Polyethylene cross-linked and modified polypropylene combination thereof

A polyethylene cross-linking and cross-linking product technology, which is applied in the field of polypropylene compositions, can solve the problems of difficult processing, inconvenient practical application, and high price of POE raw materials, and achieve good toughening performance and remarkable toughening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

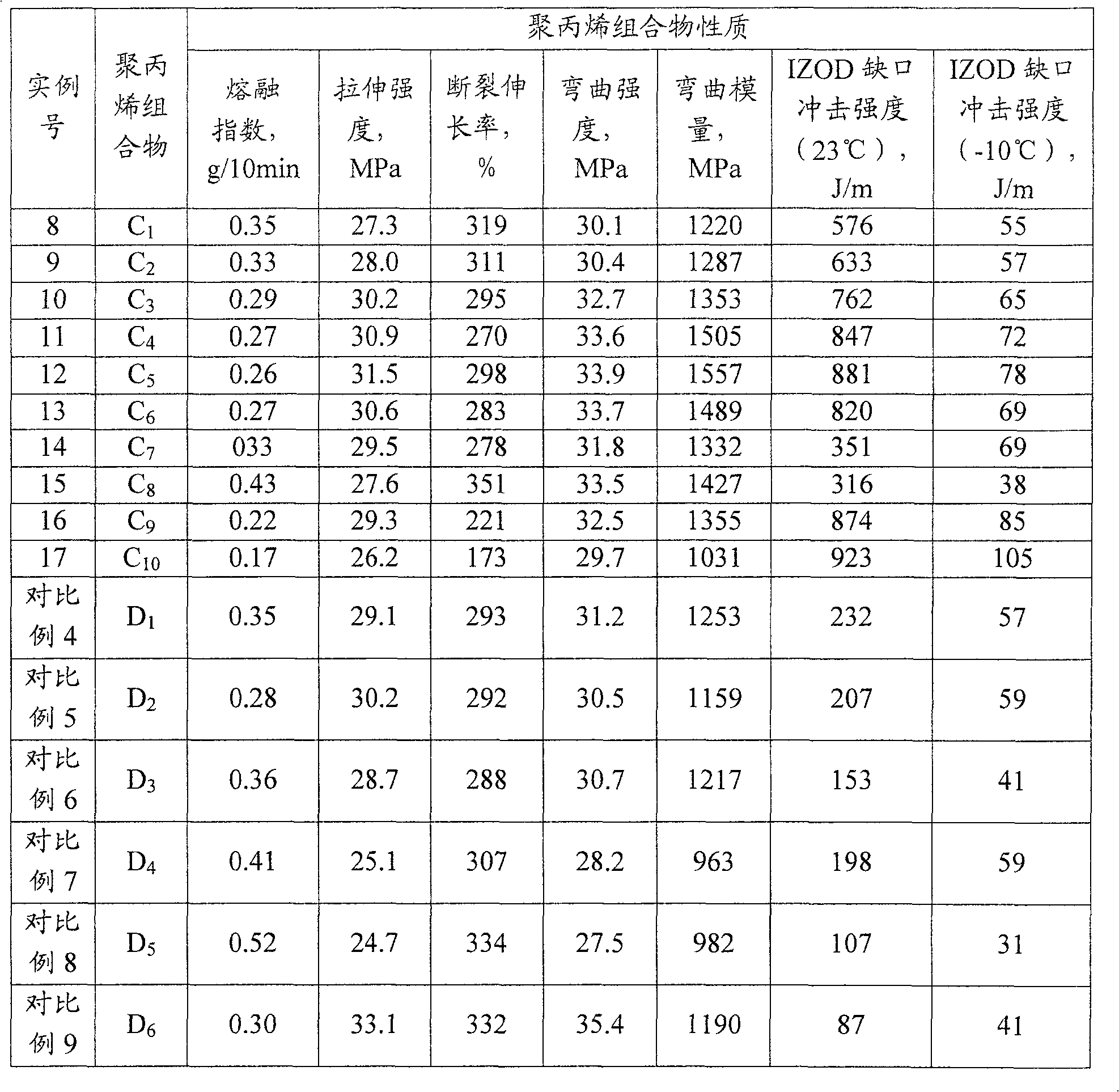

Examples

preparation example Construction

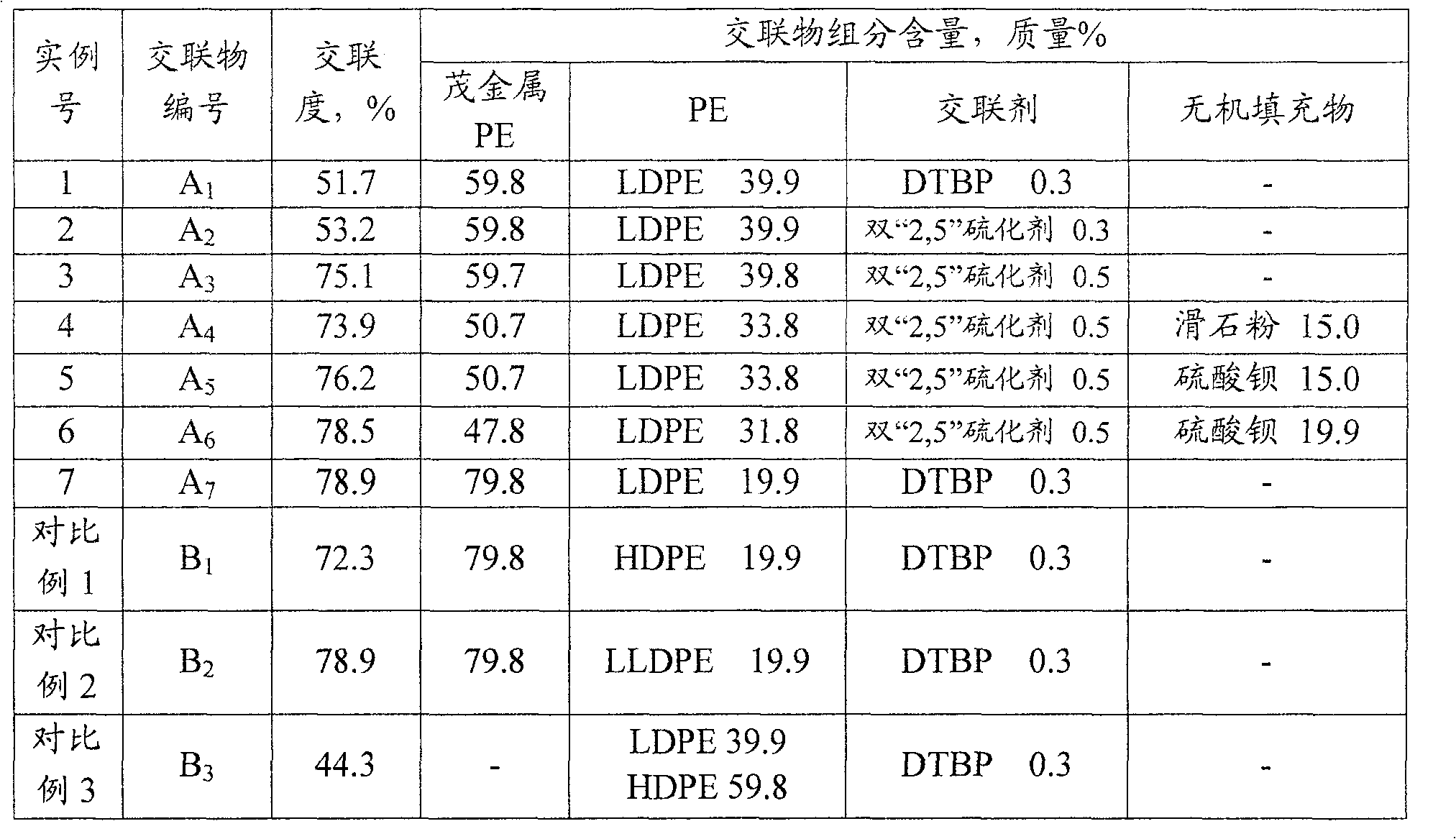

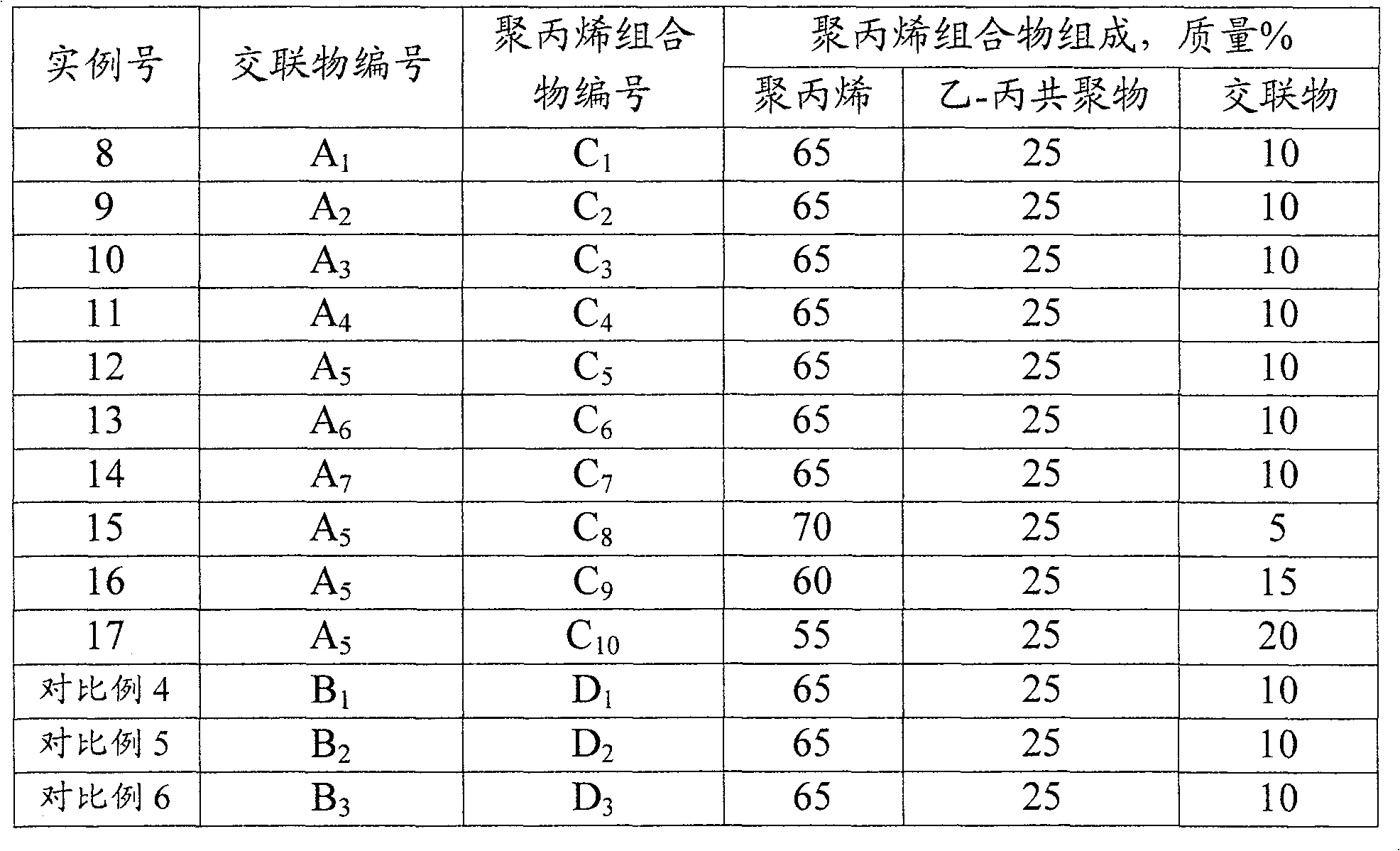

[0019] The preparation method of the metallocene polyethylene cross-linked product of the present invention is as follows: metallocene polyethylene, low-density polyethylene, and inorganic rigid filler are sequentially added to a low-speed mixer according to the proportion in the cross-linked product for pre-mixing, and the above-mentioned mixed The materials are fed into the corotating parallel twin-screw extruder for granulation.

[0020] The rotational speed of the low-speed mixer is 80-150 rpm, the pre-mixing time is preferably 1-5 minutes, and the mixing time after adding the crosslinking agent is preferably 5-20 minutes. The mixing temperature is preferably 15-40°C. After the mixed materials are put into the extruder, it is preferable to control the temperature of each zone of the extruder to be between 170-220° C., the rotational speed of the screw to be 150-250 rpm, and the rotational speed of the feeder to be 20-50 rpm.

[0021] The polyethylene cross-linked product ...

example 1

[0030] The following example prepares the polyethylene cross-linked product described in the present invention.

[0031] Get 1800 grams of metallocene polyethylene [Exxon company produces, trade mark EXCEED 350D65, metallocene catalyst is two (cyclopentadienyl) zirconium dichlorides, melt index 1.2g / 10min, density is 0.918g / cm 3 ], 1200 grams of low-density polyethylene (produced by Qilu Petrochemical Company, brand name TN26, melt index 2.7g / 10min, density of 0.920g / cm2 produced by high-pressure gas-phase method 3 ), 9 grams of di-tert-butyl peroxide (DTBP).

[0032] Mix EXCEED 350D65 and TN26 in a mixer with a rotation speed of 100 rpm at 25°C for 3 minutes, then add DTBP and mix for 10 minutes to form a mixture. Put the mixture into the co-rotating parallel twin-screw extruder to granulate, control the temperature of each zone of the extruder to control the temperature of the first to fifth zones of the extruder to be 170°C, 190°C, 200°C, 210°C, 215°C, and the sixth to eig...

example 2

[0034] Prepare polyethylene cross-linked product A according to the method of example 1 2 , the difference is that 9 grams of double "2,5" vulcanizing agent is used instead of DTBP, and the obtained polyethylene cross-linked product A 2 The cross-linking degree and composition are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com