Connecting node of concrete filled steel tubular column and reinforced concrete beam and construction method of connecting node

A technology for reinforced concrete beams and concrete-filled steel tube columns, which is applied to the joints between concrete-filled steel tube columns and reinforced concrete beams and their construction fields, and can solve the problems of weakened steel tube sections and reduced binding force of tubular concrete

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0085] This embodiment provides a connection node between a steel tube concrete column and a reinforced concrete beam, which is characterized in that: at the intersection of the steel tube concrete column and the reinforced concrete beam, the steel tube of the steel tube concrete column is provided with a plurality of first openings, The outer peripheral surface of the steel pipe is provided with a reinforcing plate corresponding to the position of the opening, and the reinforcing plate is provided with a second opening overlapped with each of the openings, and the reinforced concrete beam is provided with a second opening which is respectively connected to the respective openings. A plurality of steel bars corresponding to the first openings, each of the steel bars of the reinforced concrete beam passes through the first openings and the second openings at corresponding positions.

Embodiment 2

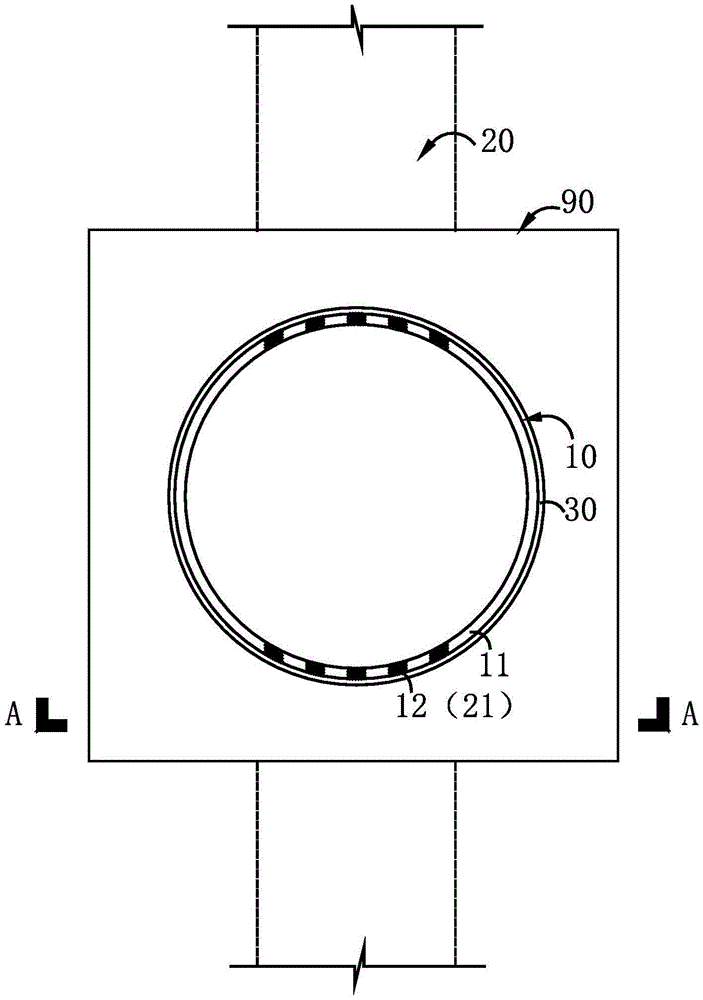

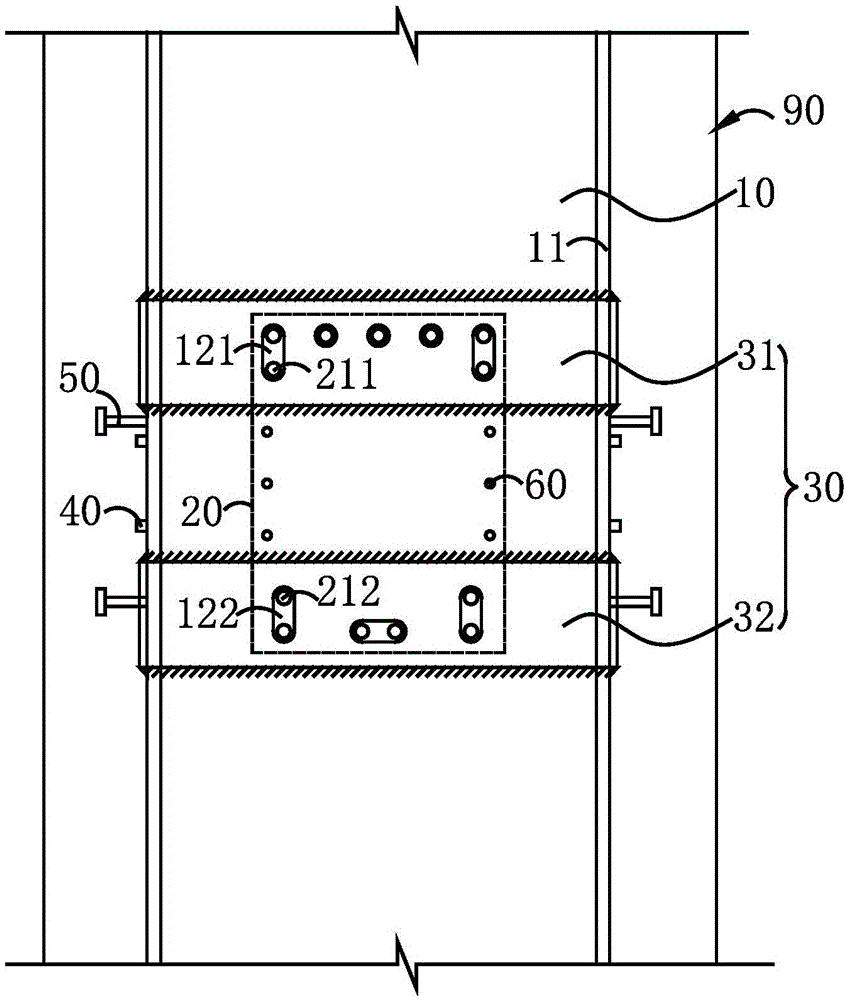

[0087] This embodiment provides a connection node of a steel tube concrete column and a reinforced concrete beam, such as figure 1 As shown, it is set at the intersection of the steel tube concrete column 10 and the reinforced concrete beam 20. The steel pipe 11 of the concrete-filled steel tube column is provided with a number of first openings 12, a reinforcement plate 30 is provided on the outer peripheral surface of the steel pipe 11 corresponding to the first opening, and the reinforcement plate 30 is provided with the respective first openings. In the second opening where the holes 12 overlap, the steel bars 21 of the reinforced concrete beam respectively pass through the first opening 12 and the second opening at the corresponding positions, so that the concrete-filled steel tube column 10 and the reinforced concrete beam 20 intersect to form a connection node. Specifically, such as figure 2 As shown, at the intersection of the concrete-filled steel tube column 10 and th...

Embodiment 3

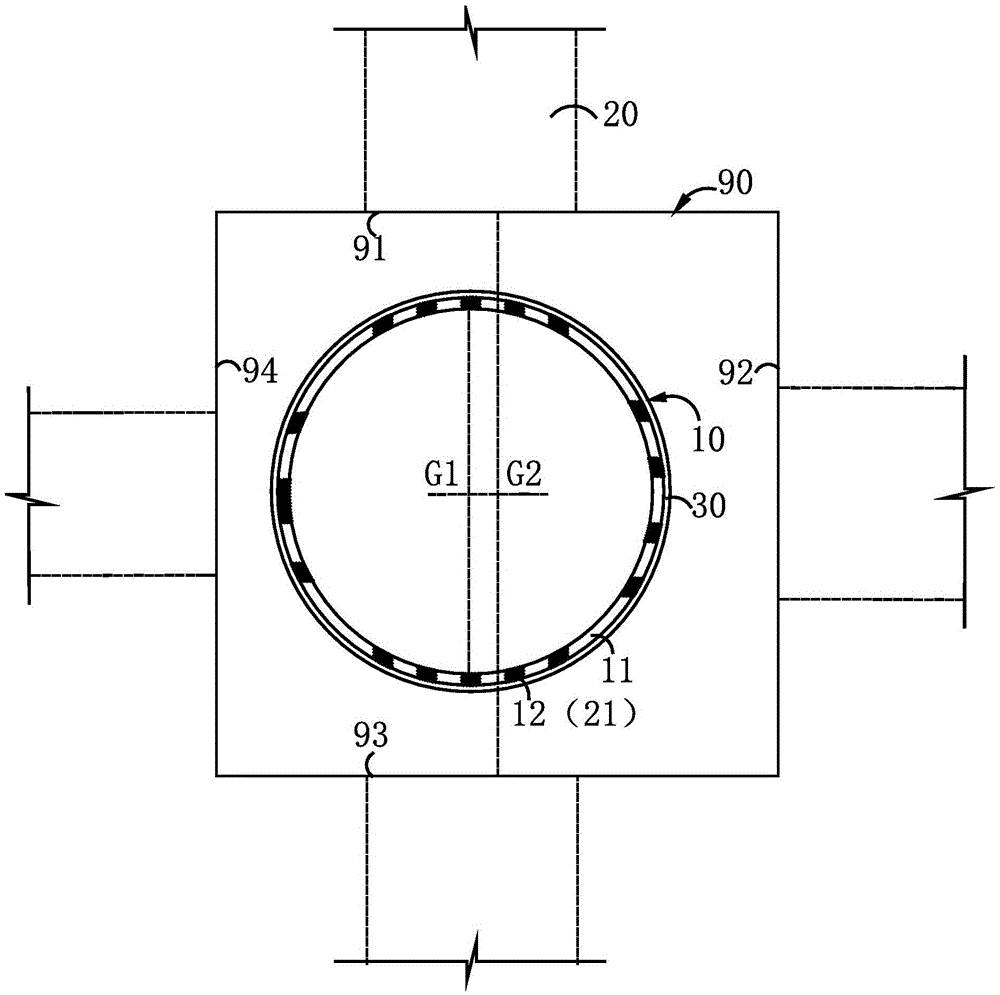

[0098] The difference between this embodiment and the second embodiment is that the concrete-filled steel tube column and the laminated column in this embodiment are eccentrically arranged. Such as image 3 As shown, the four sides of the laminated column 90 are the upper side 91, the right side 92, the lower side 93 and the left side 94, respectively. The steel tube 11 center G1 of the concrete-filled steel tube column (ie the center of gravity of the concrete-filled steel tube column) The distances to the upper side 91, the right side 92, the lower side 93 and the left side 94 of the composite column are 800mm, 850mm, 800mm and 750mm, respectively. The center G1 of the concrete-filled steel tube column is located to the left of the center G2 of the composite column side.

[0099] In addition, in this embodiment, the concrete-filled steel tube column 10 is connected to the north-south direction (ie image 3 The reinforced concrete beam extending in the east-west direction (i.e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com