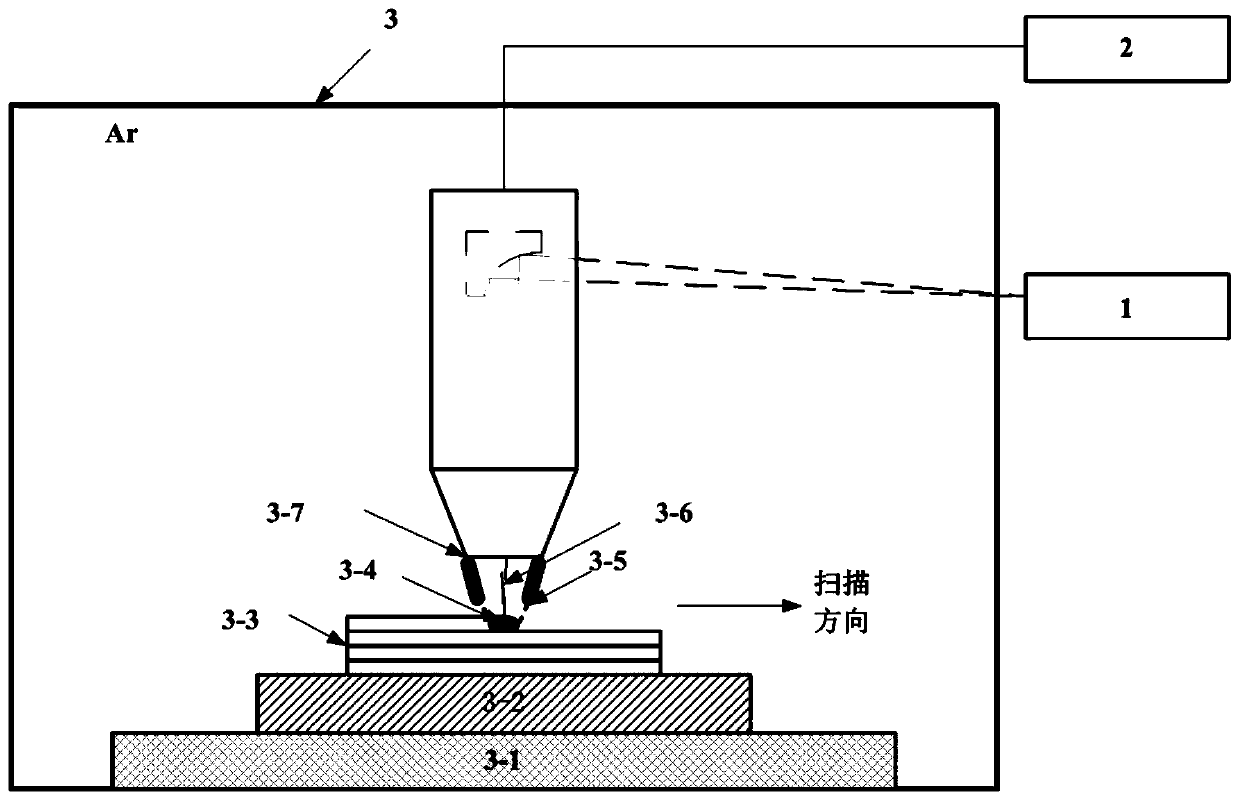

Graphene aluminum-based composite powder used for laser deposition manufacturing, and preparation method and application thereof

ActiveCN110666179AInterface is well integratedStrong compactnessAdditive manufacturing apparatusIncreasing energy efficiencyMetal matrix compositeDeposition process

Graphene aluminum-based composite powder used for laser deposition manufacturing, and a preparation method and application thereof belong to the field of metal-based composite materials. In the graphene aluminum-based composite powder used for laser deposition manufacturing, the mass ratio of a few layers of graphene nanosheets prepared by a thermal expansion-ultrasonic combined method to aluminummatrix powder equals to 1: (666-1999), and the sphericity is 0.85-0.9. The few layers of graphene nanosheets are prepared by the thermal expansion ultrasonic combined method, and wet ball-milling isadopted, so that the few layers of graphene nanosheets are uniformly dispersed on the surface of aluminum powder particles under a scanning electron microscope. The laser deposition process is adoptedfor forming, and a graphene aluminum-based composite workpiece has good interface bonding, strong compactness, no pore defects, and improved strength and toughness.

Owner:SHENYANG AEROSPACE UNIVERSITY

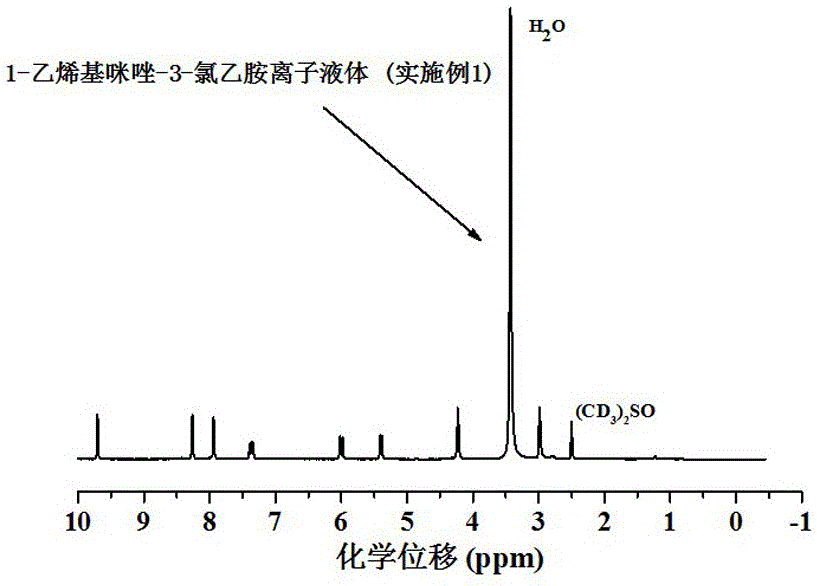

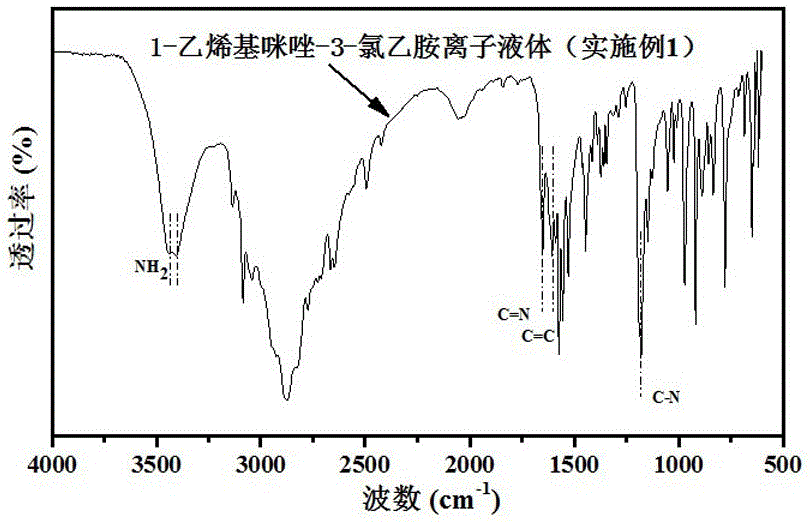

Modified cyanate resin and preparation method thereof

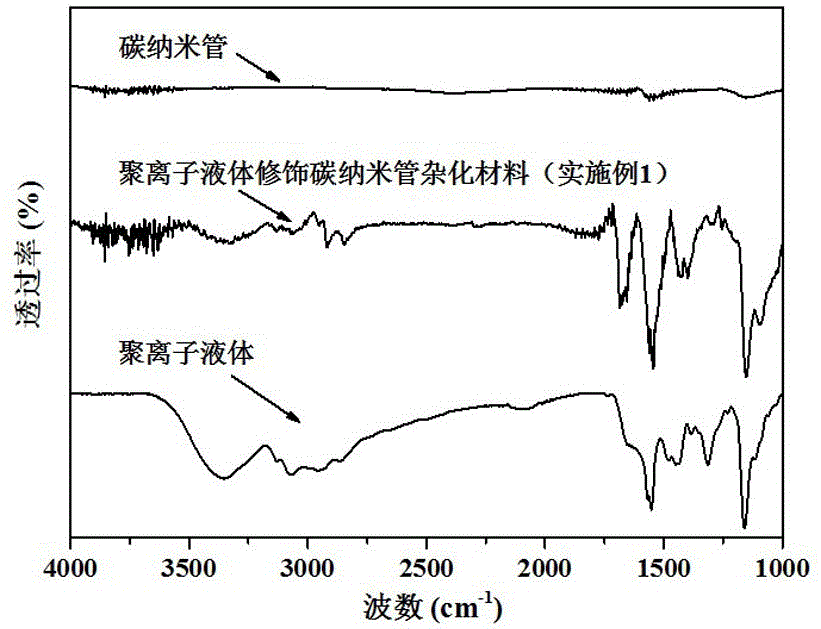

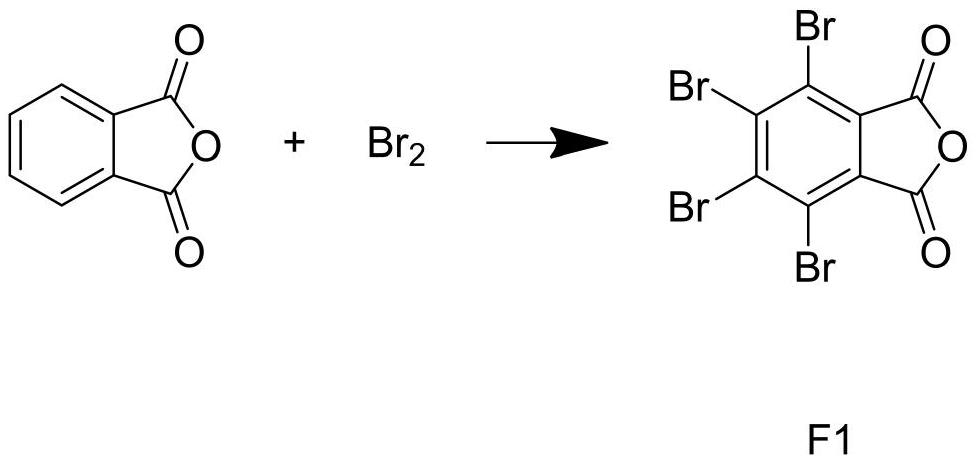

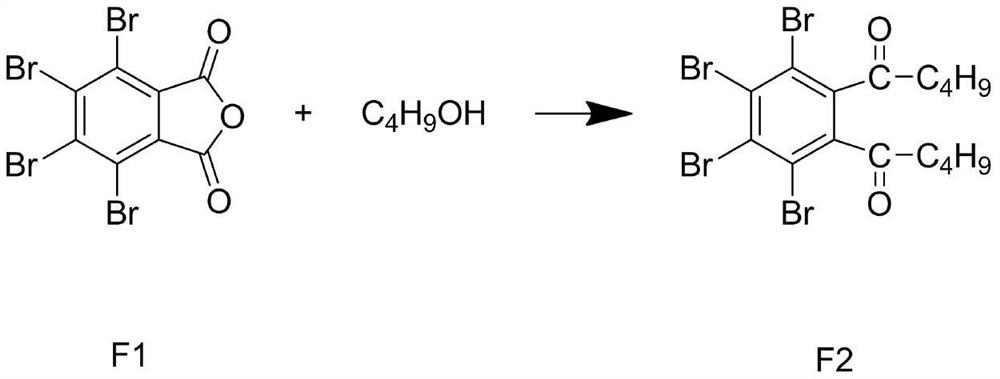

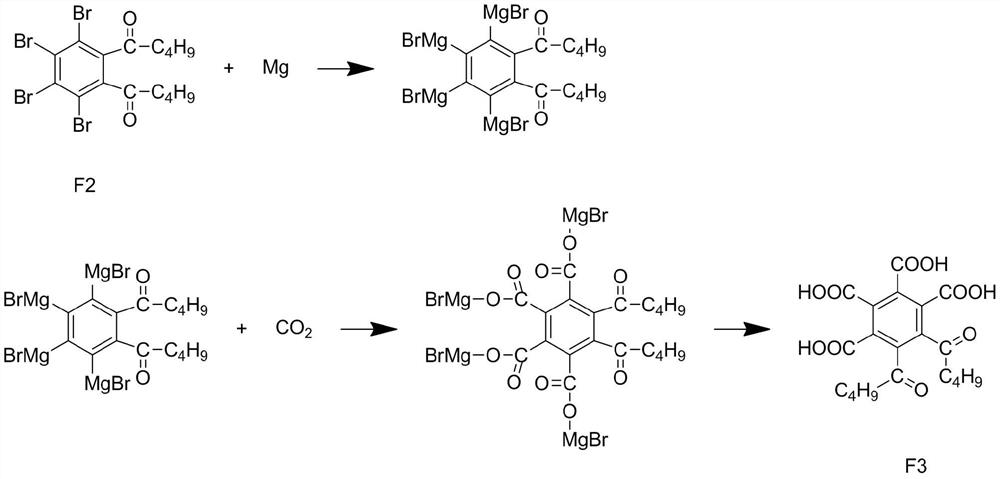

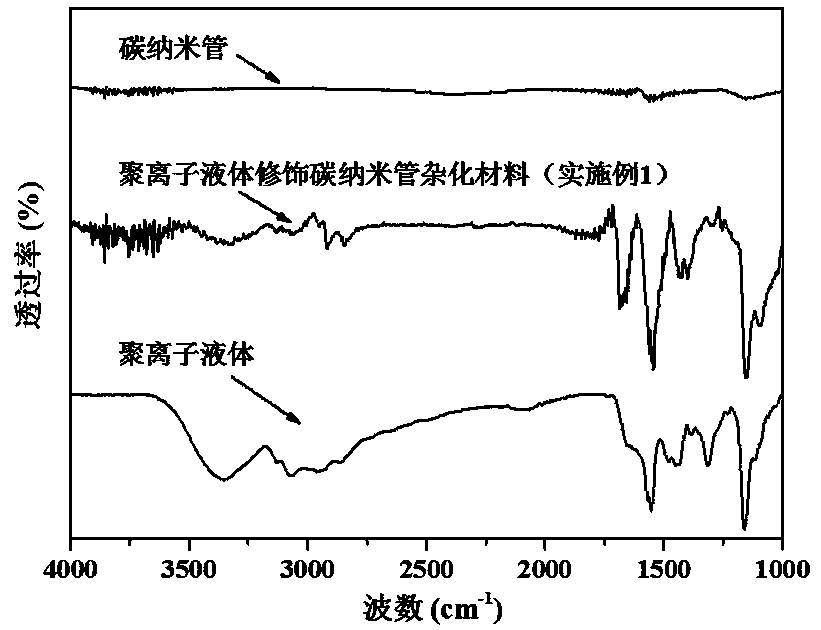

ActiveCN106046782AGood curing processSignificant synergistic catalytic effectModified carbonIn situ polymerization

The invention discloses modified cyanate resin and a preparation method thereof. The preparation method comprises the following steps: uniformly mixing 100 parts by mass of molten cyanate resin and 0.10-1.55 parts by mass of poly ionic liquid modified carbon nanotube hybrid material, and carrying out curing and after-treatment to obtain the modified cyanate resin. The synthesis process of the poly ionic liquid modified carbon nanotube hybrid material comprises the following steps: 1. synthesizing amino-terminated ionic liquid containing a transition metal; and 2. carrying out in-situ polymerization by using the ionic liquid to coat the carbon nanotubes. Compared with the cyanate resin, the modified cyanate resin prepared by the method disclosed by the invention has the advantages of favorable curing manufacturability, higher toughness, higher heat stability, stable dielectric constant and lower dielectric loss. The preparation method of the modified cyanate resin has the characteristics of simple technique, high controllability and the like.

Owner:SUZHOU UNIV

Floor adhesive based on water-based acrylic resin and preparation process of floor adhesive

ActiveCN111892889AImprove water resistanceNot easy to pull outNon-macromolecular adhesive additivesEpoxy resin adhesivesPolymer scienceAcrylic resin

The invention discloses a floor adhesive based on water-based acrylic resin and a preparation process of the floor adhesive. The floor adhesive is prepared from the following raw materials in parts byweight: 100 to 120 parts of modified waterborne acrylic emulsion; 12 to 15 parts of toughening agent; 10 to 15 parts of diluent; 2 to 3 parts of talcum powder; 2 to 3 parts of asbestos powder; 2 to 3parts of aluminum powder; and 0.8 to 1.5 parts of mildew preventive. When the floor adhesive is used, the floor adhesive and an isocyanate curing agent are mixed according to the mass ratio of 3: 1;the modified water-based acrylic emulsion and the toughening agent are prepared in the preparation process of the floor adhesive; molecules of the modified water-based acrylic emulsion contain a largenumber of silicon-oxygen bonds; the bond energy of the silicon-oxygen bond is far higher than that of carbon-carbon bonds, so that the water resistance of the prepared floor adhesive is improved; anda single toughening agent molecule contains a plurality of cyano groups with extremely strong polarity, so that the blending effect of the toughening agent and the modified water-based acrylic emulsion is improved when the toughening agent is mixed with the modified water-based acrylic emulsion, and therefore, the service life of the adhesive is further prolonged.

Owner:珠海百翔新材料有限公司

Mullite fiber toughened pot clay for pottery

The invention provides mullite fiber toughened pot clay for pottery, and belongs to the technical field of ceramic materials. The mullite fiber toughened pot clay is prepared from the following components in parts by mass: 30 to 40 parts of kaolin, 25 to 35 parts of quartz, 10 to 20 parts of hydromuscovite, 1 to 6 parts of mullite fiber, 4 to 10 parts of alumina particles, 10 to 20 parts of attapulgite and 4 to 10 parts of graphene. According to the mullite fiber toughened pot clay provided by the invention, the mullite fiber and the alumina particles are added in a conventional pot clay formula, so that the toughness of pot clay is increased by combining the mullite fiber with the alumina particles; meanwhile, by combining a fiber toughening technology with a particle toughening technology, the toughness of the pot clay can be greatly increased through compound toughening.

Owner:FOSHAN JIAYI ART CERAMICS RES CO LTD

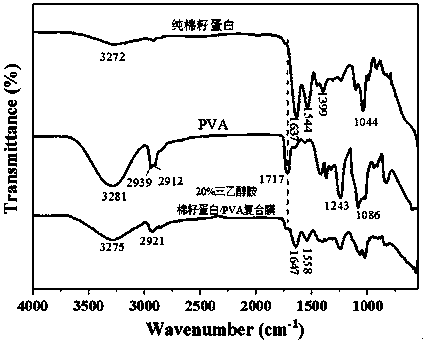

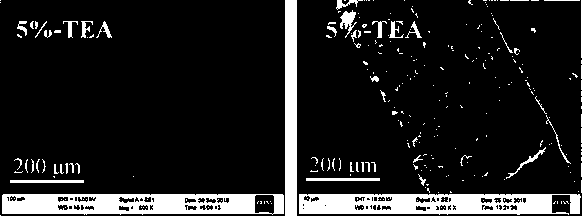

Method for preparing high-toughness cottonseed protein based composite membrane

The invention discloses a method for preparing a high-toughness cottonseed protein based composite membrane. The method comprises the following steps: (1) refining cottonseed protein; (2) preparing acottonseed protein solution and a water-soluble high polymer solution; (3) adding the cottonseed protein solution into the water-soluble high polymer solution, and carrying out uniform stirring at a certain temperature, so as to obtain a solution A; (4) adding a tertiary amine based alcoholic reagent into the solution A, and carrying out stirring for 1 to 5 hours in a thermostatic water bath withthe temperature of 40 DEG C to 60 DEG C, so as to obtain a solution B; and (5) after the solution B is cooled, preparing the cottonseed protein based composite membrane with relatively good toughnessby a casting method. Water-soluble high polymers include, but not limited to, polyvinyl alcohol, polyethylene oxide and gelatin; the addition level of the tertiary amine based alcoholic reagent is 5%to 30% the total mass of the cottonseed protein and the water-soluble high polymers; and a mass ratio of the cottonseed protein to the water-soluble high polymers is (9: 1) to (1: 9). According to themethod, on one hand, the tertiary amine based alcoholic reagent serves as a plasticizer, and thus, the elongation at break of the protein membrane is increased; and on the other hand, the tertiary amine based alcoholic reagent serves as a physical cross-linker, cross-linked bridges are formed between molecular chains of the cottonseed protein and the high polymers through hydrogen bonds under theaction of tertiary amine groups with relatively high electronegativity, a novel cross-linked network is formed, and thus, the tensile strength of the protein membrane is enhanced. Thereby, the high-toughness cottonseed protein based composite membrane is prepared.

Owner:ZHONGKAI UNIV OF AGRI & ENG

Highlight glaze for ancient building porcelain as well as preparation method and application of highlight glaze

The invention relates to highlight glaze for ancient building porcelain as well as a preparation method and application of the highlight glaze. The highlight glaze for the ancient building porcelain comprises the following components in parts by weight: 20-30 parts of potassium feldspar, 10-15 parts of hollow nanoparticles, 8-10 parts of modified glass beads, 15-20 parts of quartz, 3-6 parts of niobium oxide, 6-8 parts of magnesium oxide, 10-12 parts of a binder, 5-8 parts of barium chromate, 18-20 parts of kaolin and 50-60 parts of water. The preparation method of the highlight glaze for ancient building porcelain comprises the following steps: S1, stirring and mixing potassium feldspar, modified glass beads, quartz, niobium oxide, magnesium oxide, barium chromate, kaolin and water, and performing ball milling to obtain glaze slip; s2, stirring and mixing a binder and the hollow nanoparticles; and S3, uniformly mixing the glaze slip obtained in the step S1 and the mixture obtained in the step S2 to obtain the highlight glaze for the ancient building porcelain. The prepared highlight glaze for ancient building porcelain is smooth in glaze surface, and has excellent glossiness and good mechanical properties.

Owner:德化县万宝古建陶瓷有限公司

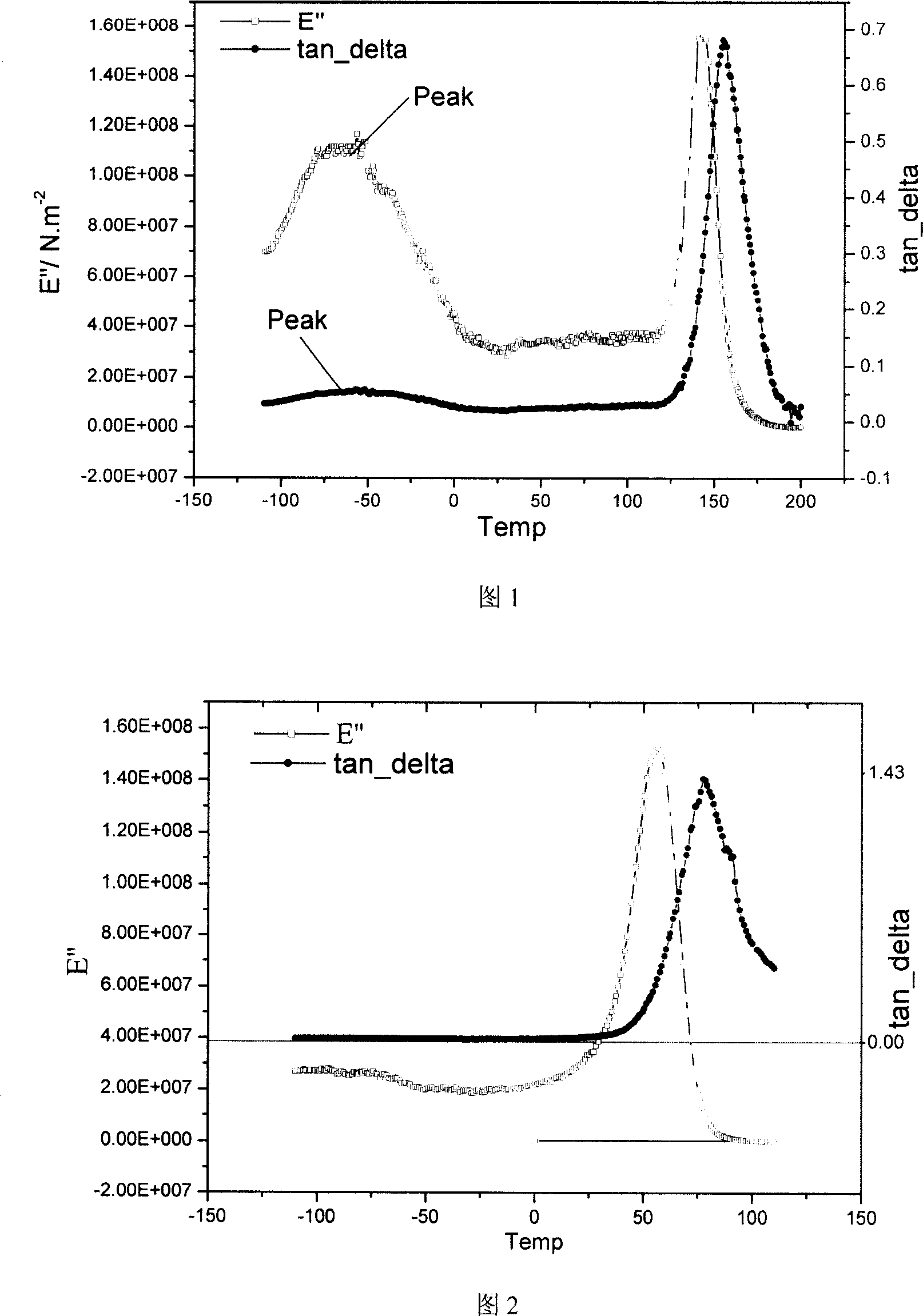

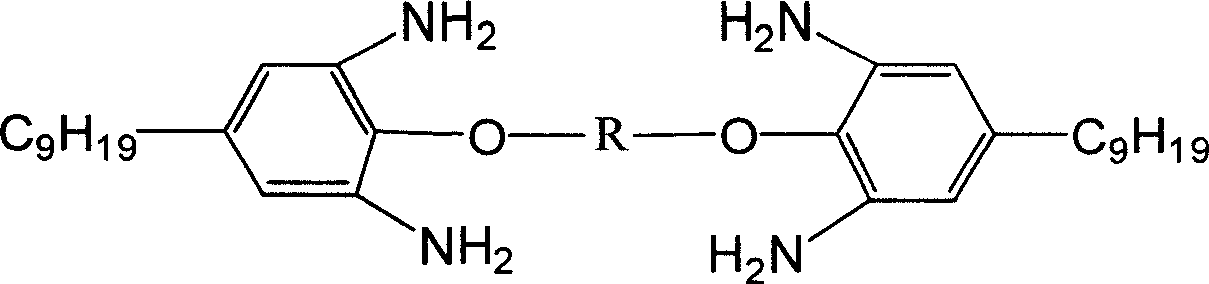

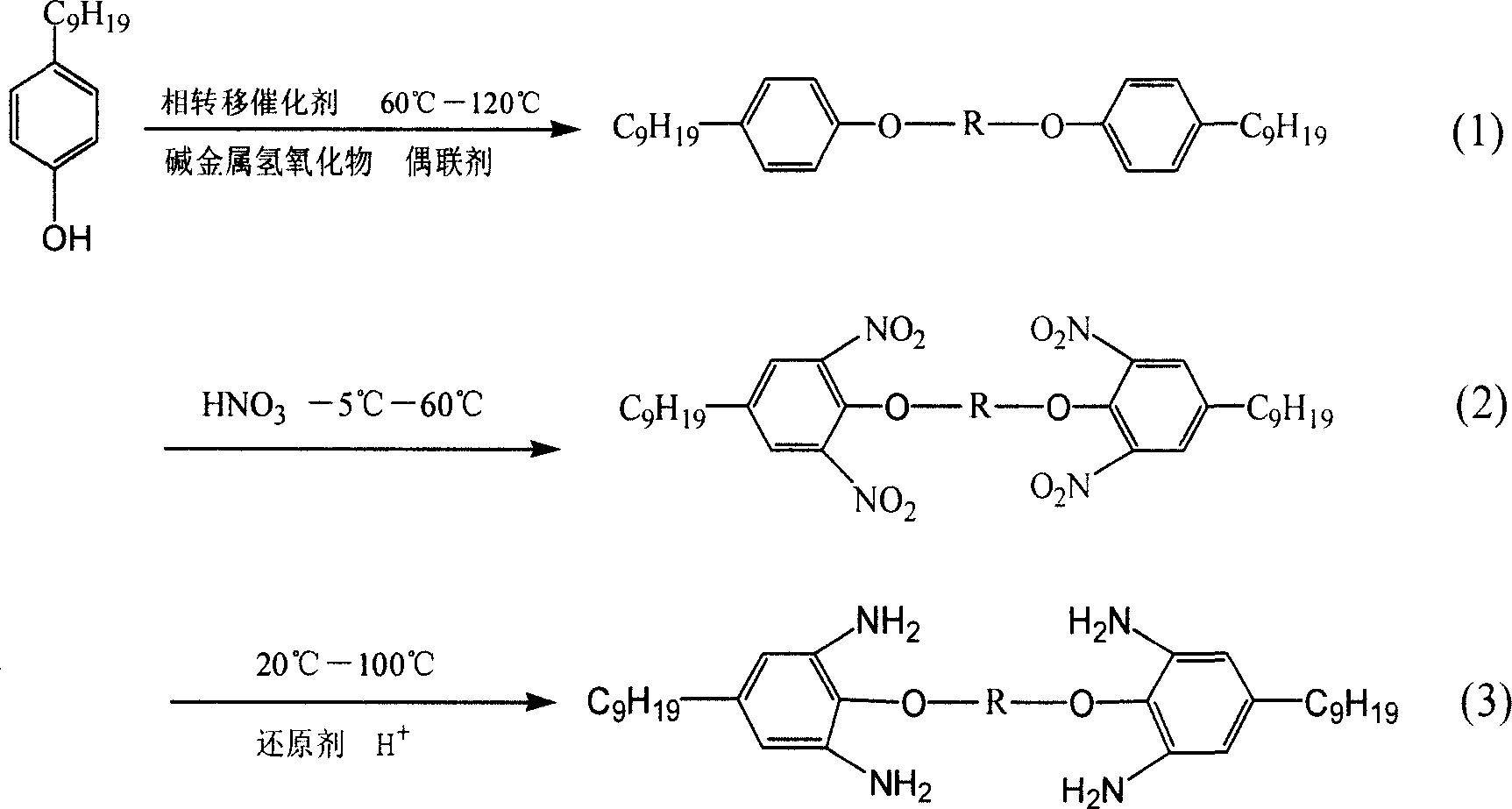

Active epoxy toughening-curing agent, and its preparing method

InactiveCN1978483ARigidity is not affectedTo achieve toughening effectOrganic chemistryEpoxyNitration

This invention involves a aromatic amine epoxy curing agent and its preparation. The curing agent takes the nonylphenol and dibromo substitute hydrocarbon as raw materials. After coupling, nitration, reduction to obtain. Not add any toughening agent circumstances, impact toughness of curing product risen 30% than ordinary aromatic amine curing agent, also molecule contains more amid, making the curing agent activity, in the medium temperature (60-100 C degree) curing resins, made up the shortcomings of high curing temperature of aromatic amine curing agent.

Owner:BEIHANG UNIV

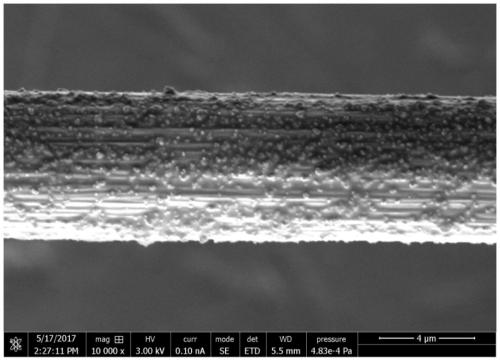

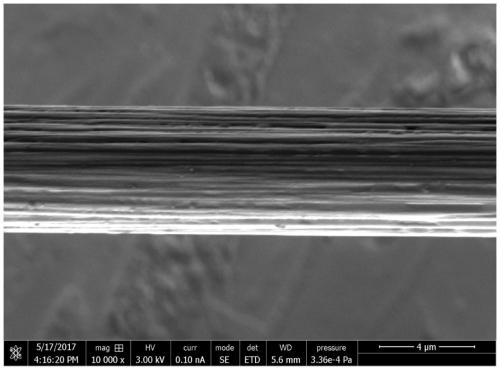

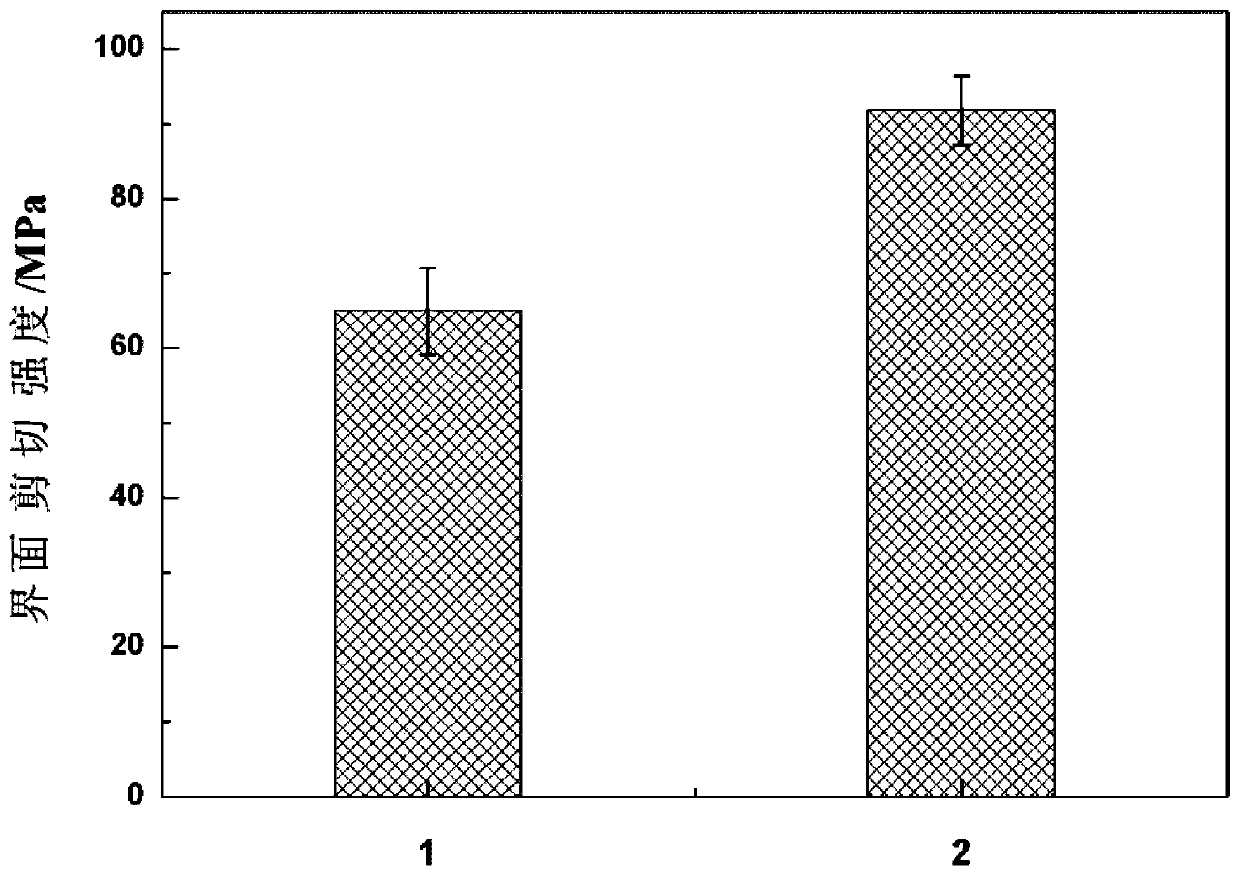

A method to simultaneously improve the interfacial strength and toughness of carbon fiber epoxy composites

The invention relates to a method capable of improving interface strength and toughness of a carbon fiber epoxy composite material at the same time. The problem in the existing carbon fiber treatmentmethod that the interface strength and toughness between the carbon fiber and the resin cannot be improved at the same time is solved. The method comprises the following steps: modifying the surface of zirconium oxide (ZrO2) by using a silane coupling agent; uniformly mixing the modified ZrO2, epoxy resin and an organic solvent to prepare a sizing agent; performing agent removing treatment on carbon fiber; enabling the carbon fiber to pass through a slurry tank with the sizing agent according to a dipping method and then drying to complete surface modification on the carbon fiber for the carbon fiber epoxy composite material. According to the method, the interface micro-area is strengthened and toughened by completely utilizing the ZrO2 and uniform distribution of the ZrO2 on the surface of the fiber, strong and weak chemical bonding which is distributed at intervals is built on the interface, the interface strength is improved through construction of chemical bonds and reduction of interface toughness caused by over-strong chemical bonds is avoided; meanwhile, the ZrO2 particles can hinder extension of crack and induce micro-crack, achieves the effect of dispersing the energy of the tip of the main crack and achieves the toughening effect.

Owner:SHAANXI UNIV OF SCI & TECH

Preparation method of high-strength casting coating for stainless steel casting

PendingCN112658203AHigh strengthReduce stress concentrationFoundry mouldsFoundry coresCarbide siliconCrazing

The invention relates to a preparation method of a high-strength casting coating for a stainless steel casting, and belongs to the technical field of casting coatings. According to the preparation method of the high-strength casting coating for the stainless steel casting, zirconium sand, zirconium oxide whiskers and silicon carbide whiskers are used as refractory fillers, the zirconium oxide whiskers and the silicon carbide whiskers are modified by ethyl orthosilicate to prepare the high-strength casting coating for the stainless steel casting, the zirconium oxide whiskers and the silicon carbide whiskers are added into the coating, so that the strength of a coating film can be effectively improved; when the whiskers are subjected to external acting force, the whiskers bridged in the coating film can generate acting force to force cracks to be closed, so that the effect of consuming some external force to do work is achieved, then the toughness and strength of the coating film are improved, and when the cracks are diffused to the whiskers from the surface of the coating film, the diffusion direction of the cracks can be changed; and the cracks are diffused along the whiskers due to dissociation of the whiskers and the coating film, so that the area of the formed new surface is increased, the cracks can be within the critical size of the new surface, and the coating film is further reinforced.

Owner:成都途伊棠涂料科技有限公司

Modified thermoplastic polymer material and preparation method thereof

The present invention provides a modified thermoplastic polymer material, the modified thermoplastic polymer material comprises an epoxy resin cured coated matter, a ligament imitation material and a to-be-modified thermoplastic polymer which are in turn connected by interwining, and the ligament imitation material includes a functional thermoplastic elastomer, an additive and the like. The modified thermoplastic polymer material selects the epoxy resin cured coated matter as an inner core material, inorganic powder can be highly dispersed in the system, and the functional thermoplastic elastomer and the like are selected as the ligament imitation material for preferential reaction with surface groups of the epoxy resin cured coated matter, so that the functional thermoplastic elastomer and the like are strongly fixed around the epoxy resin cured coated matter, a toughening effect is achieved, at the same time, the strength of the to-be-modified thermoplastic polymer is basically not damaged, and the to-be-modified thermoplastic polymer has high toughness, high flexibility, high strength, low shrinkage and the like.

Owner:谭国权

A kind of sintering process of oil fracturing proppant

ActiveCN111499344BGuaranteed performanceGuaranteed hardnessFluid removalDrilling compositionPetroleumFire clay

The invention provides a sintering process of a proppant for petroleum fracturing, which comprises the following steps: removing impurities, drying and pulverizing potassium feldspar to obtain potassium feldspar fine powder; the potassium feldspar fine powder, graphite Powder and magnesium powder are mixed evenly, fired with protective gas at 600-700°C for 1-2 h, heated to 950-1100°C for 1-2 h, cooled, taken out, and crushed again to obtain secondary powder; Powder mixed with lightly burned clay, sodium tripolyphosphate and tuff, sprayed and mixed to granulate and polish to obtain ceramic primary particles, pass through protective gas, sinter the ceramic primary particles at 1150-1210°C for 0.5-1 h, and then continue Raise the temperature to 1250-1350°C and burn for 1-2 hours to obtain the oil fracturing proppant. This method has great application prospects in avoiding the application of high-alumina minerals and ensuring the performance of oil fracturing proppant as much as possible.

Owner:郑州市新郑梅久实业有限公司

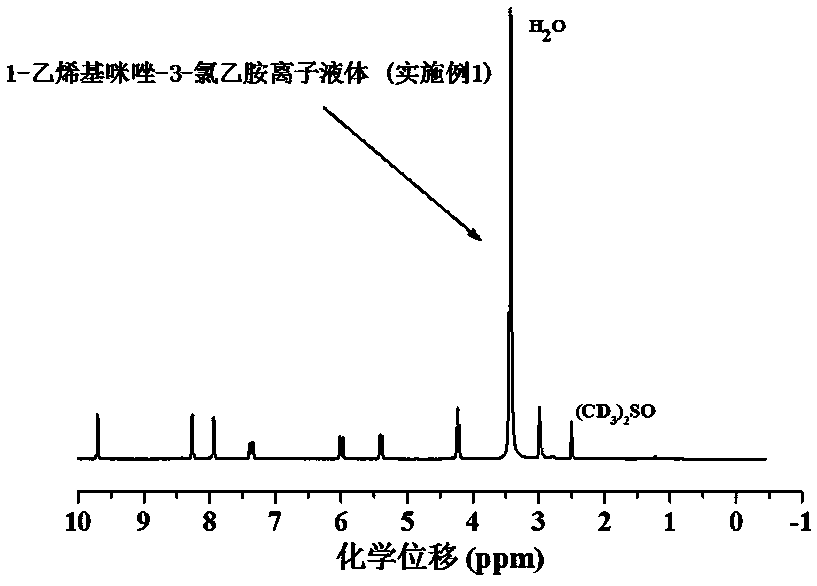

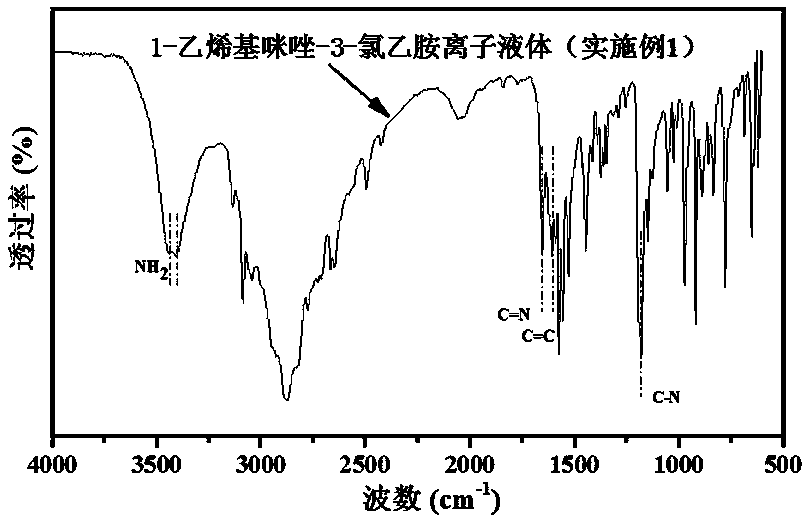

A kind of modified cyanate ester resin and preparation method thereof

ActiveCN106046782BGood curing processSignificant synergistic catalytic effectIn situ polymerizationModified carbon

Owner:SUZHOU UNIV

A method of preparing high-strength oil and gas fracturing proppant by using ceramsite waste

ActiveCN111499352BHigh strengthImprove reuseFluid removalDrilling compositionThermal insulationSodium phosphates

The invention provides a method for preparing a high-strength oil-gas fracturing proppant by using ceramsite waste, which comprises the following steps: after pulverizing the ceramic waste, ceramic fine powder is obtained; the ceramic fine powder, graphite powder, magnesium powder Mix evenly, pass in protective gas and burn at 600-700°C for 1-2 h, heat up to 950-1100°C and burn for 1-2 h, take it out after cooling, and pulverize again to obtain secondary powder; Sodium phosphate, tuff, and mineralizer are mixed, sprayed and mixed, granulated, and polished to obtain ceramic primary particles, and the protective gas is introduced, and the ceramic primary particles are fired at 1150-1210°C for 0.5-1 h, and then continue to heat up to 1250°C ‑1350℃ for 1‑2 h. The preparation of high-strength proppant for oil and gas fracturing by using the ceramic waste of insulation board provides a new direction for the treatment of construction waste.

Owner:郑州市新郑梅久实业有限公司

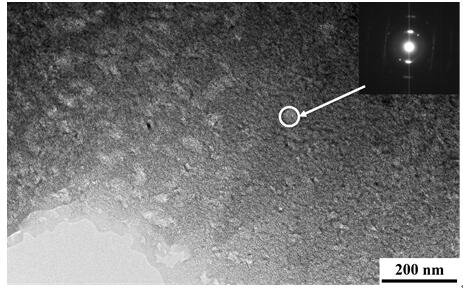

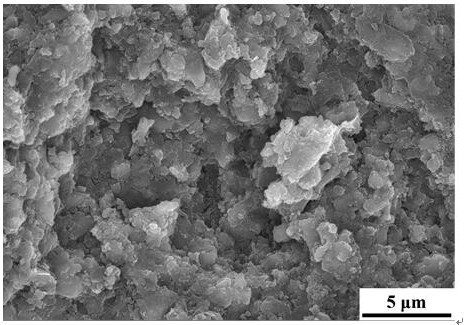

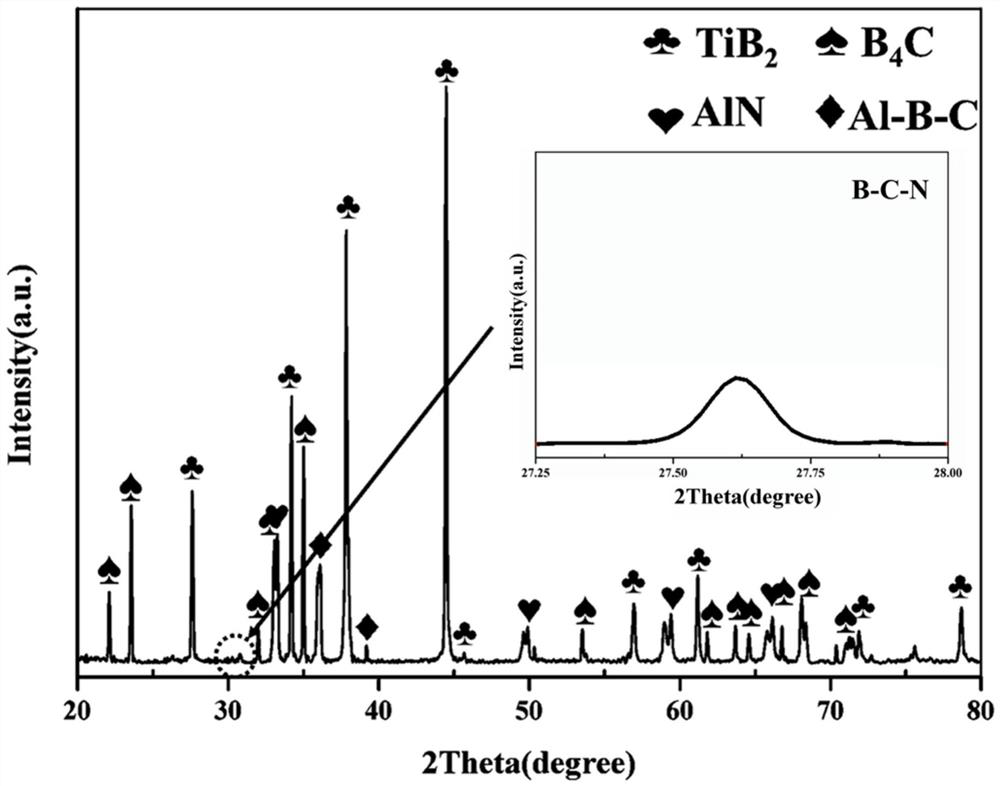

Preparation method of BCN nano amorphous phase toughened TiB2-B4C composite ceramic

The invention relates to a preparation method of BCN nano amorphous phase toughened TiB2-B4C composite ceramic, and belongs to the technical field of preparation of high-performance structural ceramic. According to the preparation method disclosed by the invention, the content proportion of each phase component in the raw material powder of the composite ceramic and the preparation process are limited, so that the BCN nano amorphous phase strengthened and toughened TiB2-B4C composite ceramic is prepared. The nano amorphous phase is an effective means for strengthening and toughening ceramic, and the main implementation ways comprise dispersion refinement, mixed crystal structure strengthening, pinning theory, residual stress field theory and the like. The invention aims to prepare a nano amorphous phase through an in-situ reaction, change the microstructure of TiB2-B4C composite ceramic and further improve the particle bonding mode and fracture mode of the TiB2-B4C composite ceramic, so that the strength and toughness of the ceramic material are improved, and a novel strengthening and toughening means of the structural ceramic material is provided.

Owner:NANJING INST OF TECH

A kind of leather boots and preparation method thereof

ActiveCN111213953BHigh modulusImprove heat resistanceFireproof paintsConjugated diene hydrocarbon coatingsImidePolymer science

The invention relates to the technical field of women's shoes, and discloses a leather boot, which includes a leather upper and a shoe sole. The leather upper is coated with a paint, and the paint includes the following components in parts by weight: 80-100 parts of acrylic acid Resin; 10-15 parts of polyetherimide; 5-6 parts of nitrile rubber; 3-4 parts of catalyst; 8-10 parts of polyvinyl alcohol; 2-4 parts of additives. The present invention has the following advantages and effects: polyetherimide is added to acrylic resin to form a dispersed phase of particles, which improves the toughness of acrylic resin; under the action of a catalyst, nitrile rubber reacts with acrylic resin to form an interpenetrating network, and introduces a flexible segment , improve the mobility of the network chain, to achieve the toughening effect; nitrile rubber changes the acrylate to a moderate network structure, improves the toughness and weather resistance of the acrylic resin, and is beneficial to improve the toughness of the leather upper after coating And weather resistance, thereby avoiding the cracking of the leather upper during storage, which can prolong the service life of the leather upper.

Owner:温州市丰盛鞋业有限公司

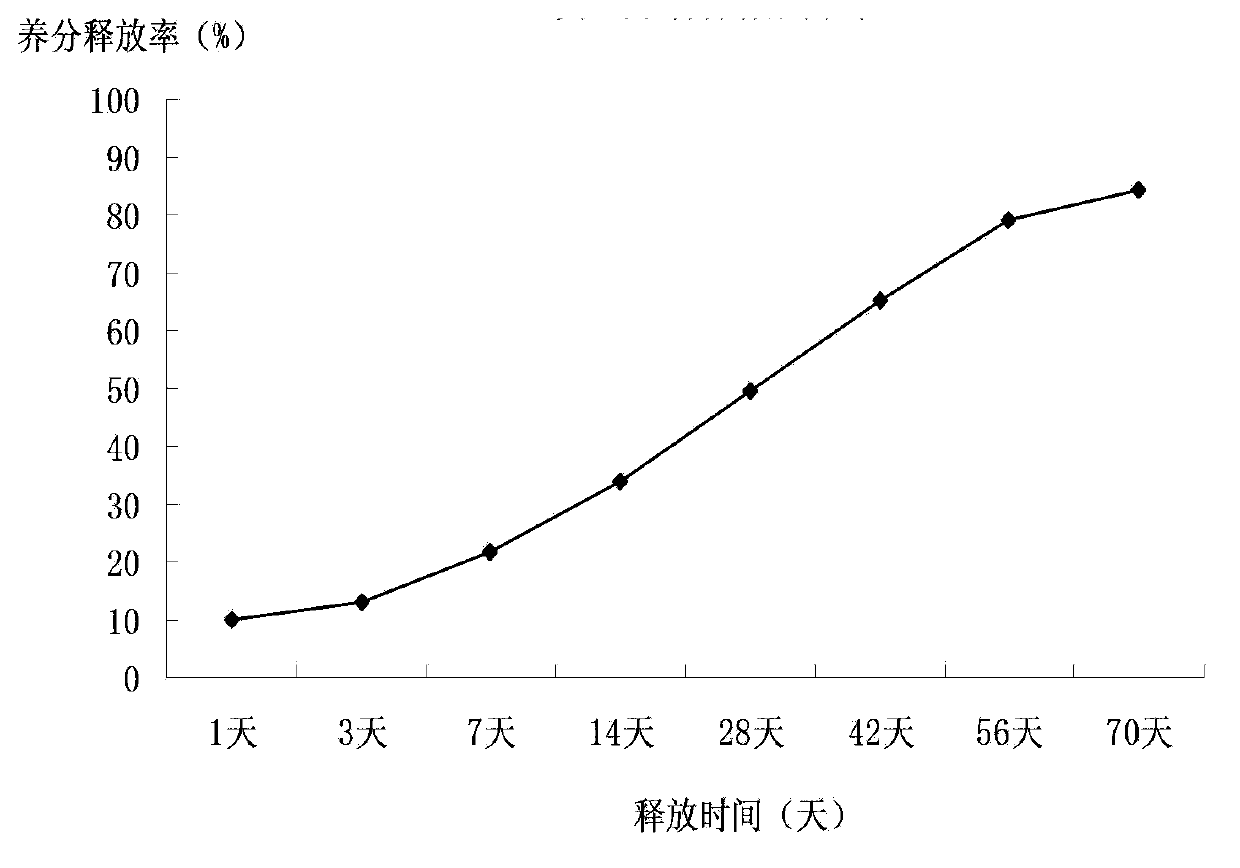

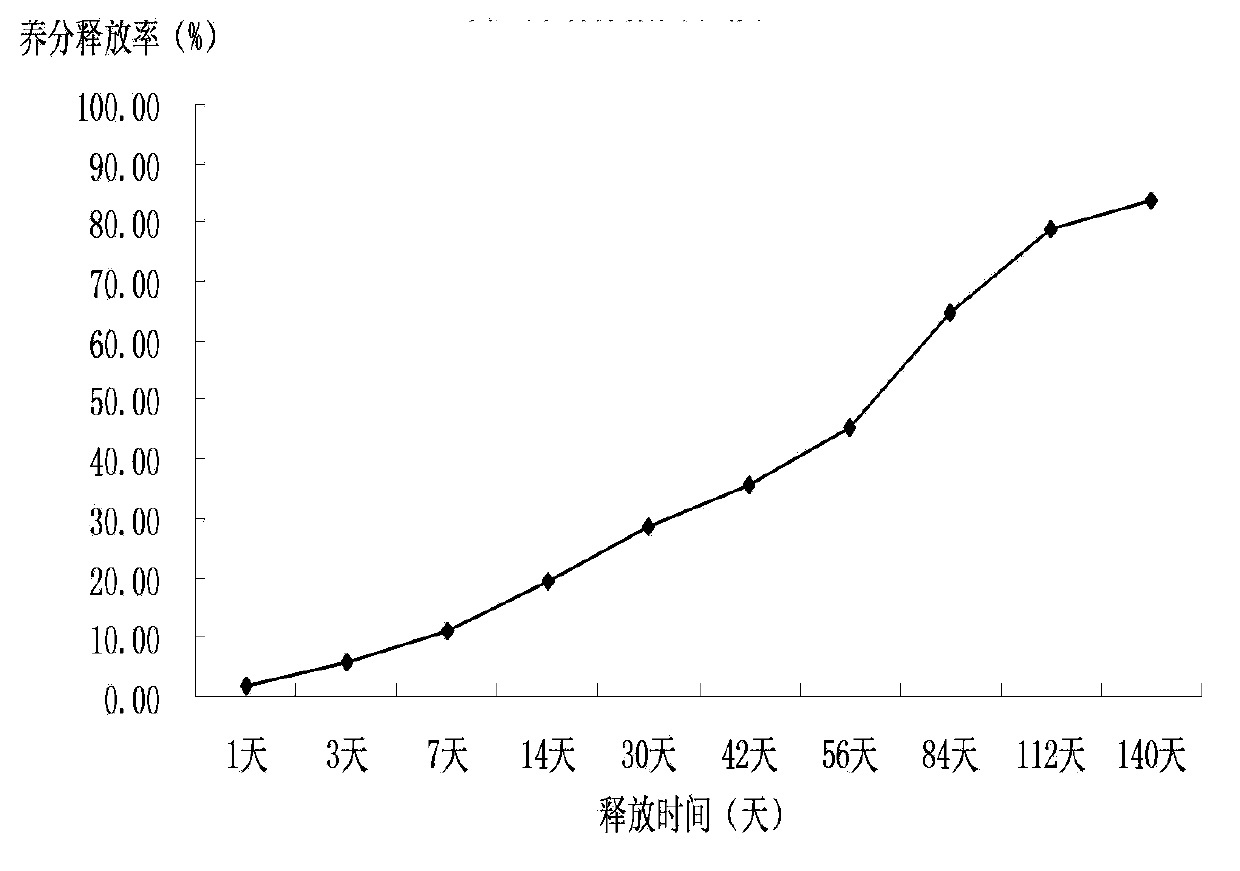

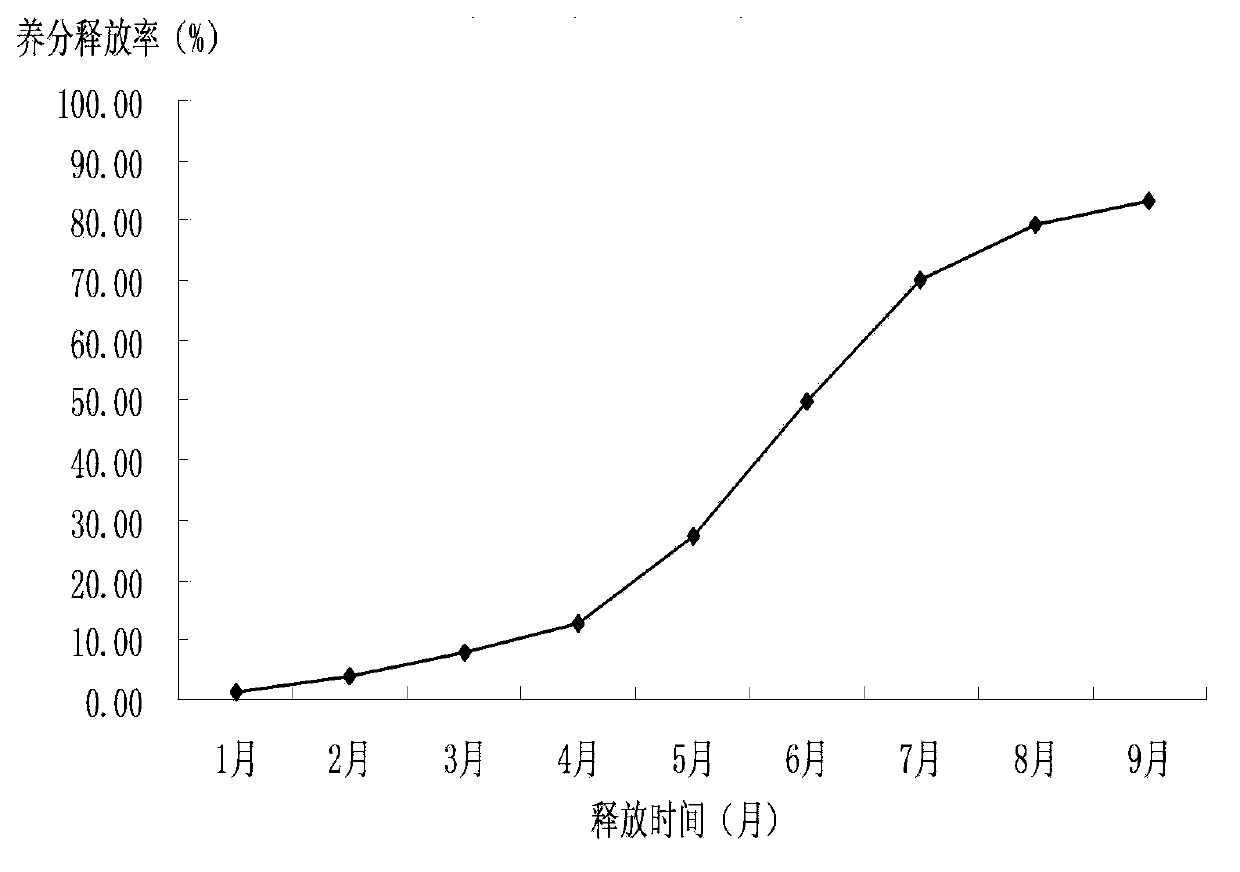

Toughening method of sulphur-coated controlled-release fertilizer

ActiveCN103044143BGood effectHigh impact strengthFertilizer mixturesNitrile rubberHyperbranched polyester

The invention relates to a method for toughening sulfur-coated controlled-release fertilizer, comprising the following steps: (1) uniformly mixing epoxy resin and toughening agent to obtain a toughening resin premix; (2) making the toughening resin premix Mix evenly with the curing agent to prepare a mixed solution; (3) spray liquid sulfur on the surface of the core fertilizer to obtain sulfur-coated fertilizer particles; (4) spray the mixed solution on the surface of the sulfur-coated fertilizer particles to obtain toughened Sulfur controlled release fertilizer. The present invention uses carboxyl-terminated hyperbranched polyester HBP-SA or carboxyl-terminated liquid nitrile rubber as a toughening agent. These two toughening agents can not only play a toughening role, but also enhance the sealing effect of the membrane material , to achieve the purpose of spraying the toughening resin on the sulfur-coated controlled-release fertilizer without spraying the sealing agent, thereby reducing the spraying steps.

Owner:河南豫邮金大地科技服务有限公司

High-tenacity conducting nanocomposite material and preparation method thereof

The invention relates to a high-tenacity conducting nanocomposite material and a preparation method thereof. The electrical conductivity of a polymer material is improved, at the same time, the mechanical properties, especially shock resistance, of the material is improved. The composite material uses carbon nanotubes as an electrically-conducting part, and is added with inorganic rigid calcium carbonate nano particles, further improves the electrical conductivity of the composite material by utilization of the volume exclusion effect of nano calcium carbonate, and at the same time, the inorganic toughening effect is achieved through the surface modification of nano calcium carbonate. The preparation method provided by the invention is simple and is suitable for industrial production; and the prepared composite material has high elastic modulus, impact strength and specific conductivity.

Owner:BEIJING UNIV OF CHEM TECH

Flame retardant permanent anti-static acrylonitrile butadiene styrene (ABS) /polyethylene terephthalate (PET) alloy and preparation method thereof

ActiveCN102643506BImprove flame retardant performanceReduce usagePolyethylene terephthalatePolyethylene terephthalate glycol

The invention discloses a flame retardant permanent anti-static acrylonitrile butadiene styrene (ABS) / polyethylene terephthalate (PET) alloy and a preparation method thereof. The flame retardant permanent anti-static ABS / PET alloy includes the following components of, by weight, 45% to 72% of ABS resins, 2% to 10% of PET, 10% to 20% of permanent anti-static agents and 15% to 25% of flame retardants. The preparation method includes adding each of the components according to the ratio into a high speed mixer for evenly mixing, feeding the mixtures into a double-screw extruder, and subjecting the mixtures to mixing, extruding, drawing, cooling and granule-cutting, and obtaining the flame retardant permanent anti-static ABS / PET alloy. The flame retardant permanent anti-static ABS / PET alloy has a good tenacity, an excellent flame retardant performance and an excellent anti-static performance, and is capable of greatly reducing product costs on the premise of meeting basic applications.

Owner:KINGFA SCI & TECH CO LTD +1

A kind of floor adhesive based on water-based acrylic resin and preparation process thereof

ActiveCN111892889BImprove water resistanceNot easy to pull outNon-macromolecular adhesive additivesEpoxy resin adhesivesAl powderPolymer science

The invention discloses a floor adhesive based on water-based acrylic resin and a preparation process thereof. The floor adhesive is prepared from the following parts by weight of raw materials: 100-120 parts of modified water-based acrylic emulsion and 12-15 parts of toughening agent , 10-15 parts of thinner, 2-3 parts of talcum powder, 2-3 parts of asbestos powder, 2-3 parts of aluminum powder, 0.8-1.5 parts of anti-mold; The modified water-based acrylic emulsion and toughening agent are prepared in the process of preparing the floor adhesive. The modified water-based acrylic emulsion contains a large number of silicon-oxygen bonds on the molecules, and the bond energy of the silicon-oxygen bonds is far The bond energy is much higher than the carbon-carbon bond, which increases the water resistance of the prepared floor adhesive. A single toughening agent molecule contains multiple extremely polar cyano groups, which makes the toughening agent compatible with the modified water-based acrylic emulsion. When mixing, the blending effect of the two is improved, thereby increasing the service life of the adhesive.

Owner:珠海百翔新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com