Active epoxy toughening-curing agent, and its preparing method

A curing agent and epoxy technology, used in the field of thermosetting resin curing, can solve the problems of high curing temperature and decreased resin tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

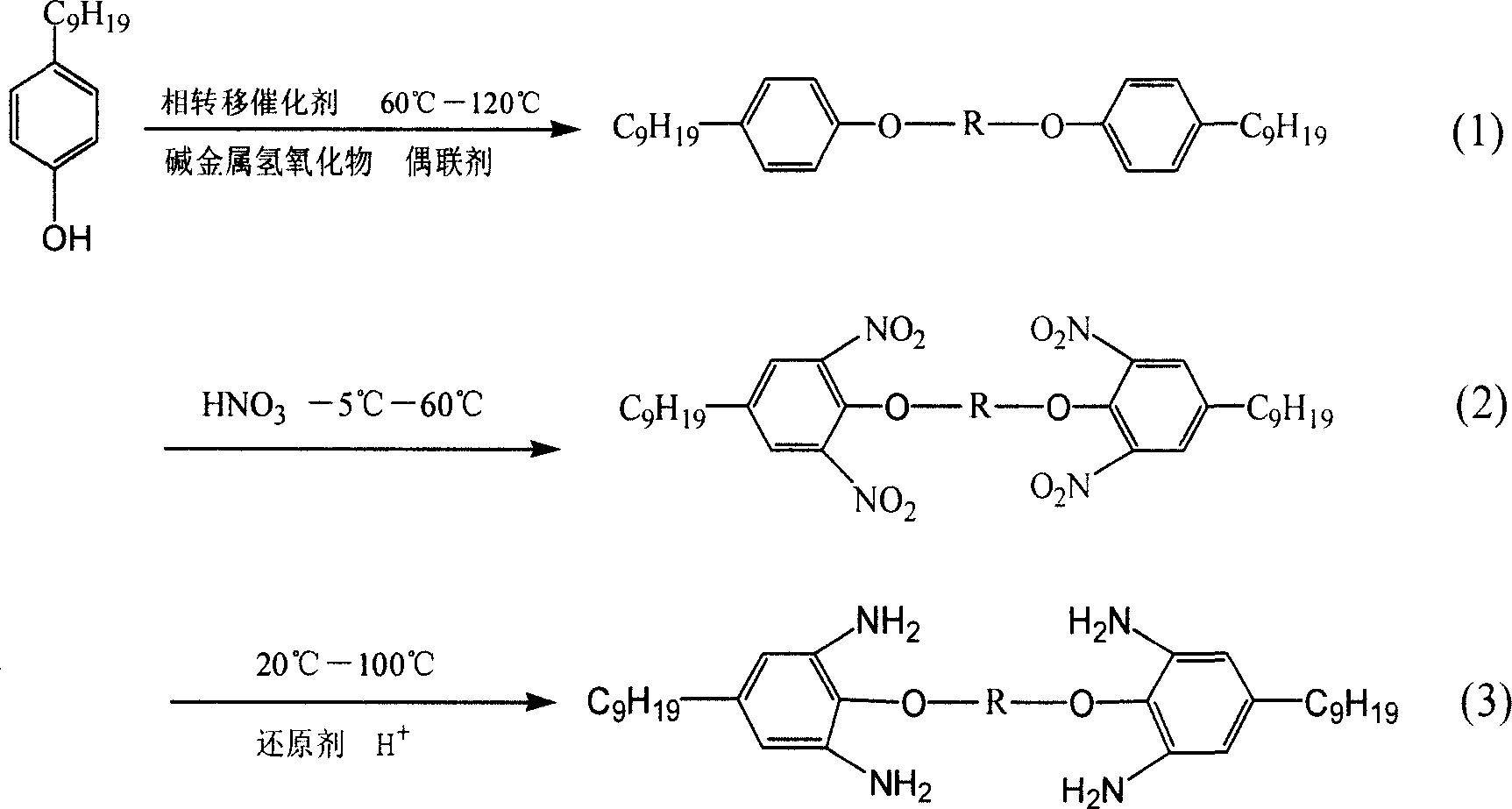

[0021] step 1:

[0022] Mix 44g of nonylphenol, 2.52g of tetraethylammonium bromide, and 200ml of 15% NaOH solution and heat to 70°C, add 20.2g of 1,3-dibromopropane, continue heating to 90°C, mechanically stir for 5h, stop Heat, continue stirring to room temperature, add 50ml of diethyl ether for extraction, wash the organic phase with saturated brine until neutral, dry over anhydrous sodium sulfate, and remove the solvent under reduced pressure to obtain 40.2g of the product with a yield of 84.6%.

[0023] Step 2:

[0024] Dissolve 4.87 g of the product of the above steps in 10 ml THF, add 10.2 g of 37% nitric acid dropwise into the system, control the temperature at 50 ° C, monitor with TLC, stir mechanically, react for 4 h, remove THF under reduced pressure, and extract with ether; Wash with brine until neutral, dry over anhydrous sodium sulfate, and remove the solvent under reduced pressure to obtain 2.45 g of product with a yield of 37.1%.

[0025] Step 3:

[0026] Mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com